Grinding device, grinding method, and method of manufacturing glass sheet

The technology of a grinding device and a grinding method is applied in the direction of a grinding device, an abrasive surface adjustment device, and a manufacturing tool, and can solve problems such as damage to a grinding pad, cracking of a glass plate, and damage to a glass plate, and achieve easy maintenance, prevention of damage, and improvement The effect of continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, preferred embodiments of the polishing apparatus, the polishing method, and the manufacturing method of the glass plate of the present invention will be described with reference to the drawings.

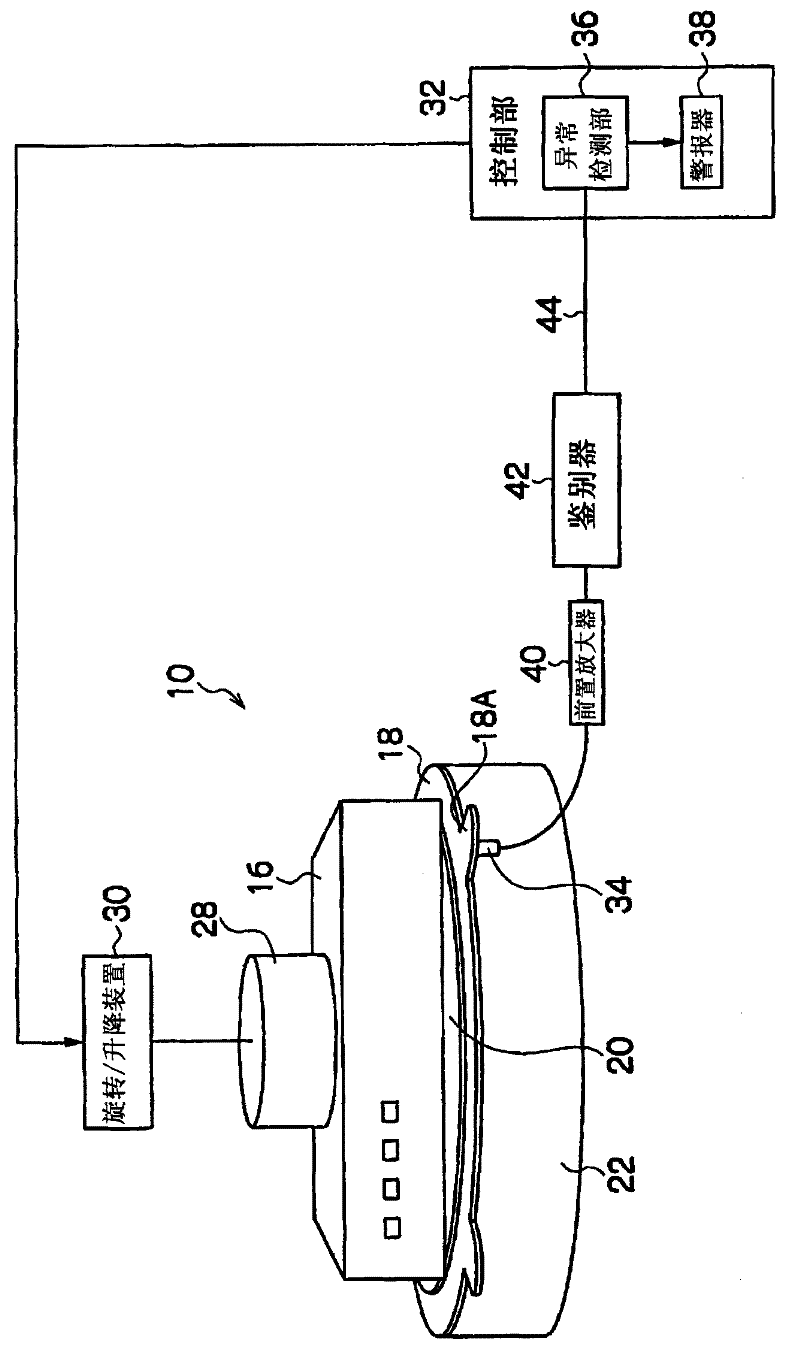

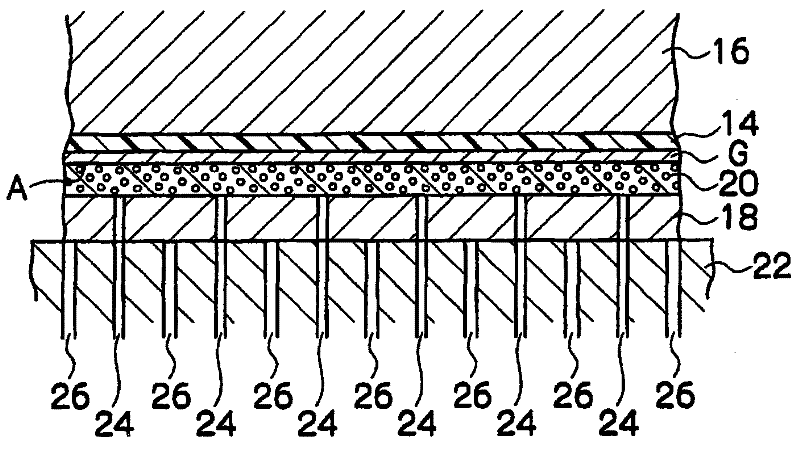

[0047] figure 1 It is a perspective view which shows the grinding|polishing apparatus 10 of embodiment. and, figure 2 It is an enlarged cross-sectional view showing the structure of a main part of the polishing device 10 .

[0048] The grinding device 10 is a glass plate G produced in a rectangular shape (for example, one side is 2000×2200mm to 2200×2600mm, and the thickness is 0.7mm, and it is made of an alkali-free glass material for FPD use before grinding by the float method. The glass plate (for example, AN100.)} grinds into a grinding device for the flatness required by the glass plate for liquid crystal display.

[0049] Its structure includes: a grinding head 16, holding a glass plate G on the lower surface of the grinding head via a sheet-shaped hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com