Power generation system utilizing waste heat of high-temperature flue gas

A power generation system, high-temperature flue gas technology, applied in the steam generation method using heat carrier, preheating, liquid degassing, etc., can solve the problems of high cost of system transformation, low efficiency of waste heat utilization, etc., to improve work ability, The effect of increasing power generation and improving waste heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

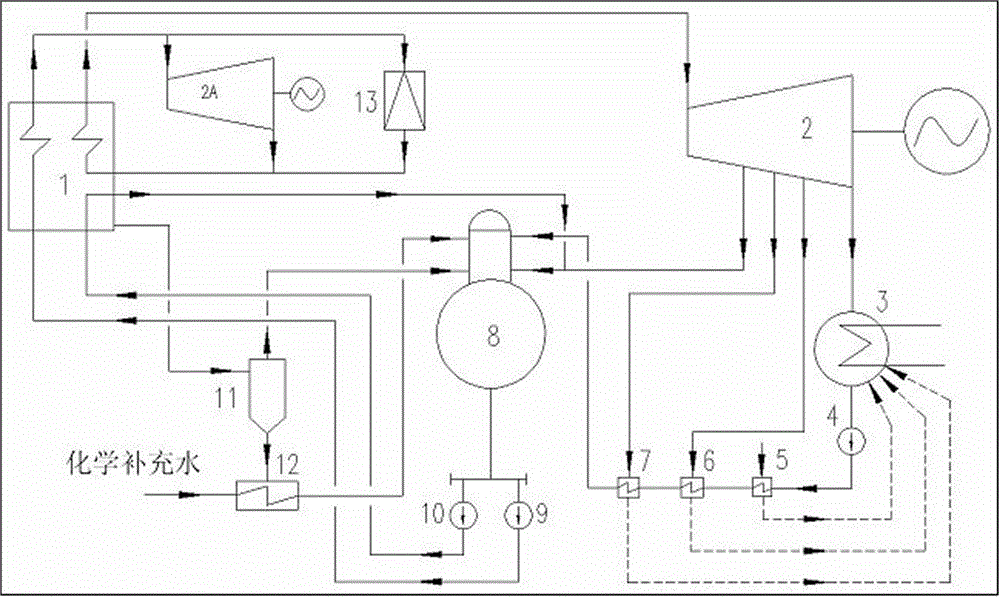

[0027] As shown in the figure, the specific implementation method is as follows:

[0028] A power generation system using high-temperature flue gas waste heat, including a dual-pressure waste heat boiler 1 with a reheater inside, characterized in that: the high-pressure steam of the double-pressure waste heat boiler 1 is passed into a back-pressure steam turbine generator set 2A for power generation , the steam generated by the back-pressure turbo-generator unit 2A returns to the dual-pressure waste heat boiler 1 to be heated by the reheater, and the reheated steam enters the turbo-generator unit 2 through the steam pipeline to generate power. The turbo-generator unit 2. The steam after power generation is passed into the condenser 3, and the condensed water formed in the condenser 3 is passed through the condensed water pump 4 into the steam seal heater 5, the first-level low-pressure heater 6 and the second-level low-pressure heater 7 for heating , the heated condensed water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com