Integrated sand making complete equipment

A complete set of equipment, sand powder technology, applied in chemical instruments and methods, solid separation, separating solids from solids with air flow, etc., can solve problems such as dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

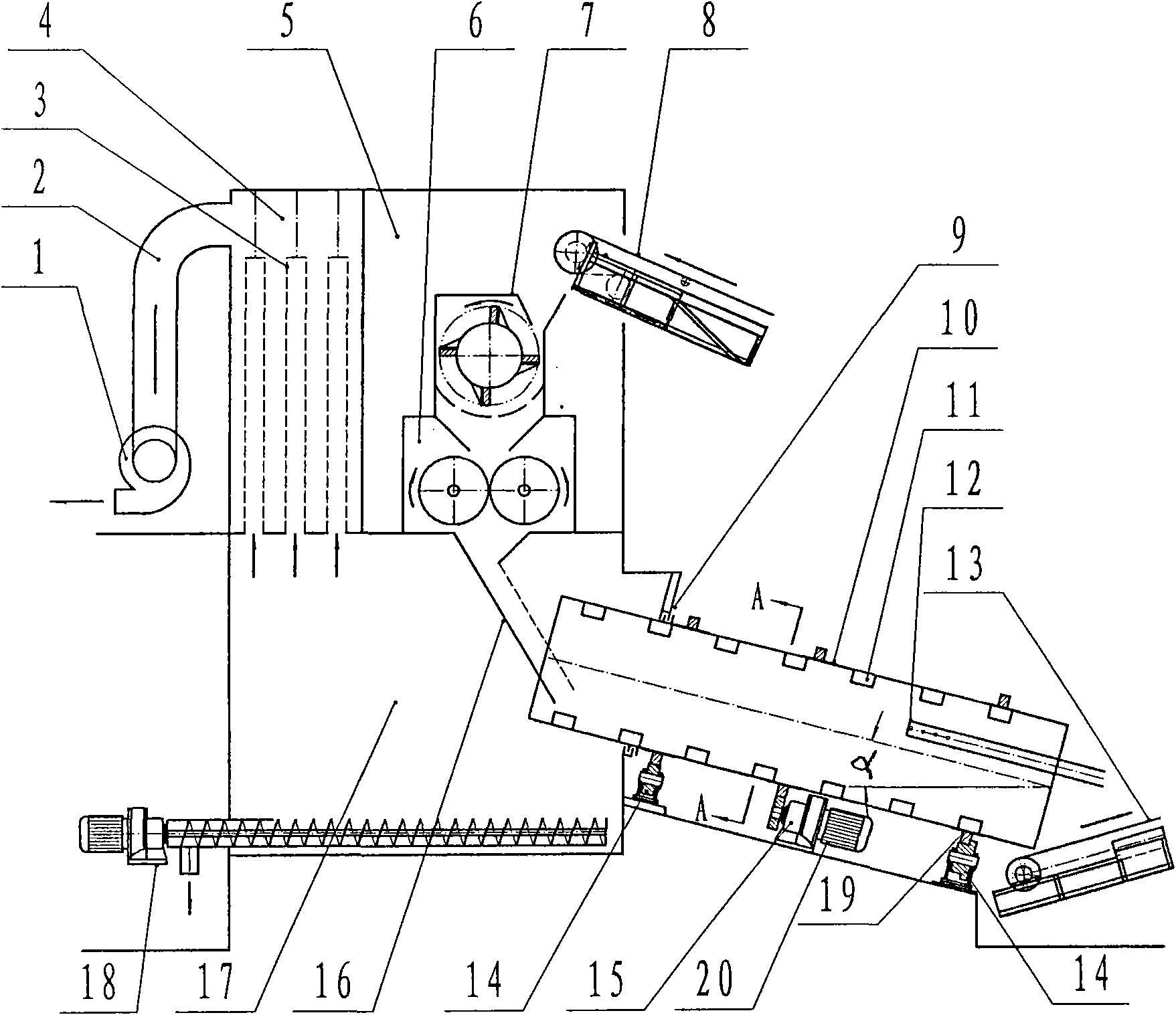

[0029] In this example, the structure of the integrated sand making equipment is as follows figure 1 , figure 2 As shown, it includes a crushing device, a sand powder separation device, a dust removal device, a crushing chamber 5, a dust removal chamber 4 and a dust settling chamber 17; the crushing chamber 5, the dust removal chamber 4 and the dust settling chamber 17 are integral structures, and its appearance A small building, its interior is divided into three chambers by partitions, the two upper chambers are dust removal chamber 4 and crushing chamber 5, and the lower chamber is dust settling chamber 17.

