Biomass carbonization device

A biomass charcoal and chemical device technology, which is applied in the fields of biofuels, waste fuels, special forms of dry distillation, etc., can solve the problems of long carbonization time, environmental pollution, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

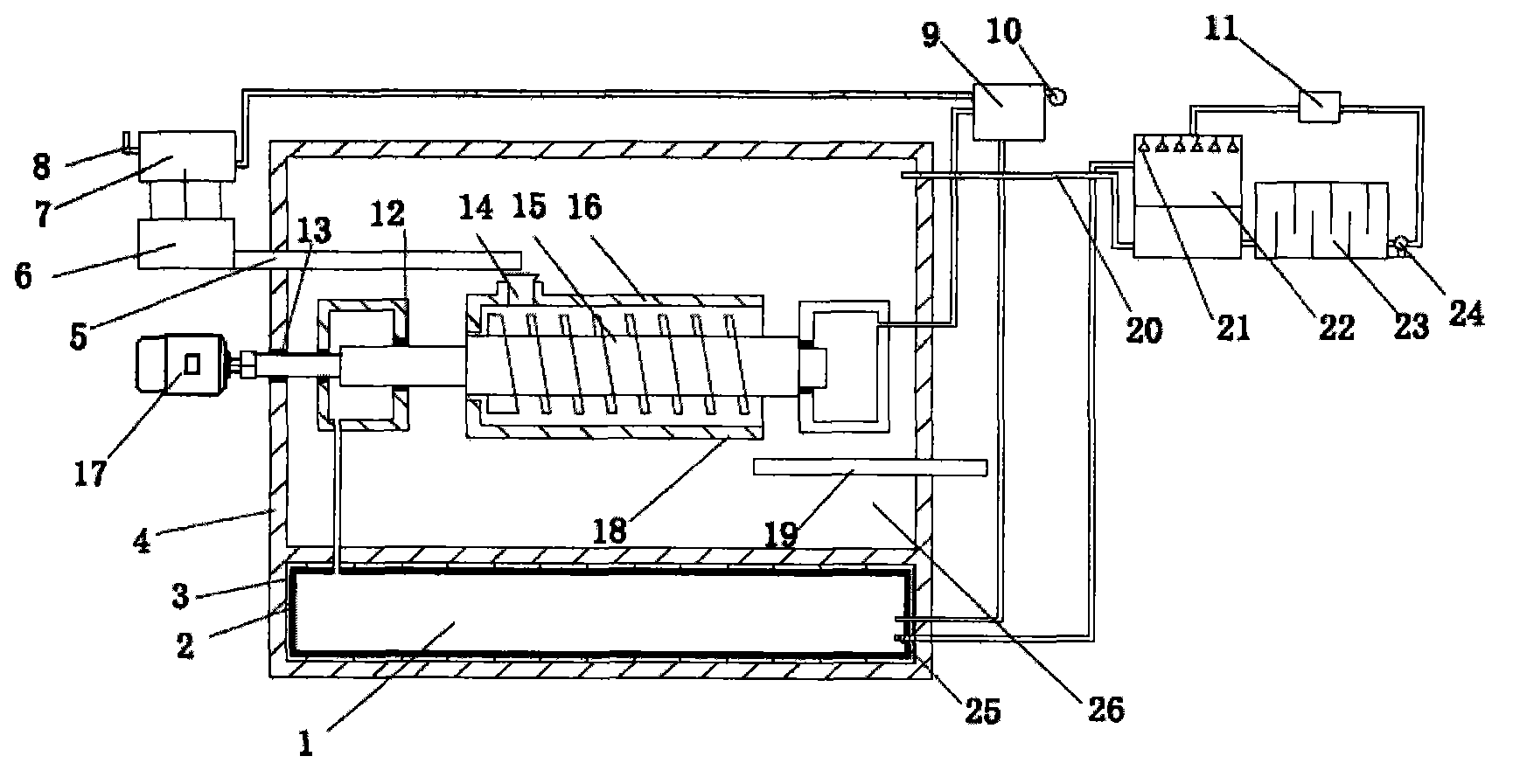

[0011] A biomass carbonization device of the present invention will be further described below in conjunction with the accompanying drawings.

