Triangular flash circulating system and method thereof

A circulation system and flash evaporation technology, which is applied in the direction of steam engine devices, intermeshing engines, machines/engines, etc., can solve the problems of thermal energy to be improved, and achieve the effect of improving waste heat utilization efficiency, making full use of waste heat resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

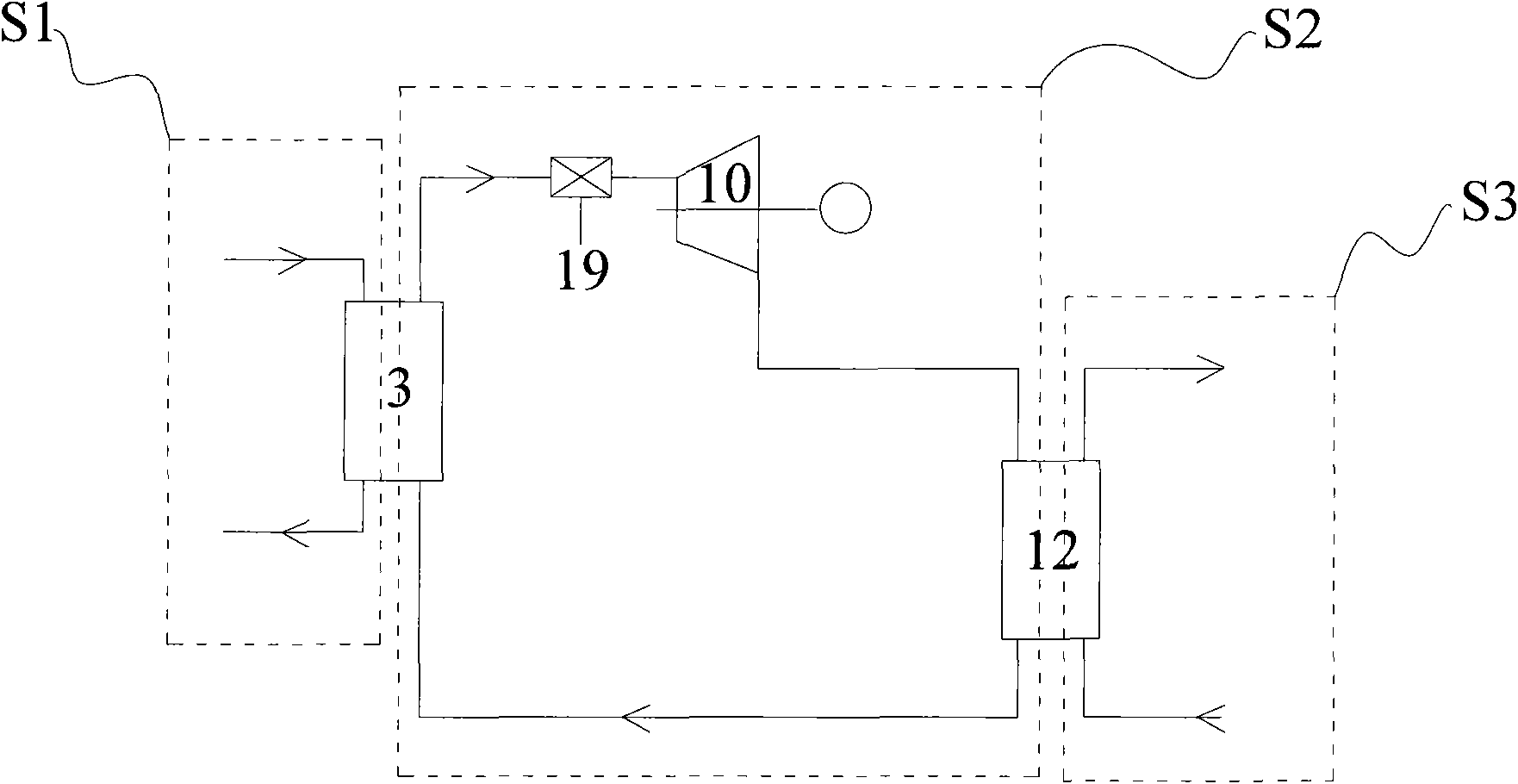

[0028] See figure 1 , which is a schematic structural diagram of a triangular flash cycle system in Example 1 of the present invention.

