Method for plating parylene film on surface of LED chip

A technology of LED chips and dimethylbenzene, which is applied in the field of polymer vacuum coating, can solve problems such as product failure and impact on service life, and achieve the effects of convenient operation, improved reliability, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail through the following embodiment in which the plated part is an LED chip, and the plated part can also be a lithium-iron battery or a solar photovoltaic electric panel.

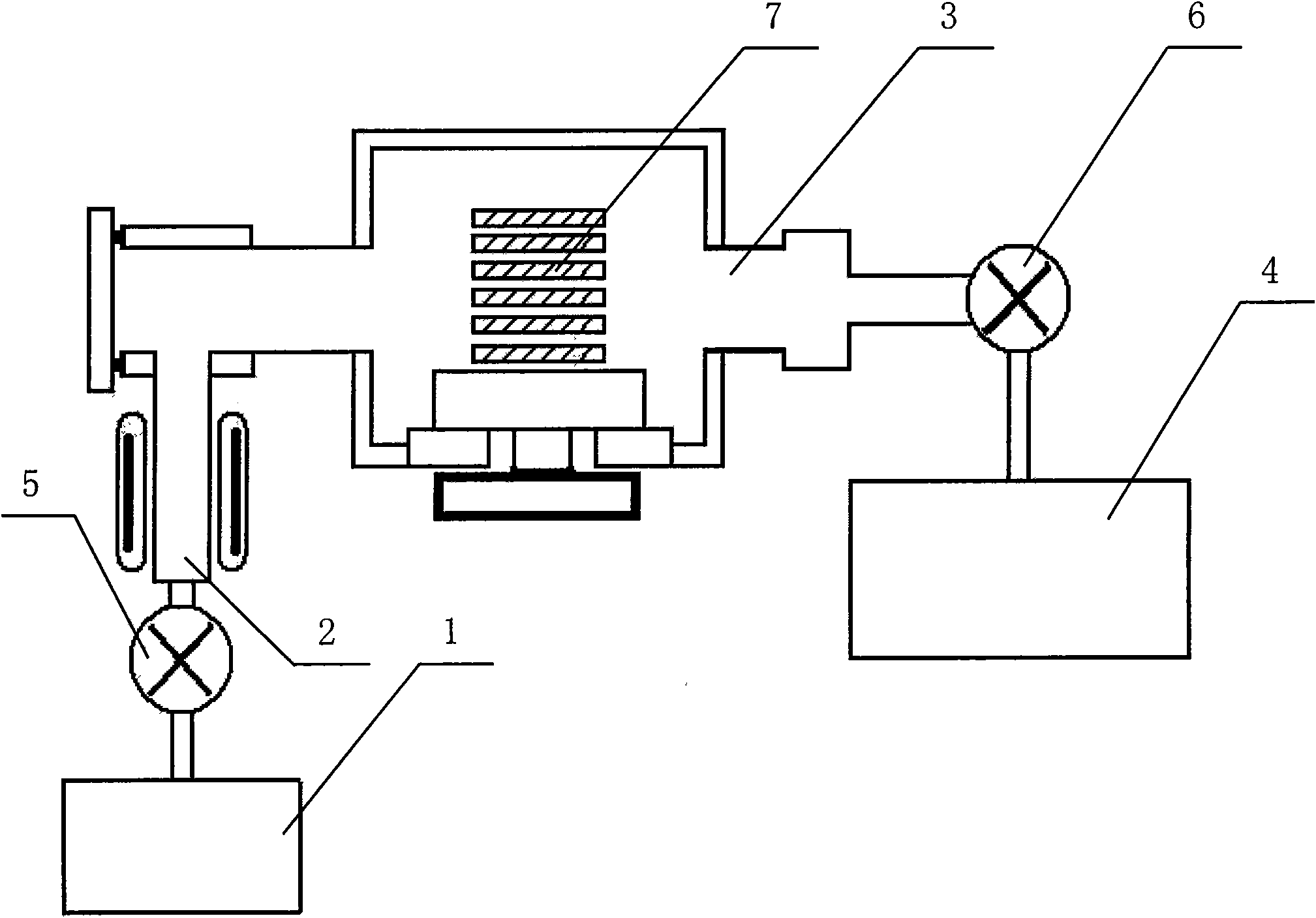

[0015] See attached figure 1 , the coating device of the present invention comprises: vaporization chamber 1, cracking chamber 2, deposition chamber 3, cold trap chamber 4, concrete plating steps are as follows:

[0016] a. Cleaning

[0017] (i) Ultrasonic cleaning of the LED chip with absolute ethanol for 6 minutes, and then vacuum drying for 8 minutes, the temperature of the drying oven is 90° C., and the pressure is 100 Pa.

[0018] (ii), the above-mentioned ultrasonically cleaned LED chips are placed in the aqueous solution of silane coupling agent alcohol and soaked for 1 minute, then rinsed twice with ethanol aqueous solution, put into a vacuum drying oven after drying for 8 minutes, and the drying oven temperature is 90°C, pressure 100P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com