Marine electric cantilever crane

A crane and electric technology, which is applied in the field of marine electric cantilever cranes, can solve the problems of increased cost, low work efficiency, troublesome operation, etc., and achieve the effect of compact space, high work efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

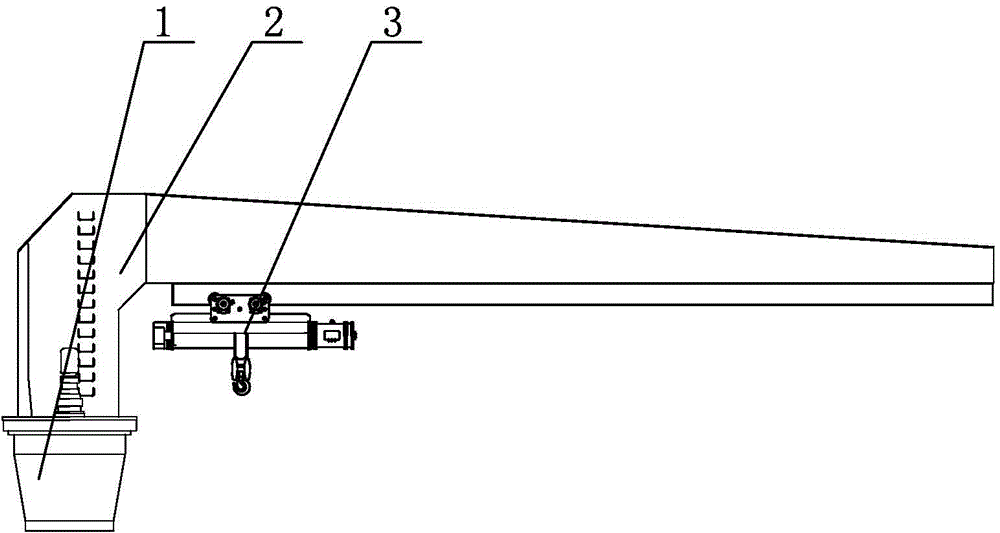

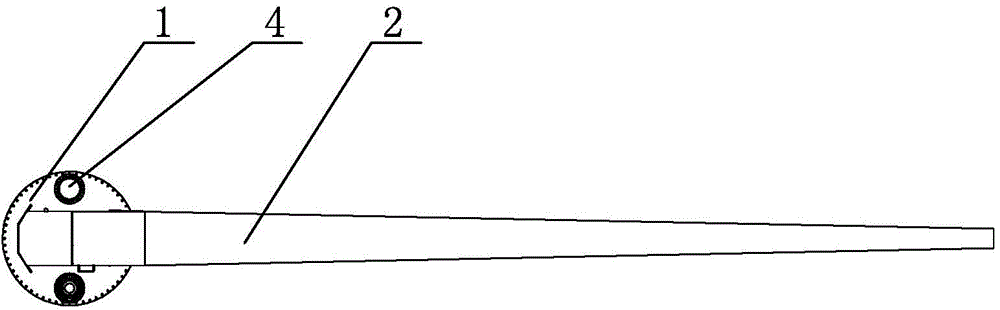

[0015] like figure 1 and figure 2 As shown, the marine electric cantilever crane of this embodiment includes a base 1 connected to the deck of the ship. A cantilever 2 is welded on the base 1. The cantilever 2 is in a right-angled structure. Elevating hoist 3 is located on base 1 and is also equipped with an electric rotary reducer 4 that controls the rotary work of the crane.

[0016] The electric hoist 3 is connected with the wireless button box through an electric signal.

[0017] During actual use, the electric lifting hoist 3 is activated through the button box, and the electric lifting hoist 3 can walk to the corresponding position. Easy to operate.

[0018] The above description is an explanation of the present invention, not a limitation of the invention. For the limited scope of the present invention, please refer to the clai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com