Tamping Coke Coke Oven Electromagnetic Compound Tamping Machine

A compound type and tamping machine technology, applied in the coking oven, petroleum industry, etc., can solve the problems of large spare parts reserves, complex structure, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

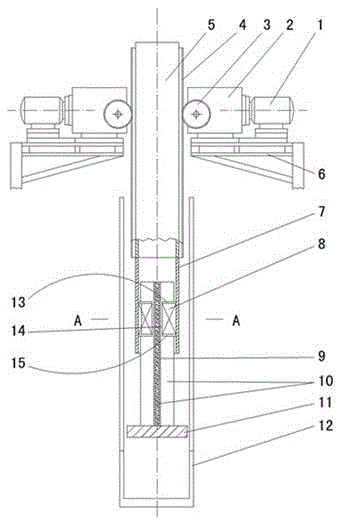

[0015] Such as figure 1 , 3 As shown: 6 is a fixed steel structure, 10 is a hammer rod, a hammer head 11 is connected to the lower end of the hammer rod 10, and the hammer head 11 is matched with the tamping groove 12.

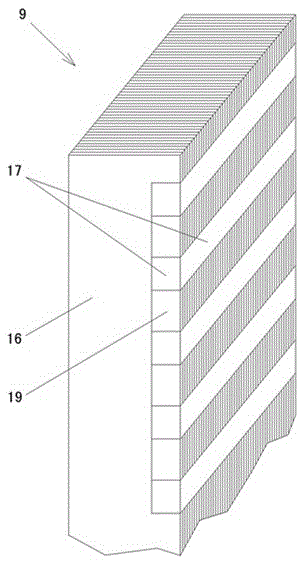

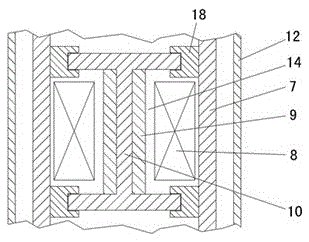

[0016] 7 is the lower steel structure. A symmetrical linear motor is installed between the lower steel structure 7 and the hammer rod 10. The linear motor is controlled by the electronic control device to run in both forward and reverse directions, that is, the hammer rod 10 can be lifted upward by the linear motor. , The hammer rod 10 can also be driven downward by a linear motor. The cross section of the hammer rod 10 is in the shape of "Н", the mover part 9 of the linear motor is fixed on the bottom surface of the side groove of the hammer rod 10 along the direction of the hammer rod 10, and a parallel upper mounting plate 13 is fixed on the side surface of the lower steel structure 7 And the lower mounting plate 15, the stator part 8 of the linear motor is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com