Control method of refrigerator

A control method and refrigerator technology, which are applied to household refrigerators, refrigerators, refrigeration components, etc., can solve problems such as temperature rise in storage rooms, storage of unfavorable items, and refrigerators can no longer perform refrigeration and air supply, and achieve good utilization, Good defrosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

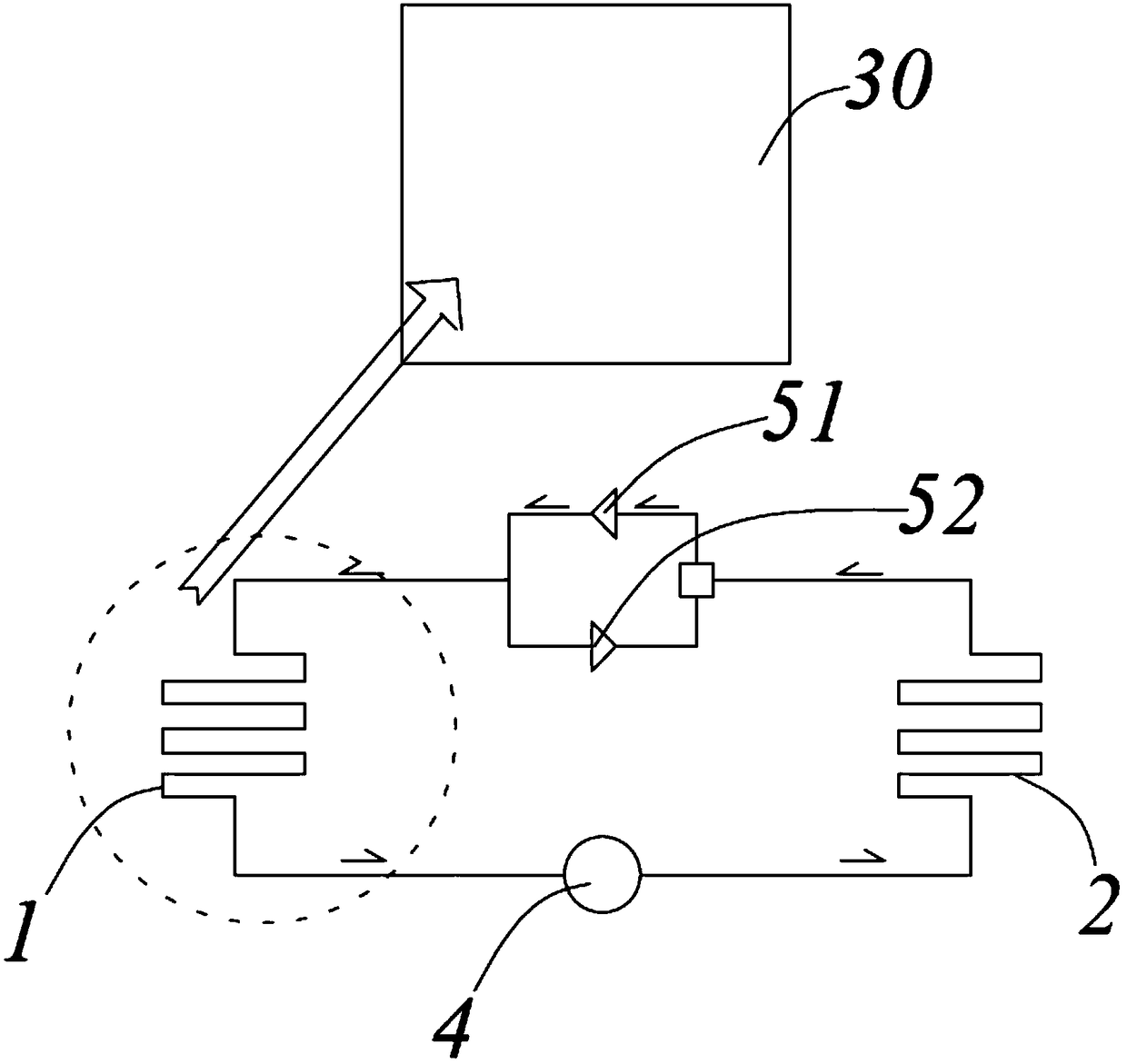

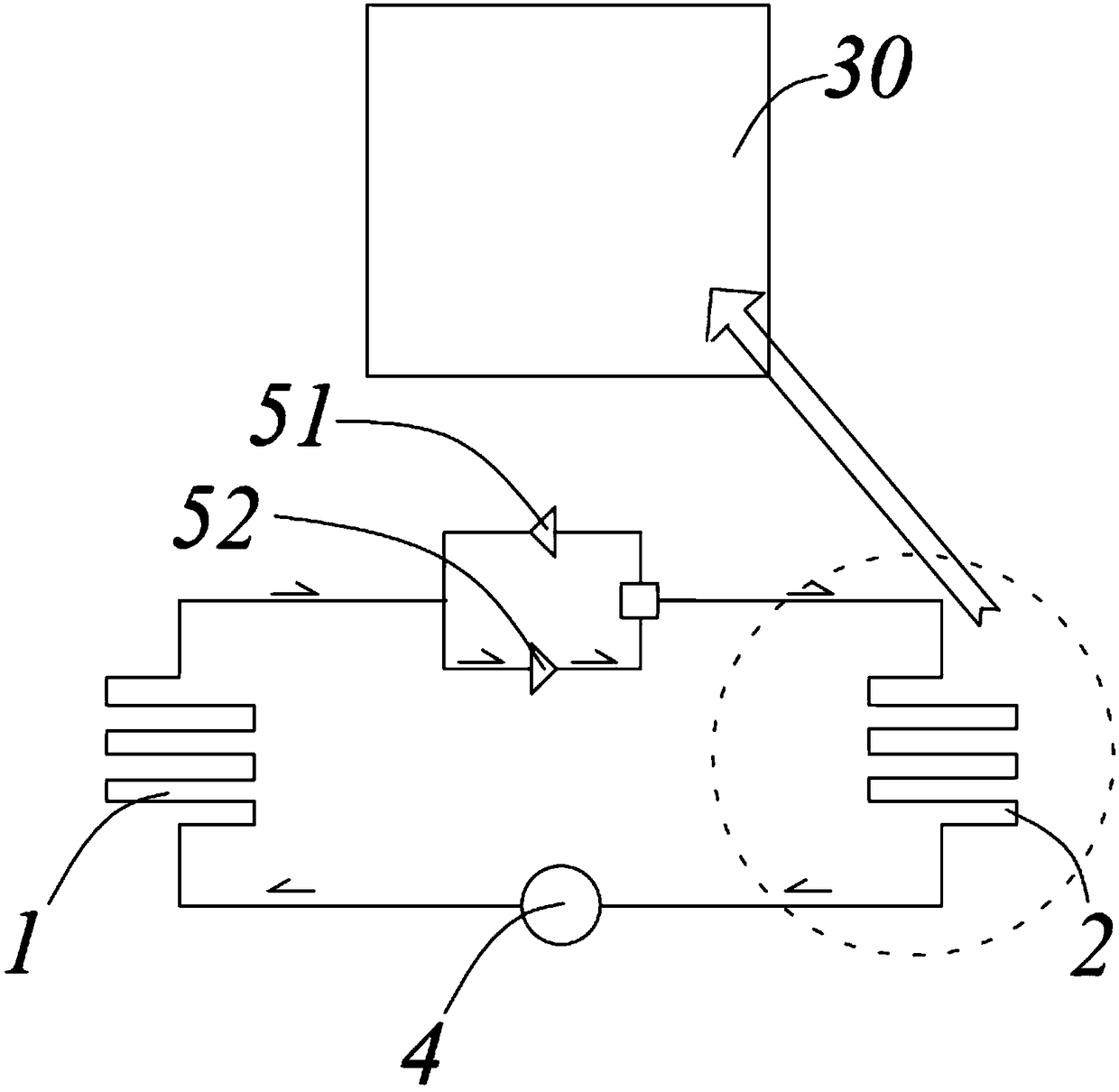

[0045] Such as Figure 1 to Figure 2 As shown, the throttling element includes two parallel first one-way valves 51 and second one-way valves 52 facing opposite directions. A one-way valve only allows refrigerant to flow in one direction. The compressor 4 is a two-way compressor 4 that allows the refrigerant to flow forward or backward, that is, the compressor 4 can control the refrigerant to flow in two different directions. The compressor 4 and the throttling element are respectively communicated with both ends of the first heat exchanger 1 to form a refrigerant flow circuit. When the compressor 4 makes the refrigerant flow forward, the refrigerant passes through the first one-way valve 51, and when the compressor 4 makes the refrigerant flow in the reverse direction, the refrigerant passes through the second one-way valve 52, so that refrigeration The circulation of the agent forms a channel.

[0046] In the first embodiment, the compressor 4 can allow the refrigerant to...

