Smoke damper door

A baffle door and flue gas technology, which is used in exhaust gas devices, combustion product treatment, combustion methods, etc., can solve problems such as operation errors, unit trip failures, and large flue gas flow resistance, reducing leakage and The effect of good strength and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

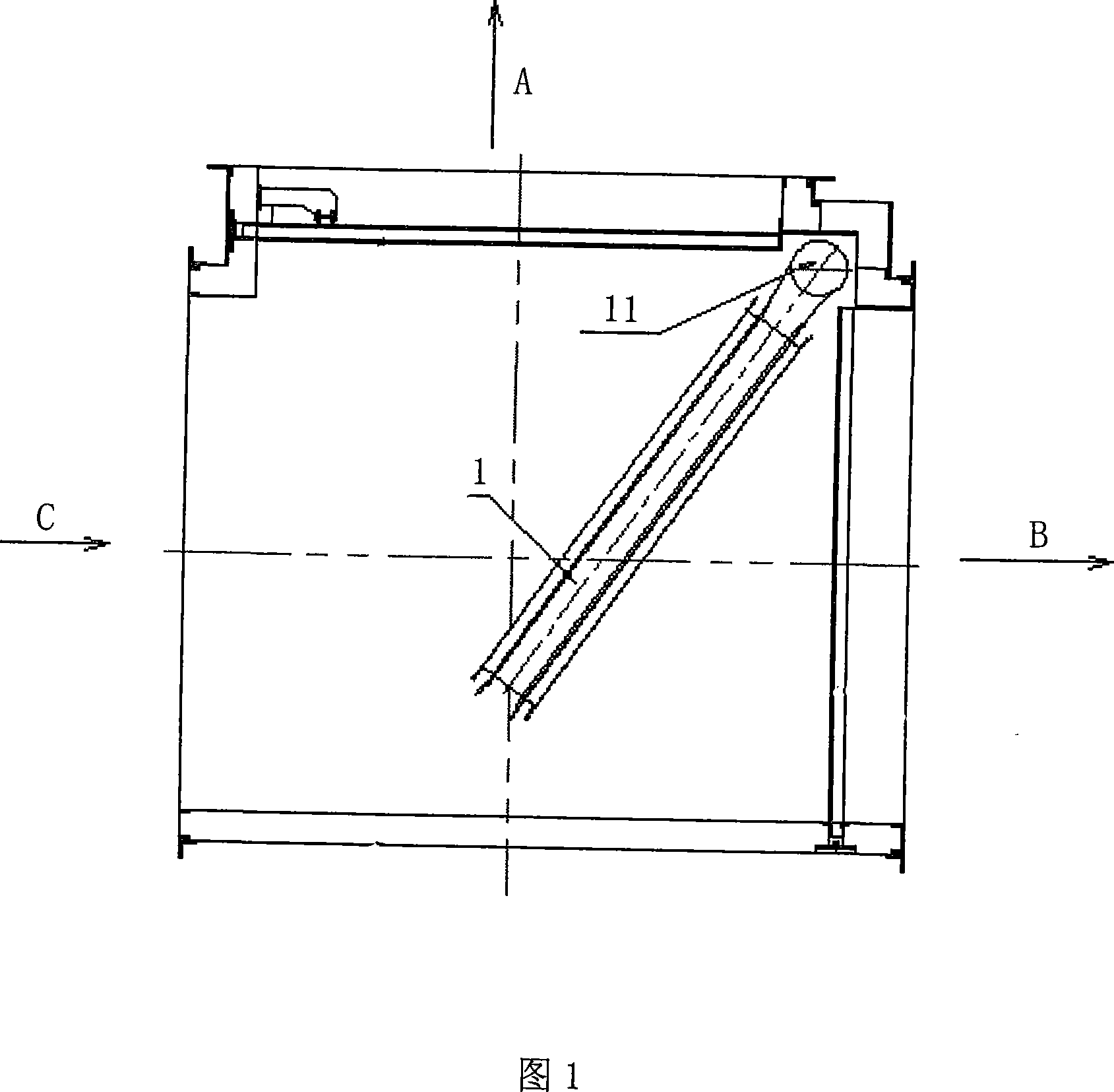

[0027] For the baffle door shown in Figure 1, the baffle 1 adopts a single-axis single-blade structure, that is, the rotating shaft 11 is located on the top of the baffle 1, and the baffle can rotate around the axis 0-90° in the flue. When the baffle plate 1 closes the side channel of the chimney A upwards, the flue gas C is introduced into the waste heat boiler; when the baffle 1 closes the side channel of the boiler B downward, the flue gas C is introduced into the bypass chimney; but it is not possible to close both at the same time exit, causing the gas turbine to trip.