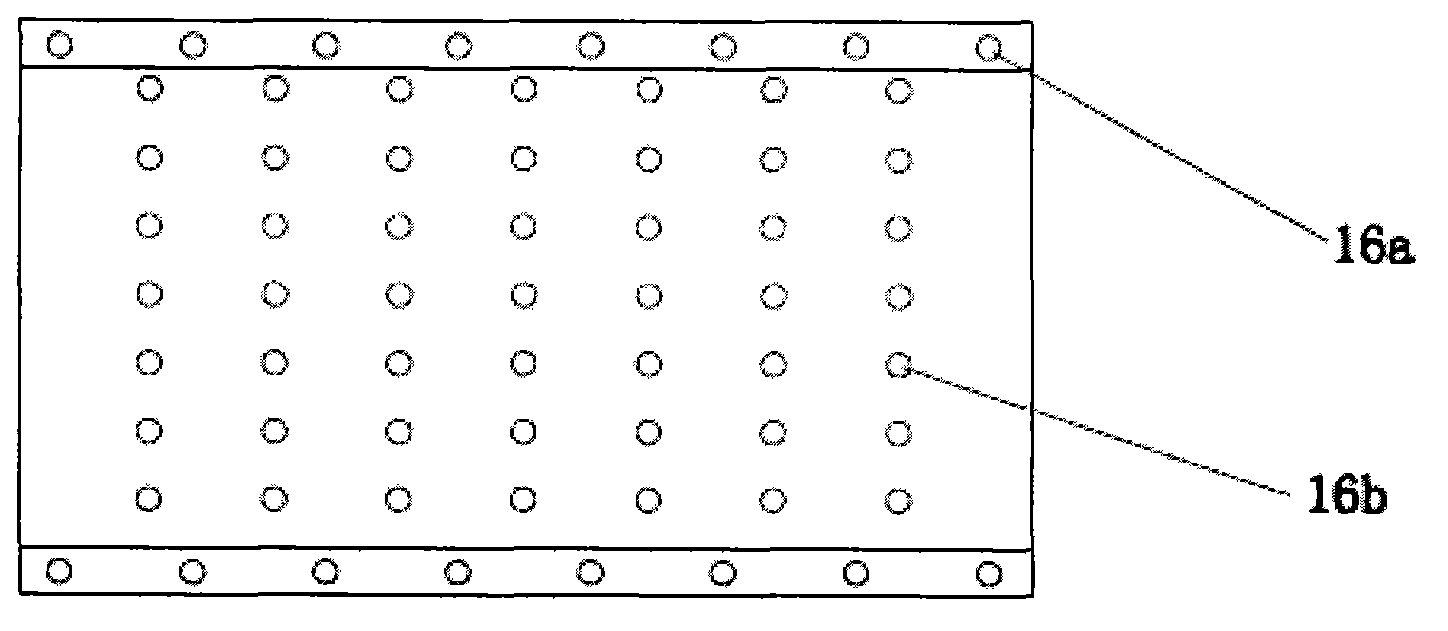

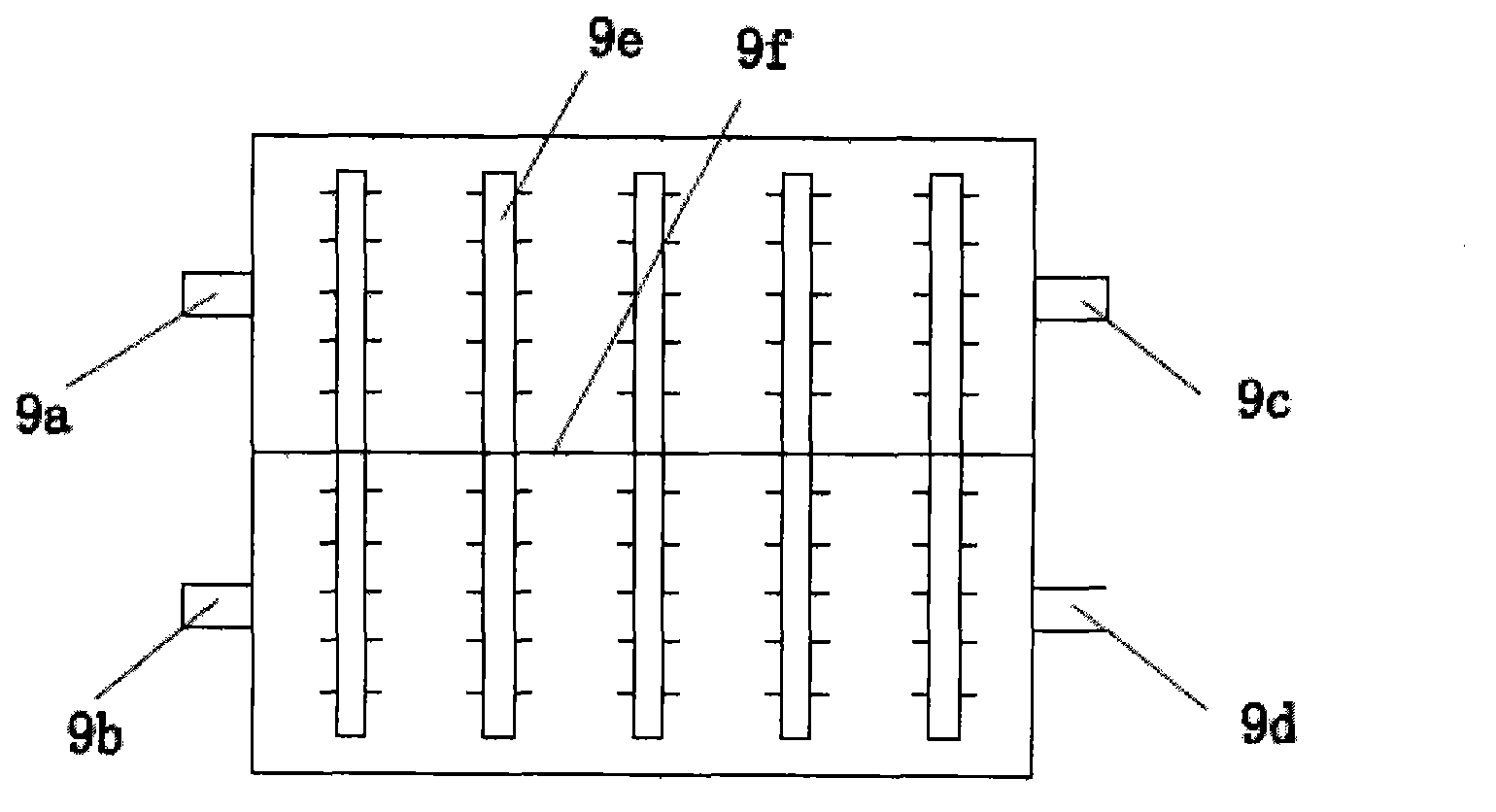

[0012] A biomass carbonization device of the present invention, the pyrolysis gas produced in the carbonization chamber 26 passes through the heat pipe air preheater 9, the pipeline 20, enters the combustion chamber 1 after spraying the settling chamber 22, and the hot air heated by the heat pipe air preheater 9 Combustion, the high-temperature flue gas produced is used as the main energy source of carbonization, so that the whole process basically does not require the addition of external energy to realize the orderly progress of the carbonization process. The high-temperature flue gas directly passes through the hollow screw shaft 15 with a heat storage body to heat the biomass. This design can not only heat the biomass, but the hollow screw shaft 15 with a heat storage body is driven by the motor 17 to rotate. It will also promote t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com