Preparation method of vermiculite-based flexible sealing material

A technology of flexible sealing and sealing materials, applied in the direction of coating, grain processing, etc., to achieve the effect of smooth surface, good flexibility and improved temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

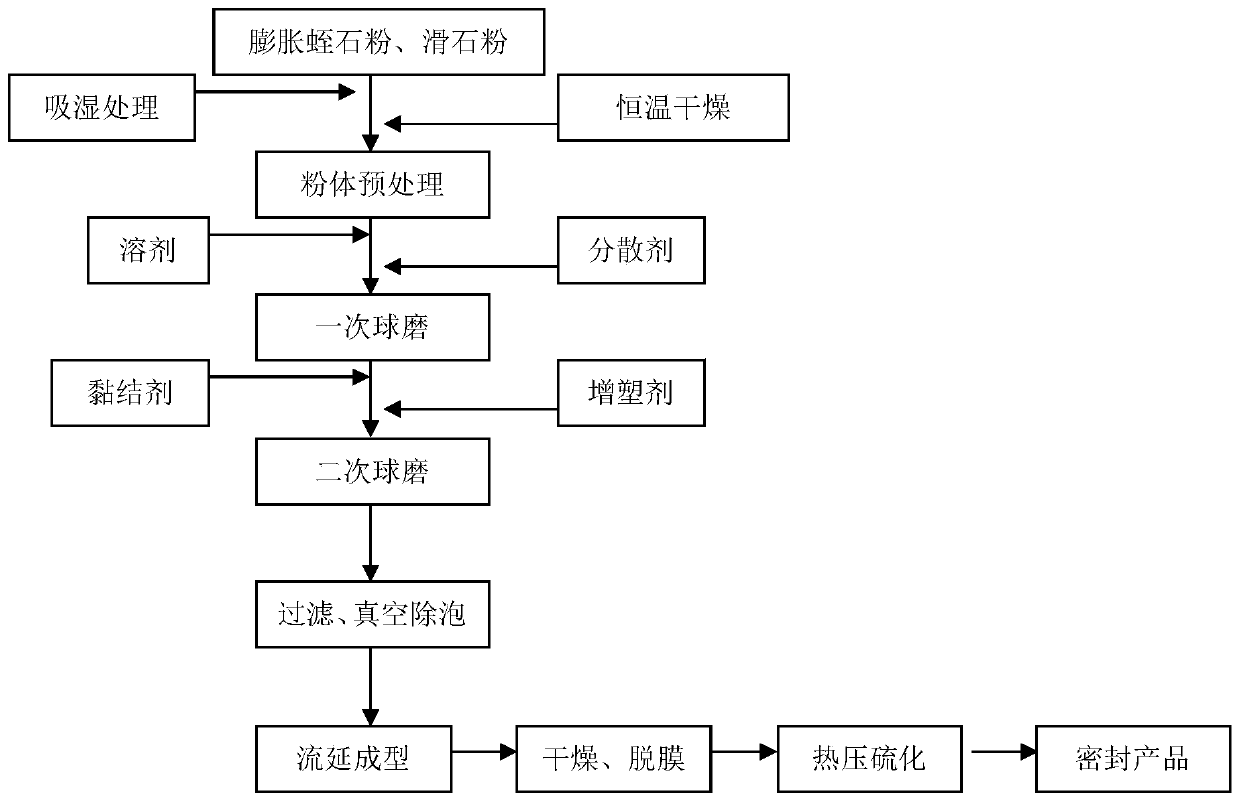

Method used

Image

Examples

Embodiment 1

[0038] 1) Raw material formula

[0039] High-temperature expanded vermiculite powder 500g, chemically expanded vermiculite powder 500g, dispersant vinyltriethoxysilane (A151) 15g, solvent toluene 1000g, binder nitrile rubber (NBR) 100g, plasticizer phthalate Butyl ester (DBP) 100g.

[0040] 2) Preparation process

[0041] Pretreatment: Process a): In a standard constant temperature and humidity curing box, the vermiculite-based powder is subjected to moisture absorption treatment, the relative humidity is controlled at 20%, and the treatment time is 2h; wherein the vermiculite-based powder is 500g of high-temperature expanded vermiculite powder It is mixed with 500g of chemically expanded vermiculite powder; the particle size distribution of high-temperature expanded vermiculite is D10=8.146μm, D50=27.50μm, D90=74.99μm, and the particle size distribution of chemically expanded vermiculite is D10=6.963μm, D50=32.34μm , D90=98.94μm;

[0042] Process b): Dry the treated vermic...

Embodiment 2

[0049] 1) Raw material formula

[0050] High-temperature expanded vermiculite powder 400g, chemically expanded vermiculite powder 400g, talc powder 200g, dispersant stearic acid 15g, solvent ethanol 1000g, binder polyvinyl butyral (PVB) 100g, plasticizer phthalate Butyl ester (DBP) 100g.

[0051] 2) Preparation process

[0052]Pretreatment: Process a): In a standard constant temperature and humidity curing box, the vermiculite-based powder is subjected to moisture absorption treatment, the relative humidity is controlled at 30%, and the treatment time is 2h; the vermiculite-based powder is 400g of high-temperature expanded vermiculite powder 1. Mix 400g of chemically expanded vermiculite powder and 200g of talc powder; the particle size distribution of high-temperature expanded vermiculite is D10=8.146 μm, D50=27.50 μm, D90=74.99 μm, and the particle size distribution of chemically expanded vermiculite is D10=6.963 μm, D50=32.34 μm, D90=98.94 μm, the particle size distributi...

Embodiment 3

[0060] 1) Raw material formula

[0061] High-temperature expanded vermiculite powder 250g, chemically expanded vermiculite powder 250g, talc powder 500g, dispersant fish oil 15g, solvent is 800g of methyl ethyl ketone / ethanol / cyclohexanone mixed system, wherein methyl ethyl ketone: ethanol: The mass ratio of cyclohexanone is 1:2:1, the binder polyvinyl butyral (PVB) is 100 g, and the plasticizer is dibutyl phthalate (DBP) 100 g.

[0062] 2) Preparation process

[0063] Pretreatment: Process a): In a standard constant temperature and humidity curing box, the vermiculite-based powder is subjected to moisture absorption treatment, the relative humidity is controlled at 30%, and the treatment time is 2h; the vermiculite-based powder is 250g of high-temperature expanded vermiculite powder 1. Mix 250g of chemically expanded vermiculite powder and 500g of talc powder; the particle size distribution of high-temperature expanded vermiculite is D10=8.146 μm, D50=27.50 μm, D90=74.99 μm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com