Air-conditioning device capable of realizing gradient utilization for waste heat of ship, and working method

An air-conditioning device and ship technology, applied in the steam generation method using heat carrier, steam generation method, hull ventilation/heating/cooling, etc., can solve the problem of increased power consumption of air-conditioning device compressors, decreased operating efficiency, and increased ship air-conditioning devices operating costs etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

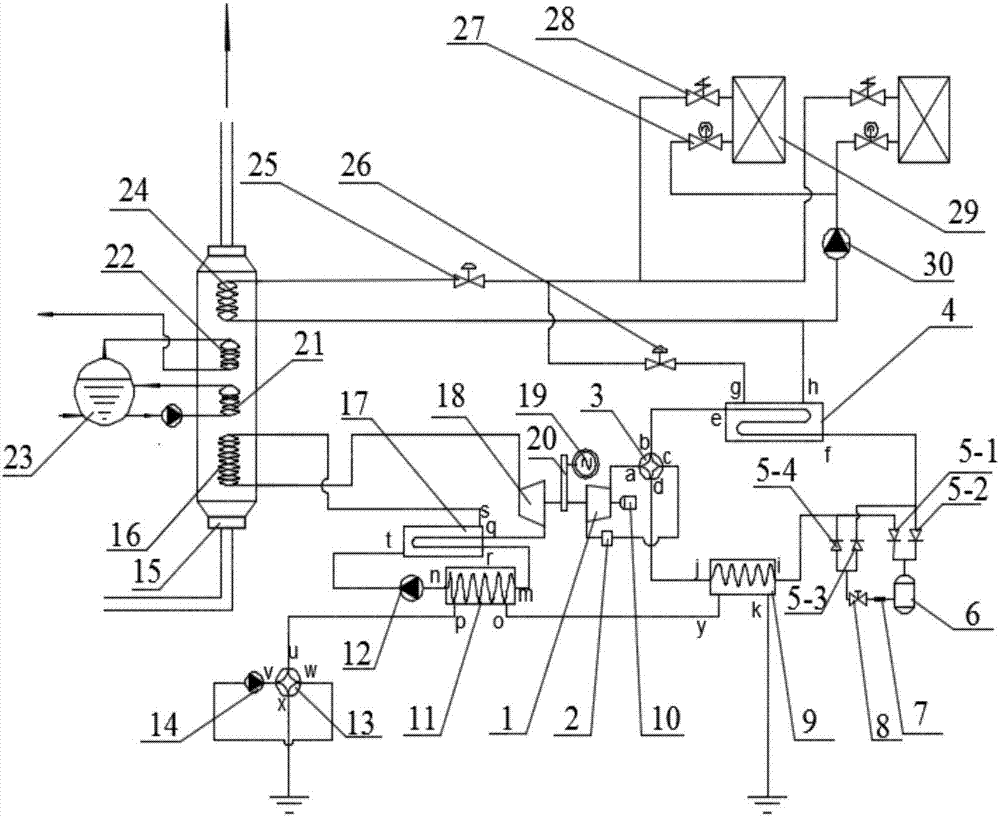

[0034] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0035] Such as figure 1 Shown here is a cascade-utilizing air-conditioning device for ship waste heat, including: heat pump system, organic working fluid Rankine cycle system, seawater circulation system, air conditioning terminal system, flue gas pipeline system, electric motor 10, generator 19 And the shaft switch 20, the heat pump system includes: a compressor 1, a gas-liquid separator 2, a four-way reversing valve 3, a first heat exchanger 4, a first one-way valve 5-1, a second one-way Valve 5-2, third one-way valve 5-3, fourth one-way valve 5-4, high-pressure accumulator 6, filter drier 7, throttle valve 8, second heat exchanger 9, the four-way The reversing valve 3 includes an inlet a, a first outlet b, a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com