Patents

Literature

33results about How to "Use properly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

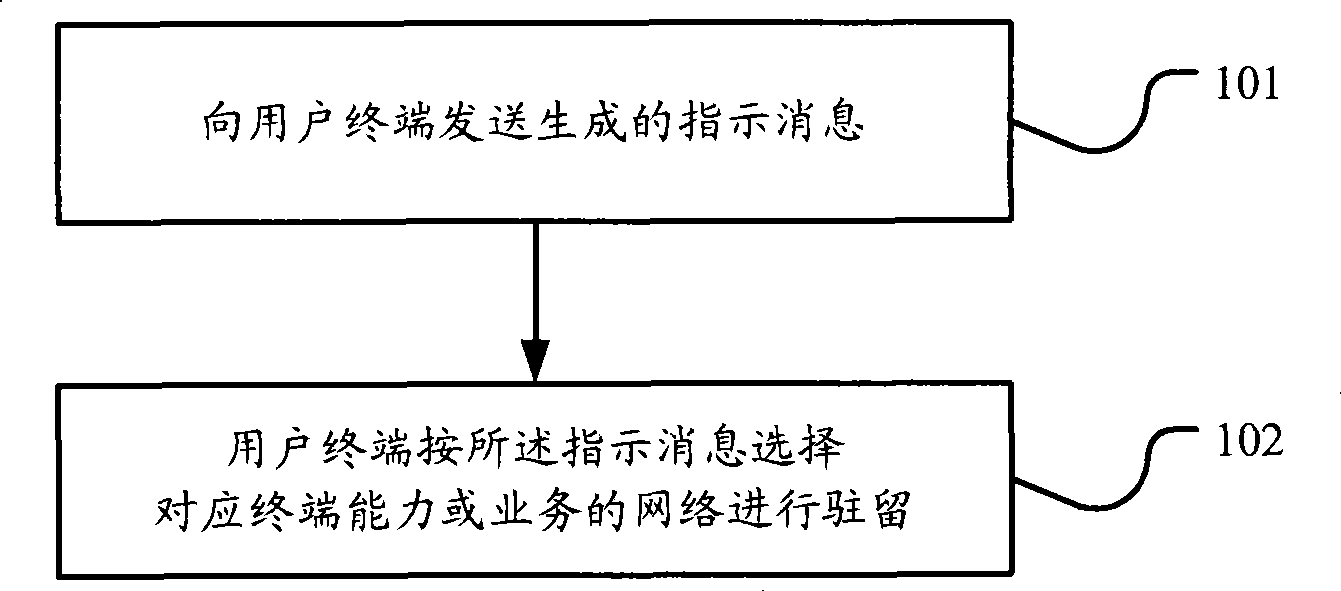

Method for resident network, network system, network side apparatus and user terminal

ActiveCN101365163AOptimize residencyUse properlyAssess restrictionRadio/inductive link selection arrangementsComputer networkNetworked system

The embodiment of the invention discloses a method for a user terminal to linger on network. The method comprises the following steps: a network side generates an indication message for indicating that a user terminal lingers on the network; and the network side sends down the indication messaged to the user terminal and indicates that the user terminal selects a corresponding network to linger on according to the indication message. Correspondingly, the embodiment of the invention provides a network system, which comprises network side equipment and the user terminal. The network side equipment is used for generating the indication message that the user terminal lingers on the network, sending down the indication message to the user terminal, and indicating that the user terminal chooses the corresponding network to linger on according to the indication message. The user terminal is used for receiving the indication messaged sent down by the side network. The embodiment of the invention further provides the side equipment and the user terminal correspondingly. The technical scheme of the embodiment of the can optimize the lingering of UE on network, and take the best advantages of network resources.

Owner:HUAWEI TECH CO LTD

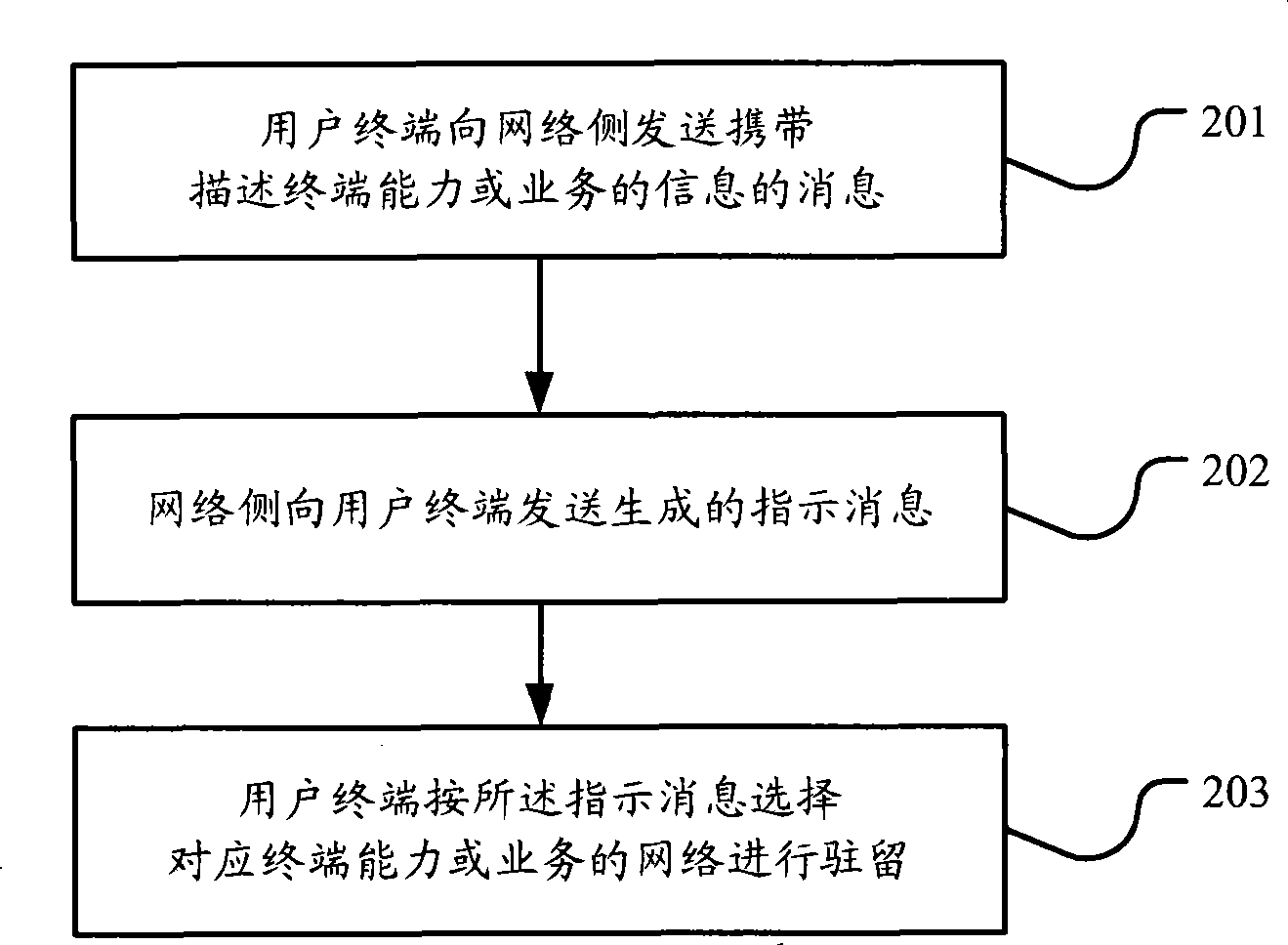

Biomarkers and assays for diabetes

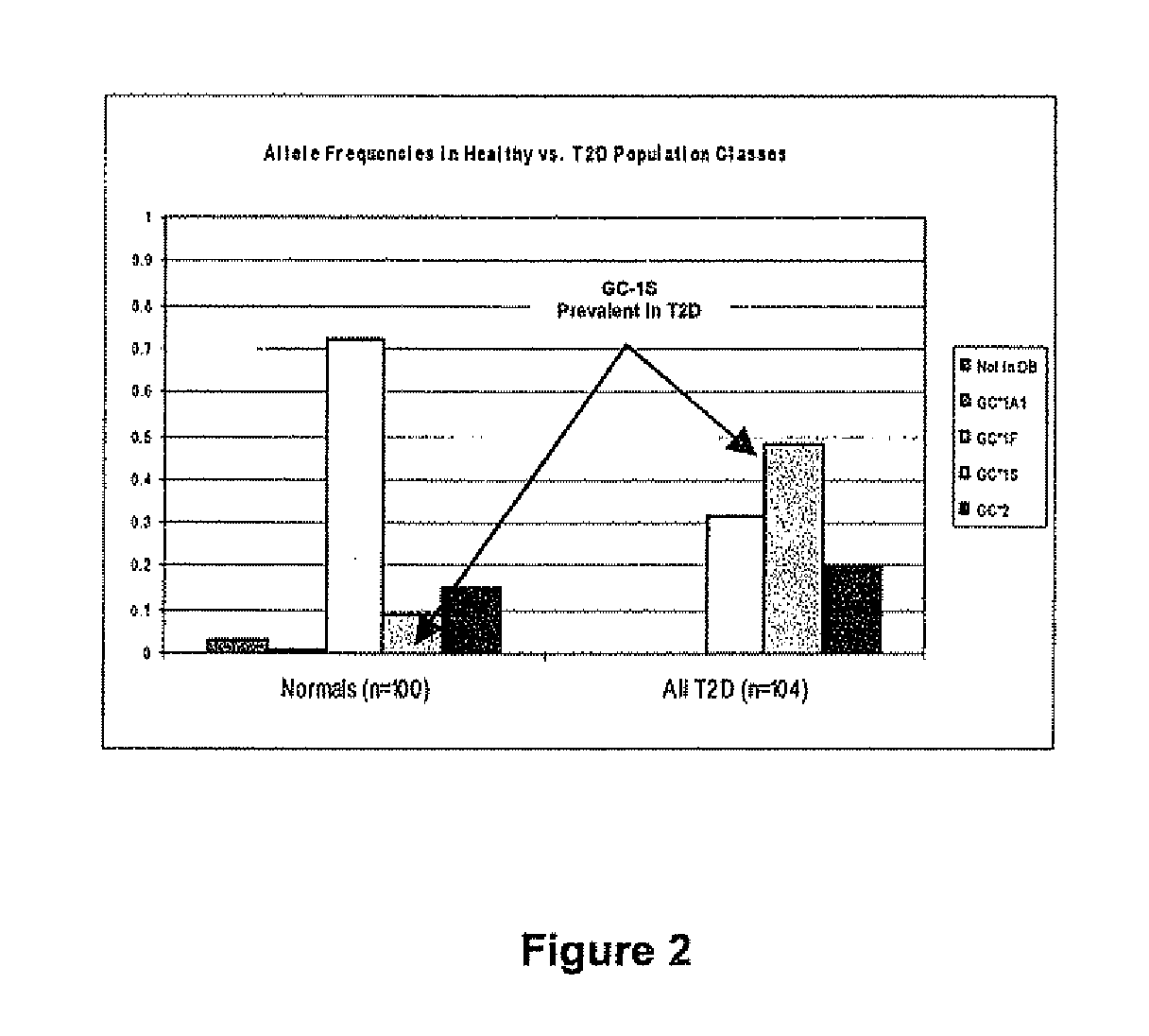

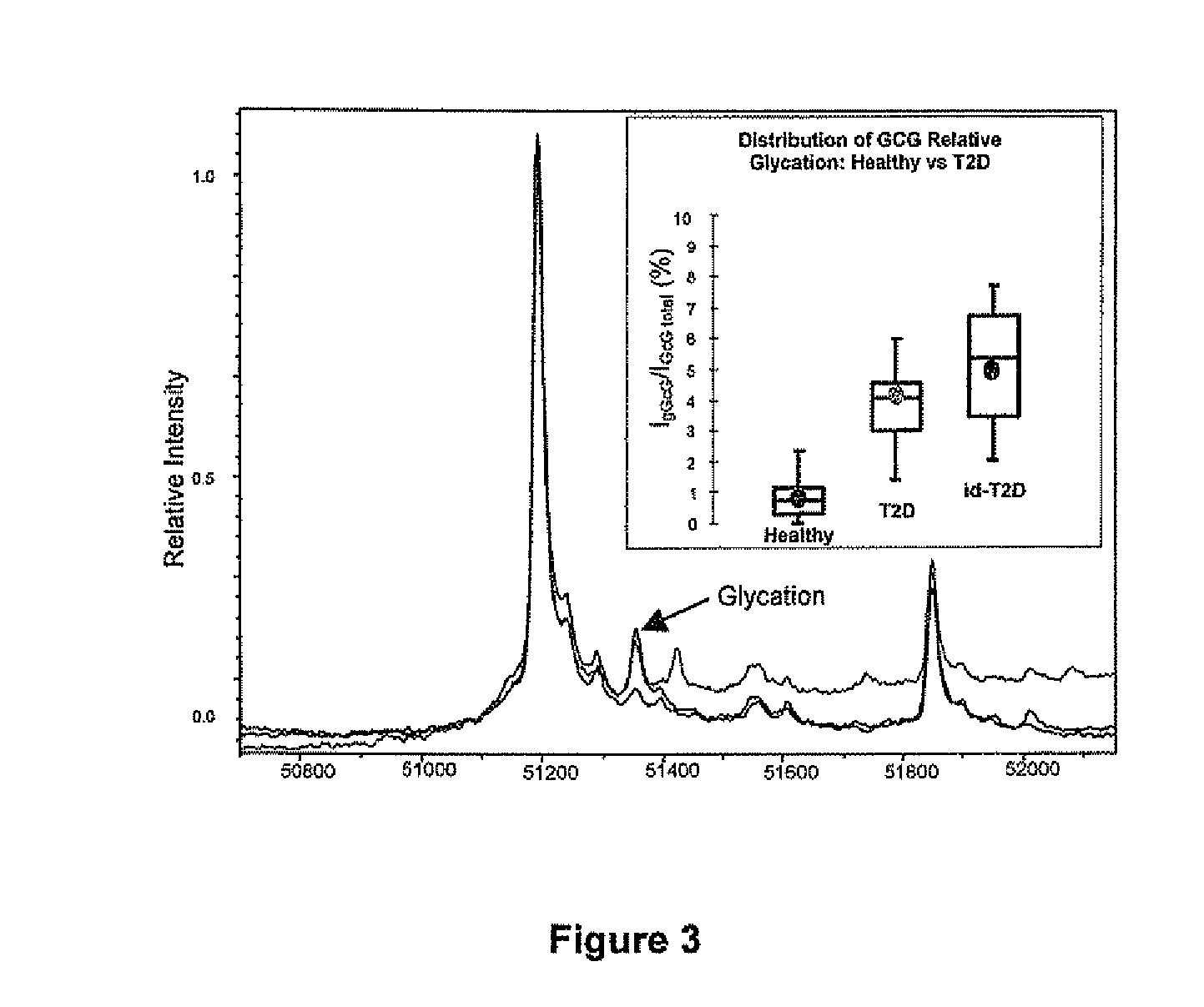

InactiveUS20110250618A1Use properlyEfficient use ofDisease diagnosisBiological testingGlobulinBeta-2 microglobulin

The present invention is directed to novel biomarkers and combinations thereof. The present invention also provides assays and data evaluation methods related to the detection and monitoring of diseases, particularly, diabetes. In particular, the biomakers in accordance with the present invention include, but are not limited to, modified forms of nominally wild-type proteins, such as Gc-Globulin or GcG (also known as Vitamin D binding protein), beta-2-microglobulin (b2m), cystatin C (cysC), Albumin and Hem A&B. Particular forms of diabetes contemplated by the methods of the present invention include, but are not limited to, type 1 diabetes (T1D), type 2 diabetes (T2DM), pre-T1D and pre-T2DM. The present invention also provides methods of detecting multiple biomarkers in a single assay and to employ data evaluation methods that is able to accurately use these data in the determination and monitoring of diseases, such as diabetes.

