Electromagnetic tamping machine of tamping coke oven

An electromagnetic type and tamping machine technology, applied in the coking oven, petroleum industry, etc., can solve the problems of large spare parts reserves, heavy maintenance workload, high equipment failure rate, etc., and achieve simple overall structure, low maintenance rate, and reduced The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

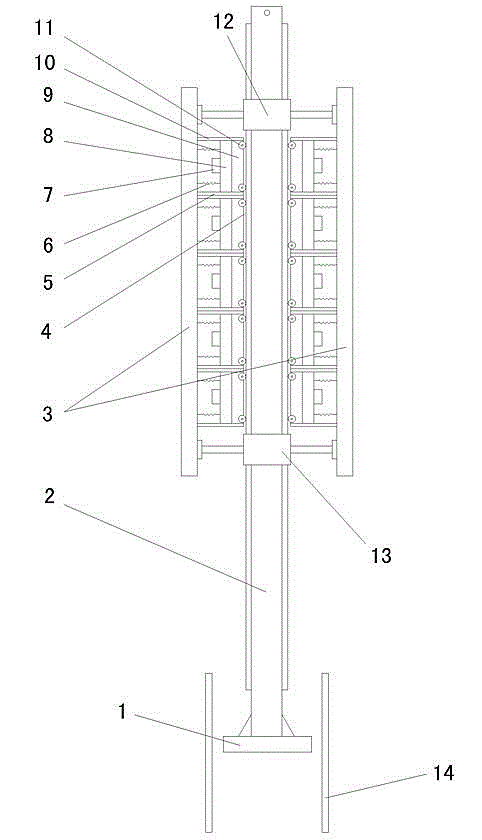

[0010] like figure 1 Shown: 3 is a steel structure, which is made by welding section steel. The steel structure 3 is equipped with a vertical hammer rod 2, and a hammer head 1 is installed under the hammer rod 2, and the hammer head 1 is connected with a driving mechanism. The driving mechanism is a linear motor connected with the control device. The linear motors are symmetrically distributed on both sides of the hammer rod 2, with at least one set on each side. In this embodiment, five sets are installed on each side and arranged up and down.

[0011] The stator part 9 of each group of linear motors is all fitly installed between the upper slideway 10 and the glideway 5, and can move in the horizontal direction relative to the upper slideway 10 and the glideway 5. The upper slideway 10 and the glideway 5 are fixedly connected with the steel structure 3 by welding.

[0012] Rollers 11 are installed on the shell of the stator part 9 of the linear motor near the hammer rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com