Embodiment approach 2

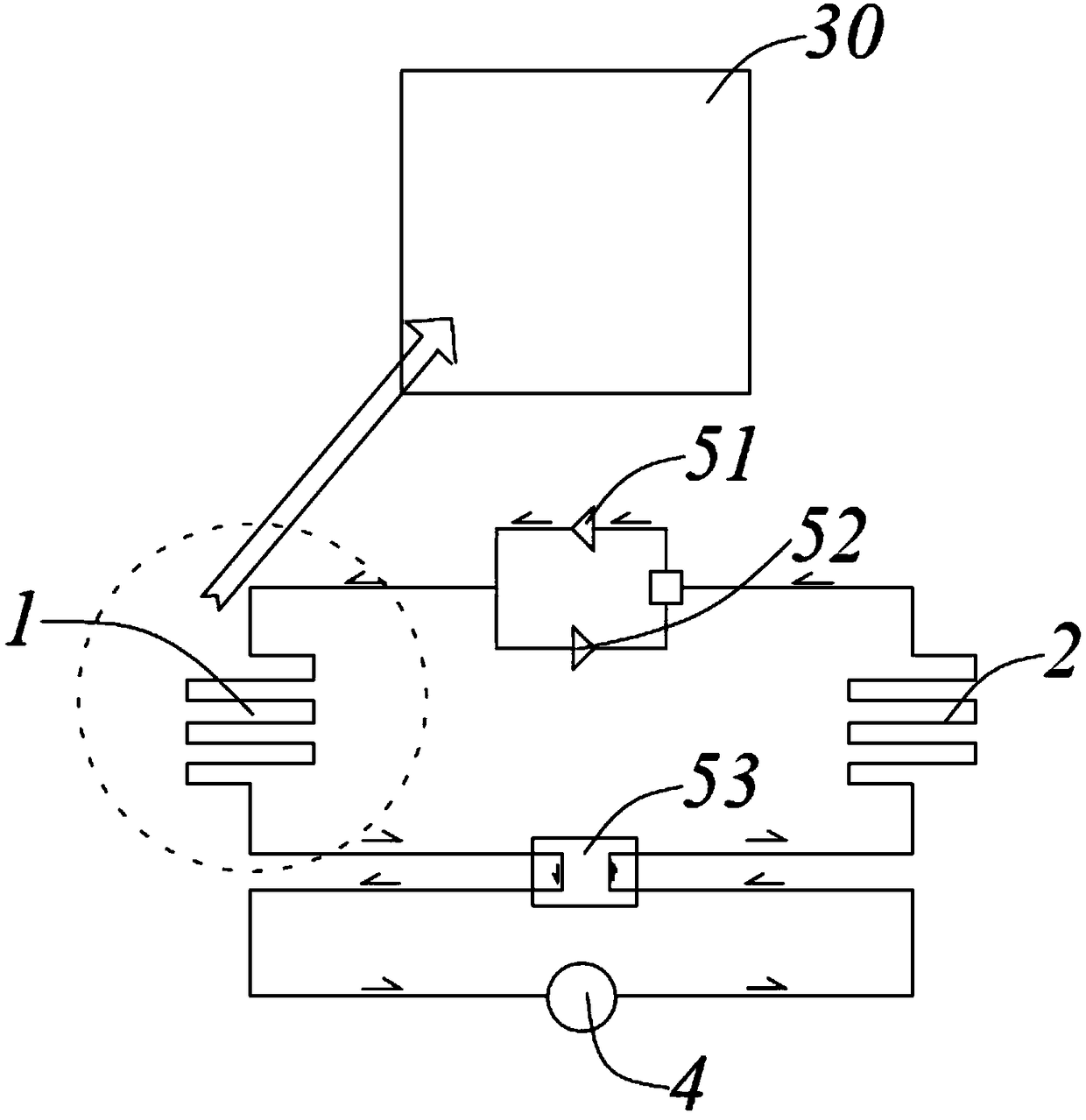

[0052] Such as Figure 3 to Figure 4 As shown, the throttling element includes two parallel first one-way valves 51 and second one-way valves 52 facing in opposite directions, and the compressor 4 is a one-way compressor 4 that only allows refrigerant to flow in one direction. . In this embodiment, since the one-way compressor 4 is used, the temperature control system in this embodiment further includes a four-way valve 53 . The four-way valve 53 includes an inlet and an outlet respectively connected to both ends of the compressor 4 , and two other communication ports respectively connected to the first heat exchanger 1 and the second heat exchanger 2 . In this embodiment, the inlet of the four-way valve 53 refers to the end where the refrigerant flows out, and the outlet of the four-way valve 53 refers to the end where the refrigerant flows in.

[0053] When the inlet of the four-way valve 53 is connected to the first heat exchanger 1 and the outlet is connected to the seco...

Embodiment approach 3

[0060] Such as Figure 5 to Figure 6 As shown, the throttling element is a two-way valve 54, and the compressor 4 is a two-way compressor 4 that allows the refrigerant to flow in the forward or reverse direction. The compressor 4 and the two-way valve 54 are respectively connected to the Both ends of the heater 1; so that when the compressor 4 makes the refrigerant flow forward or reverse, the refrigerant can pass through the two-way valve 54.

[0061] In the third embodiment, the two-way compressor 4 and the two-way valve 54 that allow the refrigerant to flow in both directions are used, so that when the compressor 4 controls the refrigerant to change the flow direction, the two-way valve 54 can allow the refrigerant to pass through.

[0062] In the third embodiment, the "controlling the forward flow of the refrigerant and flowing from the second heat exchanger to the first heat exchanger" includes:

[0063] Control the compressor to run forward;

[0064] The "controlling t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com