Owner:ARIZONA STATE UNIVERSITY

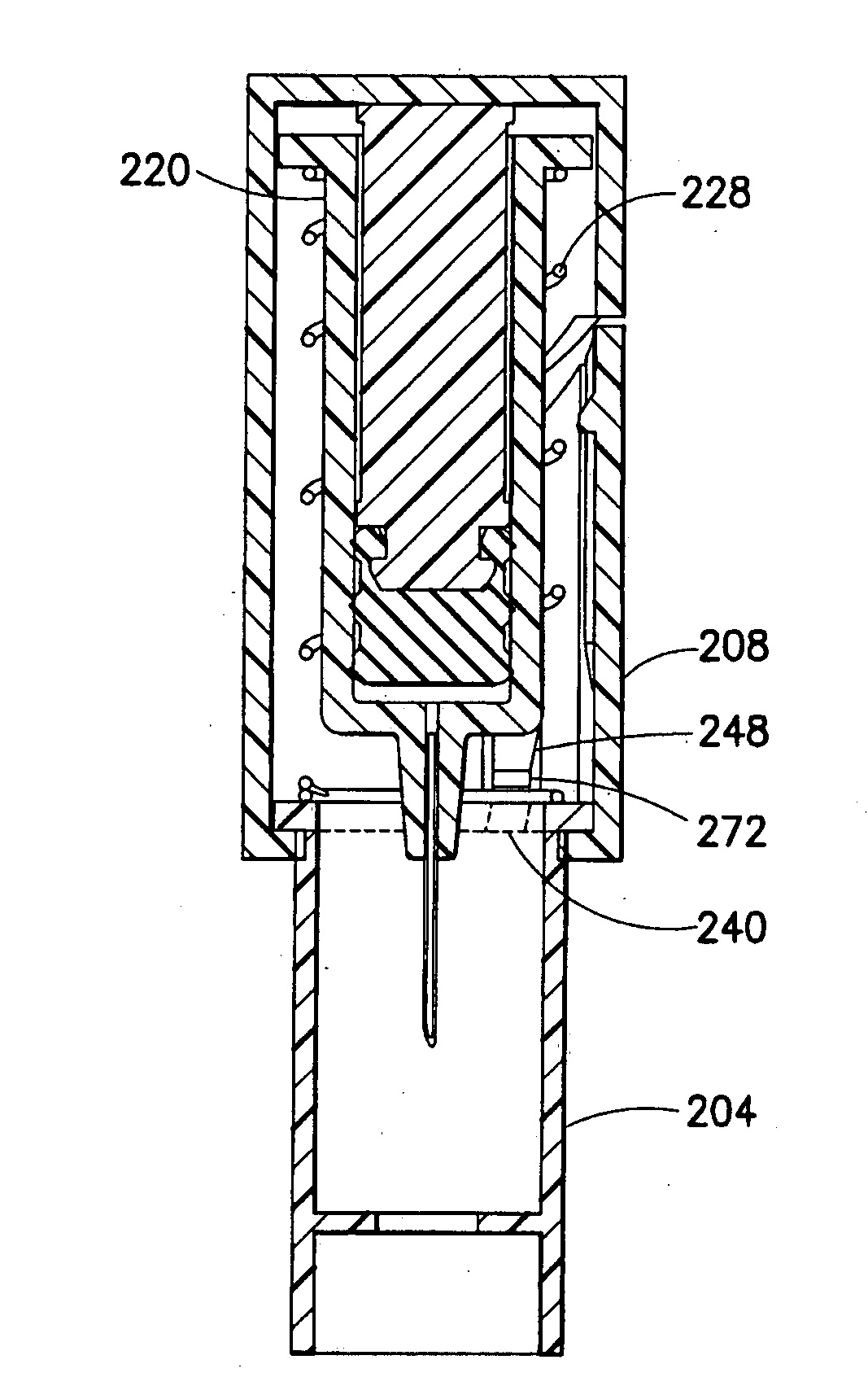

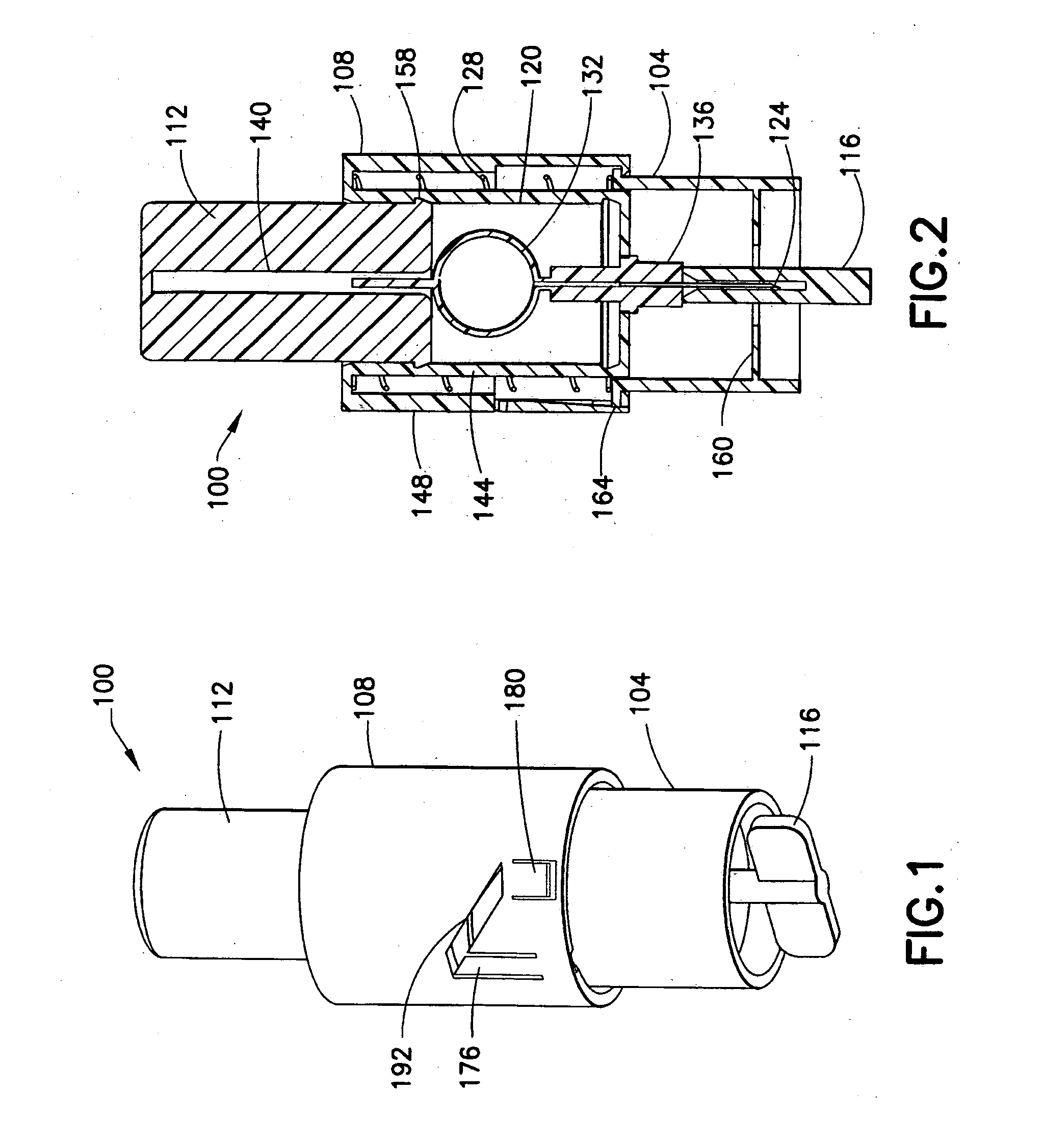

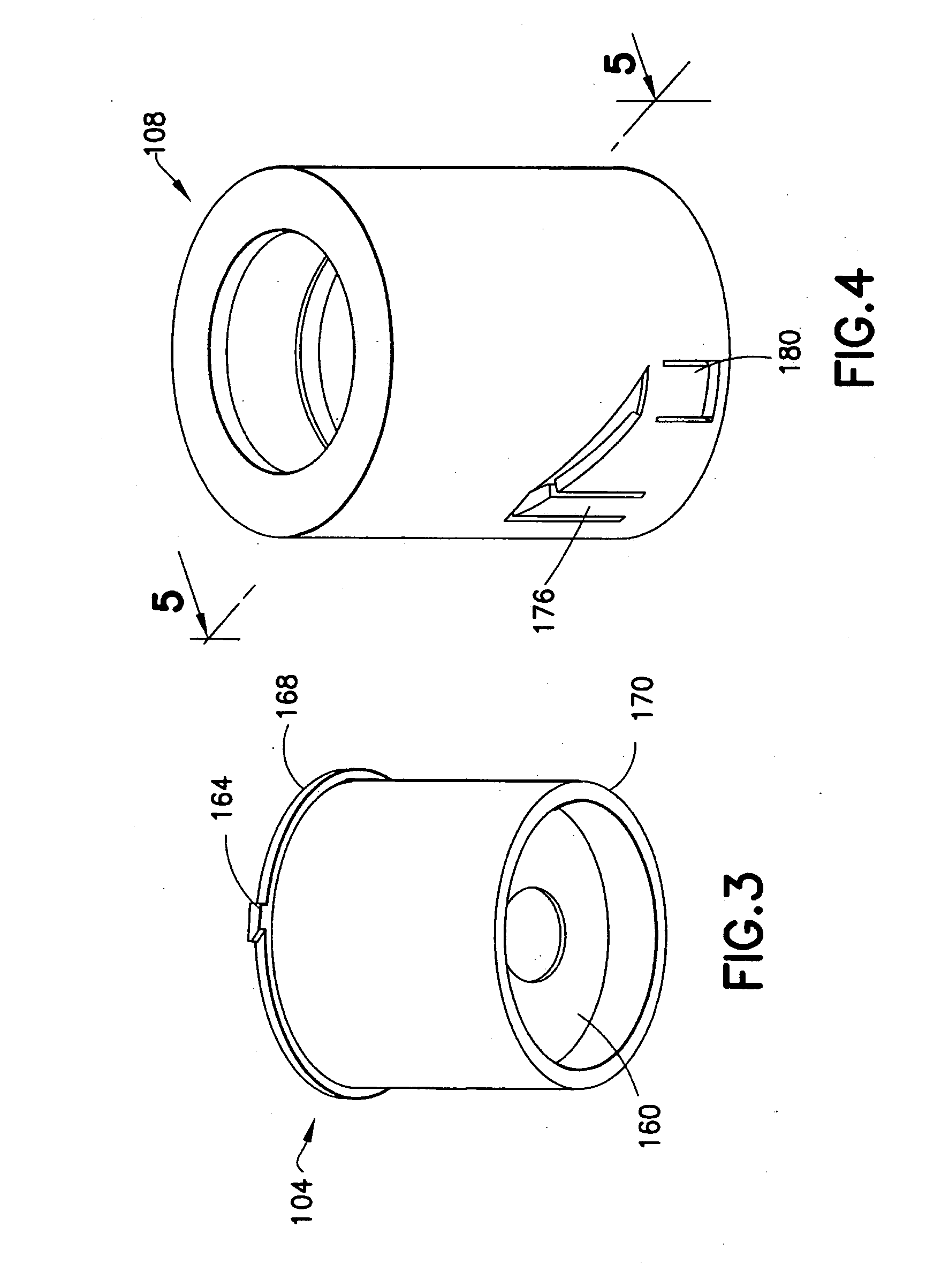

Single-use injector of low cost

An injection device (100, 200), including a safety shield (104, 204) and a housing (108, 208). The safety shield (104, 204) has a first end and a surface disposed at a second end thereof for contacting a patient's skin, and a shield tab (164, -240) extending therefrom. The housing (108, 208) is slidably disposed with respect to the safety shield (104, 204) and includes a guide groove (172, 252) for engaging the shield tab (164, 240) to guide movement of the housing (108, 208) relative to the safety shield (104, 204). The guide groove (172, 252) has first (184, 256) and second (188, 260) axial portions and a substantially helical portion (192, 264) connecting the first and second axial portions (184,188, 256, 260). The device (100, 200) also includes a medicament container (120, 220) connected with the housing (108, 208) and having a needle (124, 224) affixed thereto in communication with a medicament disposed within the medicament container (120, 220). The medicament container (120, 220) is displaceable relative to the safety shield (104, 204) from an initial position to an injection position, to a withdrawn position.

