Application of composite membrane in lithium-sulfur battery

A lithium-sulfur battery and composite membrane technology, applied in the direction of lithium storage battery, secondary battery, battery pack components, etc., can solve the problems of consumption of lithium nitrate, poor battery stability, low capacity retention rate, etc., and achieve delayed use and good utilization. , the effect of improving the capacity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

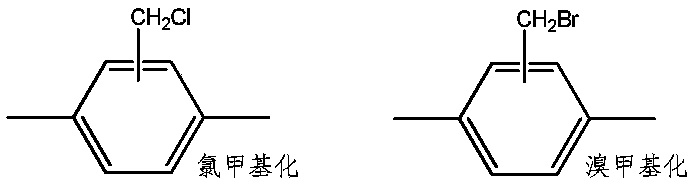

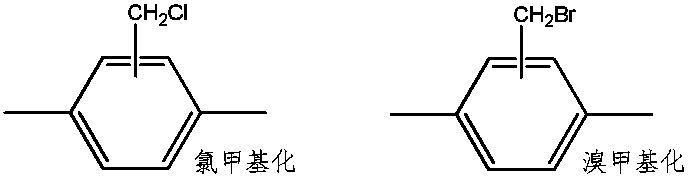

[0028] Preparation of a composite membrane rich in nitrate ions: soak 1 g of chloromethyl polystyrene in 10% aqueous solution of trimethylamine for 24 hours at room temperature to obtain quaternized polystyrene with a quaternization degree of 100 mmol / g. The degree of chloromethyl is 100mmol / g, the quaternized polystyrene and lithium nitrate are mixed and dissolved in N-methylpyrrolidone (NMP) according to the mass ratio of 1:1, and a film-forming solution with a concentration of 10% is prepared. The film-forming solution is cast to form a film. Naturally dry at 70°C, vacuum dry at 70°C to remove water and set aside.

[0029] The negative electrode of the lithium-sulfur battery is a lithium foil with a thickness of 100 microns, and the positive electrode is prepared by the following method: 20 parts by mass of Super P carbon, 70 parts by mass of elemental sulfur, and 10 parts by mass of polyvinylidene fluoride (PVDF) in Blended in N-methylpyrrolidone (NMP), coated onto alumin...

Embodiment 2

[0032] Preparation of a composite membrane rich in nitrate ions: Soak 1g of chloromethyl polyethersulfone with a chloromethyl degree of 100mmol / g in 10% triethylamine aqueous solution at room temperature for 24 hours to obtain a quaternization degree of 100mmol / g g of quaternized polyethersulfone and cesium nitrate are mixed and dissolved in N-methylpyrrolidone (NMP) according to the mass ratio of 1:2 to form a film-forming solution with a concentration of 15%. The film-forming solution is cast to form a film. Naturally dry at 70°C, vacuum dry at 70°C to remove water and set aside.

[0033] The negative electrode of the lithium-sulfur battery is a lithium foil with a thickness of 100 microns, and the positive electrode is prepared by the following method: 20 parts by mass of Super P carbon, 70 parts by mass of elemental sulfur, and 10 parts by mass of polyvinylidene fluoride (PVDF) in Blended in N-methylpyrrolidone (NMP), coated onto aluminum foil. The sulfur content in the ...

Embodiment 3

[0036] Preparation of a composite membrane rich in nitrate ions: soak 3g of chloromethyl polyethersulfone with a chloromethyl degree of 30mmol / g in 10% triethylamine aqueous solution at room temperature for 24 hours to obtain a quaternization degree of 100mmol / g g quaternized polyethersulfone. Mix it with lithium nitrate at a mass ratio of 1:1 and dissolve in N,N-dimethylformamide (DMF) to prepare a film-forming solution with a concentration of 20wt.%. The film-forming solution is cast to form a film. Naturally dry at 70°C, vacuum dry at 70°C to remove water and set aside.

[0037]The negative electrode of the lithium-sulfur battery is a lithium foil with a thickness of 100 microns, and the positive electrode is prepared by the following method: 20 parts by mass of Super P carbon, 70 parts by mass of elemental sulfur, and 10 parts by mass of polyvinylidene fluoride (PVDF) in Blended in N-methylpyrrolidone (NMP), coated onto aluminum foil. The sulfur content in the positive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com