Biomass dry distillation pyrolysis device

A biomass and biomass gas technology, which is applied in the fields of biofuels, special forms of dry distillation, indirect heating dry distillation, etc., can solve the problems of complex and low exhaust gas temperature, and achieve the effects of simple system, high calorific value and high utilization value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

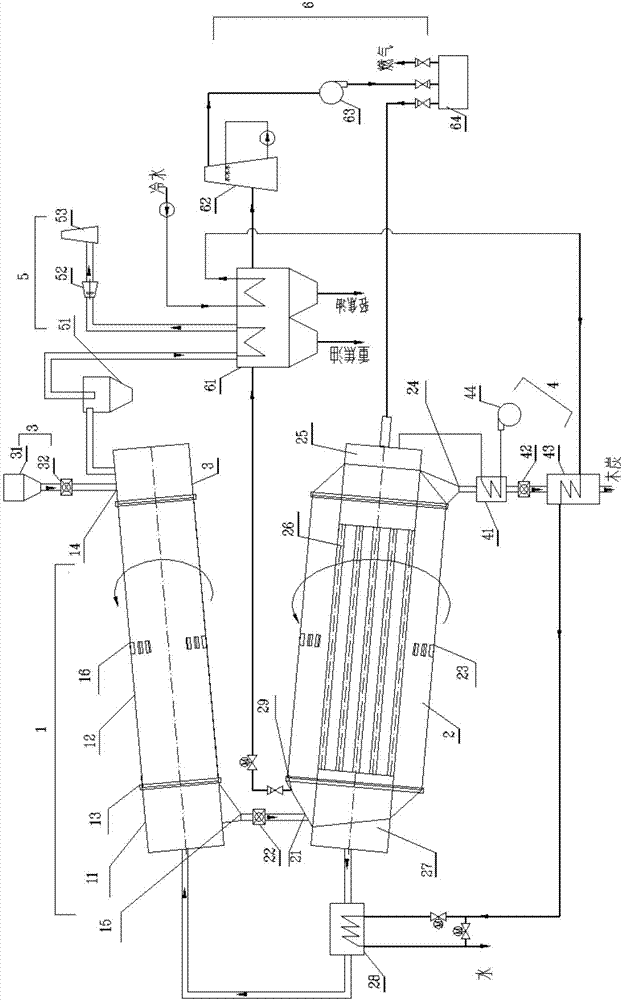

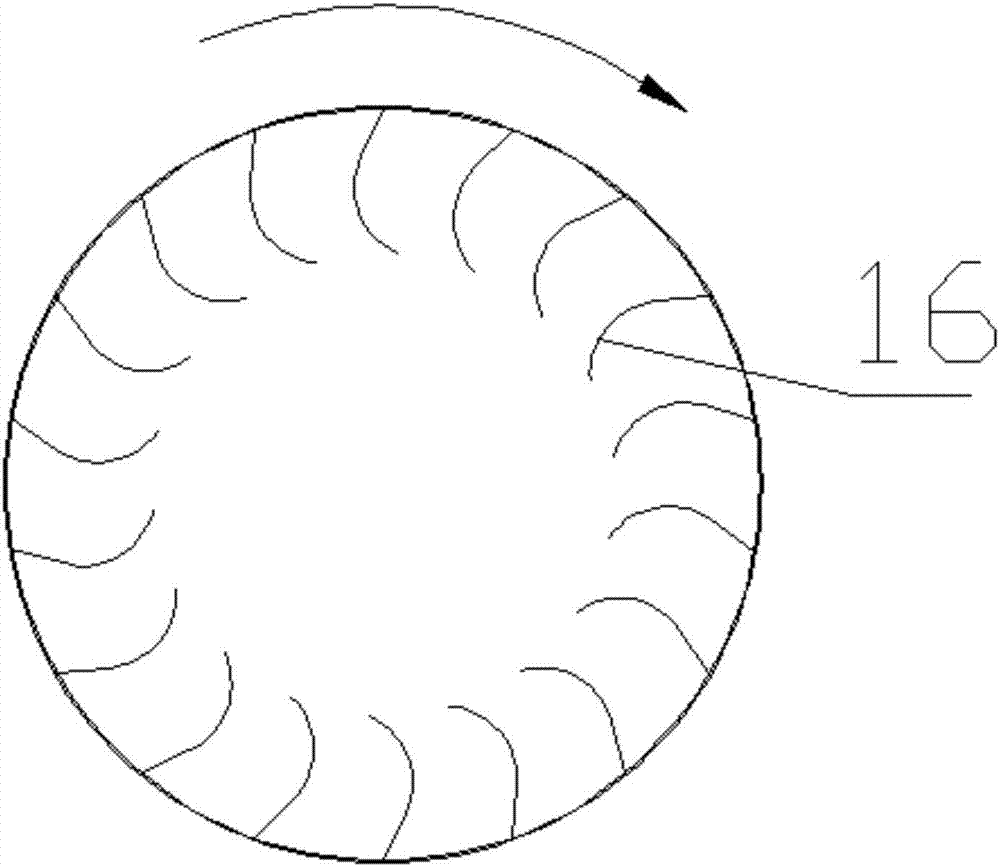

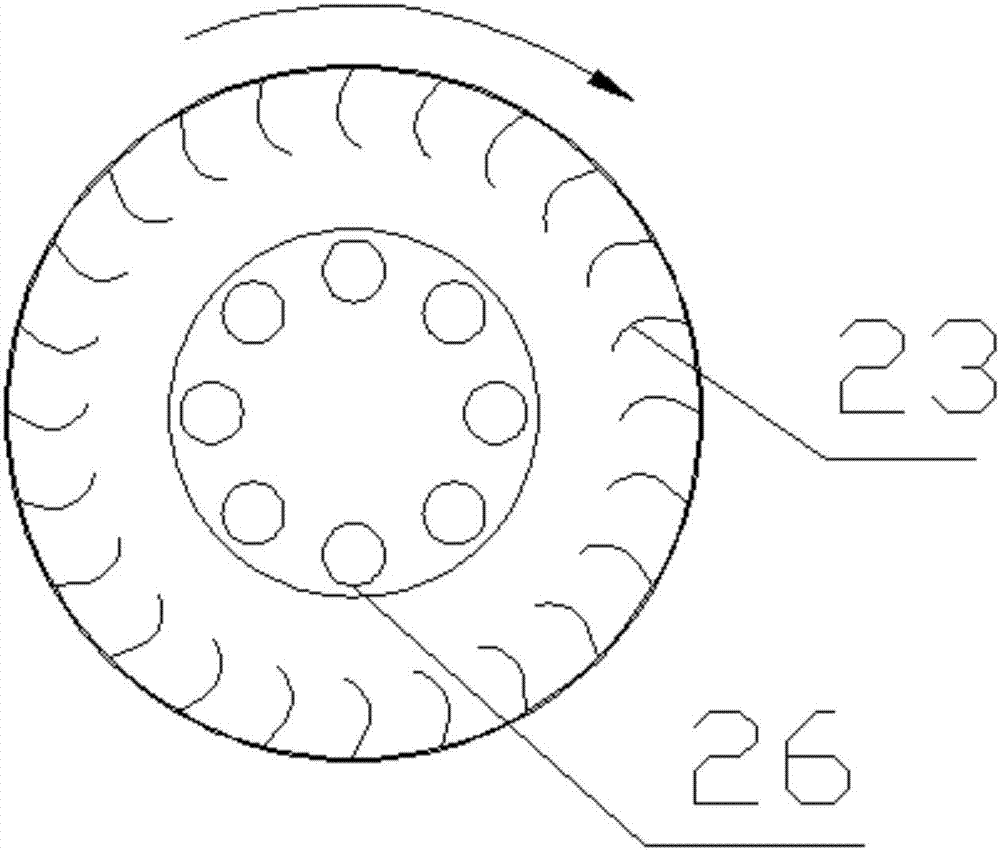

[0028] Please also see Figure 1 to Figure 3 , a biomass carbonization pyrolysis device, comprising a rotary baking chamber (1), a rotary carbonization pyrolysis chamber (2), a biomass feeding system (3), a heating system, a charcoal discharge cooling system (4), It consists of a flue gas system (5), a biomass gas purification system (6), and the like. The rotary baking chamber (1) is a cylindrical structure, the two ends are closed by the first end cover (11) and the middle part is the first drum (12), and the first drum is driven by a frequency conversion motor (not shown in the figure). Schematic) low-speed rotation, the dynamic and static joints are connected by a sealing ring (13), the first drum is inclined at a certain angle from the first feeding end (14) to the first discharging end (15), and several winches are installed on the inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com