Grinding device, grinding method, and manufacturing method of glass plate

A technology of grinding device and grinding method, applied in grinding device, abrasive surface adjusting device, feeding device, etc., can solve the problems of glass plate breakage, grinding pad damage, bad influence of glass plate, etc., achieve easy maintenance, prevent damage, improve The effect of continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, with reference to the drawings, preferred embodiments of the polishing apparatus, polishing method, and glass plate manufacturing method of the present invention will be described.

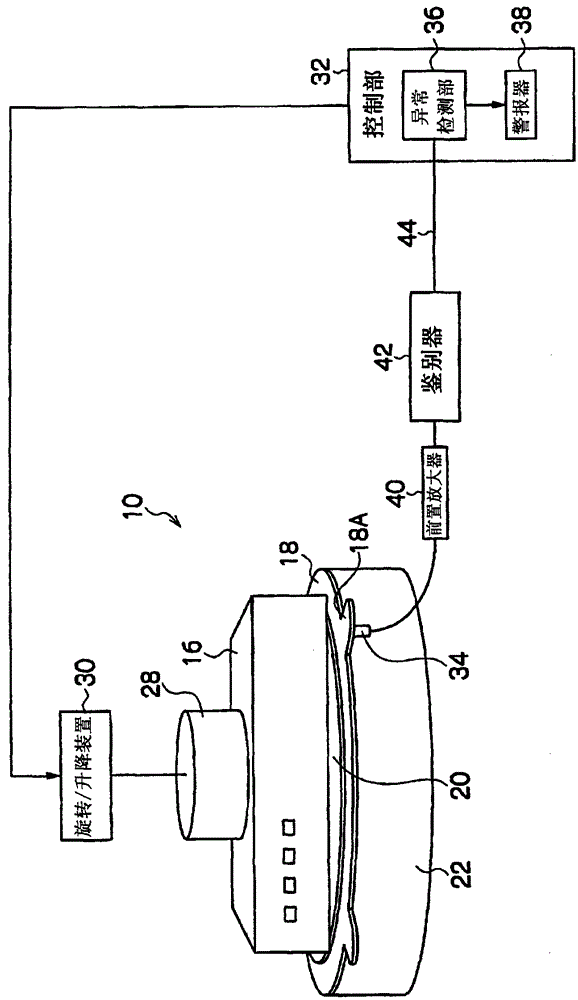

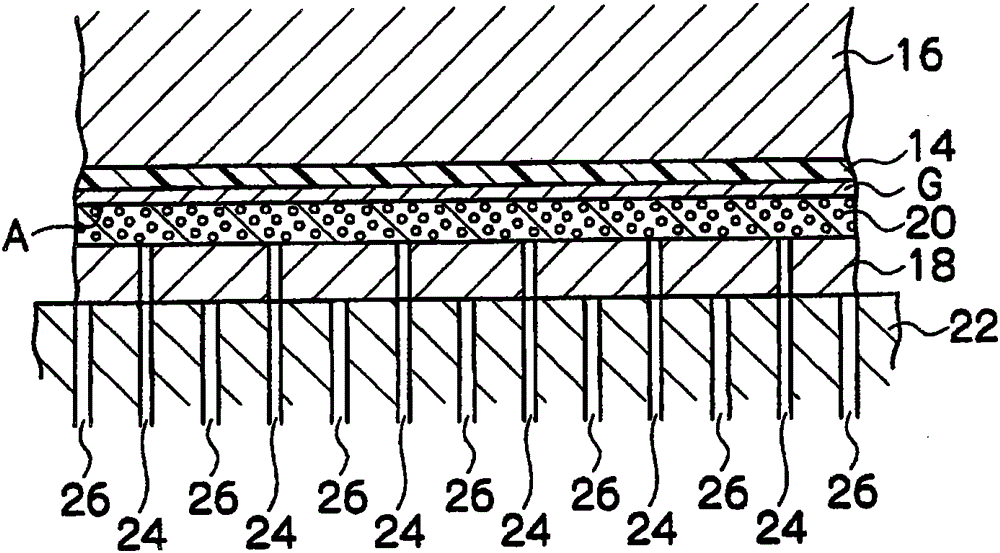

[0047] figure 1 It is a perspective view showing the polishing apparatus 10 of the embodiment. and, figure 2 It is an enlarged cross-sectional view showing the structure of the main part of the polishing apparatus 10.

[0048] The polishing device 10 is a rectangular glass plate G {for example, one side is 2000×2200mm-2200×2600mm, the thickness is 0.7mm, and it is made of alkali-free glass-based materials for FPD use before polishing. The glass plate (for example, AN100.)} is a polishing device that grinds the flatness required for the glass plate for liquid crystal displays.

[0049] The structure includes: a polishing head 16, holding a glass plate G on the lower surface of the polishing head via a sheet-shaped holding member 14; and a polishing platform 22, holding a polishing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com