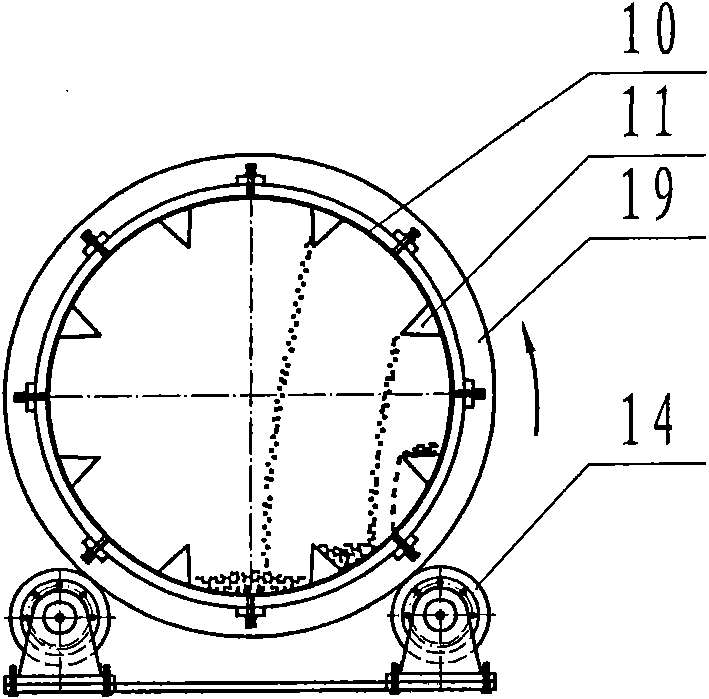

[0030]The sand powder separation device includes a drum 10 with a lifting plate 11 on the inner wall, a supporting wheel 14 supporting the drum, a transmission mechanism 15 connecting the motor 20 and the drum 10, and a water spray head 12 connected with a water pipe; the drum 10 is inclined Installed horizontally, the angle α between the axis and the horizontal dire...

Embodiment 2

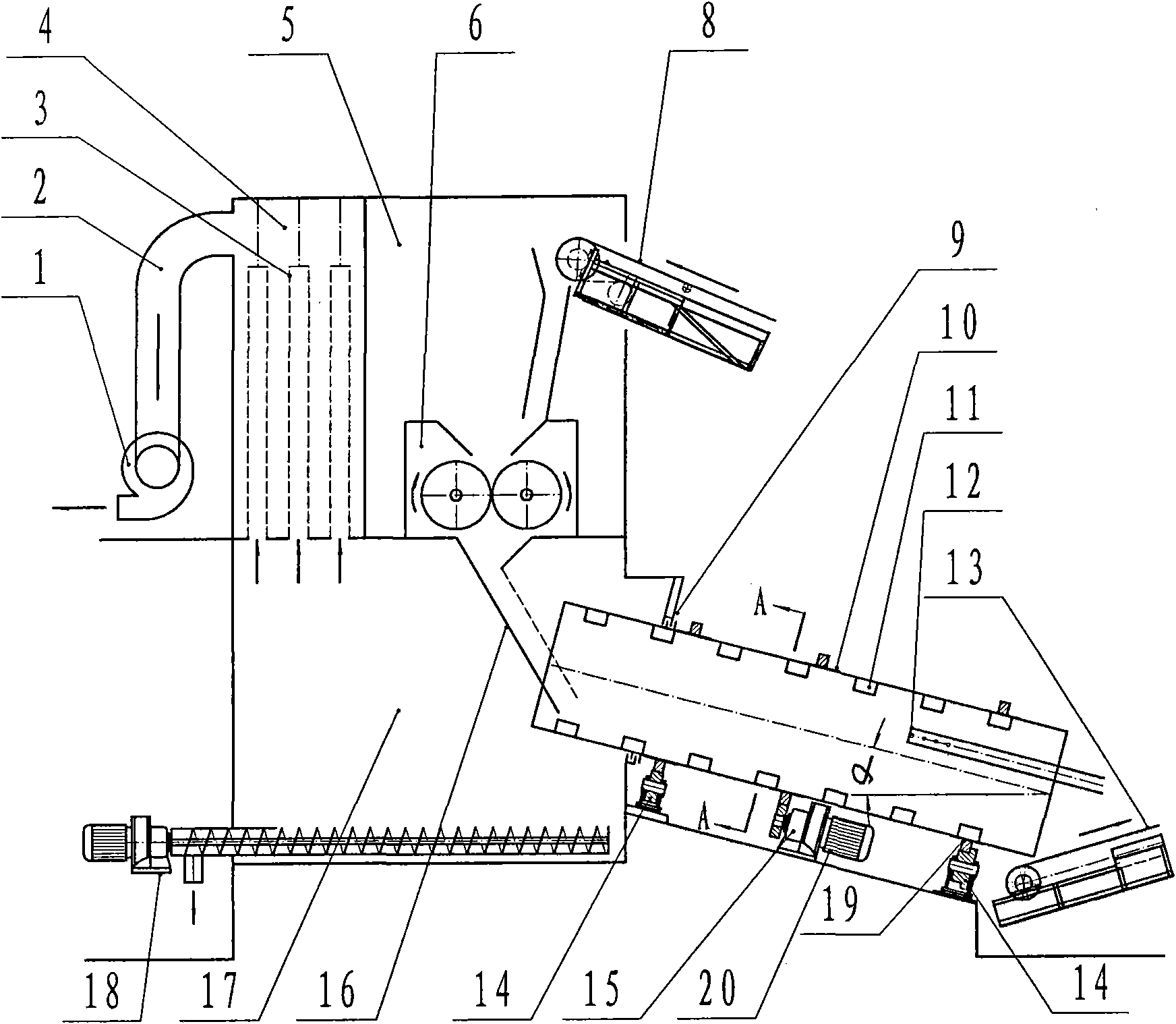

[0035] In this example, the structure of the integrated sand making equipment is as follows image 3 shown. The difference from Example 1 is:

[0036] 1. In the sand powder separation device, the angle α between the axis of the drum 10 and the horizontal direction is 15°,

[0037] 2. In the sand powder separation device, the water spray head 12 connected with the water pipe is located in the middle of the drum.

[0038] 3. The crushing device is a double roller machine 6, which is installed in the crushing chamber 5, and its discharge port is connected to the discharge port opened on the bottom wall of the crushing chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com