Method for recovering zinc by using rotary kiln and device thereof

A rotary kiln and electric furnace technology, applied in the direction of improving process efficiency, can solve problems such as waste, ineffective recycling, environmental pollution, etc., and achieve good social and environmental benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The method and device for recovering zinc using a rotary kiln according to the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

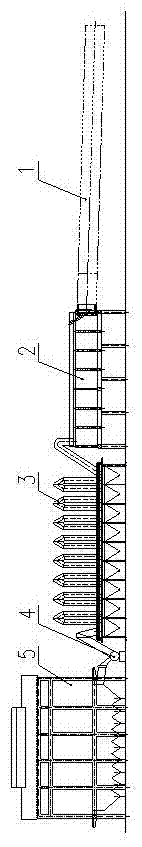

[0015] see figure 1 Shown is a schematic structural view of the rotary kiln zinc recovery device of the present invention, and the present invention will be described in detail below in conjunction with the device. The specific structure of the device is: comprising a rotary kiln 1, the gas outlet of the rotary kiln 1 is connected with the entrance of the settling chamber 2, the gas outlet of the settling chamber 2 is connected with the inlet of the surface cooler 3, and the gas outlet of the surface cooler 3 The centrifugal fan 4 communicates with the entrance of the dust collection chamber 5 .

[0016] The method for utilizing the rotary kiln to reclaim zinc of the present invention comprises the following steps: (1) mix electric furnace ash, anthracite and gas slime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com