Process and device for dual continuous steel making with iron-containing material rotary hearth furnace

A rotary hearth furnace and material technology, applied in the field of iron and steel metallurgy, can solve the problems of high cost and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Iron-containing materials: iron ore fine powder, carbon-containing materials: coal powder.

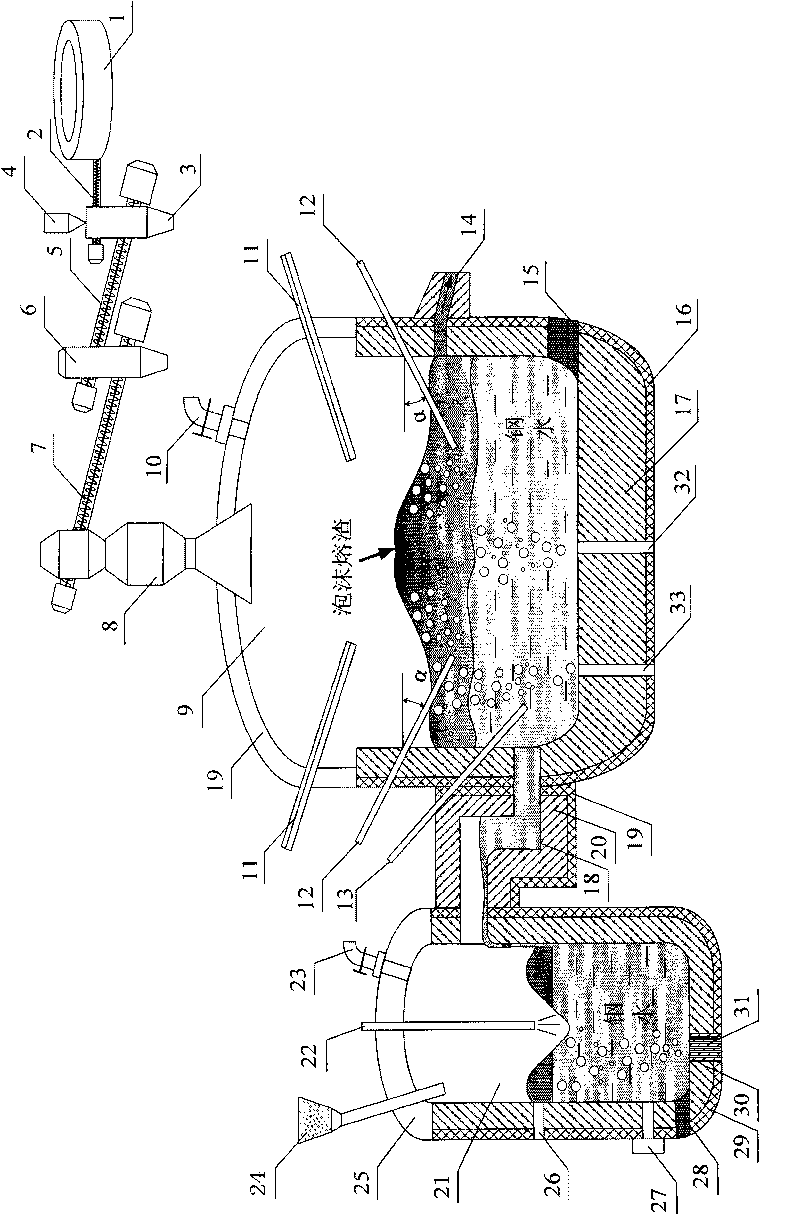

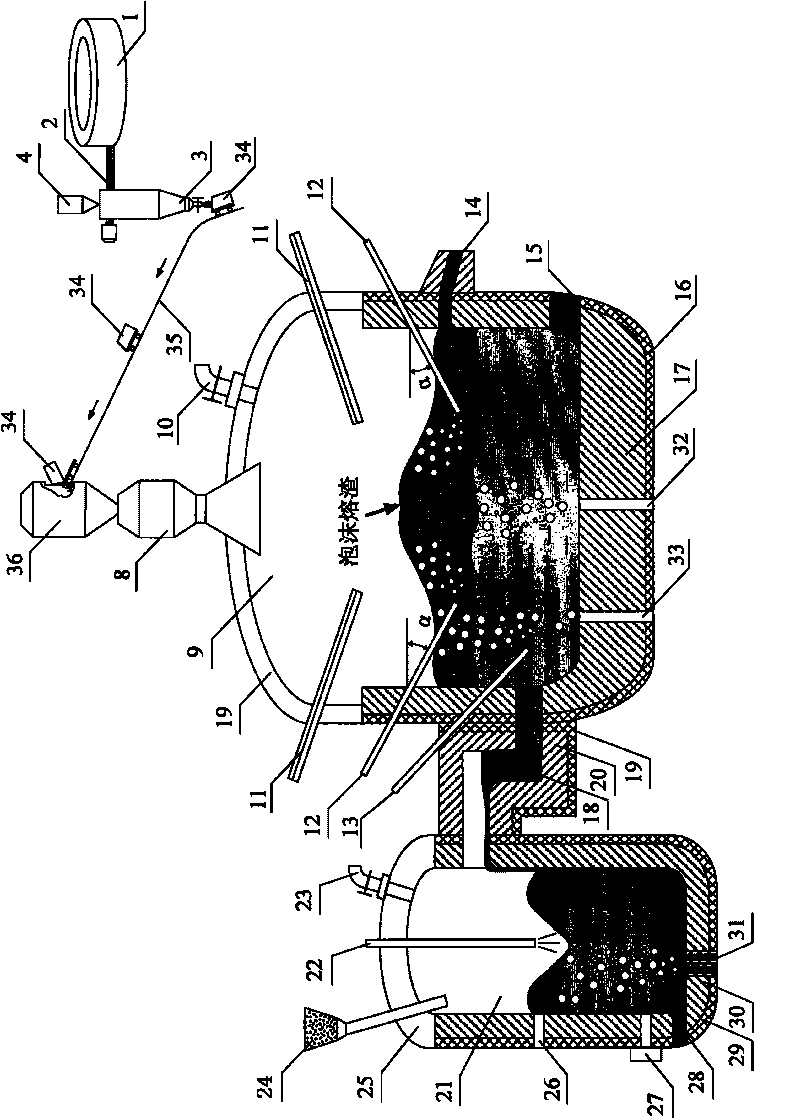

[0064] The continuous steelmaking equipment of the present invention includes: a smelting furnace 9 and an oxygen blowing furnace 21, the smelting furnace 9 and the oxygen blowing furnace 21 are connected through the siphon outlet 18 of the smelting furnace; 9 The upper part is equipped with a gas-oxygen combustion gun 11, a coal-oxygen gun 12, and an argon gun 13. The lower part of the melting furnace is equipped with a slag outlet 14 of the melting furnace, a steel opening 15 at the bottom of the melting furnace, a water-cooled furnace wall 16 of the melting furnace, and a refractory material furnace of the melting furnace. Wall 17, melting furnace cover 19; melting furnace siphon tapping outlet 18, melting furnace siphon tapping outlet water cooling wall 19, melting furnace siphon tapping outlet refractory wall 20, melting furnace bottom oxygen blowing bricks 32 and 33; The o...

Embodiment 2

[0072] Iron-containing materials: iron ore powder 50%, iron-containing metallurgical dust 50%, carbon-containing materials: coal powder.

[0073] Iron-containing metallurgical dust composition: iron oxide scale, blast furnace dust, converter dust, electric furnace dust, sintering pellet dust, etc.

