Method and device for preparing flake metal powder by dry ball milling

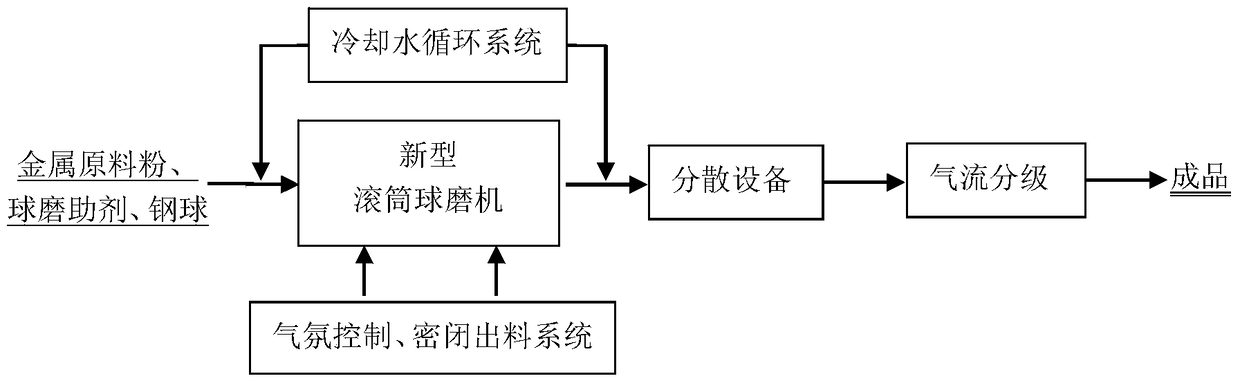

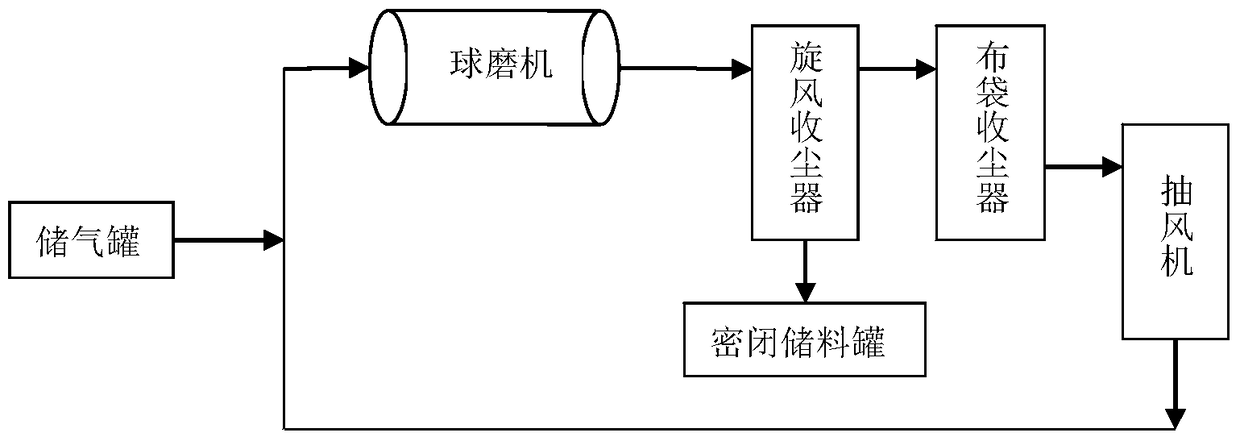

A flake metal and ball milling technology, applied in the field of electronic materials, can solve the problems of inability to enlarge production equipment, poor powder dispersion, low production efficiency, etc., and achieve good sealing and cooling effects, improved production efficiency, and no dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Put the mixed material containing 600 kg of zinc powder raw materials, 18 kg of ball milling aids and 2400 kg of 6mm, 3000 kg of 9.5mm, and 600 kg of 12mm steel balls into the 5M 3 In the new roller ball mill, through the atmosphere control system, the mixed atmosphere in which the proportion of nitrogen in the ball mill cylinder is controlled is 90% to 95%, and the ball is milled under airtight conditions, the ball milling speed is 34rpm, the ball milling time is 8 hours, and the ball milling temperature is 25°C. The zinc powder after ball milling enters the closed discharge system, the nitrogen pressure in the cylinder is 0.02MPa, the fan operation frequency is 40Hz, the ball mill speed is 32rpm, and the powder discharge time is 8min. After dispersing by dispersing equipment and grading by airflow, a flake zinc powder product with an average particle size of 13.24 μm, a bulk density of 1.04 g / mL and a sieving rate (-325 mesh) of 98% was obtained.

Embodiment 2

[0041] Put the mixture containing 500 kg of aluminum powder raw materials, 8 kg of ball milling aids and 2000 kg of 6mm, 2500 kg of 9mm, and 500 kg of 12mm steel balls into the 5M 3In the new roller ball mill, the atmosphere control system is used to control the mixed atmosphere with a nitrogen ratio of 95% to 98% in the cylinder, and the ball is milled under airtight conditions. The ball milling speed is 32rpm, the ball milling time is 10 hours, and the ball milling temperature is 20°C. The aluminum powder after ball milling enters the closed discharge system, the nitrogen pressure in the cylinder is 0.01MPa, the fan operation frequency is 40Hz, the ball mill speed is 30rpm, and the powder discharge time is 6min. After dispersing by dispersing equipment and grading by air flow, a flake aluminum powder product with an average particle size of 16.35 μm, a bulk density of 0.32 g / L, and a sieving rate (-325 mesh) of 99% was obtained.

Embodiment 3

[0043] Put the mixture containing 600 kg of atomized zinc powder, 9 kg of ball milling aids and 2500 kg of 6mm, 3000 kg of 9mm, and 500 kg of 12mm mixed steel balls into the 5M3 new roller ball mill, and control the nitrogen in the cylinder through the atmosphere control system A mixed atmosphere with a ratio of 97% to 98% is ball milled under airtight conditions with a ball milling speed of 30 rpm, a ball milling time of 8 hours, and a ball milling temperature of 20°C. The zinc powder after ball milling enters the closed discharge system, the nitrogen pressure in the cylinder is 0.02MPa, the fan operation frequency is 42Hz, the ball mill speed is 30rpm, and the powder discharge time is 10min. After dispersing by dispersing equipment and grading by air flow, a flake zinc powder product with an average particle size of 18.60 μm, a bulk density of 0.9 g / L, and a sieving rate (-325 mesh) of 96% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com