Owner:BECTON DICKINSON & CO

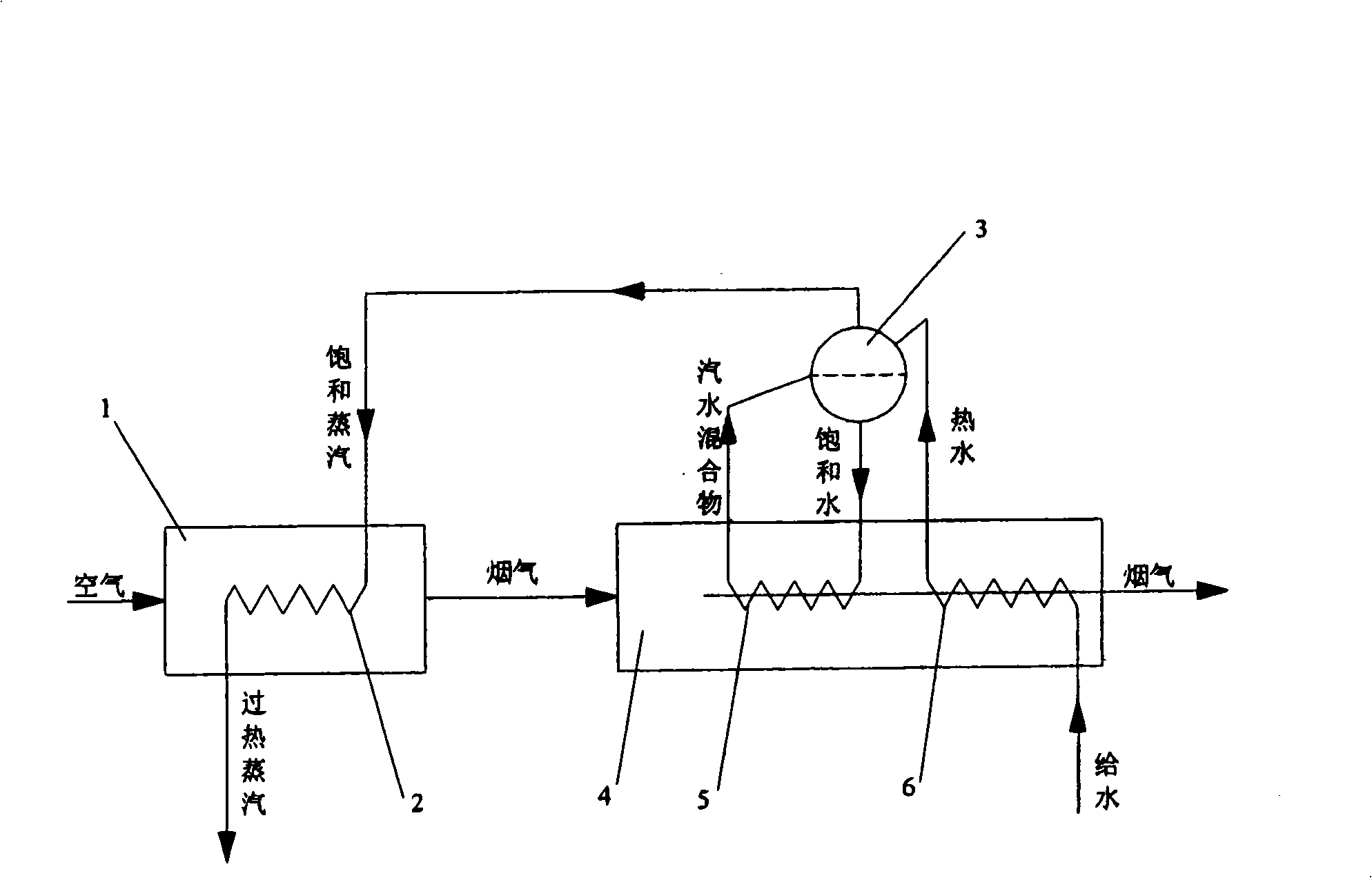

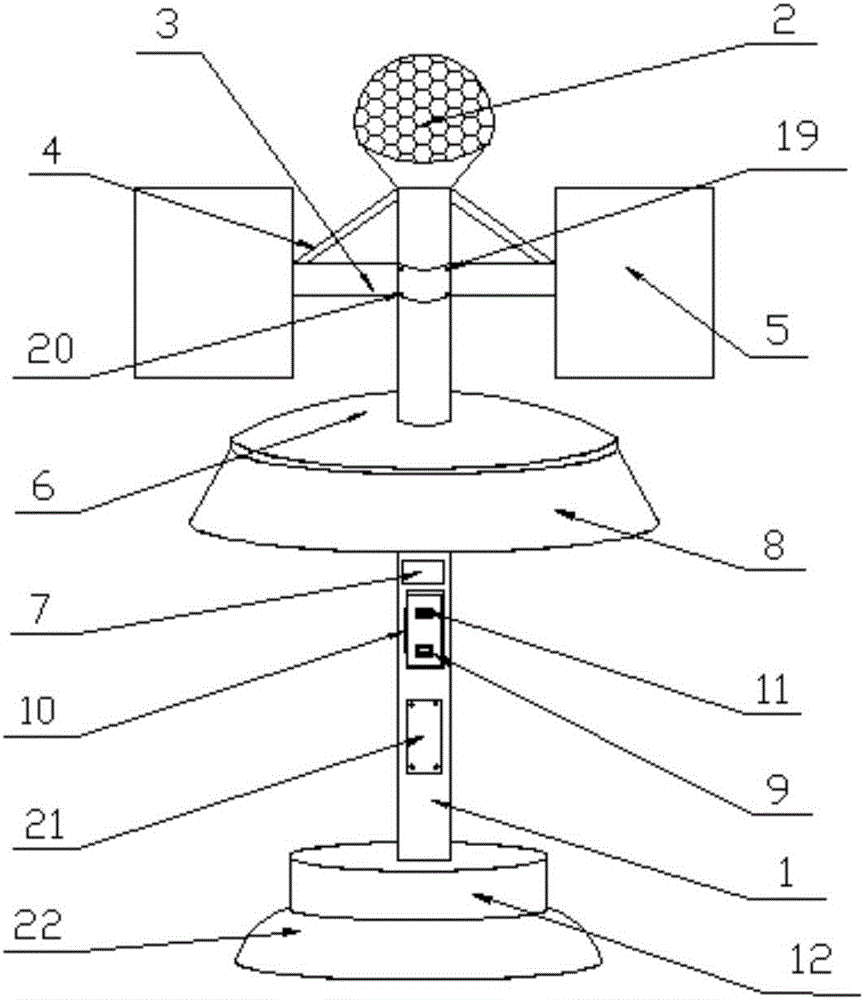

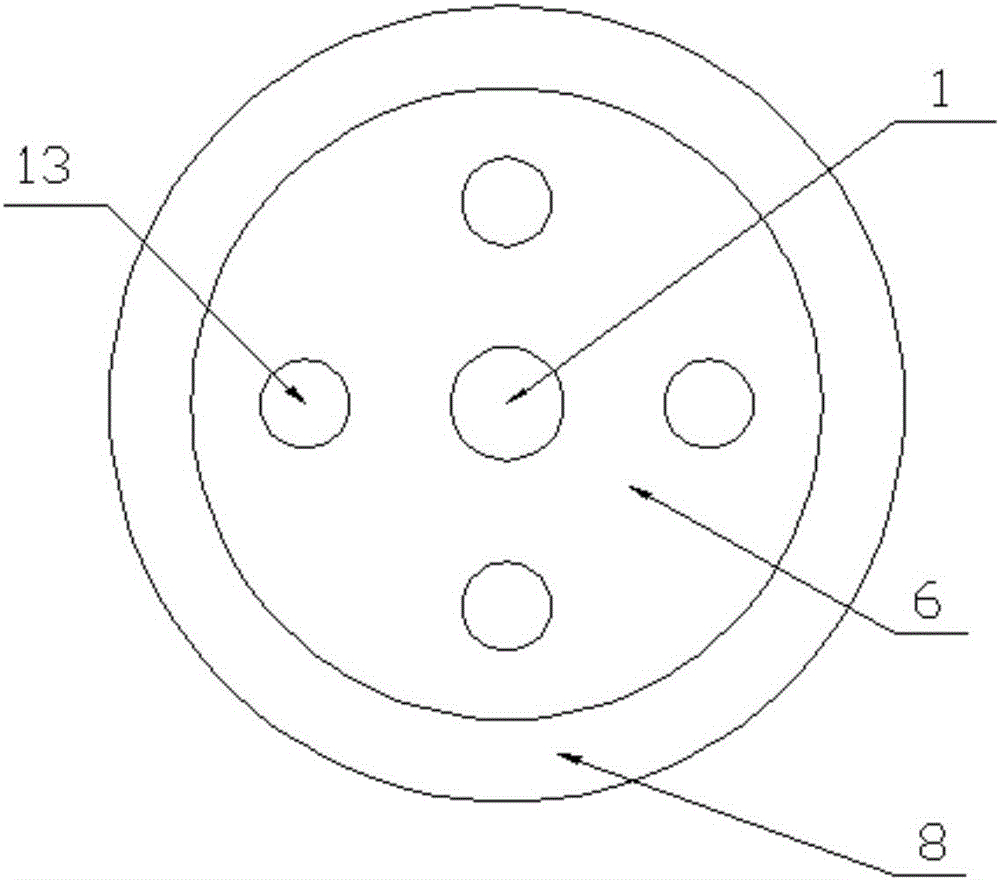

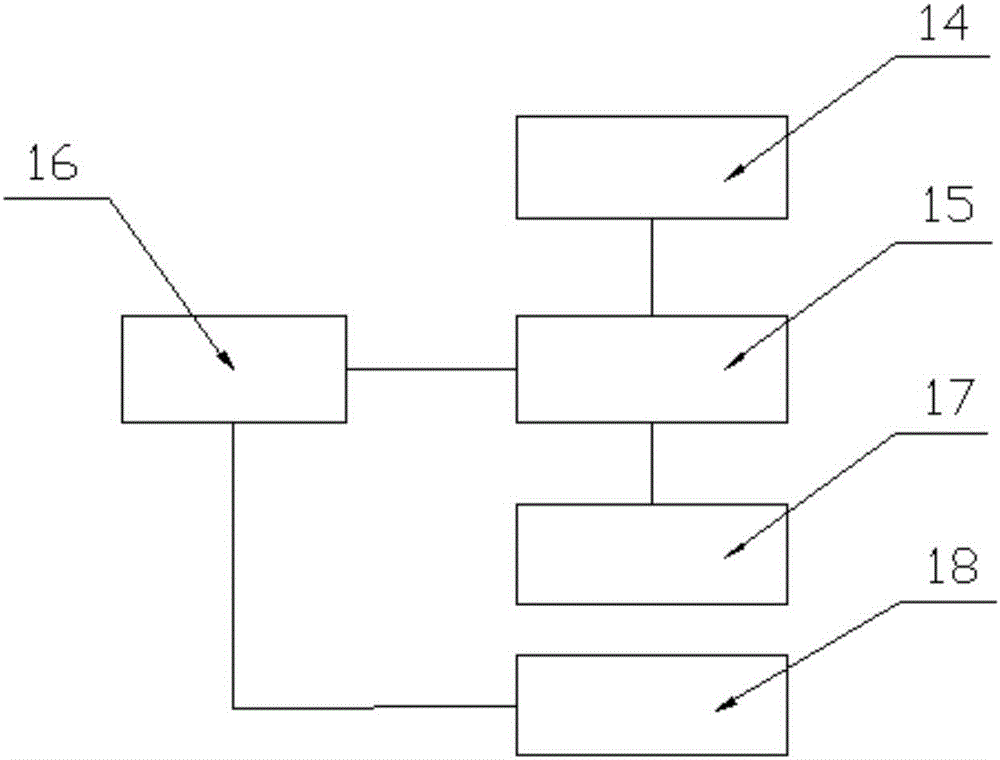

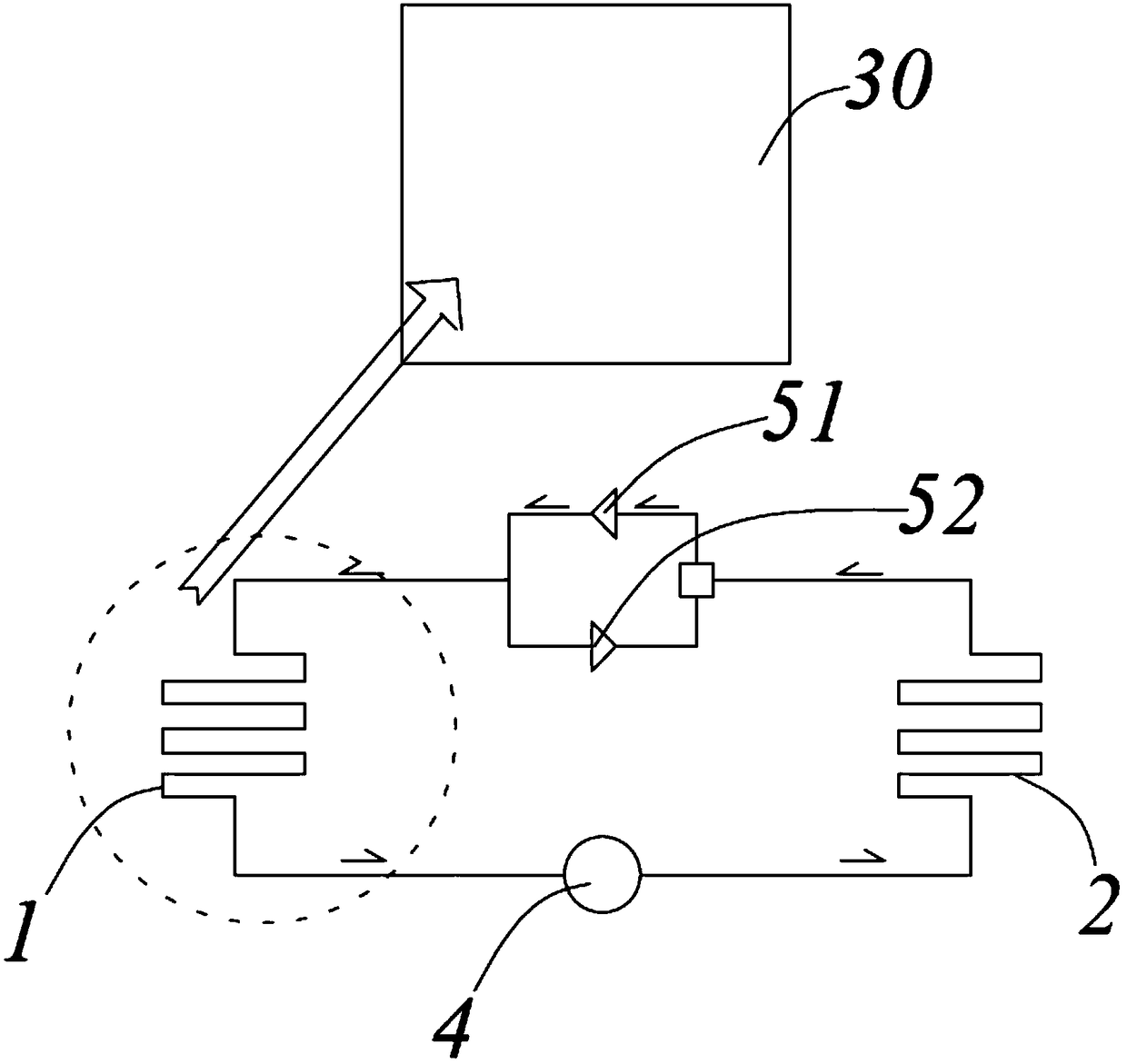

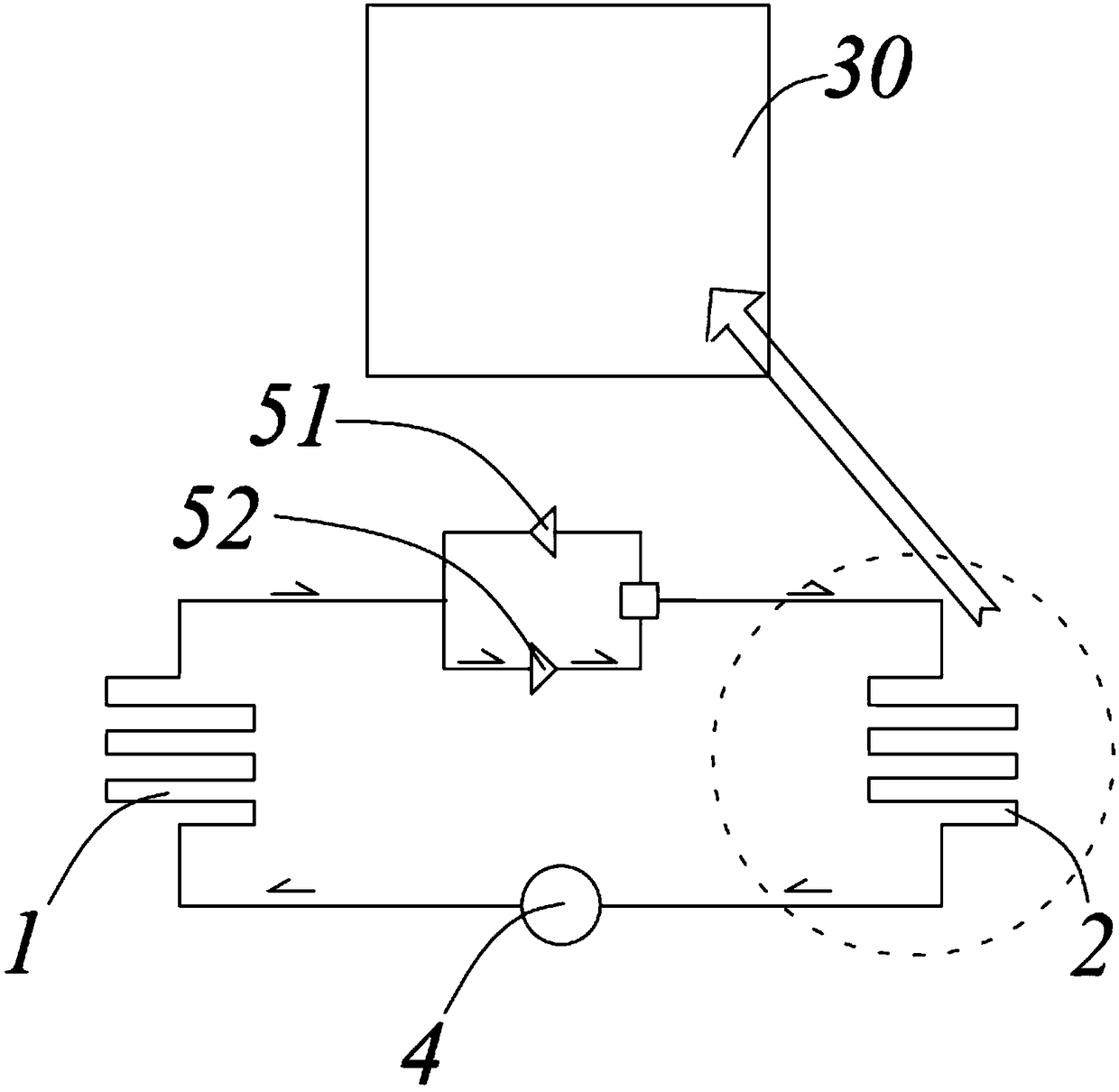

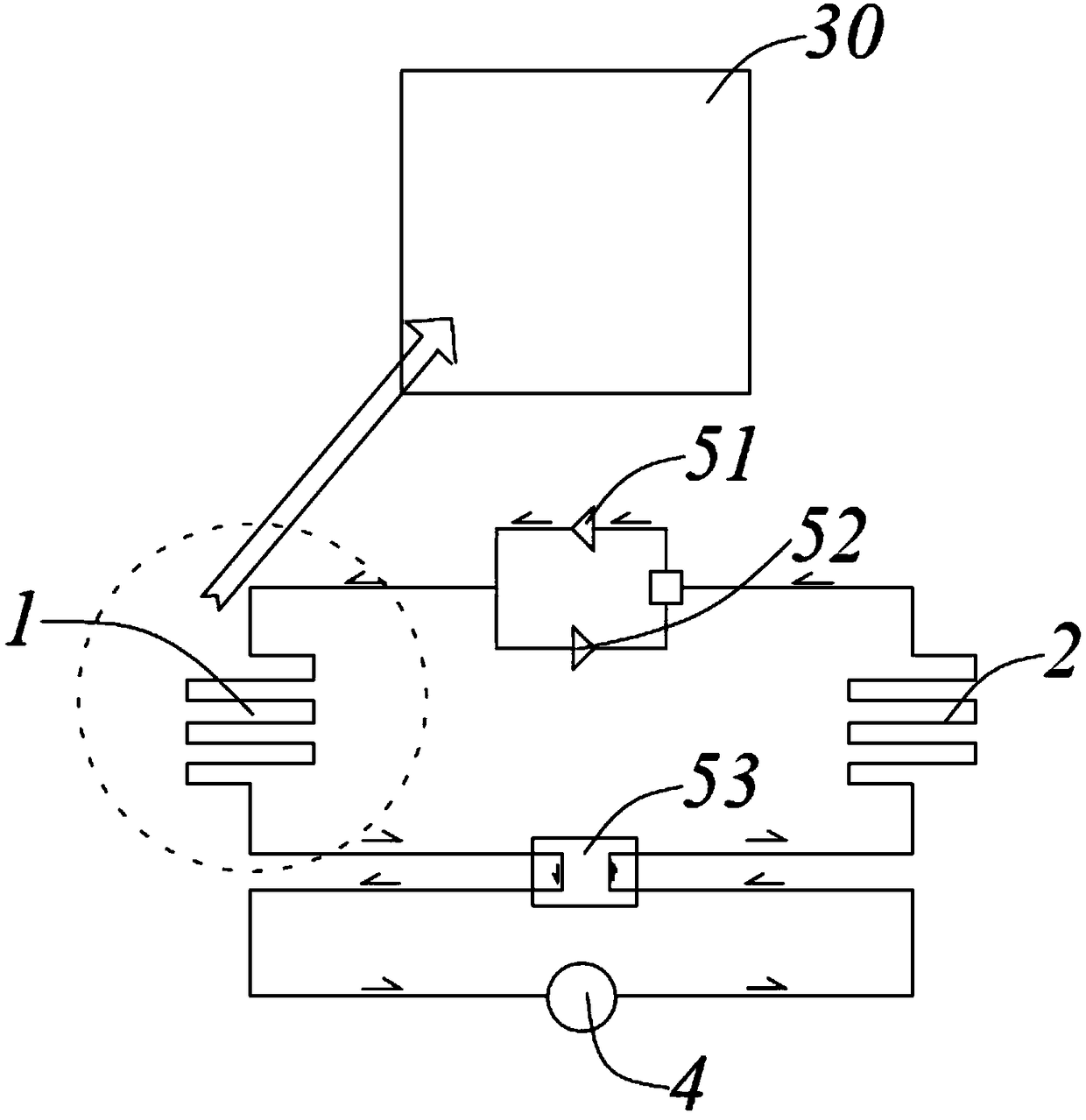

Flue gas waste heat recovery system of metallurgy electric furnace

InactiveCN101315183AImprove utilization efficiencyUse properlyWater circulationSteam generation using hot heat carriersCoalFlue gas

The invention provides a metallurgic electric furnace flue gas waste heat recovery system for realizing high-efficiency recovery of waste heat of a metallurgic electric furnace. The system comprises a waste heat boiler (4). The waste heat boiler is arranged outside an electric furnace (1). The flue gas exhaust from the electric furnace is guided into the waste heat boiler. The waste heat boiler comprises an evaporation heating surface (5), a coal economizer (6) and a steam tank (3). The coal economizer supplies water to the waste heat boiler. The hot water flowing out of the exit of the coal economizer is supplied to the steam tank. The bottom of the steam tank is connected with the entrance of the evaporation heating surface. The steam tank supplies saturated water to the evaporation heating surface. The middle part of the steam tank is connected with the exit of the evaporation heating surface. The steam-water mixture enters the steam tank after heat absorption and undergoes steam-water separation in the steam tank. The system further comprises a radiation heating surface which is arranged inside the electric furnace. The entrance of the radiation heating surface is connected with the steam tank. The saturated steam inside the steam tank flows to the radiation heating surface, the radiation heating surface absorbs the high-temperature radiation heat inside the electric furnace and heats the saturated steam to form superheated steam, and the superheated steam is guided out of the exit of the radiation heating surface.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

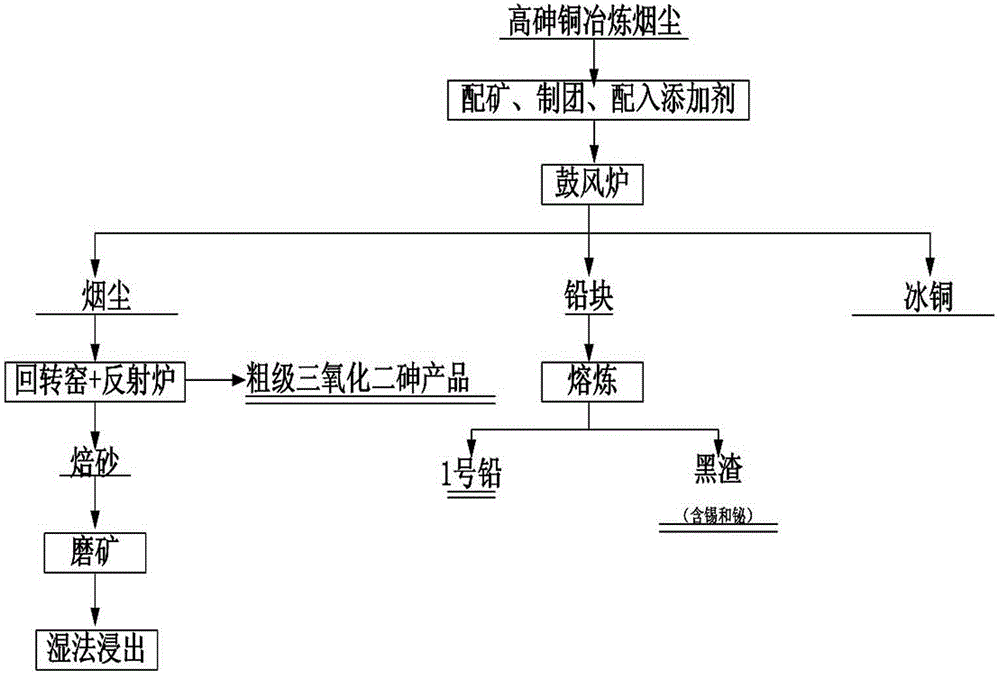

Method for recovering valuable metals from complex high-arsenic-and-copper smelting flue dust

ActiveCN106282584AReasonable technical arrangementUse properlyProcess efficiency improvementReverberatory furnaceIndium

The invention discloses a method for recovering valuable metals from complex high-arsenic-and-copper smelting flue dust, belongs to the technical field of metallurgy, and concretely relates to a method for recovering valuable metals from high-arsenic-and-copper smelting flue dust containing complex components. The method comprises the following steps: 1, the high-arsenic-and-copper smelting flue dust is reduced and molten at a high temperature in order to make lead, bismuth and tin be reduced and enter metallic lead, arsenic and indium enter the flue dust and copper enter slag; 2, the obtained flue dust undergoes arsenic removal treatment in a rotary kiln, obtained calcine undergoes further arsenic removal in a reverberatory furnace to obtain an arsenic trioxide product, and indium enriched in the calcine is leached by sulfuric acid and is recovered; 3, the metallic lead is processed in a smelting furnace in the presence of sodium carbonate and sodium chloride to obtain a qualified product metallic lead, and tin and bismuth contained in slag are recovered in a tin smelting raw material form; and 4, copper contained in the slag in a matte form is recovered as a copper smelting raw material. The method has the advantages of no generation of dangerous waste arsenic calcium slag, no generation of a hydrogen arsenide gas in the whole treatment process, no water system expansion problem, and good utilization of the valuable metals.

Owner:云南锡业研究院有限公司研究设计院

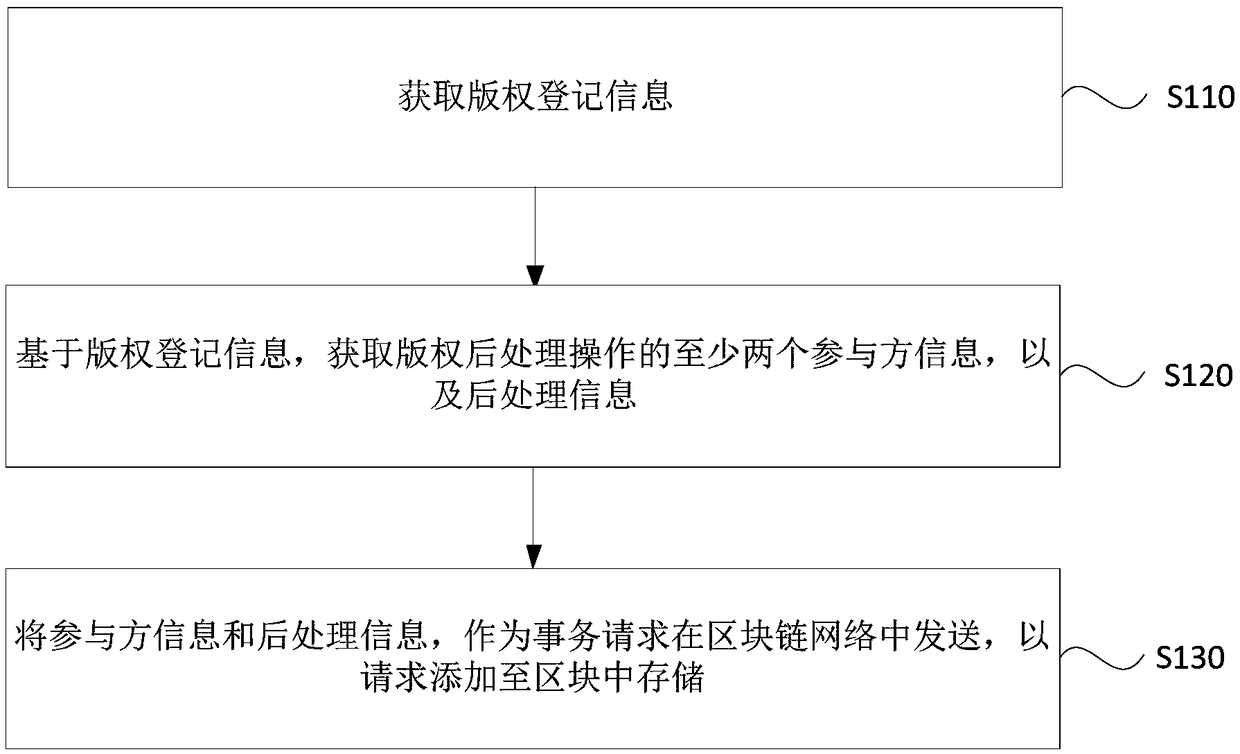

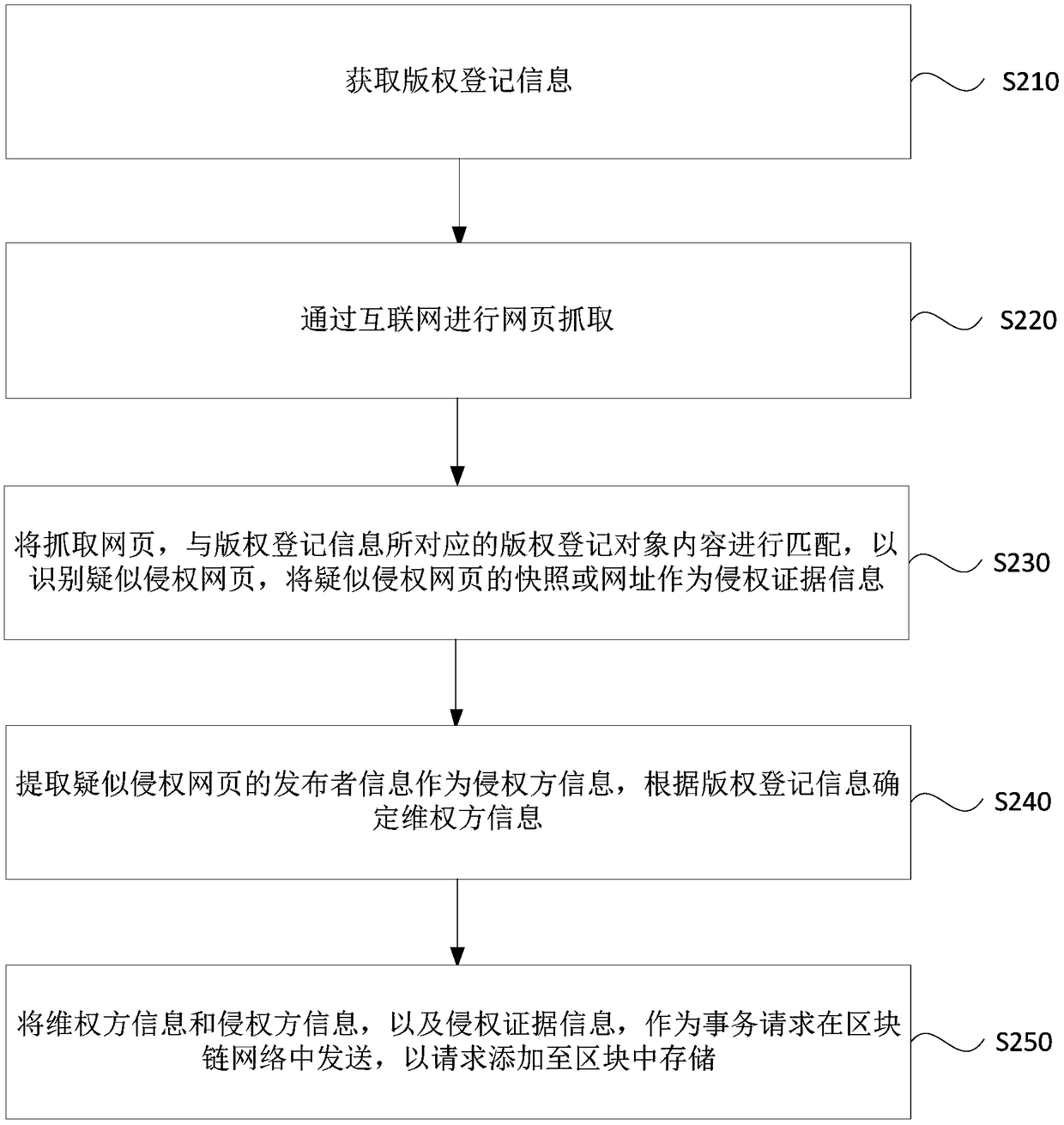

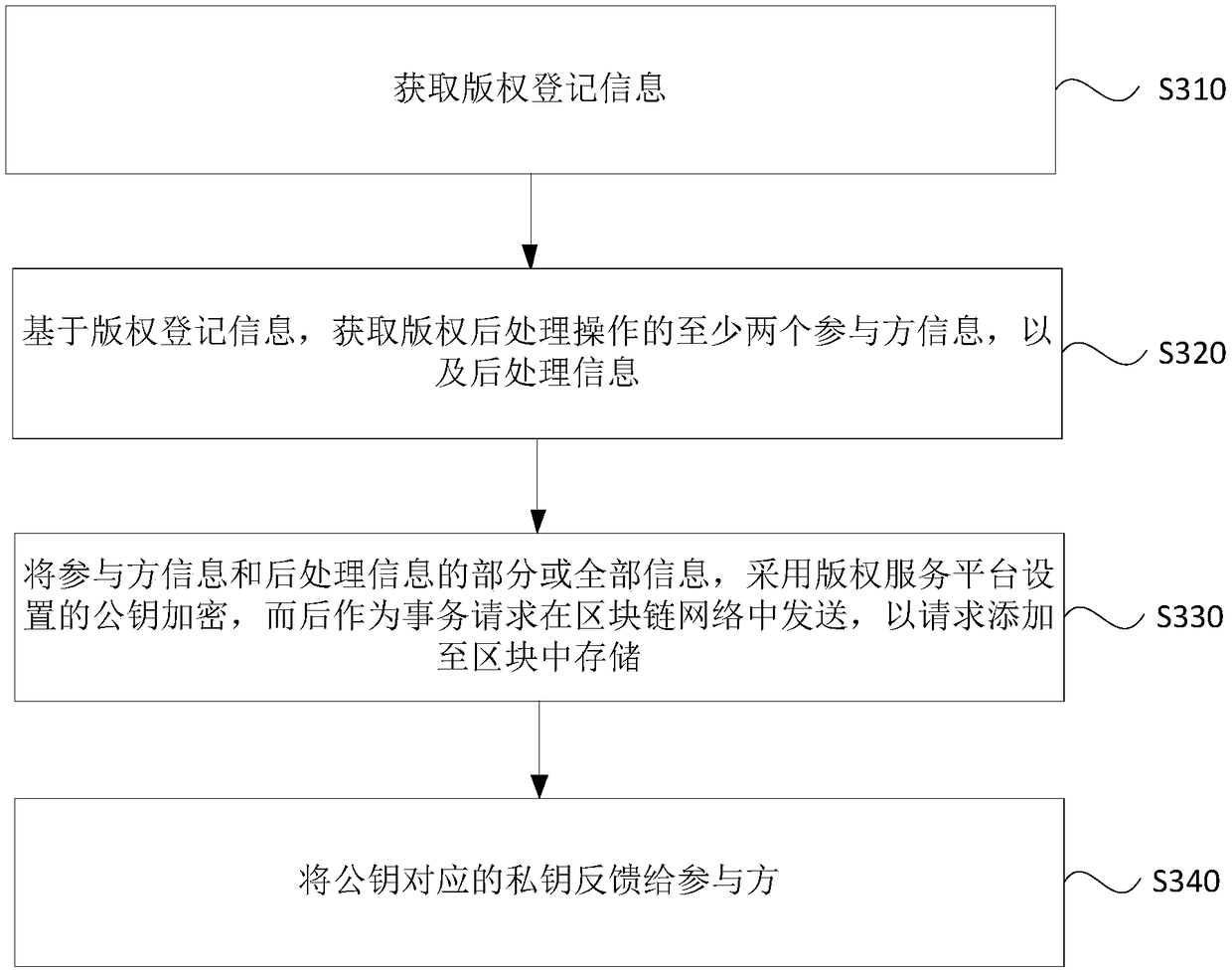

Post-processing method and device based on copyright registration information, apparatus and medium

The embodiment of the invention discloses a post-processing method and device based on copyright registration information, an apparatus and a medium. The method is applied to a copyright service platform. The method comprises the following steps: obtaining copyright registration information; acquiring at least two participant information of a copyright post-processing operation and post-processinginformation based on the copyright registration information; sending the participant information and the post-processing information as transaction requests in a block chain network to request to beadded to a block for storage. As the copyright post-processing operation information is stored in the block chain, the technical proposal provided by the embodiment of the invention makes the copyright post-processing operation information transparent to both the copyright service platform and the transaction parties and cannot be tampered with, thereby ensuring the credibility, accuracy and transparency of the copyright post-processing operation information.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