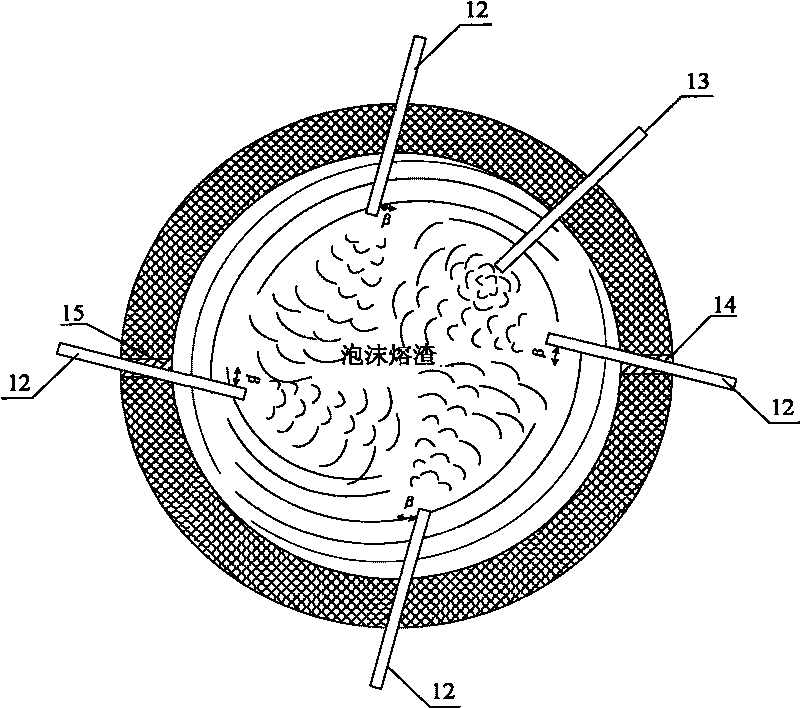

[0074] 50% of iron ore powder and 50% of iron-containing metallurgical dust are pre-reduced in a rotary hearth furnace and fed into the smelting furnace together with limestone and dolomite flux. The coal oxygen lance 12 on the side wall of the smelting furnace forms an included angle of 30 degrees with the horizontal plane of the slag layer, such as figure 1 and 3 The α angle shown; at the same time, it forms an angle of 0 degrees with the diameter of the melting furnace, and inserts into the slag in the middle layer of the slag zone, as shown figure 2 β angle shown. The high-temperature pre-reduced iron-containing material in the discharge bin 3 of the rotary hearth furnace o...

Embodiment 3

[0076] Iron-containing materials: 100% iron-containing metallurgical dust, carbon-containing materials: one or more of coke oven gas, blast furnace gas, natural gas, and produced gas.

[0077] What the slag coal oxygen lance (12) injects is: one or more of coke oven gas, blast furnace gas, natural gas, and generated coal gas. The coal oxygen lance 12 on the side wall of the smelting furnace forms an included angle of 45 degrees with the horizontal plane of the slag layer, such as figure 1 and 3 The α angle shown; at the same time, it forms an included angle of 30 degrees with the diameter of the melting furnace, and is inserted into the slag in the middle layer of the slag zone, such as figure 2 Shown β angle, others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com