High-frequency electric collective oil-gas-water three-phase flow separator

A technology of oil-gas-water and three-phase flow, which is applied in the field of dehydration treatment of crude oil with high water content, aged oil and crude oil containing high polymer and demulsifier. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the drawings.

[0019] The invention is a high-frequency electric coalescing three-phase flow separator for oil, gas and water. The material used in the tank body of the separator should meet the relevant national standards. The pressure component steel in the separator adopts killed steel smelted in an electric furnace or an oxygen converter. After the equipment tank body is processed and produced, its heat treatment state must be strictly controlled to meet the relevant standards and non-destructive testing shall be performed. The internal and external walls of the equipment should be treated with anti-corrosion, and the tank body adopts RLHY-12 / 150 thermal insulation coating.

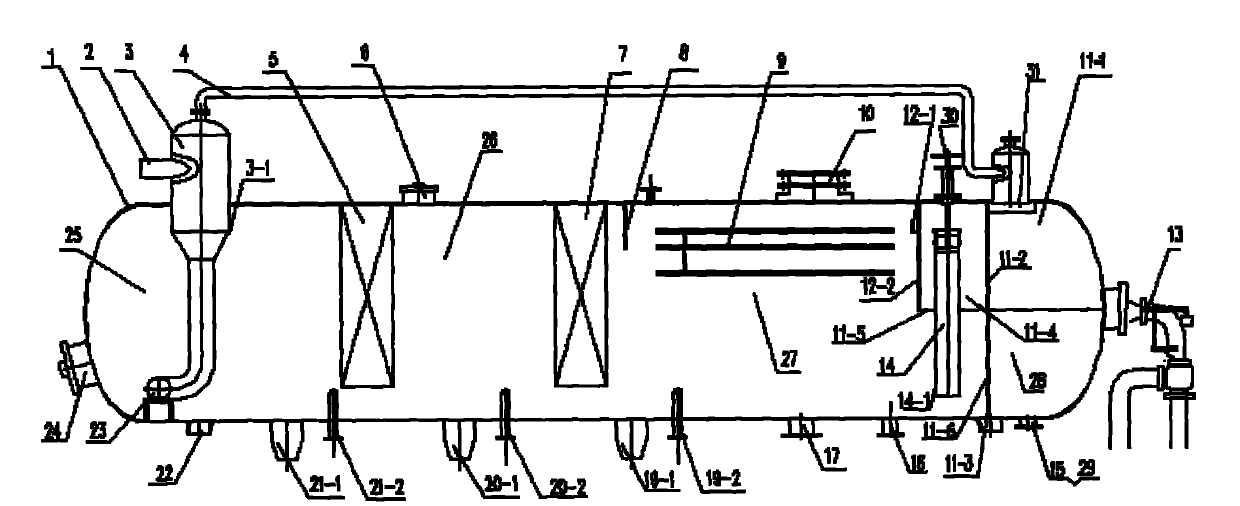

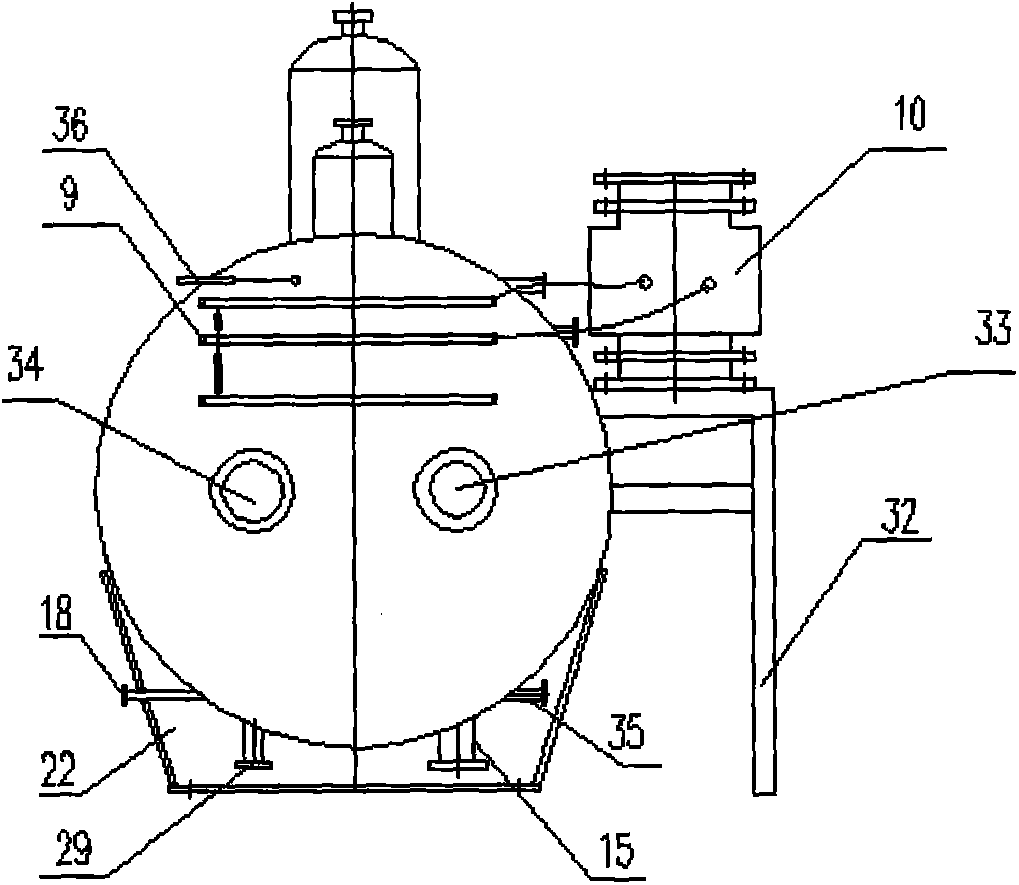

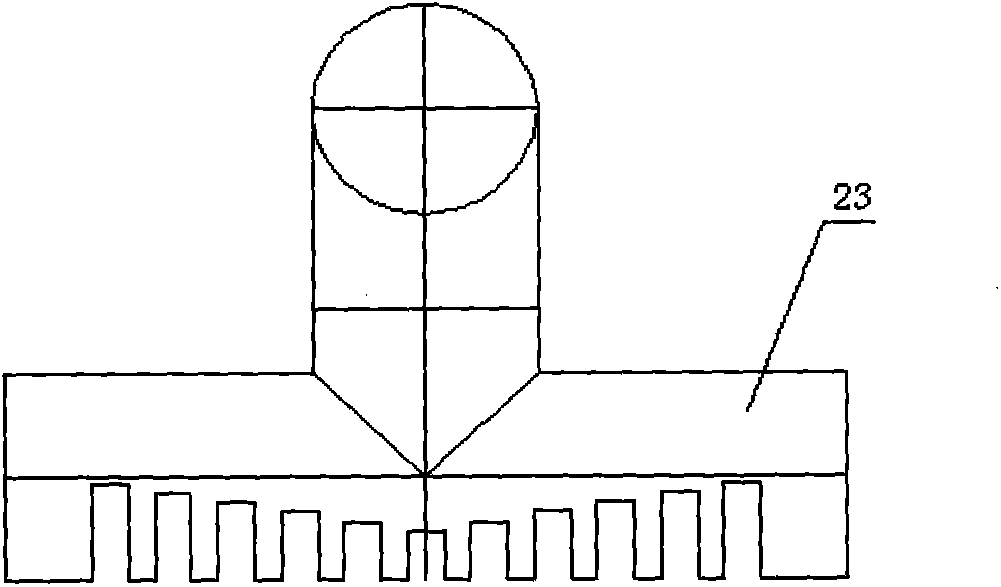

[0020] Such as Figure 1 to Figure 5 As shown, the high-frequency electric coalescing oil-gas-water three-phase flow separator of the present invention includes a horizontal tank 1 and a high-frequency rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com