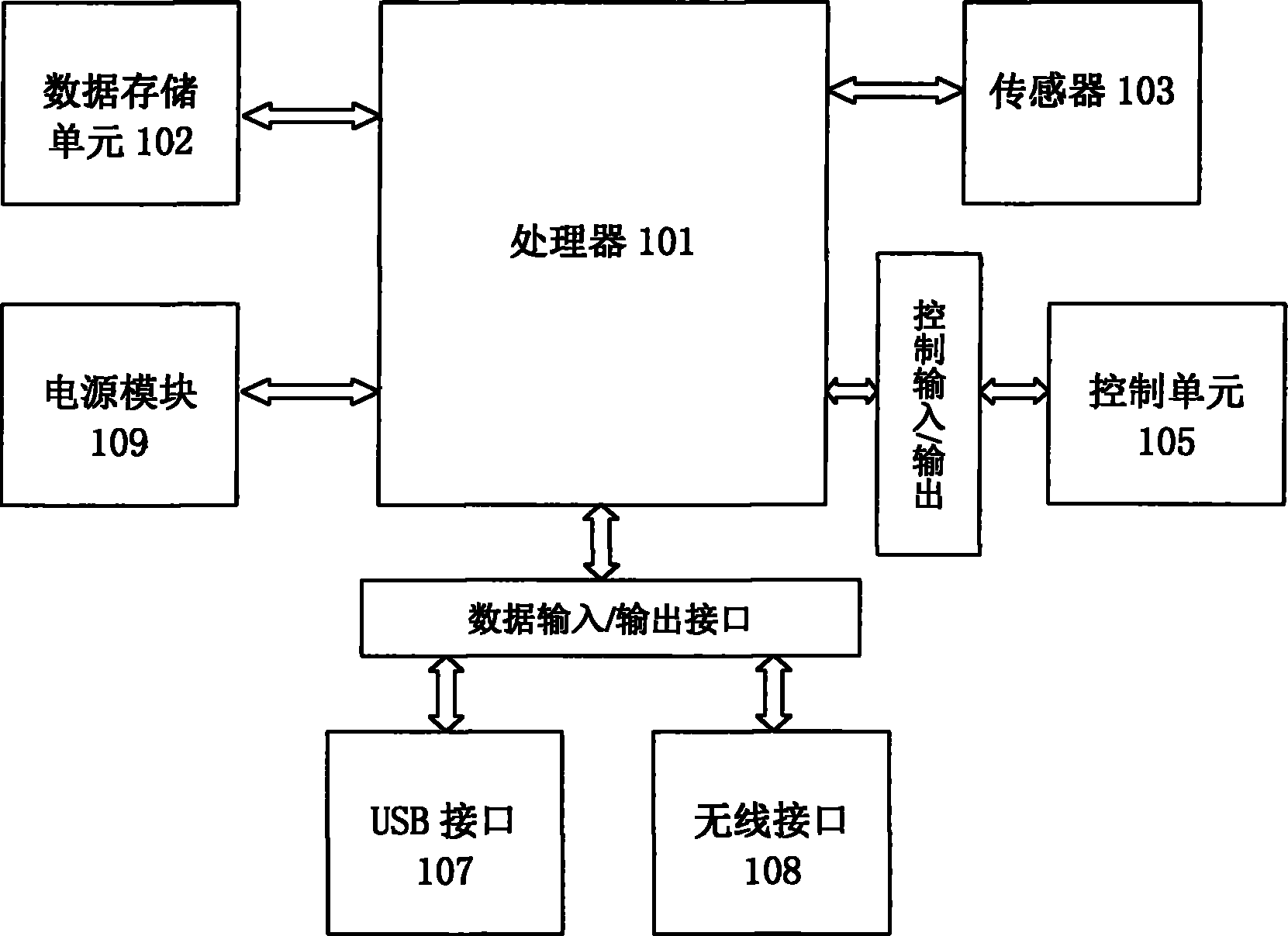

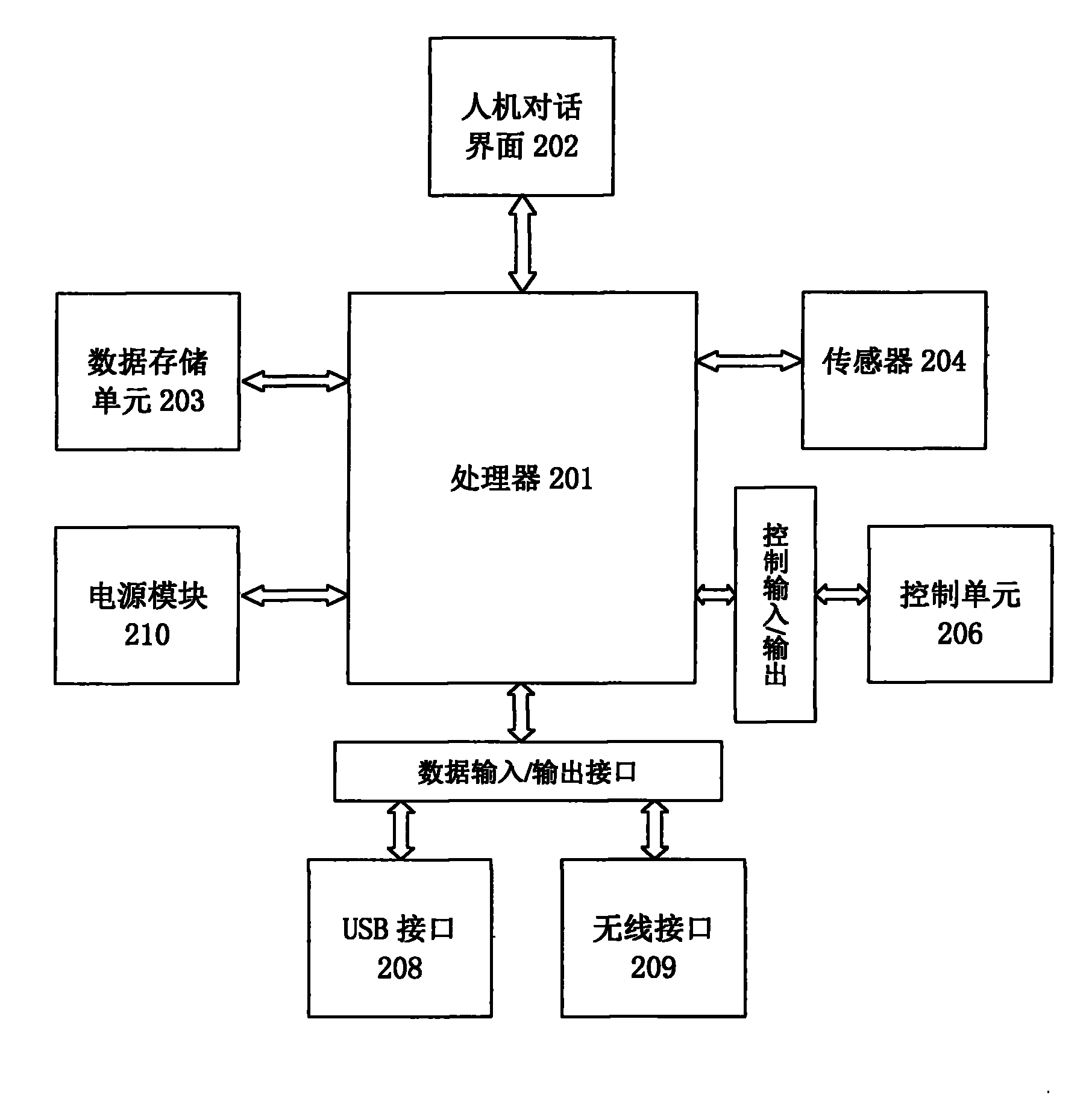

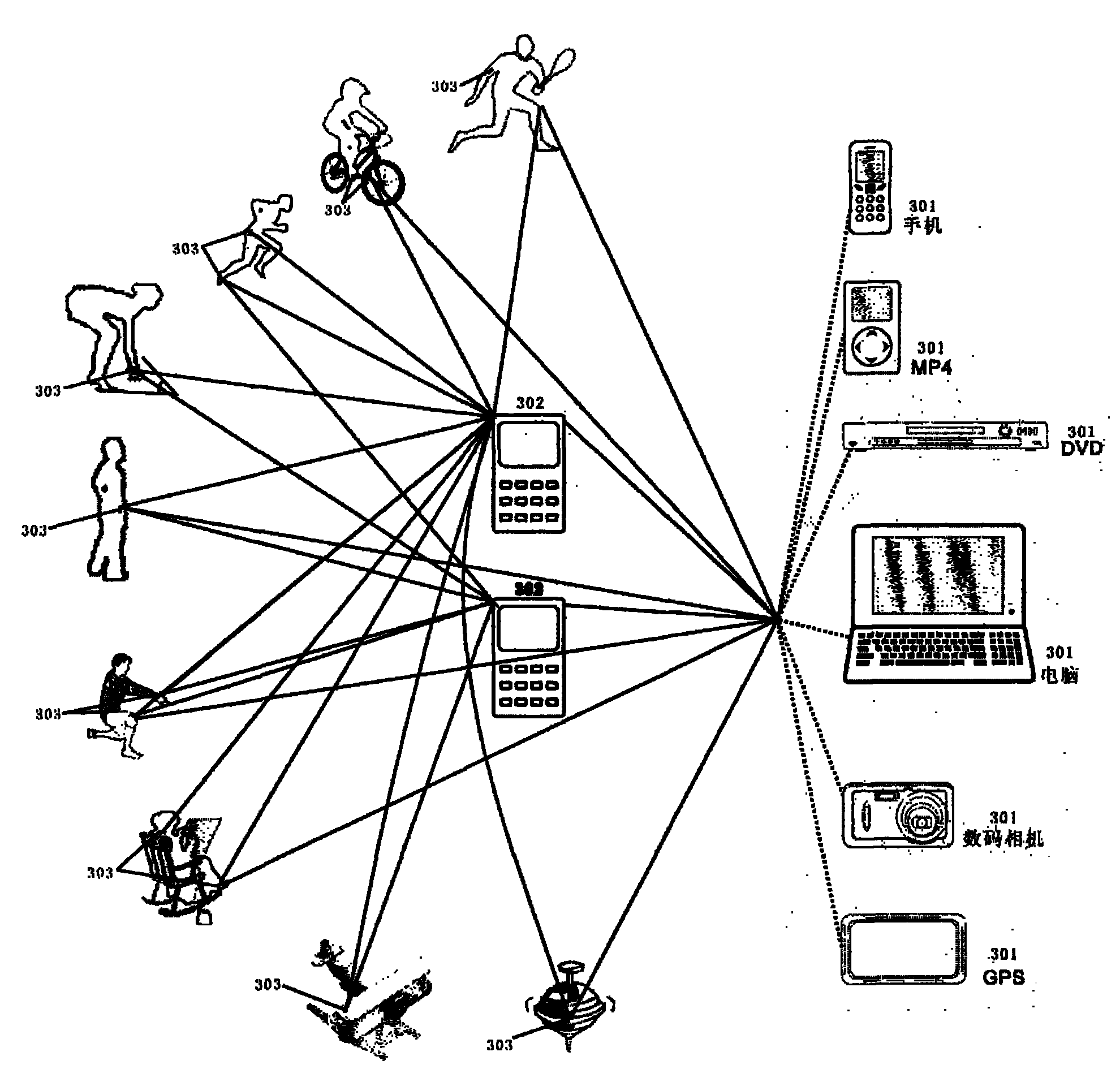

Multifunctional movement monitoring device and method

InactiveCN101776868AUse properlySmall sizeProgramme control in sequence/logic controllersLearning abilitiesSingle point

The invention relates to a multifunctional movement monitoring device and method. The monitoring device comprises a processor, a sensor and a control unit, wherein the processor is used for analyzing and processing different types of data information; the sensor is connected with the processor and comprises a movement, scene and distance sensing component which is used for carrying out single-point or multi-point detection on an object to collect the one-dimensional or multi-dimensional spatial attitude and the movement scene information of the object; the control unit is based on a preset application mode or a self-compiled application mode to send out control instructions; the processor responds to the collected spatial attitude and movement scene information; and an executing machine can execute codes to carry out the preset or self-compiled actions of a single user or networking users. The invention has relevant functions suitable for original applications of users who can change the applications according to the requirements of the users, has application learning ability, is convenient for the users to modify the application modes or compile the application modes, and can be stored in dozens of modes to be convenient for the users to use, so that the resources are better utilized and the invention is more humanized.

Owner:彭钢 +1

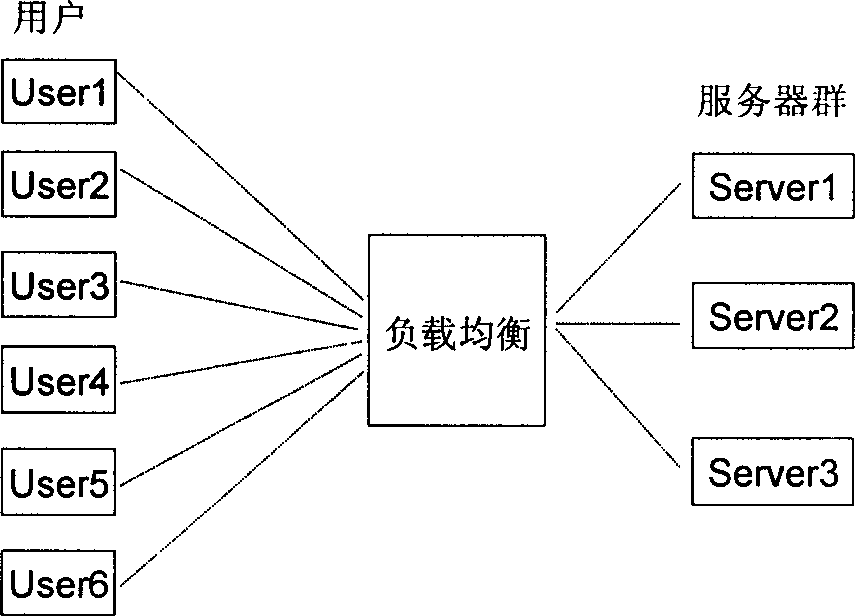

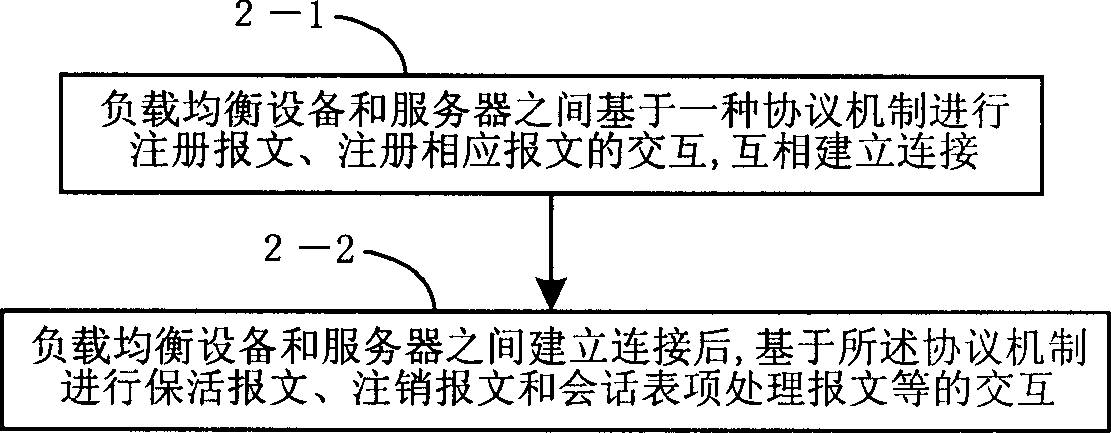

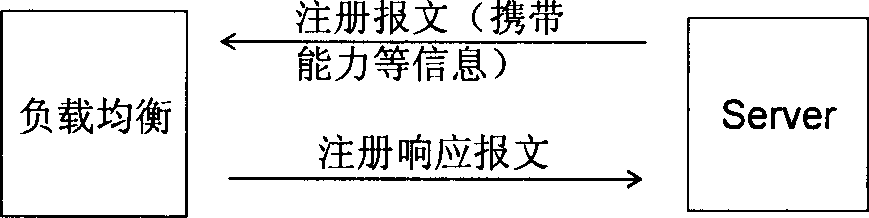

Method for improving load balance apparatus and servicer processing performance

The invention provides a method for improving processing performance of load equalizing device and server, mainly comprising: making interaction of various messages between the load equalizing device and server, and according to the interactive messages, they make corresponding configuration processing. And it can better dispose new servers and better use resources of the load equalizing device and improve safety of the load equalizing device and other processing functions.

Owner:HUAWEI TECH CO LTD

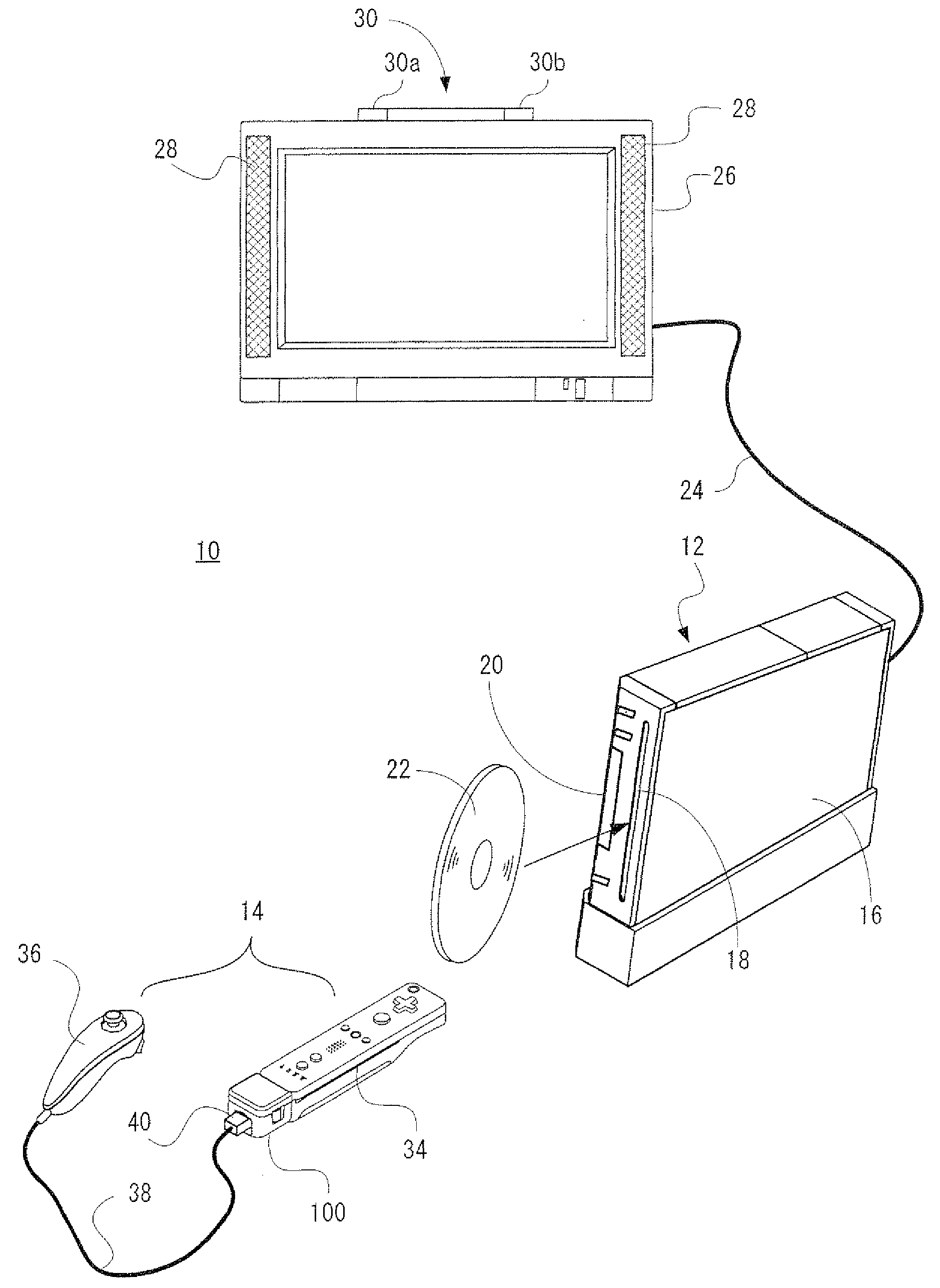

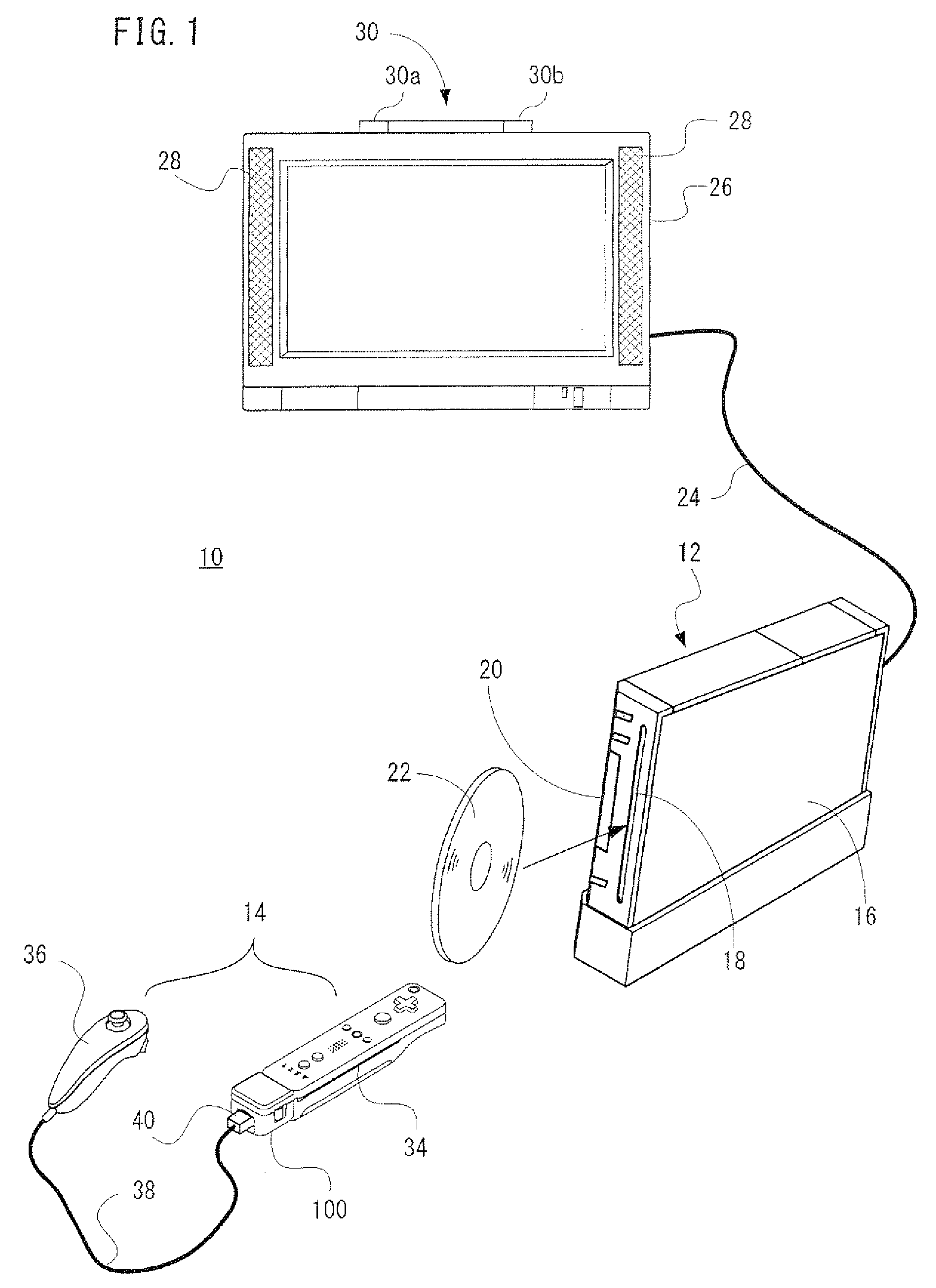

Game program and game apparatus

A game apparatus performs game processing on the basis of operation data output from a first input device including a first acceleration sensor and an angular velocity sensor and a second input device including a second acceleration sensor. The game apparatus calculates an orientation of an object within a game space on the basis of a first acceleration and a second acceleration, and causes the object to make a predetermined motion on the basis of the angular velocity data.

