Sewage filtering treatment device and using method thereof

A treatment device and sewage technology, which is applied in the field of sewage filtration treatment devices and filtration devices, can solve problems such as easy blockage, weak continuous operation ability, and influence on filtration efficiency, etc., and achieve simple and reasonable structure, strong continuous operation ability, and strong practicality value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

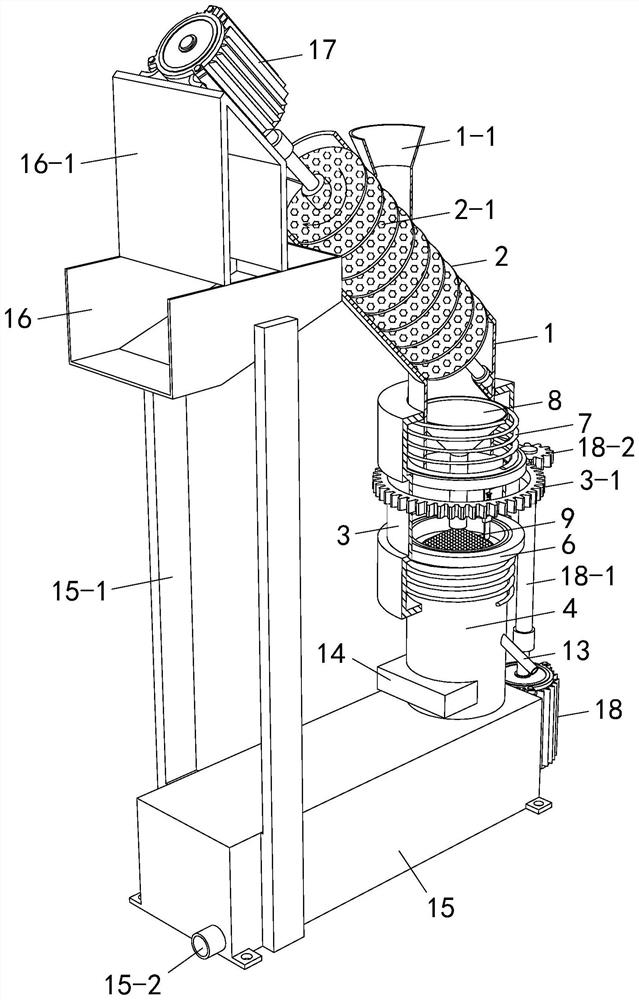

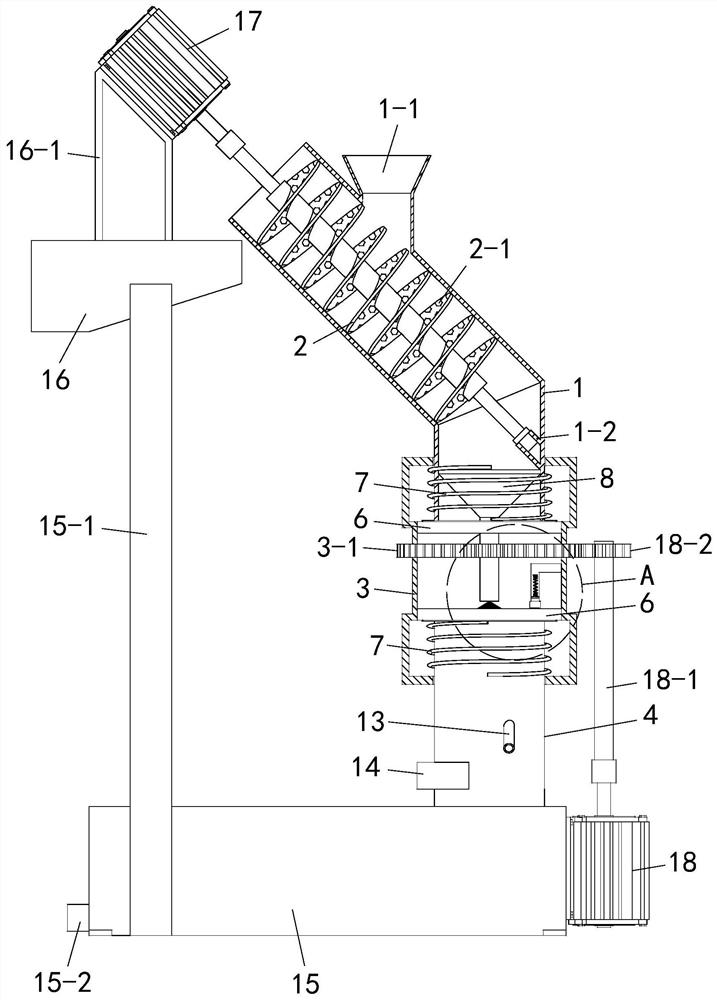

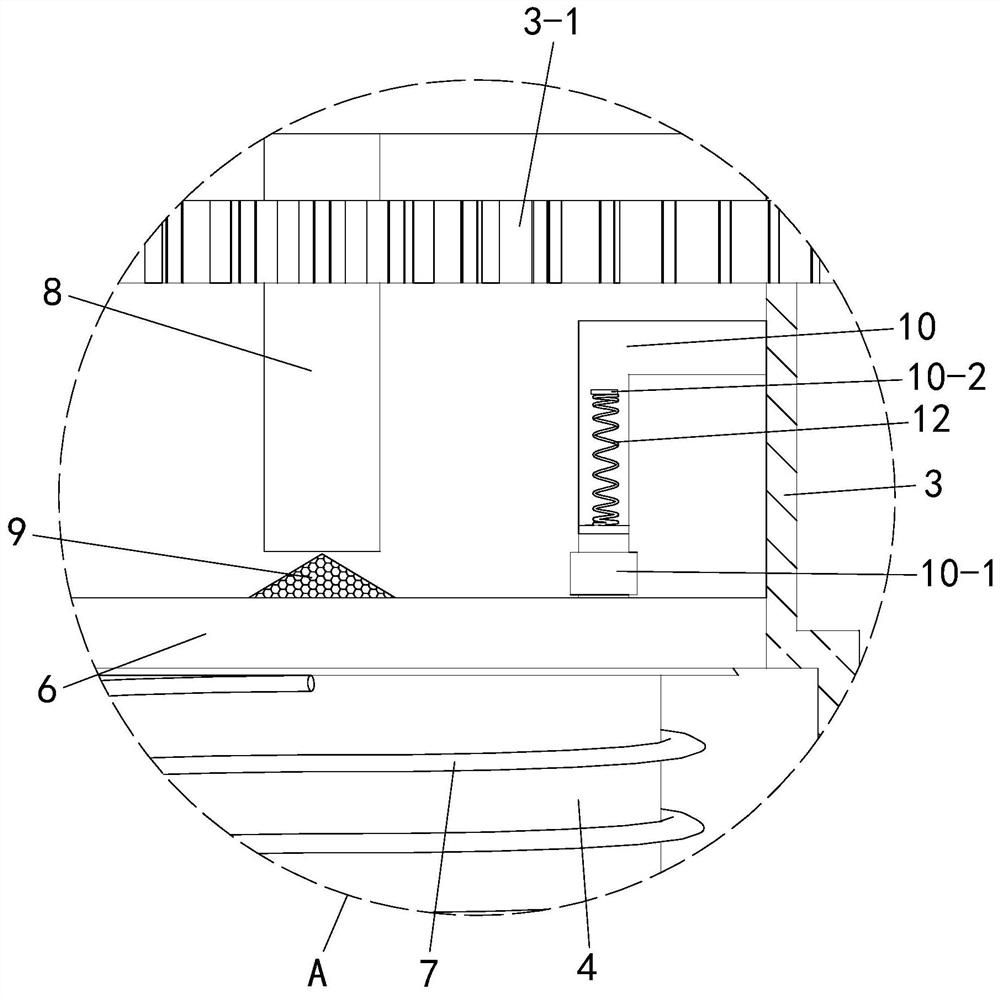

[0018] Specific implementation mode one: as Figure 1 to Figure 5 As shown, the present invention discloses a sewage filtration treatment device, comprising a first filter cylinder 1, a screw blade shaft 2, a rotating cylinder 3, a second filter cylinder 4, a funnel 8, a conical filter screen 9, a telescopic scraper 11, The water storage tank 15, the first driving motor 17 and the second driving motor 18, the upper part of the first filter cartridge 1 is vertically arranged on the inclined lower part, the upper part of the first filter cartridge 1 is provided with a water inlet 1-1 near the top position, and the spiral The blade shaft 2 is coaxially arranged in the upper section of the first filter cartridge 1, the edge of the blade of the spiral blade shaft 2 fits with the inner wall of the first filter cartridge 1, and the blades are densely covered with a number of water holes 2-1, and the lower end of the spiral blade shaft 2 It is rotationally connected with the slot 1-2 ...

specific Embodiment approach 7

[0024] Specific implementation mode seven: as Figure 1 to Figure 5 As shown, this embodiment discloses a method for using a sewage filtration treatment device described in Embodiment 2, and the method includes the following steps:

[0025] Step 1: The first drive motor 17 and the second drive motor 18 are respectively connected to the power supply and started, the first drive motor 17 drives the screw blade shaft 2 to rotate, and the screw blade shaft 2 is transported to the top, and the second drive motor 18 drives to rotate The barrel 3 drives the mounting frame 10 on its inner wall to rotate, and the telescopic scraper 11 on the mounting frame 10 moves around the annular groove 9-1 and intermittently passes through the slope block 9-2;

[0026] Step 2: Pour the sewage to be filtered into the upper section of the first filter cartridge 1 through the water inlet 1-1, and perform a first-stage filtration through the spiral blade shaft 2, and the impurities are conveyed out by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com