Integrated waste water treatment equipment

A technology for sewage treatment equipment and boxes, applied in water/sewage treatment equipment, water/sewage treatment, water/sludge/sewage treatment, etc. 16 Inconvenient installation and other problems, to achieve the effect of small footprint and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

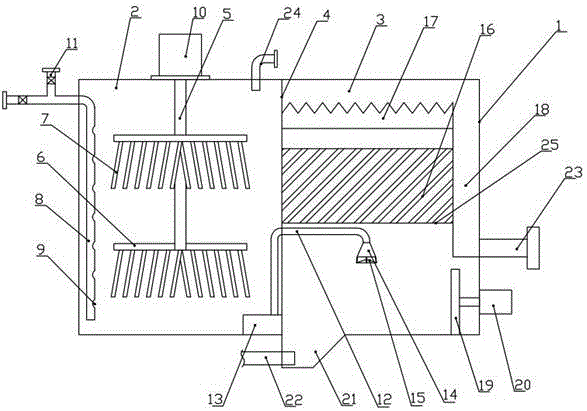

[0015] The invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0016] figure 1 The integrated sewage treatment equipment provided by the invention is shown, comprising a casing 1, a partition 4 that divides the casing 1 into a stirring chamber 2 and a sedimentation chamber 3, the partition 4 is arranged in the middle of the casing 1, and makes the stirring The chamber 2 and the precipitation chamber 3 are distributed left and right; the stirring chamber 2 is equipped with a stirring shaft 5; the stirring shaft 5 is equipped with a fixed frame 6, and the fixed frame 6 is hingedly equipped with a stirring blade 7, and the stirring blade 7 is installed On the lower surface of the fixed mount 6, the stirring blade 7 can swing freely on the fixed mount 6; a vertical dosing pipeline 8 is also arranged in the tank body, and a plurality of medicine feeding holes 9 are provided on the dosing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com