Highlight treatment device for notebook computer cover plate

A high-light processing, notebook technology, applied in feeding devices, maintenance and safety accessories, milling machine equipment, etc., can solve problems such as time-consuming, affecting production capacity, etc., to achieve the effect of improving continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

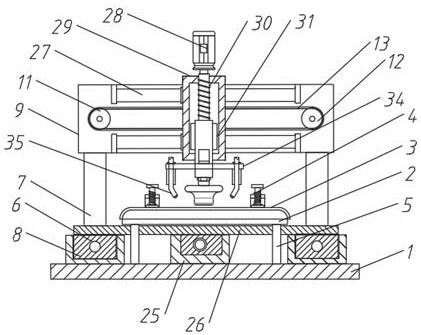

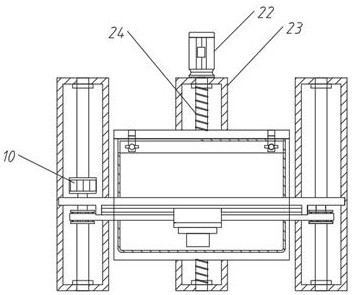

[0028] see figure 1 , in the embodiment of the present invention: a high-gloss processing device for a notebook cover, including a workbench 1, above the workbench 1 is provided with a mold plate 2 for placing the notebook cover 3 through a support rod 5, the mold plate 2 The rear side is provided with a clamping member 4 for clamping and fixing the notebook cover 3, a first screw drive mechanism is fixed between the die plate 2 and the worktable 1, and both sides of the first screw drive mechanism are provided with The sliding rod 6 is provided with a sliding seat 8 that moves along the sliding rod 6, and a supporting column 7 is fixed on the sliding seat 8, and a supporting plate 9 is installed across the top of the two supporting columns 7 to support the sliding rod 6. A third motor 10 is provided on the rear left side of the plate 9 , and a driving pulley 11 and a driven pulley 12 are installed on the left and right ends of the front side of the support plate 9 through the...

Embodiment 2

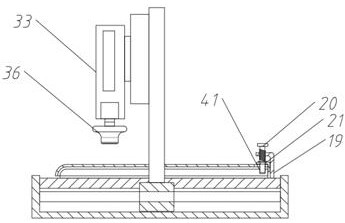

[0030] see Figures 1~8 , the difference between this embodiment and Embodiment 1 is:

[0031] In this embodiment, the notebook cover 3 is made of aluminum alloy material and is formed by stamping. The structure of the notebook cover 3 includes a circular arc plate 15, a side panel 16 and an upper panel 14. The two sides of the upper panel 14 and A side panel 16 and a circular arc plate 15 are stamped and formed on the front side respectively, and the rear side of the upper panel 14 of the notebook cover 3 also has a margin for fixing the notebook cover 3. The end is provided with a through hole.

[0032] In this embodiment, the outer shape of the mold plate 2 is the same as that of the notebook cover 3 , the inner side of the notebook cover 3 is fitted with the outer surface of the mold plate 2 , and the left and right ends of the rear of the mold plate 2 are provided with openings. There are positioning holes 41 for matching with the through holes of the notebook cover 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com