Radiation coating, its preparing method and composition for making said coating

A heat-dissipating coating and composition technology, which can be applied to coatings, devices for coating liquids on surfaces, epoxy resin coatings, etc. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

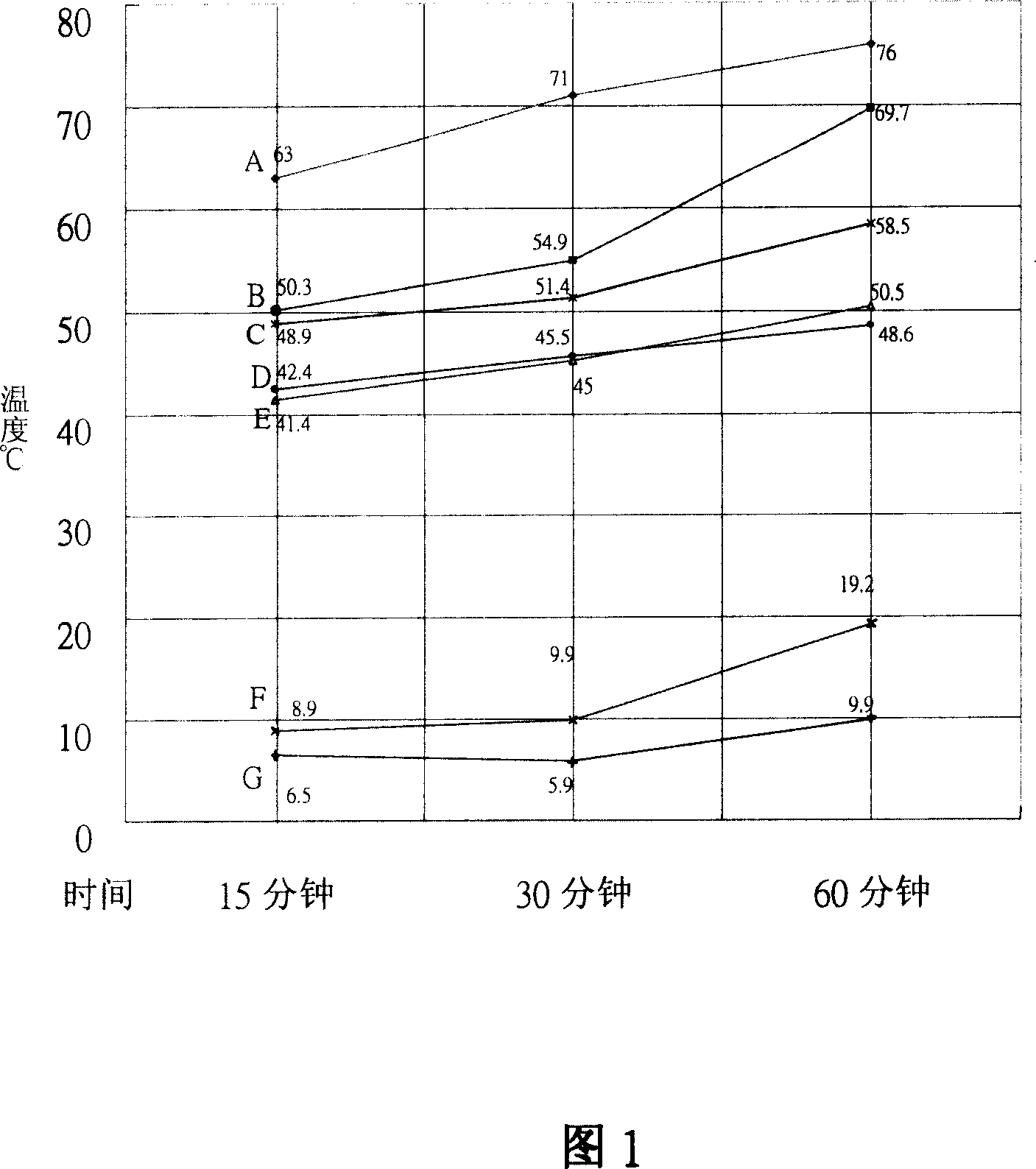

[0026] Embodiment 1. Test of heat dissipation effect of heat dissipation coating

[0027] Compositions for making heat-dissipating coatings

[0028] Take 1 kg of toluene, mix 0.2 kg of boron nitride into it, stir for 30 minutes, then add 0.24 kg of epoxy resin, stir for 1 hour, then put it into a ball mill and mix for 4 hours to obtain the present invention. Compositions for making heat-dissipating coatings.

[0029] surface area

[0030] First, take two common aluminum sheets (5cm×5cm×2mm) as the base material of heat dissipation fins, one of them is used as the bare chip of the control group, and the other sheet forms a heat dissipation coating with a thickness of 15mm on its surface. The formation method is to uniformly spray the composition on the surface of an aluminum sheet, and then heat and bake at a temperature at which the solvent toluene can be removed (for example, 80° C.) to obtain the heat dissipation coating of the present invention, and then use the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com