[0029] The triangular flash cycle system provided in this embodiment includes a decompression mechanism, an evaporator 3, a first screw expansion power machine 10, and a condenser 12, and the evaporator 3, a decompression mechanism, the first screw expansion power machine 10, and a condenser 12 pass through The pipelines are connected in sequence to form a working medium circulation passage S2, the evaporator 3 is provided with a heating passage S1 for heating the working medium in the working medium circulation passage S2, and the condenser 12 is provided with a cooling passage S3 for cooling the working medium in the working medium circulation passage S2 .

Embodiment 2

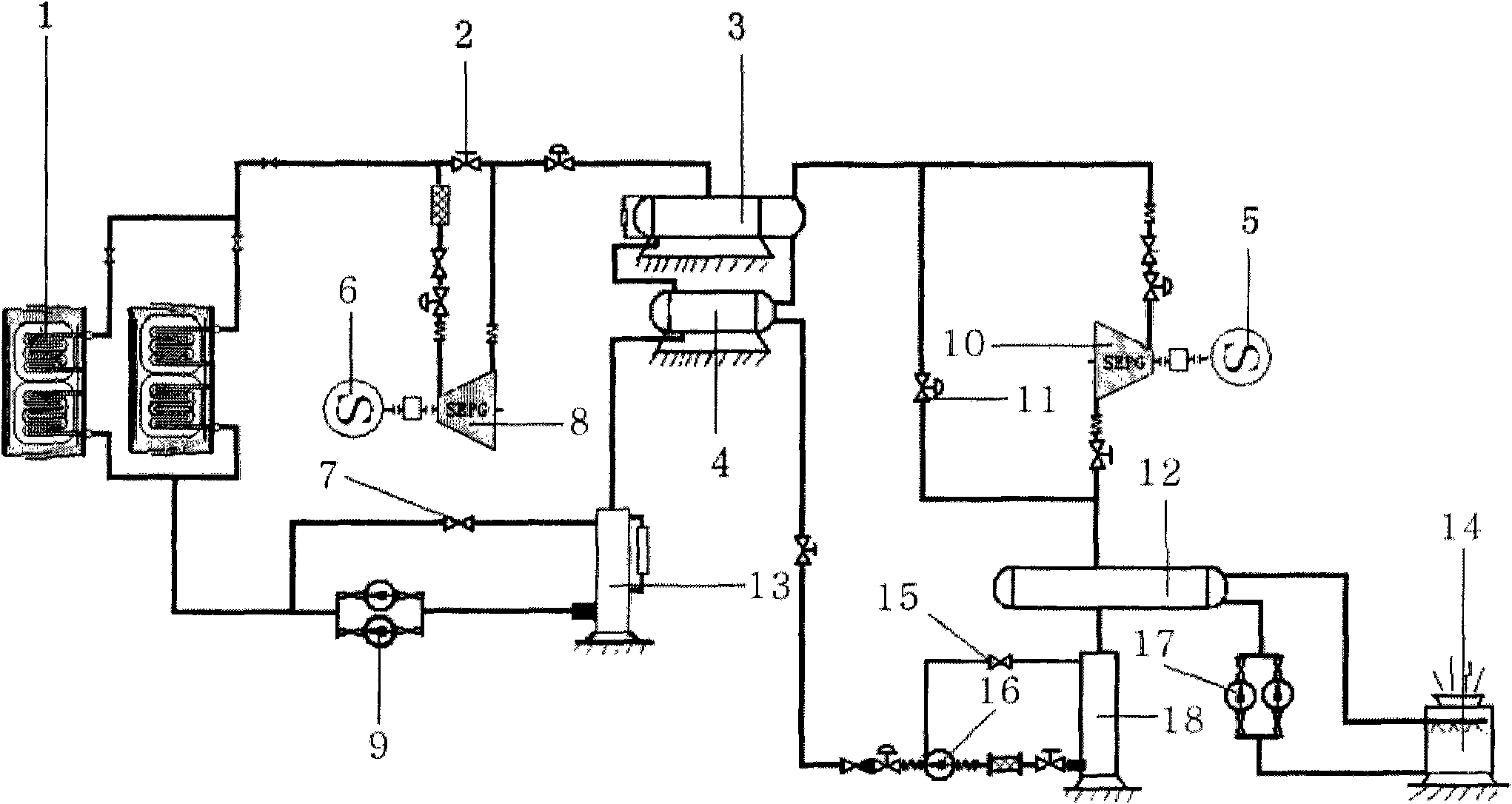

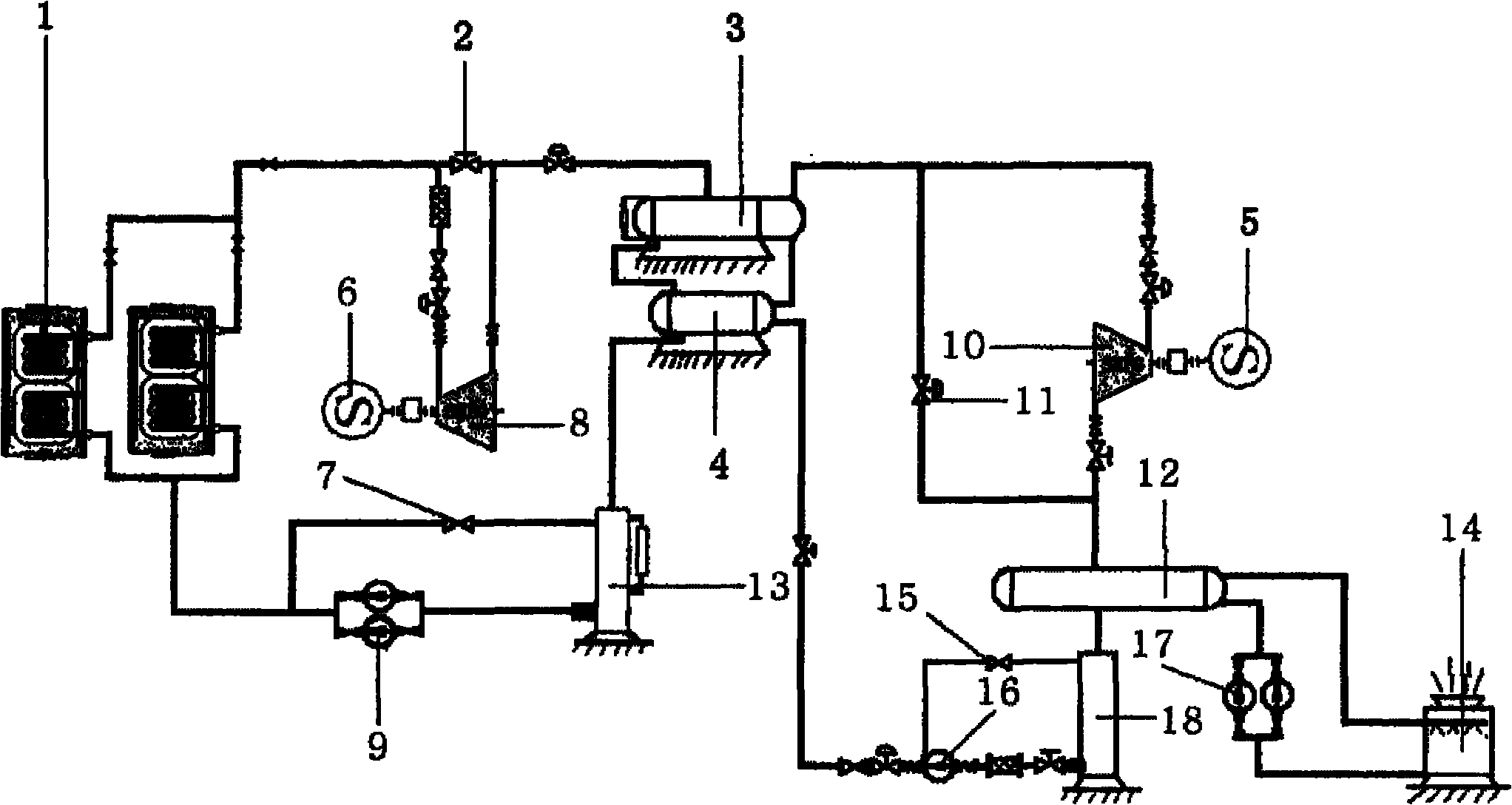

[0031] In the triangular flash cycle system provided in this embodiment, the heating path S1 includes a heat source body 1, a second screw expansion power machine 8, and an evaporator 3, and the heat source body 1, the second screw expansion power machine 8, and the evaporator 3 are formed by sequentially connecting through pipelines The heating passage; the working fluid circulation passage S2 includes the evaporator 3 in the heating passage S1, the decompression mechanism (not shown in the figure), the first screw expansion power machine 10, the condenser 12, the evaporator 3, the decompression mechanism, the first The screw expansion power machine 10 and the condenser 12 are sequentially connected by pipelines to form a working medium circulation passage S2; the condenser 12 is provided with a cooling passage S3 for cooling the working medium circulating in the working medium circulation passage S2; the cooling passage S3 includes a cold water source body 14. The cold water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com