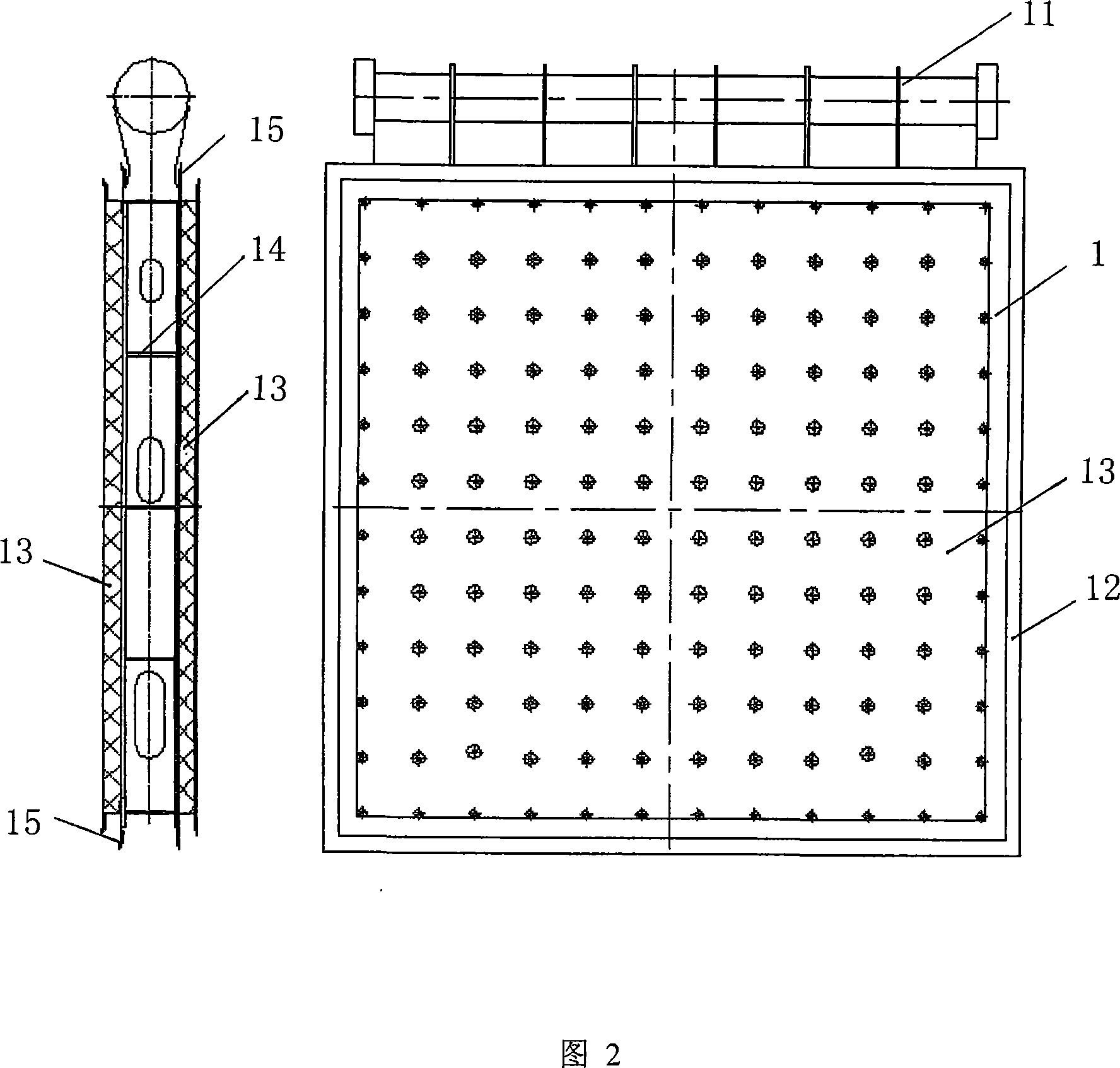

[0028] The baffle plate 1 shown in Figure 2 is surrounded by a metal frame structure 12, with a metal reinforcing rib 14 in the middle, and a cladding layer 13 of a refractory fiber material on both sides. The refractory fiber material can be ceramic fiber or glass fiber. This embodiment uses Ceramic fiber, elastic sheet metal 15 is arranged around frame 12.

