System used for sinter ore cooling and sensible heat efficient recycling

A sinter and sensible heat technology, which is applied in the field of sinter cooling and sensible heat recovery in the iron and steel industry, can solve the problems of low accumulation height of sinter material layers, increased fan power and power consumption, and heavy equipment maintenance workload. To achieve full utilization of sintering waste heat, improve the efficiency of waste heat utilization, and reduce the effect of cooling air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

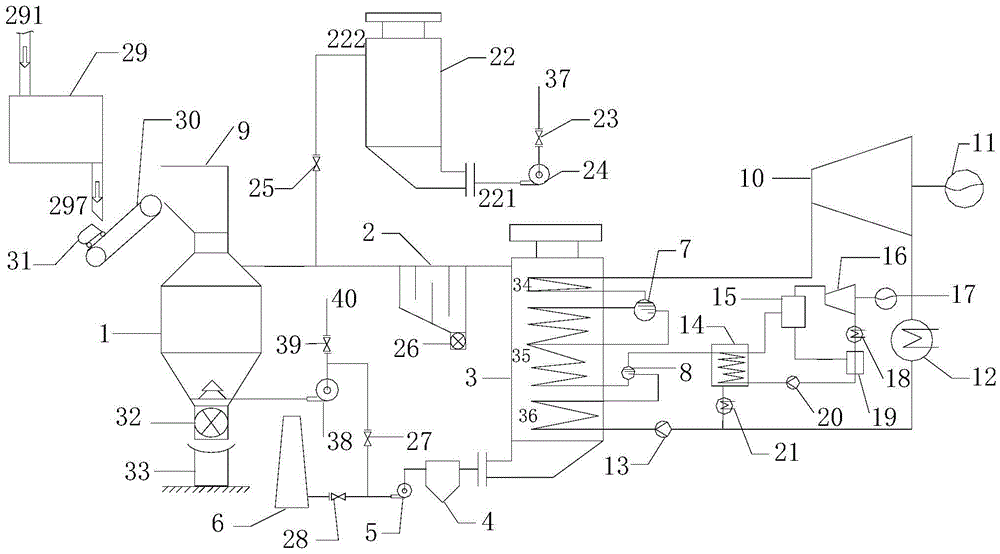

[0049] A system for cooling sinter and efficient recovery and utilization of sensible heat of the present invention will be described in detail below in conjunction with the embodiments and drawings.

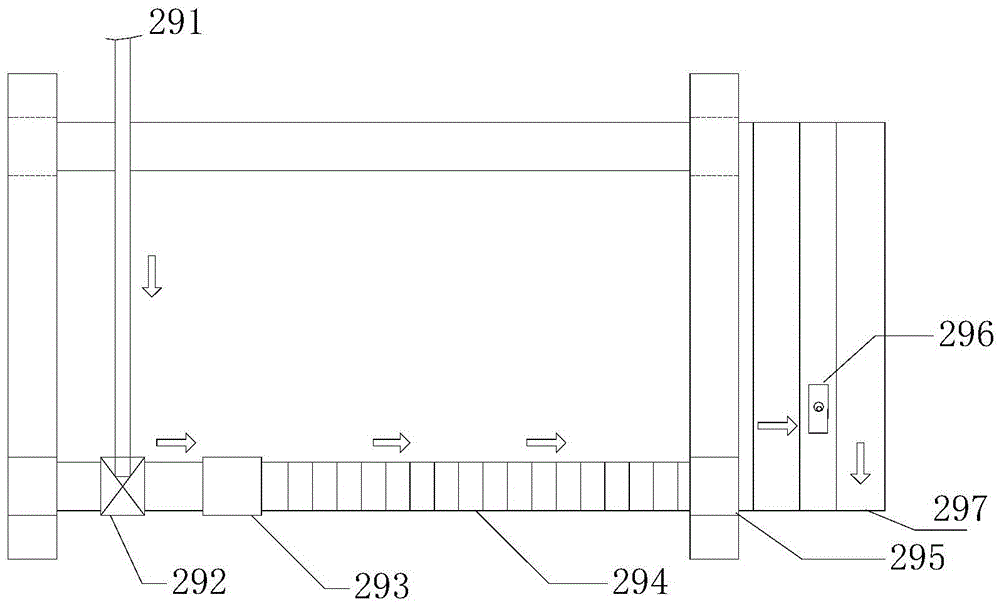

[0050] Such as figure 1 As shown, a system for sinter cooling and efficient recovery of sensible heat in the present invention includes: a stepping sintering machine 29 only used for sintering mixed iron ore materials, and a stepping sintering machine 29 for sintering sintered cakes after sintering. The cooled vertical cooling kiln 1 is arranged between the discharge port of the stepping sintering machine 29 and the feed port of the vertical cooling kiln 1 receiving funnel 9 for sending the output of the stepping sintering machine 29 into The feeding mechanism of the vertical cooling kiln 1 is connected to the gas outlet on the upper part of the vertical cooling kiln 1 through pipelines, respectively, the gravity dust collector 2 used for dedusting the high-temperature flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com