Owner:NINTENDO CO LTD

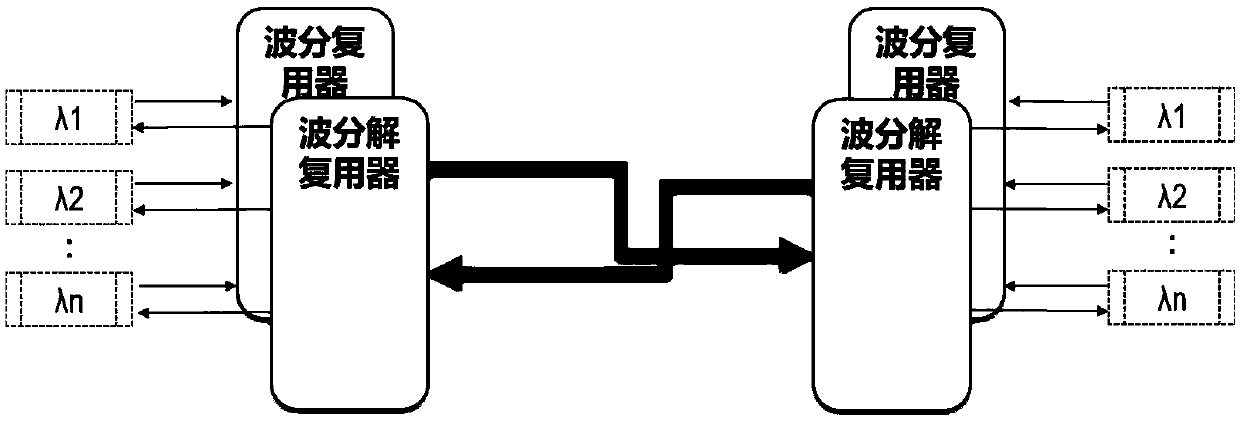

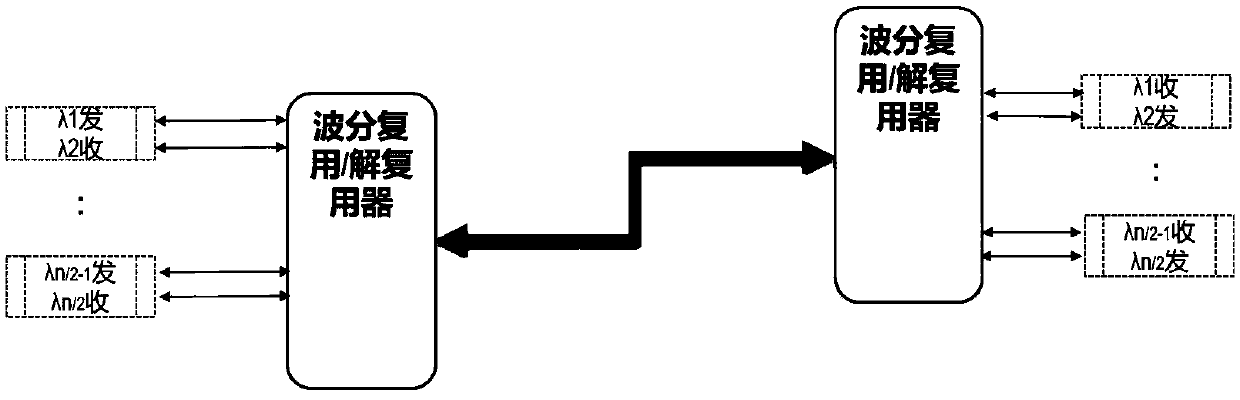

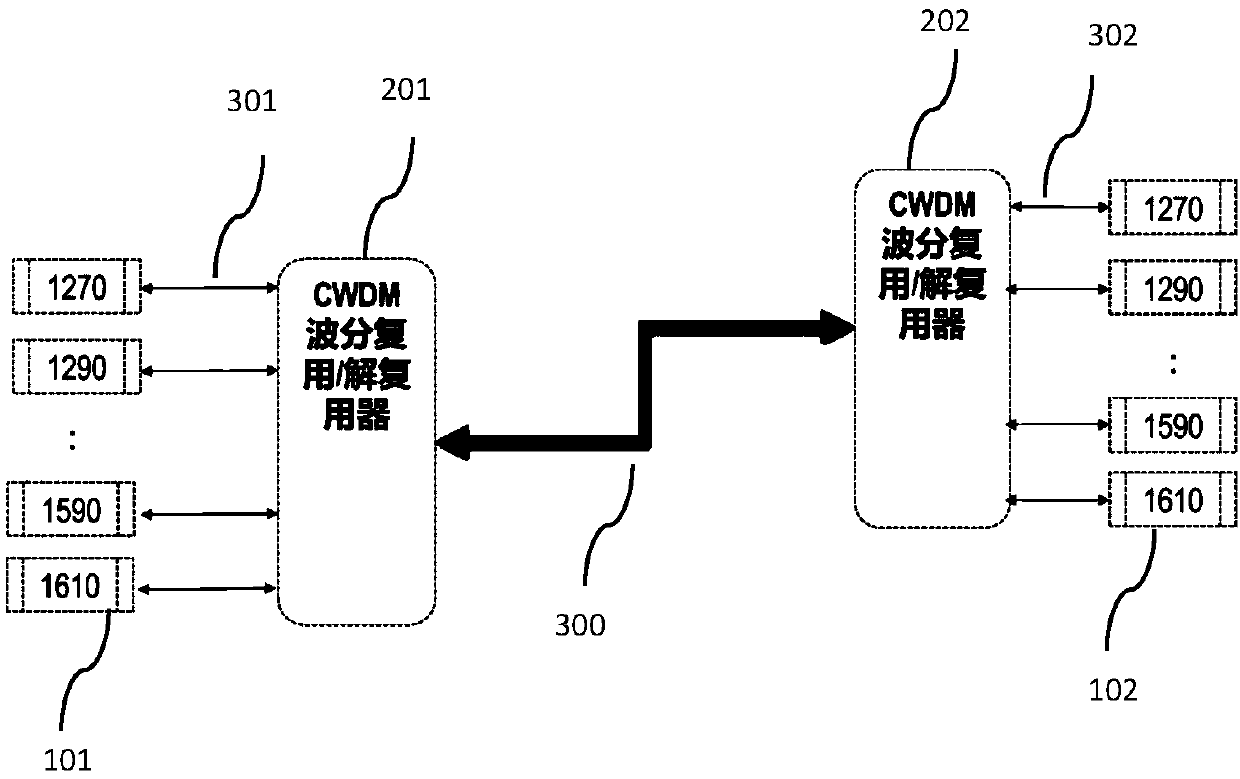

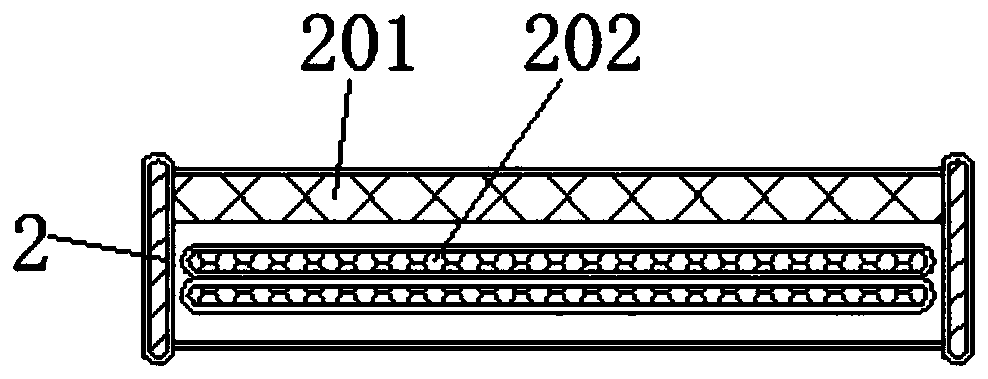

Wavelength division multiplexing optical transmission system composed of single-fiber bidirectional optical modules

PendingCN109581597ASave fiber resources and wavelength division multiplexing devicesUse properlyOptical light guidesWave bandTransmission system

The invention discloses a wavelength division multiplexing optical transmission system composed of single-fiber bidirectional optical modules. The two sets of single-fiber bidirectional optical modules, a pair of wavelength division multiplexing / demultiplexing devices 201 and 202 and a communication optical fiber 300 connected with the first wavelength division multiplexing / demultiplexing device 201 and the second wavelength division multiplexing / demultiplexing device 202 are included; and the two sets of single-fiber bidirectional optical modules are n pairs of single-fiber bidirectional optical modules with the same wavelength, the two sets of single-fiber bidirectional optical modules 101n and 102n with the working wavelength being lambda1, lambda 2,..., lambda n are connected to the communication optical fiber 300 through the first wavelength division multiplexing / demultiplexing device 201 and the second wavelength division multiplexing / demultiplexing device 202, and n is larger than or equal to 2. By means of the system, the working characteristics of the single-fiber bidirectional optical modules transmitted at the same wavelength are mainly used, the aim of bidirectionally transmitting wavelength division multiplexed signals in the same long-distance optical fiber is achieved, one pair of wavelength division multiplexing / demultiplexing devices and one long-distance optical fiber are saved on the premise that the communication band is not reduced by 50%, and communication resources are maximized.

Owner:宇捷光子科技(南京)有限公司

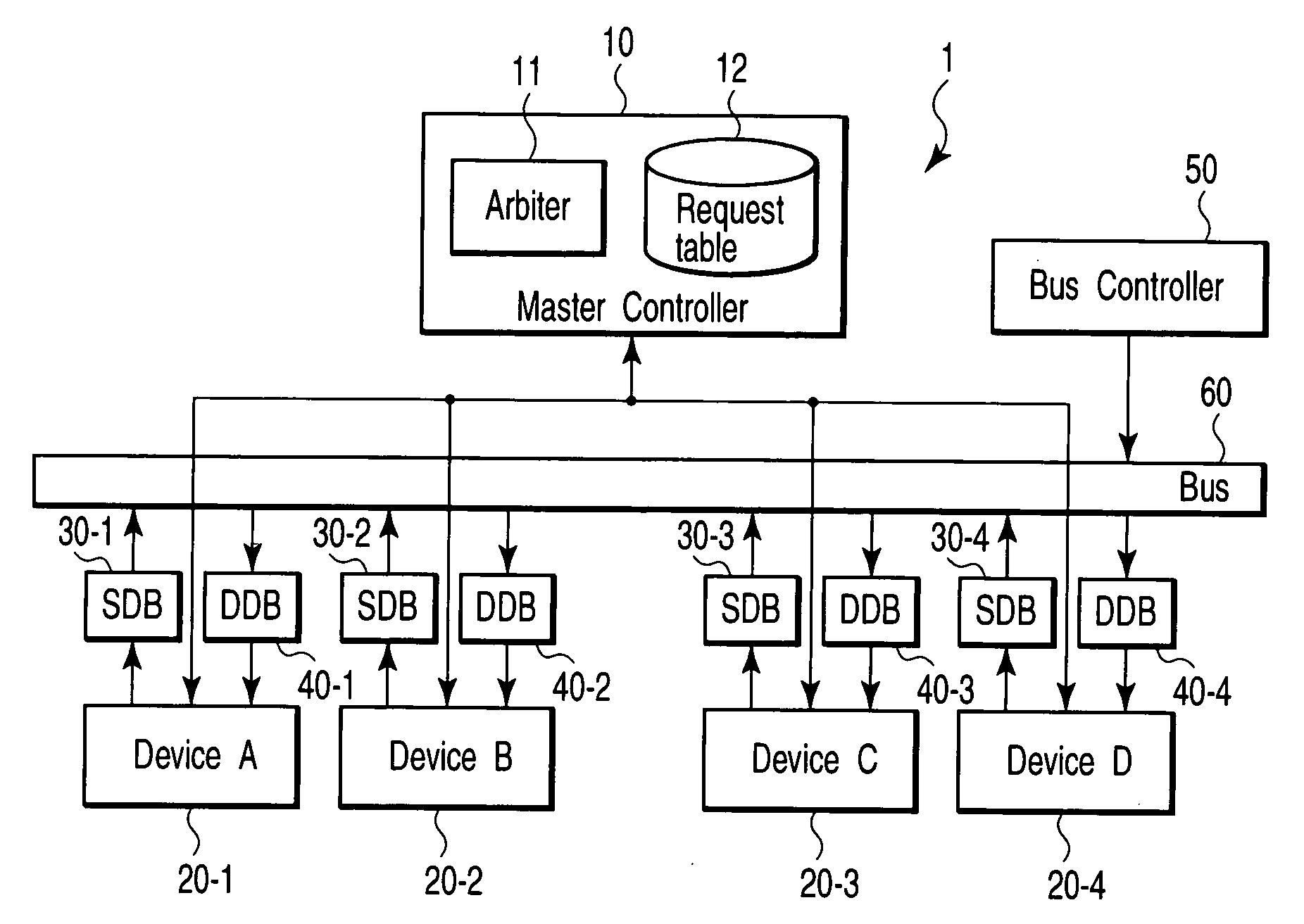

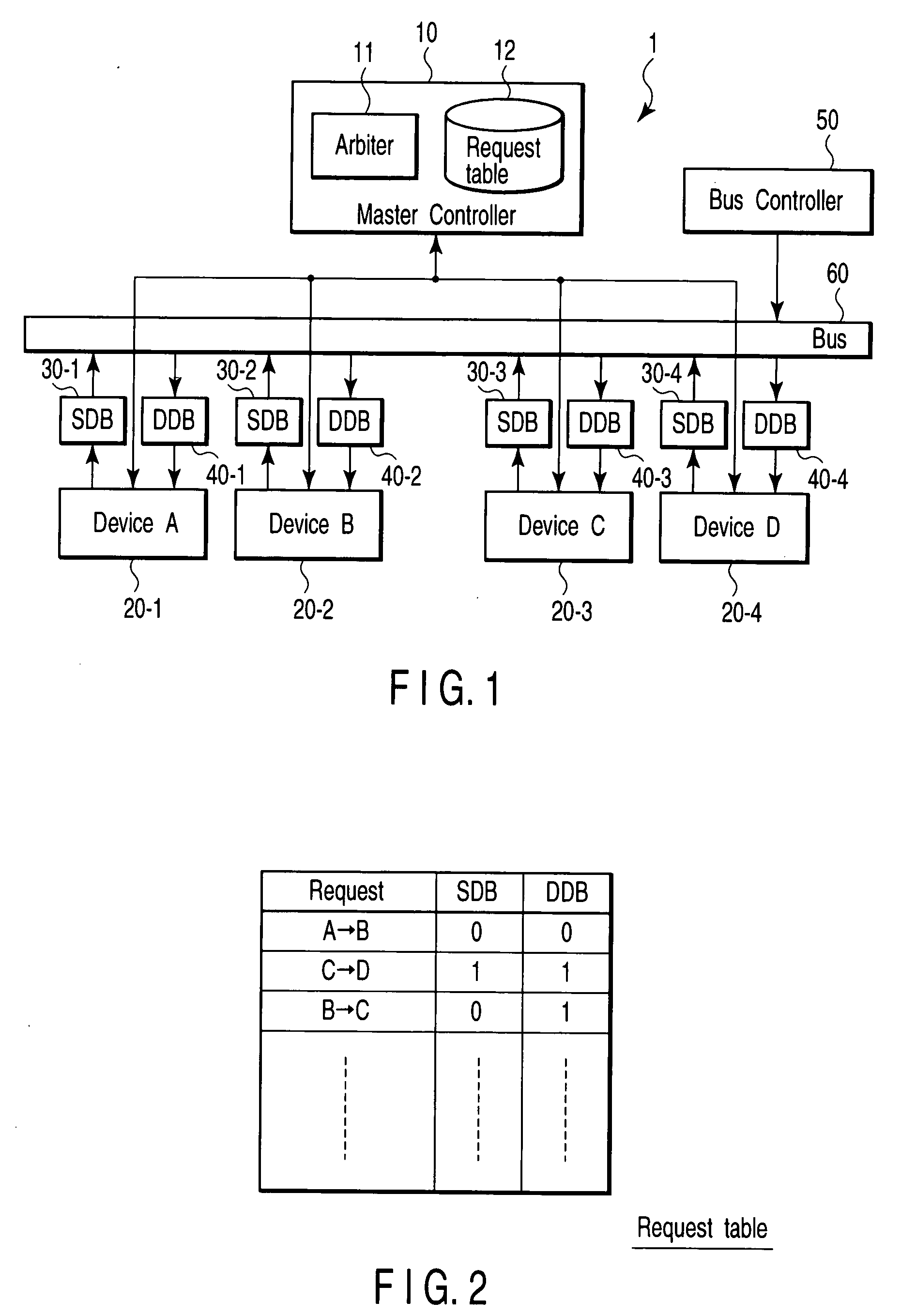

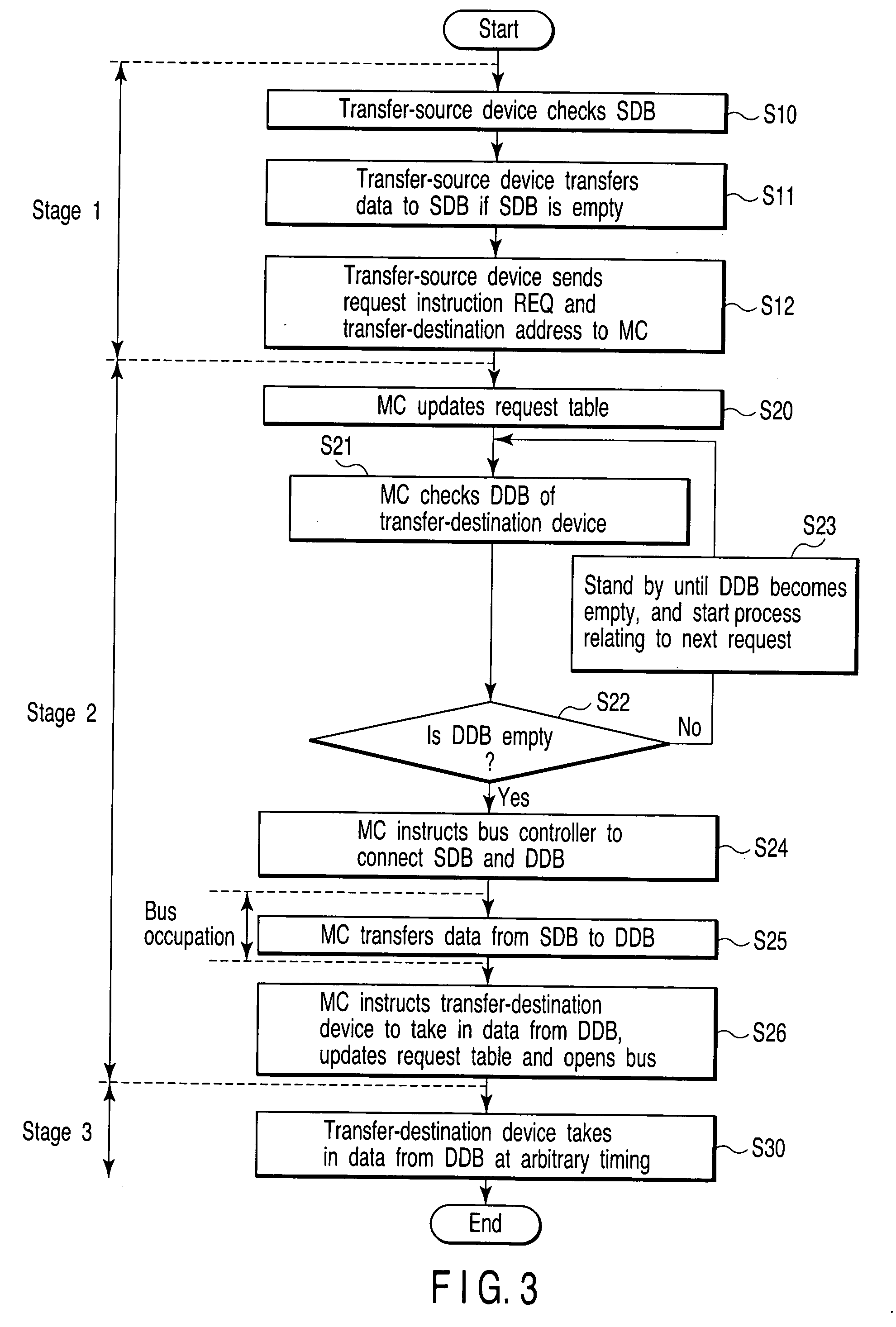

Semiconductor integrated circuit device which executes data transfer between a plurality of devices connected over network, and data transfer method

InactiveUS20060253623A1Use properlyInput/output processes for data processingData conversionData transmissionIntegrated circuit

A semiconductor integrated circuit device includes a first semiconductor device and a second semiconductor device, first and second buffer circuits, a data bus, and a control circuit. The semiconductor integrated circuit device executes data transmission / reception between the first and second semiconductor devices. The first and second buffer circuits store data. The data bus transmits the data between the first and second buffer circuits. The first semiconductor device reads out the transfer data into the first buffer circuit. The control circuit transfers the transfer data, which is stored in the first buffer circuit, to the second buffer circuit via the data bus. The control circuit acquires a right of use of the data bus after the first semiconductor device writes the transfer data into the first buffer circuit, and disclaims the right of use of the data bus after the transfer data is transferred to the second buffer circuit.

Owner:KK TOSHIBA

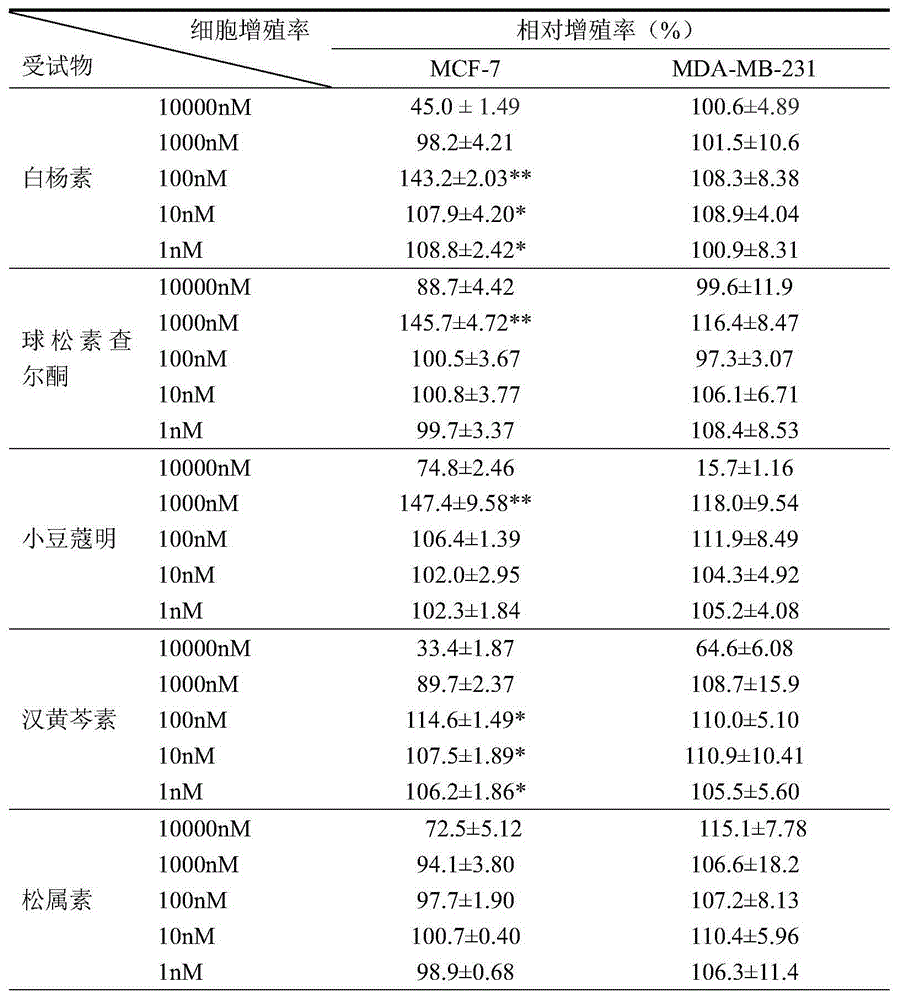

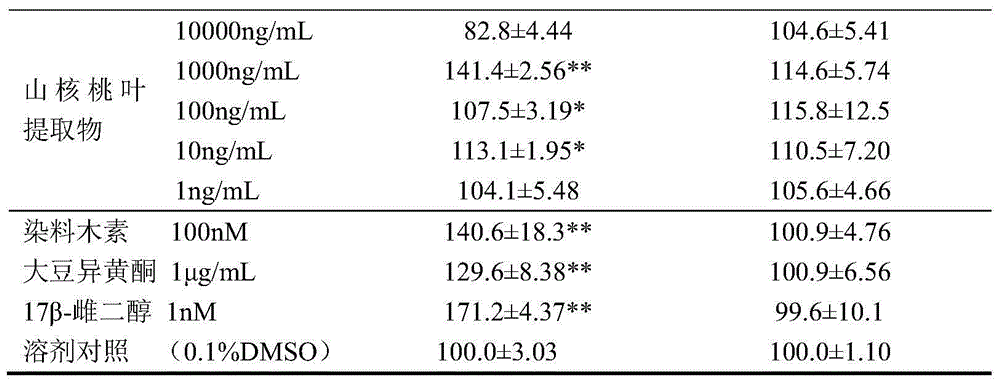

New uses of Carya cathayensis leaf extract in preparation of estrogen drugs

ActiveCN104971089AUse properlyExpand the scope of applicationNervous disorderMetabolism disorderCarya cathayensisDrug

The present invention discloses new uses of a Carya cathayensis leaf extract in preparation of estrogen drugs, wherein the Carya cathayensis leaf extract is used for preparing drugs for treatment and / or prevention of mammalian estrogen hyposecretion related diseases. According to the present invention, the Carya cathayensis leaf can be well utilized, the waste can be changed into treasure, and the application range of the Carya cathayensis leaf extract is broadened.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Device for preparing clean liquid for clean acetylene gas in chlor-alkali system and method thereof

InactiveCN103274889AUse properlyReduce usageAbsorption purification/separationBy-productNuclear chemistry

The invention discloses a device for preparing a clean liquid for clean acetylene gas in a chlor-alkali system and a method thereof. The device comprises a concentrated sodium hypochlorite storage tank, a concentrated sodium hypochlorite buffer tank, a diluted sodium hypochlorite storage tank, a diluted sodium hypochlorite head tank and a Venturi connected sequentially through a pipeline. The invention belongs to a technical improving process of recycling acetylene from concentrated sodium hypochlorite. Compared with the prior art, the method disclosed by the invention has the advantages that 1, concentrated sodium hypochlorite liquor is used to prepare a sodium hypochlorite solution, so that the byproduct is better used; 2, the use levels of liquid caustic soda and chlorine are reduced during production of an acetylene gas clearing agent, so that the expense generated is lowered; and 3, the selling pressure of the concentrated sodium hypochlorite is reduced.