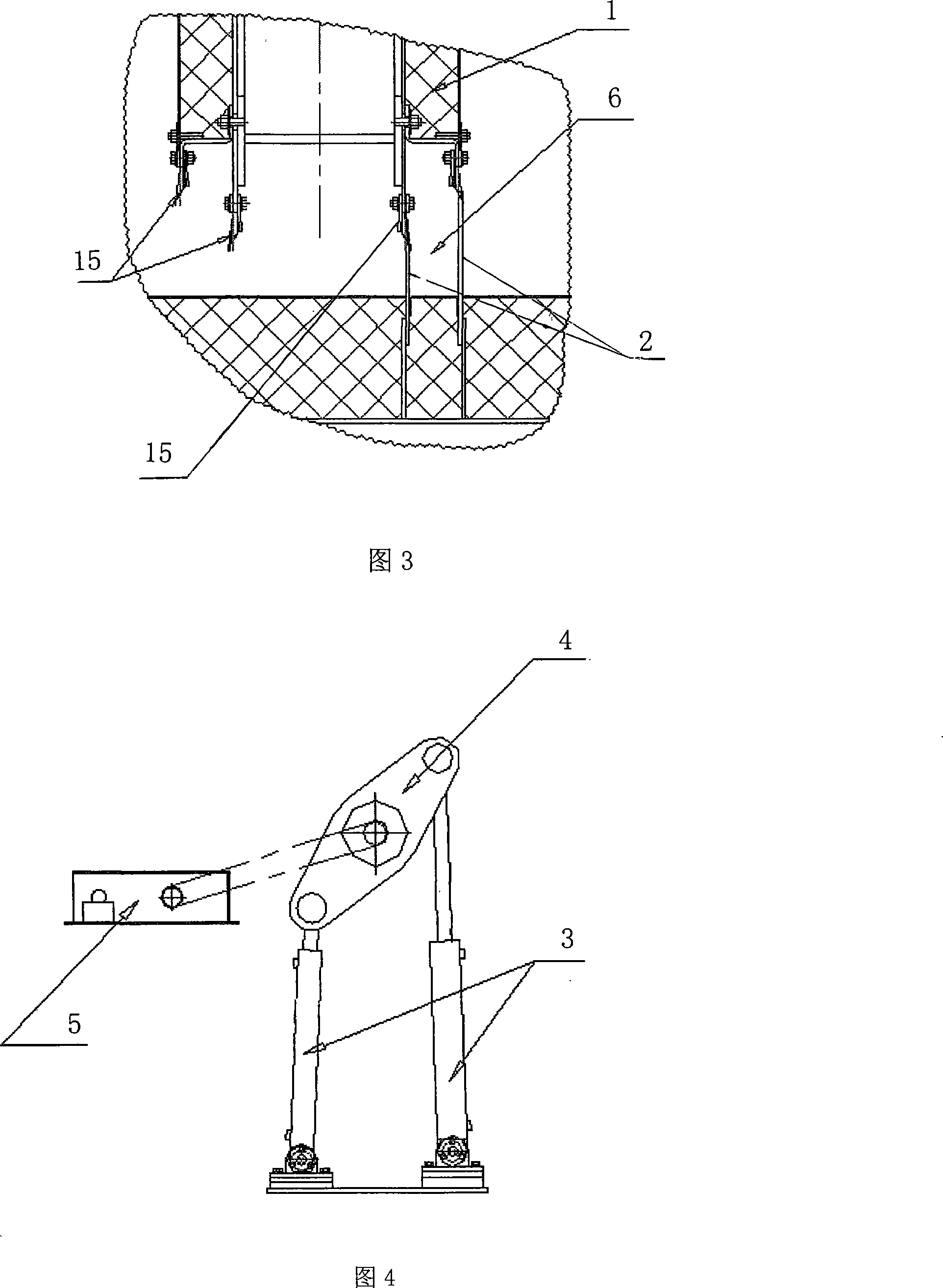

[0029] As for the sealing structure of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com