Owner:INNER MONGOLIA WUHAI CHEM IND

Commercial advertisement solar street lamp

InactiveCN106152043AUse properlyIncrease profitMechanical apparatusElectric circuit arrangementsHigh intensityCrystalline silicon

The invention provides a solar street lamp for commercial advertisement, which comprises a light pole, a crystalline silicon solar panel is arranged on the top of the light pole, a top plate and a display are set on the light pole, a USB interface is set inside the protective cover of the USB connector, and the top plate There is a high-intensity LED lamp on the top, an intelligent charge and discharge controller is installed inside the light pole, and a photosensitive controller is installed at the bottom of the intelligent charge and discharge controller. The bottom of the device is equipped with a valve-regulated sealed battery, and the bottom of the valve-regulated sealed battery is equipped with a temperature sensor. The curved crystalline silicon solar panel achieves a greater coverage of sunlight and can make better use of solar energy. The advertising board can rent out advertisers, and a solar battery power indicator and a USB interface are installed under the top plate to solve the problem of insufficient battery power of pedestrians' mobile phones. The whole device has a reasonable design and is easy to use.

Owner:ANHUI ZHUANGYUANLANG ELECTRONICS TECH

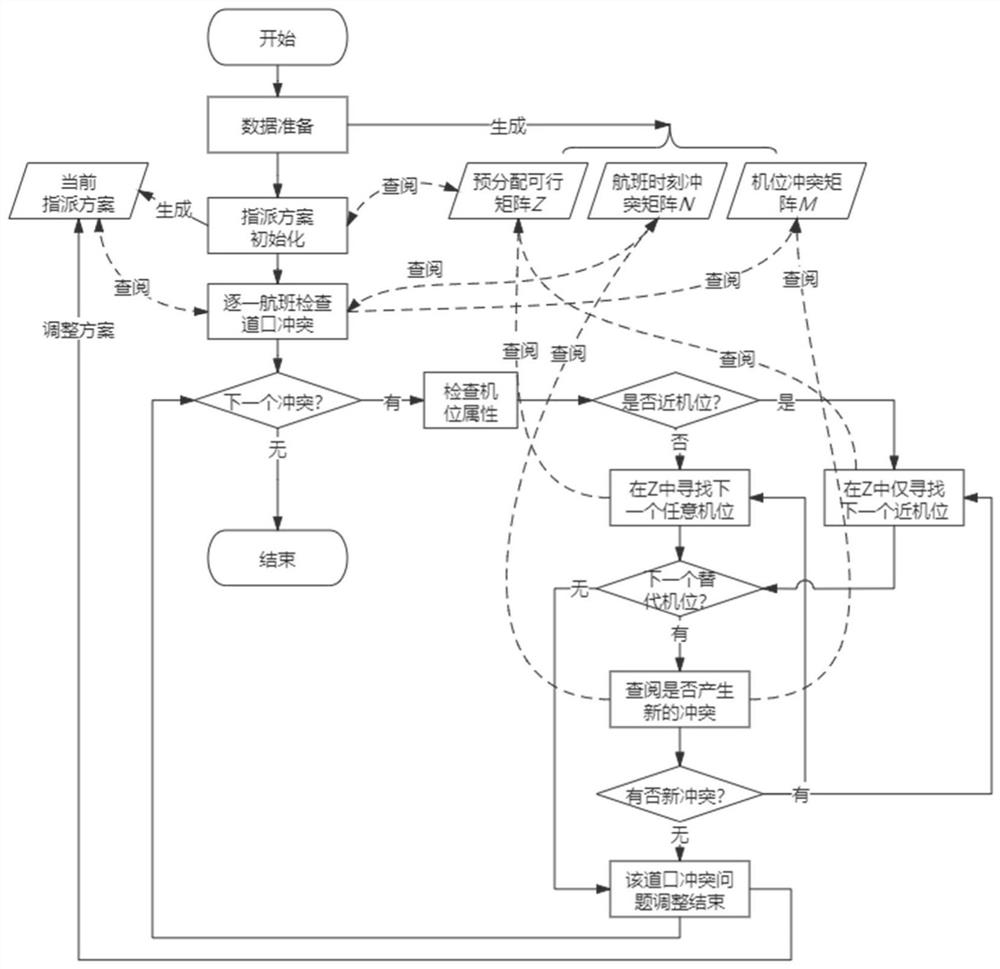

Airplane position distribution method and system for reducing flight crossing conflict rate

PendingCN112330145AFast solutionUse properlyMultiple aircraft traffic managementResourcesAirplaneReal-time computing

The invention belongs to the technical field of crossing airplane position distribution, and relates to an airplane position distribution method for reducing flight crossing conflict rate, which comprises the following steps: S1, drawing up an initial assignment matrix of flights, and maximizing the bridge leaning rate on the basis of meeting mandatory technical constraint conditions; S2, judgingwhether a crossing conflict occurs in the initial assignment matrix or not, and if the crossing conflict does not occur, taking the initial assignment matrix as a final assignment matrix; if the crossing conflict exists, entering the next step; S3, selecting an alternative machine position for each crossing with crossing conflicts, and generating a new assignment matrix; and S4, judging whether the newly generated assignment matrix in the S3 conflicts with the crossing, if so, returning to the S3, reselecting the alternative machine position, and if not, generating a final assignment matrix. The technical scheme that the assignment scheme is determined firstly and then the crossing conflict is reversely checked is adopted, time complexity is low, the solving speed is high, and the airportgate position can be well utilized.

Owner:RENMIN UNIVERSITY OF CHINA

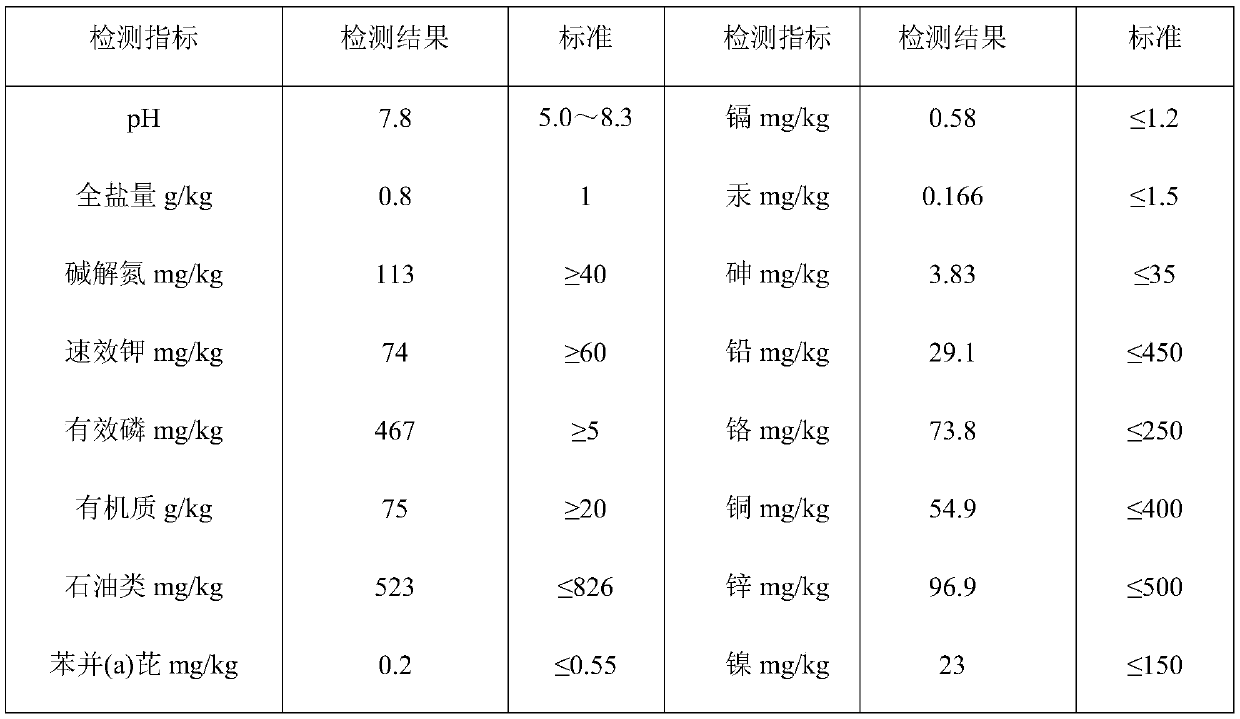

Clean treatment technology for shale gas oil-based ash residues

InactiveCN109819869AReduce environmental risksUse properlyGrowth substratesCulture mediaMicrobial agentShale gas

The invention belongs to the technical field of shale gas well drilling solid waste treatment, and particularly relates to a clean treatment technology for shale gas oil-based ash residues. After theshale gas oil-based ash residues and sludge ferment are mixed to be uniform according to the mass ratio of 1:(0.1-0.3); desalination is carried out until the salt content is smaller than 2 g / kg; a microbial agent accounting for 2% to 5% of the mass of the oil-based ash residues is added to the desalted mixture, uniform mixing is carried out, and micro-biological degradation is carried out for 3-6months; natural soil accounting for 30% to 60% of the oil-based ash residues is added to the mixture subjected to micro-biological degradation treatment to be mixed to be uniform. The shale gas oil-based ash residues treated through the technology can meet the requirement of plant greening planting.

Owner:重庆市涪陵页岩气环保研发与技术服务中心

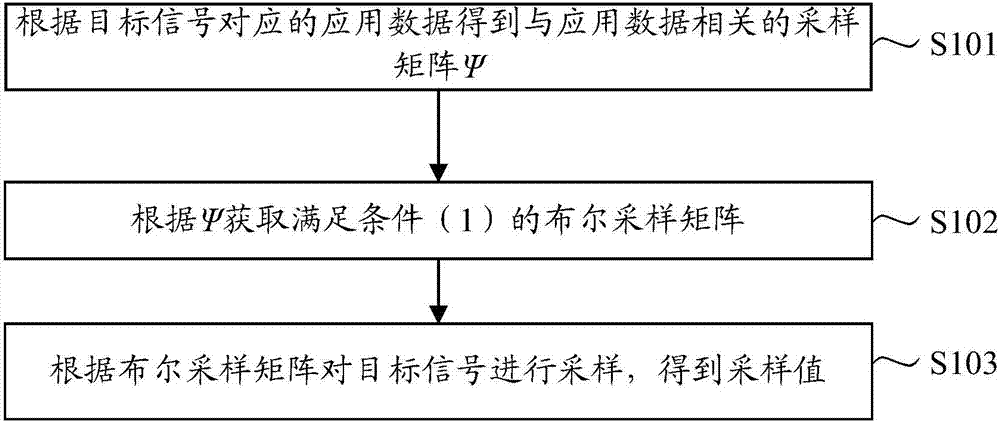

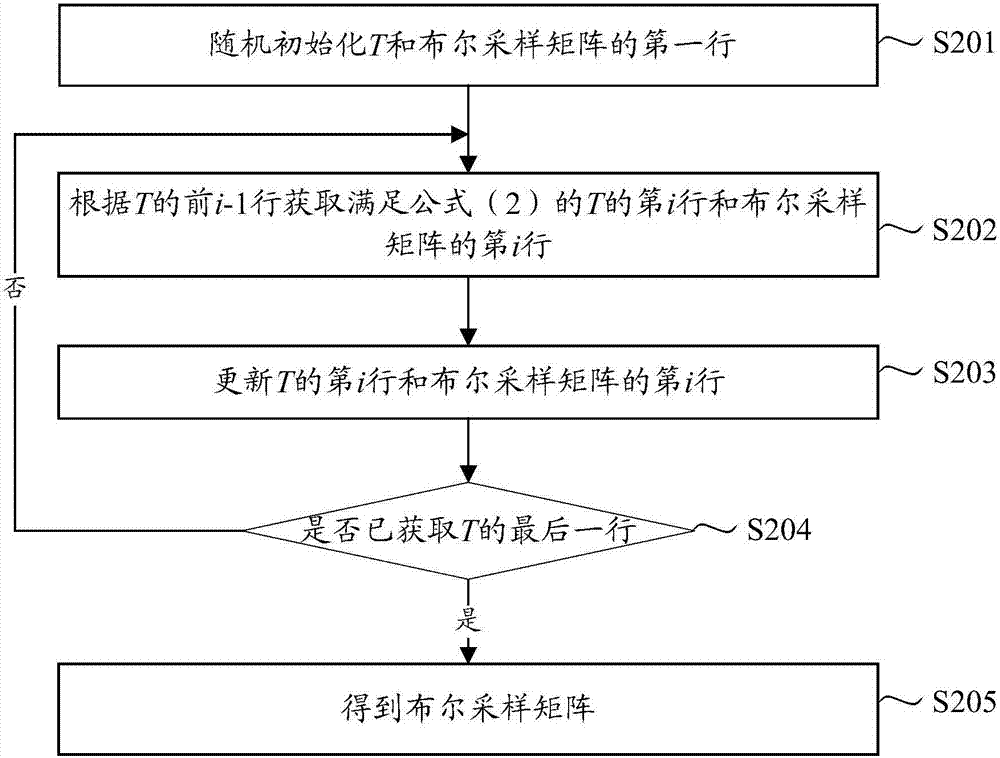

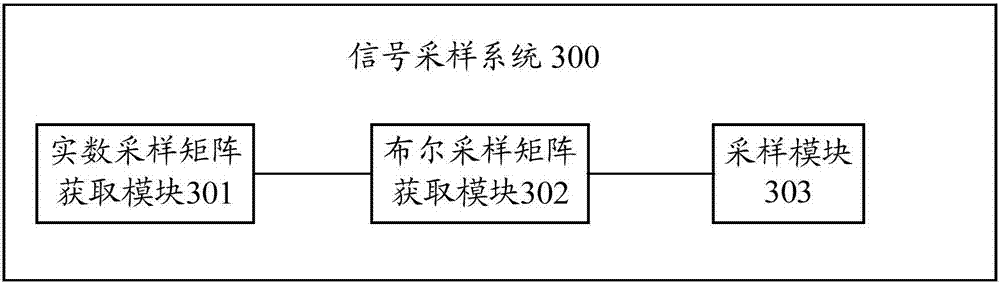

Signal sampling method, signal sampling system and signal sampling device

ActiveCN107147396AReduced complexity and power consumptionUse properlyCode conversionVIT signalsTarget signal

The embodiment of the invention provides a signal sampling method, a signal sampling system and a signal sampling device. The signal sampling method comprises the following steps: according to application data corresponding to a target signal, obtaining a real matrix psi with m rows and n columns and associated with the application data, wherein m and n are integers greater than or equal to 1; according to psi, obtaining a Boolean sampling matrix meeting the condition (1); sampling a target signal and obtaining a sampling value. According to the technical scheme of the invention, during the signal sampling process, the complexity and the power consumption of the hardware required for signal sampling based on the data-associated Boolean sampling matrix can be reduced.

Owner:HUAWEI TECH CO LTD +1

Method for extracting soluble chitin

The invention provides a method for extracting soluble chitin from shells of shellfishes. The method is characterized by including a first step of soaking in hydrochloric acid to decalcify, a second step of deproteinizing by sodium hydroxide, a third step of performing secondary soaking in hydrochloric acid to decalcify, and a fourth step of deacetylating by sodium hydroxide. The method for extracting insoluble chitin from the shells of the shellfishes effectively is simple, practical and low in cost, and accordingly resource of the shells can be well utilized.

Owner:SHANTOU TILLMAN TOY

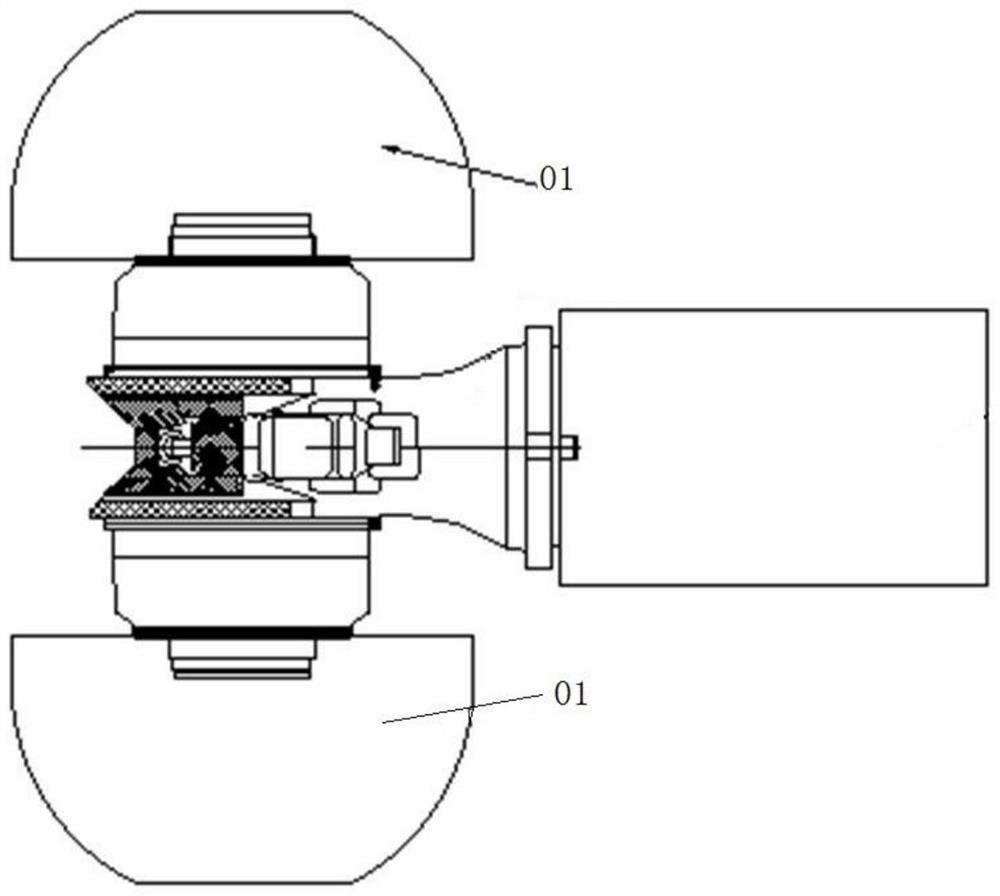

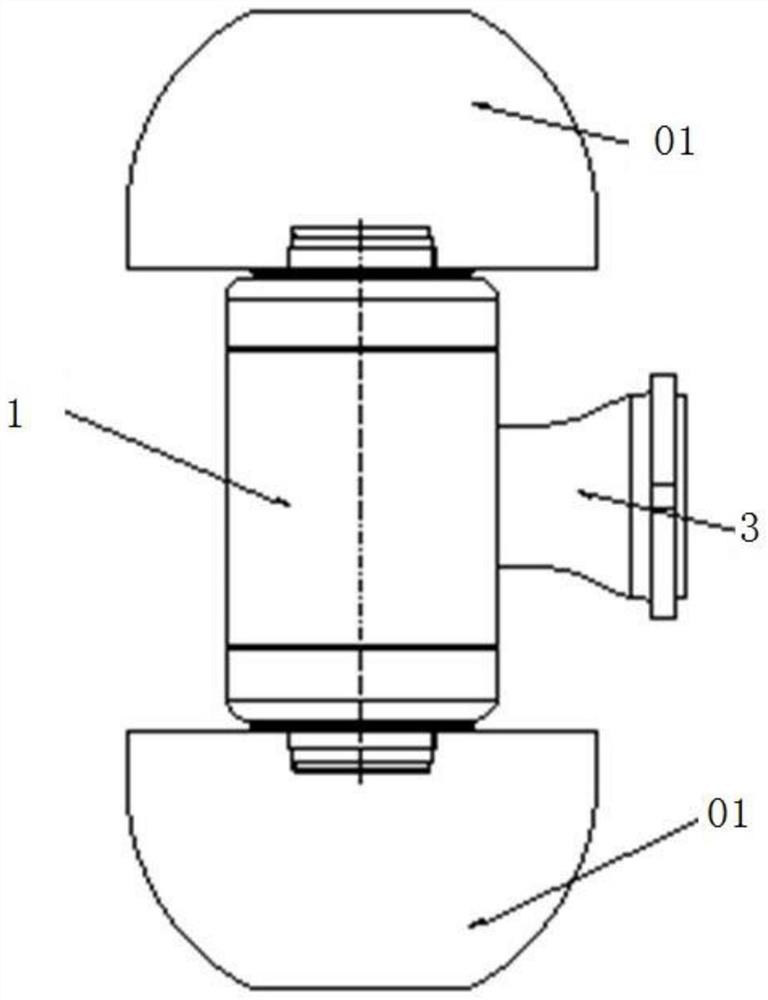

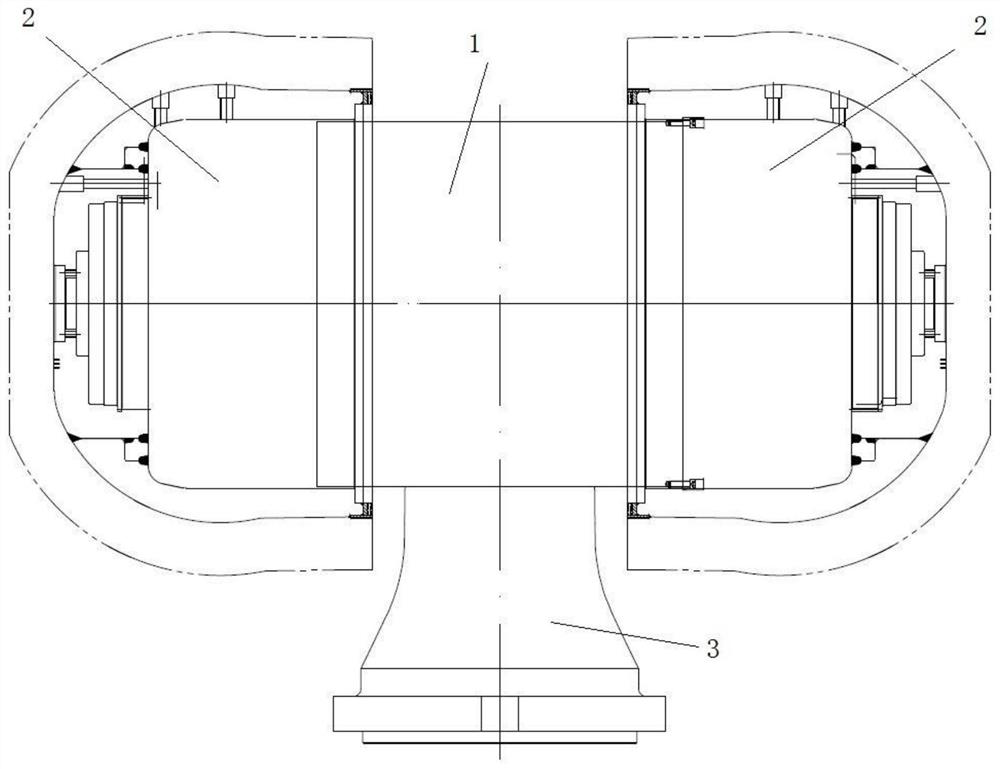

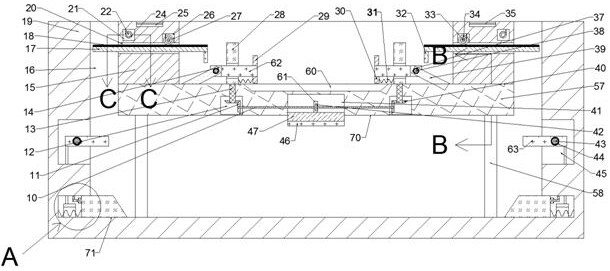

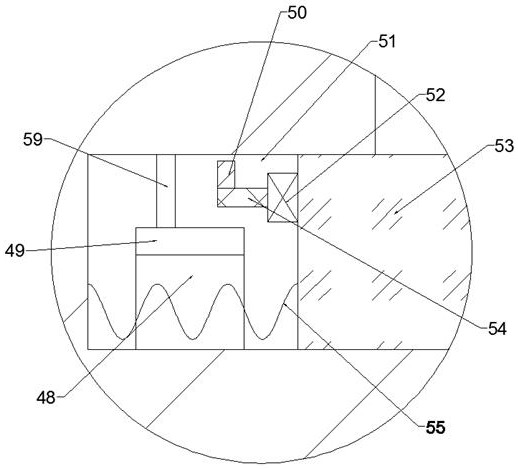

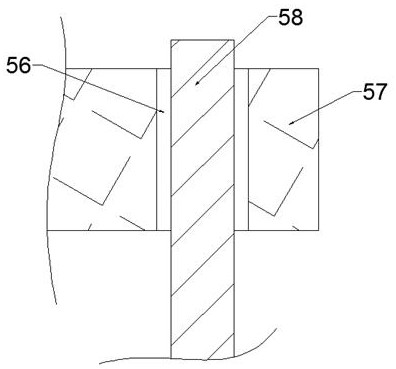

Heading machine and cutting power head device thereof

PendingCN112360456ASimple organizationUse properlyDriving meansGearing detailsDrive motorHigh torque

The invention discloses a heading machine and a cutting power head device thereof. The cutting power head device comprises a driving motor, speed reducers and cutting rollers. The driving motor is used for providing power for the rotation of the cutting rollers. The speed reducers are used for converting the high-rotating-speed low-torque power output by the driving motor into low-rotating-speed high-torque power and transmitting the low-rotating-speed high-torque power to the cutting rollers. The cutting roller are connected with the speed reducers and are driven by the driving motor to tunnel and excavate. The output end of the driving motor is connected with the speed reducers, and the driving motor and the speed reducers are arranged in a linear mode. According to the cutting power head device, the speed reducers and the driving motor are arranged in the same direction, the direction of output force does not need to be changed, arrangement of bevel gear sets in the speed reducers is avoided, and the mechanisms of the speed reducers are simplified; and the space between the cutting rollers can be better utilized, the space occupied by the speed reducers and the driving motor asa whole is reduced, and miniaturization of the cutting power head device is facilitated.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Light environment-friendly building material and preparation method thereof

The invention discloses a light environment-friendly building material. The light environment-friendly building material comprises the following raw materials in parts by weight: 20-35 parts of foamedcement, 10-20 parts of plant straw, 10-25 parts of cereal shells, 5-9 parts of light calcium carbonate, 4-8 parts of bamboo charcoal fibers, 8-12 parts of quartz sand, 7-13 parts of silicon dioxide,3-7 parts of asbestos wool, 1-3 parts of a water-based adhesive, 2-8 parts of diammonium hydrogen phosphate and 20-30 parts of purified water. The invention relates to the technical field of buildingmaterials. According to the light environment-friendly building material and the preparation method thereof in the invention, the foamed cement, the plant straw, the cereal shells and the light calcium carbonate are used as main raw materials, so the specific gravity of the building material is reduced to a great extent, waste materials are well utilized, and production cost is saved; by adding the quartz sand, the silicon dioxide, the diammonium hydrogen phosphate and the asbestos wool, the building material is hard and wear-resistant, has good tensile strength, good heat insulation performance and corrosion resistance and is not prone to combustion; and the building material is easy to manufacture.

Owner:河南晖睿智能科技有限公司

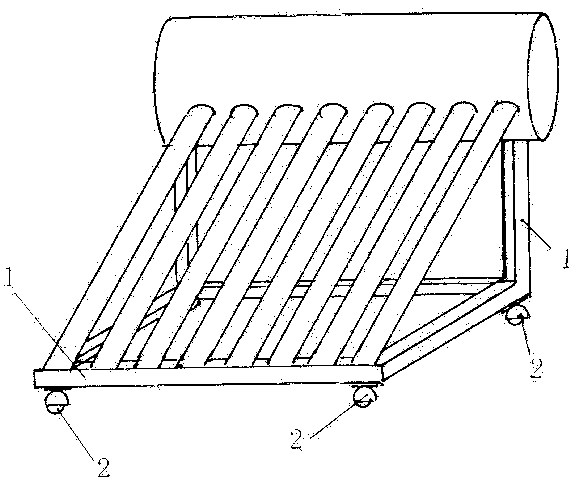

Solar water heater with trundles

InactiveCN103836827AUse properlyGood sunlightSolar heat devicesSolar thermal energy generationSolar waterEngineering

The invention provides a solar water heater with trundles. The trundles are arranged on the lower portion of a frame body of the solar water heater. The solar water heater can be moved conveniently through the trundles. Therefore, when the solar water heater is used, the position of the solar water heater can be adjusted along with moving of the sun, and sunlight energy can be utilized by the solar water heater better.

Owner:ZAOYANG NO 3 EXPERIMENTAL ELEMENTARY SCHOOL

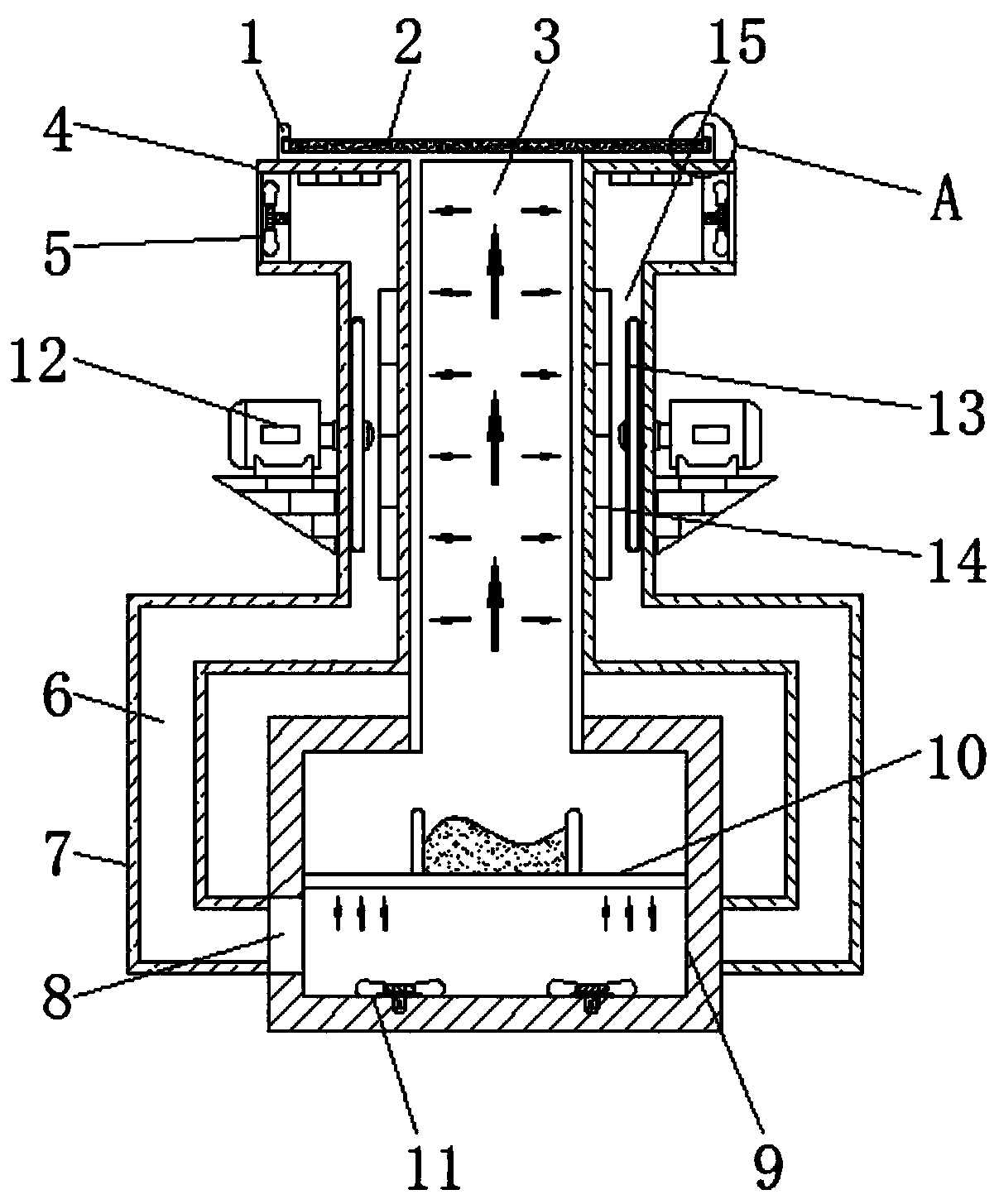

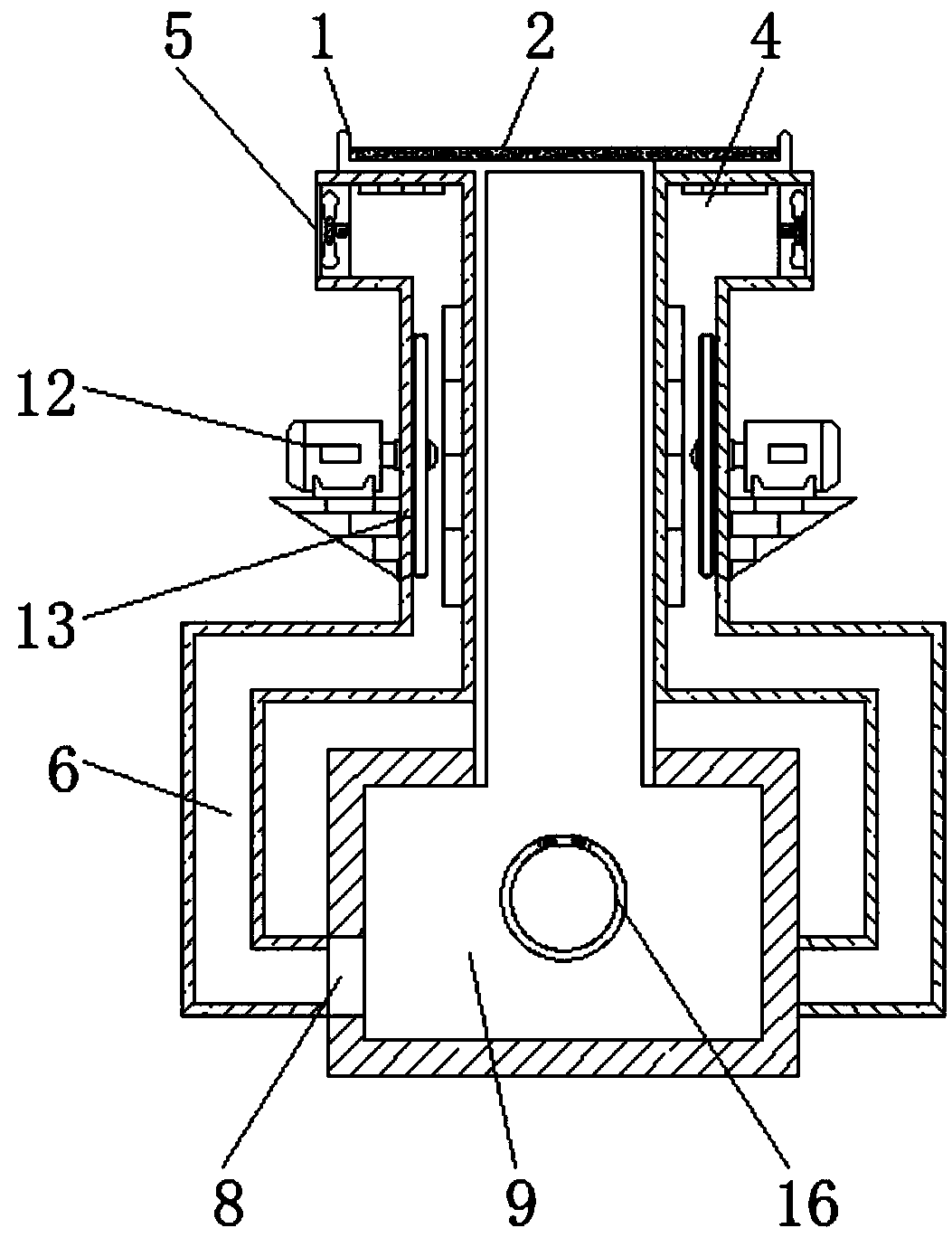

Heat exchange device based on multiple-cycle energy-saving technology

InactiveCN109000486AUse properlyAvoid wasting heatCorrosion preventionStationary conduit assembliesMotor shaftEngineering

The invention discloses a heat exchange device based on a multiple-cycle energy-saving technology. The heat exchange device comprises a smoke outlet, motors and a cover body, a treatment layer is arranged in the middle of the smoke outlet, an original chimney is fixedly connected below the treatment layer, the motors comprise shell bodies, end covers, motor shafts, and grounding devices, wherein mounting cavities are defined in the shell bodies, and one sides of the mounting cavities are opened; the opened sides of the mounting cavities are covered with the end covers, and motor bearings are arranged on the end covers; the motor shafts are arranged in the mounting cavities, and the end parts of the motor shafts are matched with inner rings of the motor bearings; and the grounding devices comprise elastic parts, cover bodies and sliding blocks, wherein the cover bodies and the sliding blocks are electrically connected, the cover bodies and the sliding blocks can move relative to each other, the two ends of the elastic parts abut against the cover bodies and the sliding blocks correspondingly, the cover bodies are arranged on the end covers, and the sliding blocks abut against the end surfaces of the motor shafts. According to the heat exchange device based on the multiple-cycle energy-saving technology, heat of the top ends of smoke inlets can be well exchanged, so that the heatof the whole device can be fully utilized and well recycled.

Owner:江苏今道高新技术发展有限公司

Exponentiation processing method, device and equipment and storage medium

PendingCN111625301AReduce business interface pressureUse properlyExecution paradigmsOperating systemSystems engineering

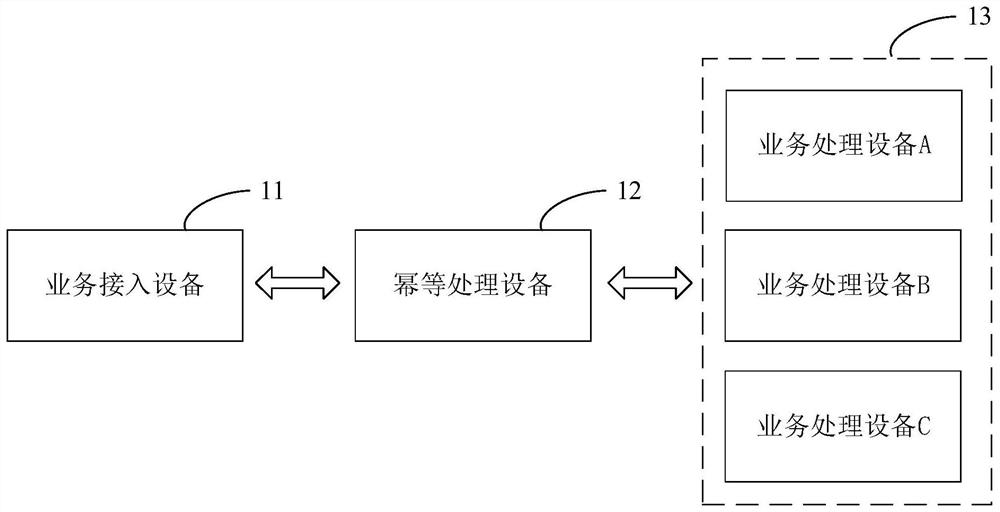

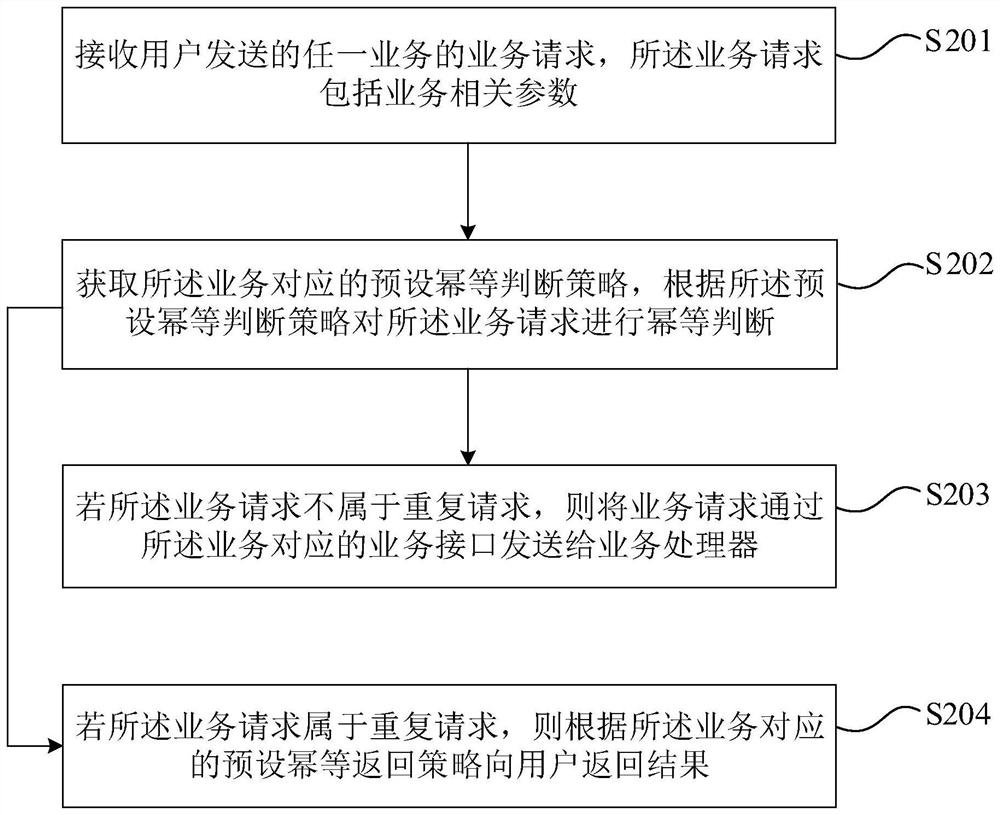

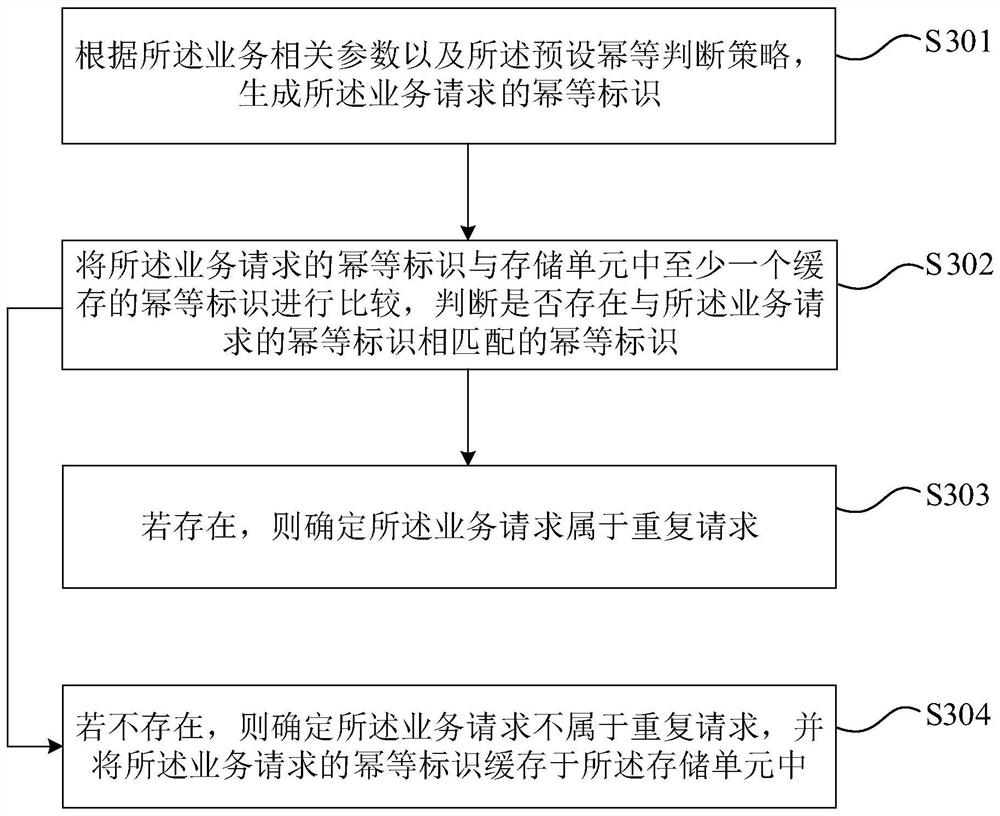

The embodiment of the invention provides an idempotent processing method and device, equipment and a storage medium, and the method comprises the steps: receiving a business request, sent by a user, of any business, and the business request comprises business related parameters; performing idempotent judgment on the service request according to a preset idempotent judgment strategy corresponding to the service; if not, sending the service request to a service processor through a service interface corresponding to the service; and if the request belongs to the repeated request, returning a result to the user according to a preset idempotent return strategy corresponding to the service. The idempotent processing process is decoupled from the service, so that the pressure of a back-end service interface is reduced, and resources of a service processor can be better utilized; the idempotent processing processes of multiple services are uniformly processed, diversified idempotent judgment strategies are supported, only the idempotent judgment strategies need to be configured and debugged in idempotent processing equipment, the influence of idempotent development process errors on subsequent services is avoided, idempotent judgment strategy configuration and debugging are simple and rapid, and the code error rate and repeated labor cost of developers are reduced.

Owner:TAIKANG LIFE INSURANCE CO LTD +1

Application of composite membrane in lithium-sulfur battery

ActiveCN111224046AUse properlyAvoid rapid and uncontrollable consumptionLi-accumulatorsCell component detailsLithium–sulfur batteryLithium sulfur

The invention relates to an application of a composite membrane in a lithium-sulfur battery. The composite membrane is prepared from one or more than two high-molecular polymers containing basic functional groups or one or more than two high-molecular polymers containing basic functional groups and other polymers which are blended to form a membrane-forming polymer, and one or more than two saltscontaining nitrate radicals, wherein the content of the high-molecular polymer containing the basic functional group in the film-forming polymer is 5-100wt%; the mass fraction of the salt containing nitrate radicals in the composite film is 0.1%-90%. The composite membrane is used in the lithium-sulfur battery, so nitrate radicals can be better utilized, the nitrate radicals are prevented from being rapidly and uncontrollably consumed, the use of the nitrate radicals is delayed, and the capacity retention ratio of the battery is further improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

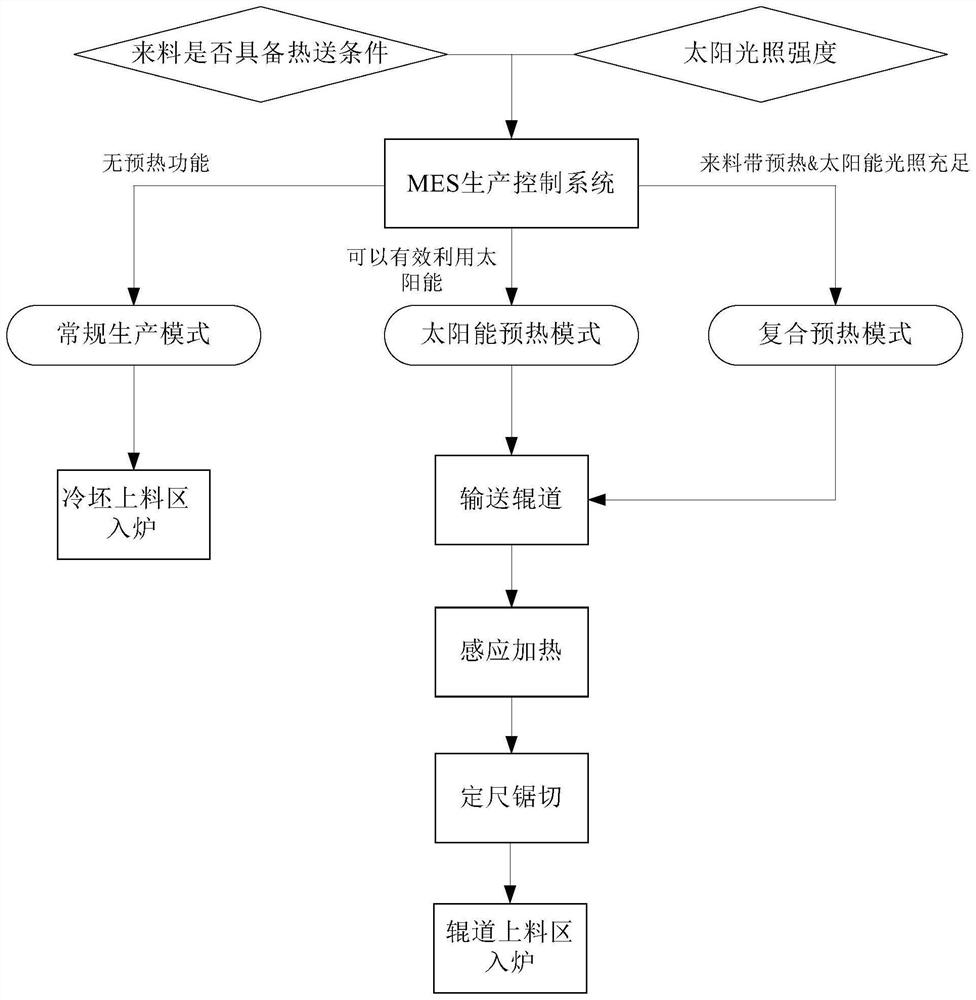

Multi-mode steel pipe rolling process

PendingCN114752746ARealize the preheating of tube billet continuous castingUse properlyBatteries circuit arrangementsFurnace typesSteel tubeProcess engineering

The invention discloses a multi-mode steel pipe rolling process which comprises the following steps: acquiring the heat temperature and solar illumination intensity of an incoming material, judging whether the incoming material has a heat delivery condition or not, and judging that a solar power generation device can perform effective power generation based on the current solar illumination intensity; a conventional production mode is adopted when it is judged that the current incoming material does not have the hot delivery condition and the solar power generation device cannot effectively generate power, and a solar preheating mode is adopted when it is judged that the current incoming material does not have the hot delivery condition and the solar power generation device can effectively generate power; and when it is judged that the current supplied material meets the hot delivery condition and the solar power generation device can effectively generate power, a composite preheating mode is adopted. After incoming materials are heated in the annular furnace to be in a hot state, the hot-state blank is subjected to perforation treatment. Therefore, the continuous casting preheating of the tube blank can be better realized; solar energy can be better utilized; the gas consumption of the annular furnace is saved by multiple methods, and the carbon consumption is greatly reduced.

Owner:TAIYUAN HEAVY IND TECH IND CO LTD

Control method of refrigerator

PendingCN108278828AGood defrosting effectUse properlyMechanical apparatusDomestic refrigeratorsRefrigerantEngineering

The invention discloses a control method of a refrigerator. A temperature control system comprises a compressor, a first heat exchanger, a throttling element and a second heat exchanger, wherein the first heat exchanger is arranged close to a first chamber; the second heat exchanger is arranged close to a second chamber; the refrigerator comprises two air channels, a first air door and a second air door; the first chamber communicates with a third chamber through one of the two air channels, and the second chamber communicates with the third chamber through another air channel; the two air channels are correspondingly controlled to be opened and closed through the first air door and the second air door. The control method comprises the steps of starting the compressor; controlling a refrigerant to flow in forward direction and flow from the second heat exchanger to the first heat exchanger; refrigerating through the first chamber; heating through the second chamber; recording the length of time that the refrigerant flows in the forward direction as T1; controlling the refrigerant to flow in reverse direction and flow from the first heat exchanger to the second heat exchanger; heating through the first chamber; refrigerating through the second chamber; recording the length of time that the refrigerant flows in the reverse direction as T2; detecting the real-time temperature theta of the third chamber; and determining the difference between the real-time temperature theta and threshold temperature T0.

Owner:HAIER SMART HOME CO LTD

Textile product shrinkage detection equipment

Textile product shrinkage detection equipment is disclosed in the invention, and comprises a box body, a lifting mechanism is arranged in the box body, the lifting mechanism comprises a water containing cavity with an upward opening, the water containing cavity is formed in the box body, two vertical rods are fixedly arranged on the inner wall of the lower side of the water containing cavity in a bilateral symmetry mode, and a pushing mechanism is arranged in the box body; and the pushing mechanism comprises motor cavities formed in the inner wall of the left side and the inner wall of the right side of the water containing cavity, carrying blocks are arranged in the motor cavities in a left-right moving mode, and motors are fixedly arranged on the end faces, away from the water containing cavity, of the carrying blocks. The device can effectively performshrinkage detection on textile products; and through a rotating wavy plate, the situation of textile products during washing is simulated, the shrinkage situation of the textile products after water immersion is detected, a producer can better utilize the textile products by detecting the products, and serious accidents are avoided.

Owner:蔡占民

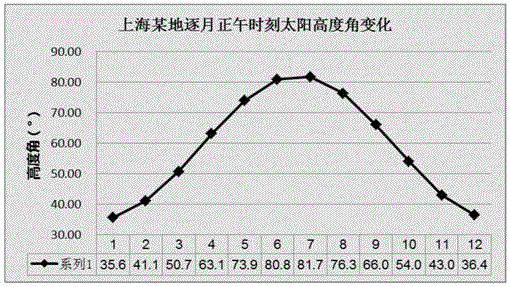

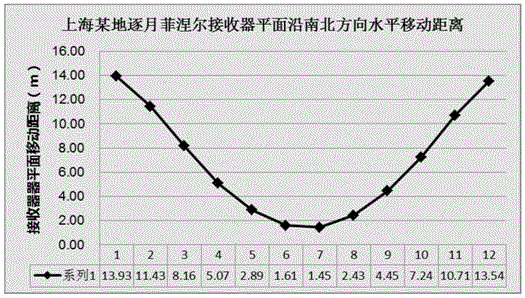

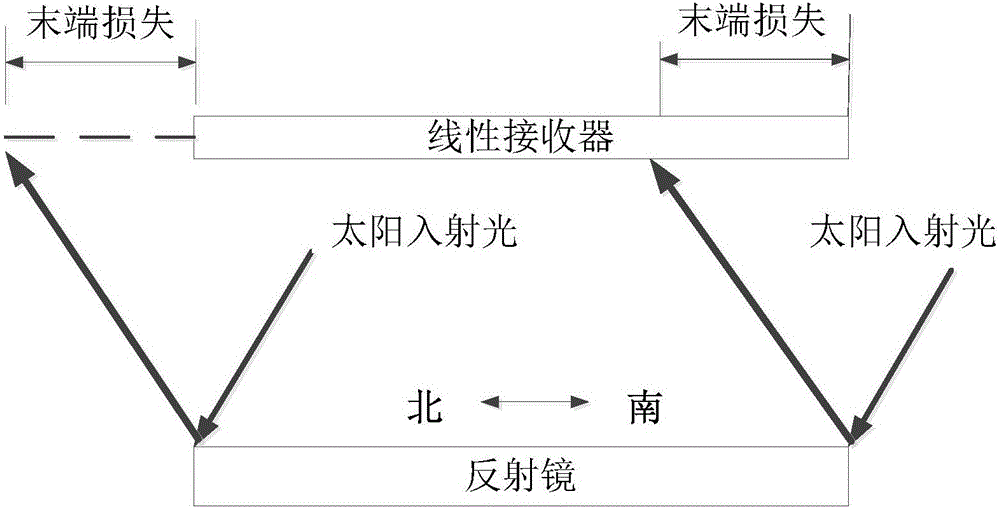

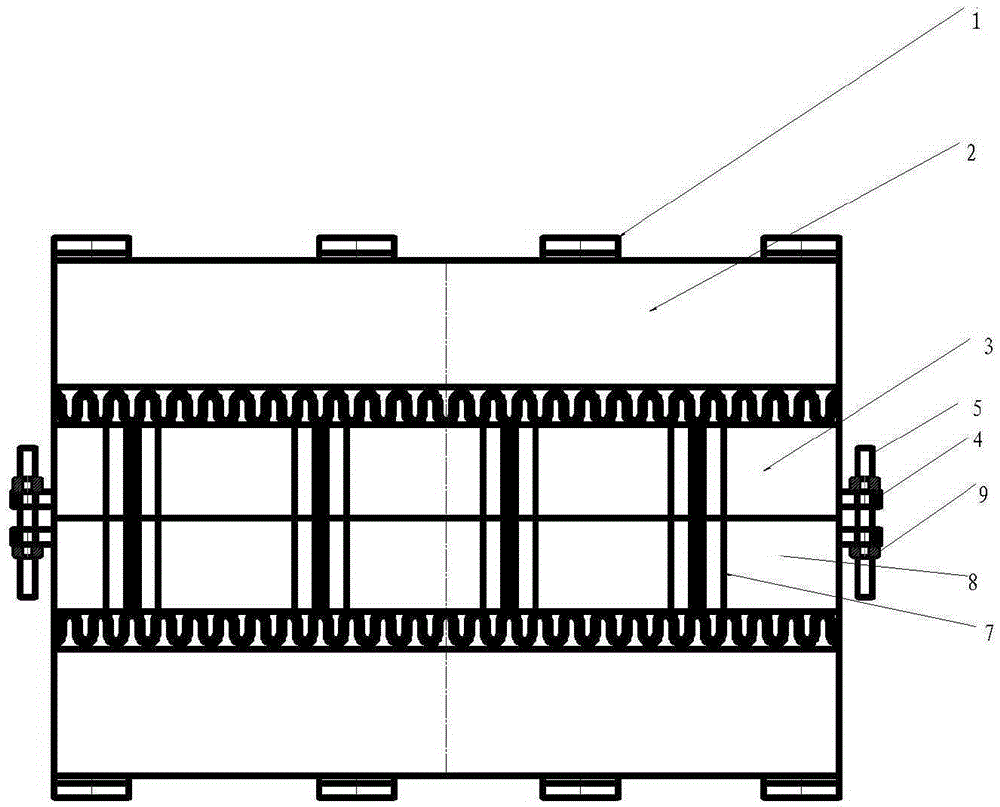

Movable solar heat collection linear receiver and use method thereof

InactiveCN106440409AEliminate end lossUse properlyPhotovoltaic supportsSolar heating energyLight beamReciprocating motion

The invention provides a movable solar heat collection linear receiver and a use method thereof. The movable solar heat collection linear receiver comprises an assembly rack, multiple reflector units arranged above the assembly rack, supports, a sliding match component and driving mechanisms, wherein the multiple reflector units form a Fresnel reflector; the supports are arranged on the middle part of the assembly rack; a heat receiver is movably arranged above the supports, and extends along the light beam intersection zone of the Fresnel reflector; the sliding match component is arranged between the supports and the heat receiver and is used for the heat receiver to reciprocate along a straight line on which the light beam intersection zone of the Fresnel reflector is located; and the driving mechanisms provide driving power for the linear reciprocating motion of the heat receiver. The movable solar heat collection linear receiver is used for solving the problem of a conventional solar energy receiver of seasonal periodical end loss, so that solar energy gathered by the Fresnel reflector can be fully collected.

Owner:东方骄英海洋发展有限公司

One-step vulcanizing assembling mold for large-tilt-angle flange conveying belt and application method thereof

The invention discloses a one-step vulcanizing assembling mold for a large-tilt-angle flange conveying belt. The one-step vulcanizing assembling mold comprises an apron mold set and a bottom plate, wherein the apron mold set comprises an inner module and an outer module; a mold cavity of the inner module and a mold cavity of the outer module are matched to form a wave shape; and a groove is also formed in the bottom surface of the inner module. According to the one-step vulcanizing assembling mold disclosed by the invention, the groove communicates with an apron shaping surface; during shaping, blocking plates and aprons are integrally connected, so that the usage is firmer, breaking is not generated, the service life of the large-tilt-angle flange conveying belt is prolonged, the producing time is shortened, and the working efficiency is improved.

Owner:QINGDAO XIUPOER TECH CO LTD

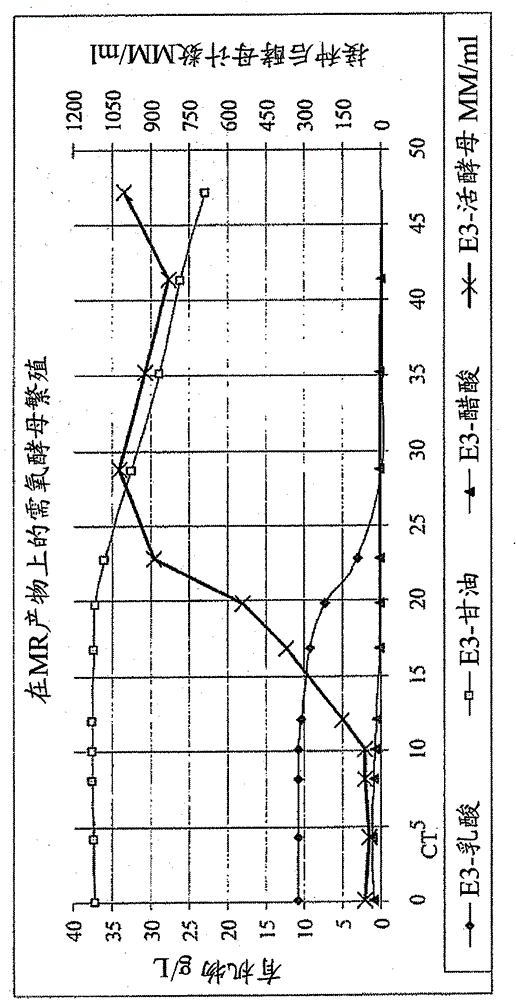

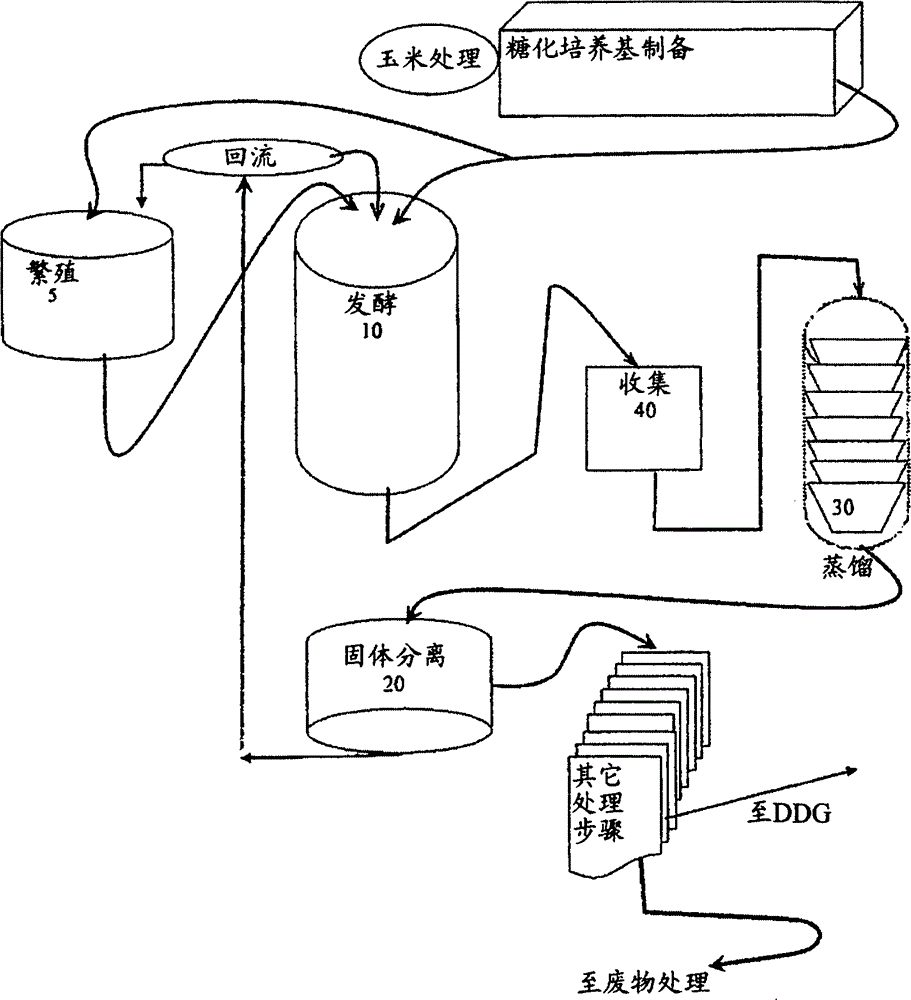

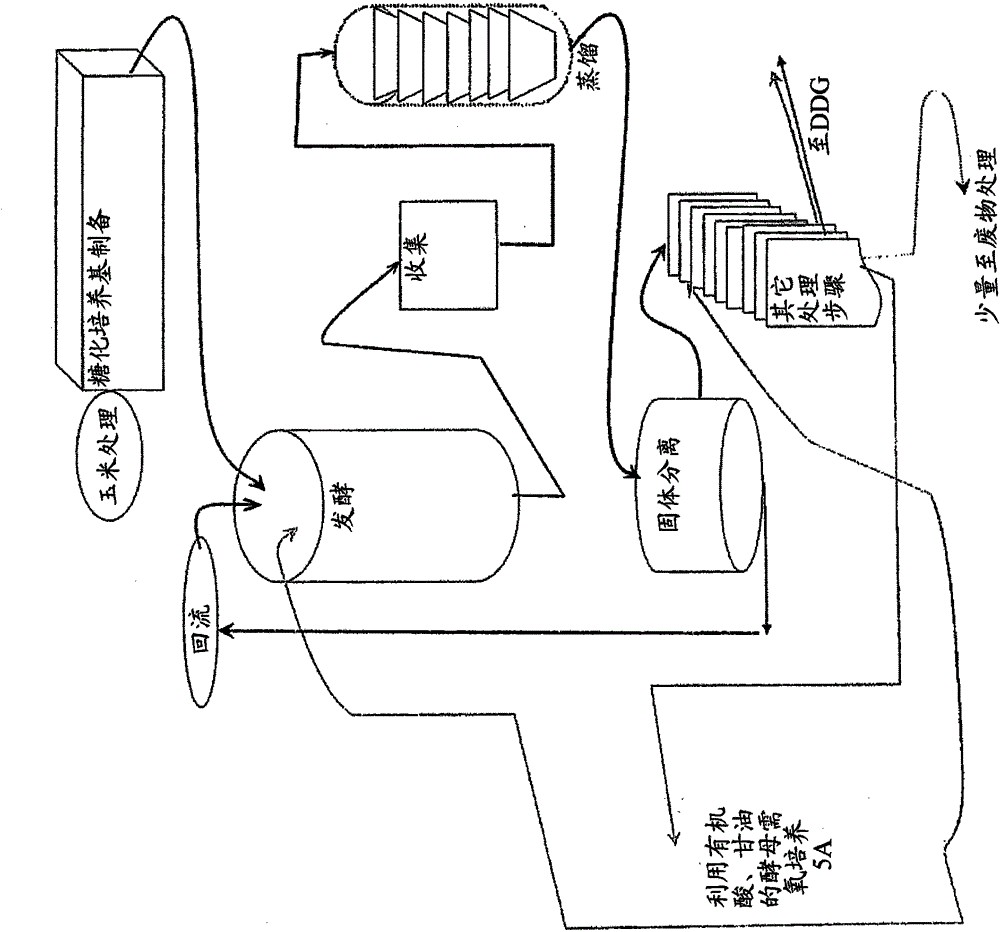

Use of ethanol plant by-products for yeast propagation

Embodiments of the invention relate, for example, to methods for reducing the load of organic acids and glycerol in water recycled to the fermentation process. Organic acids and glycerol produced during ethanol fermentation are used as a replacement for carbohydrates for propagation of yeast. The yeast may be sold as a feed product or used in subsequent fermentation.

Owner:ARCHER DANIELS MIDLAND CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com