Heat treatment method for reducing steel rail fatigue crack propagation rate

A technology of fatigue crack propagation and heat treatment method, which is applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of driving safety hazards, reduce the fatigue crack growth rate of rails, etc., and achieve the purpose of improving the service life of rails and reducing the fatigue crack growth rate , easy to promote the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

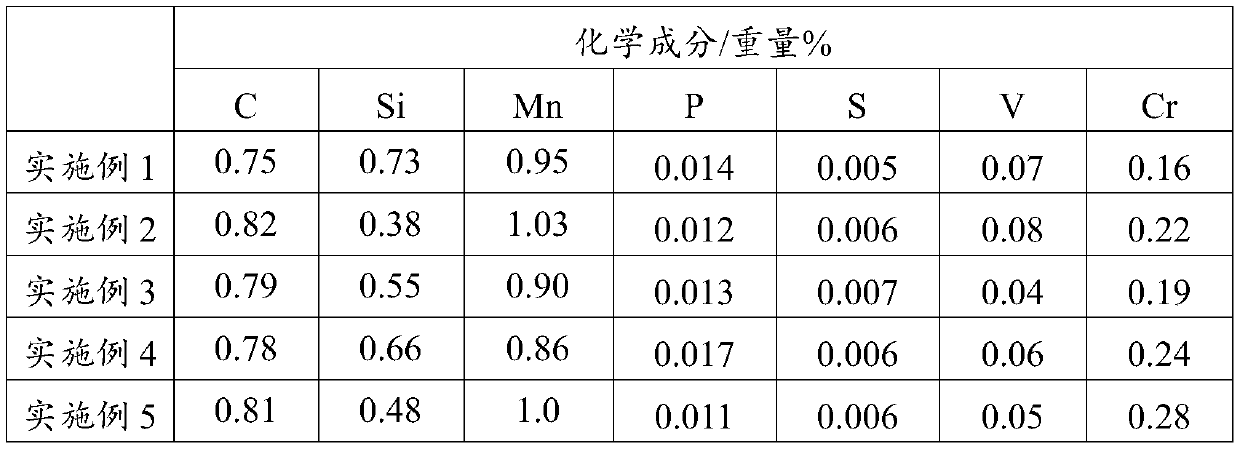

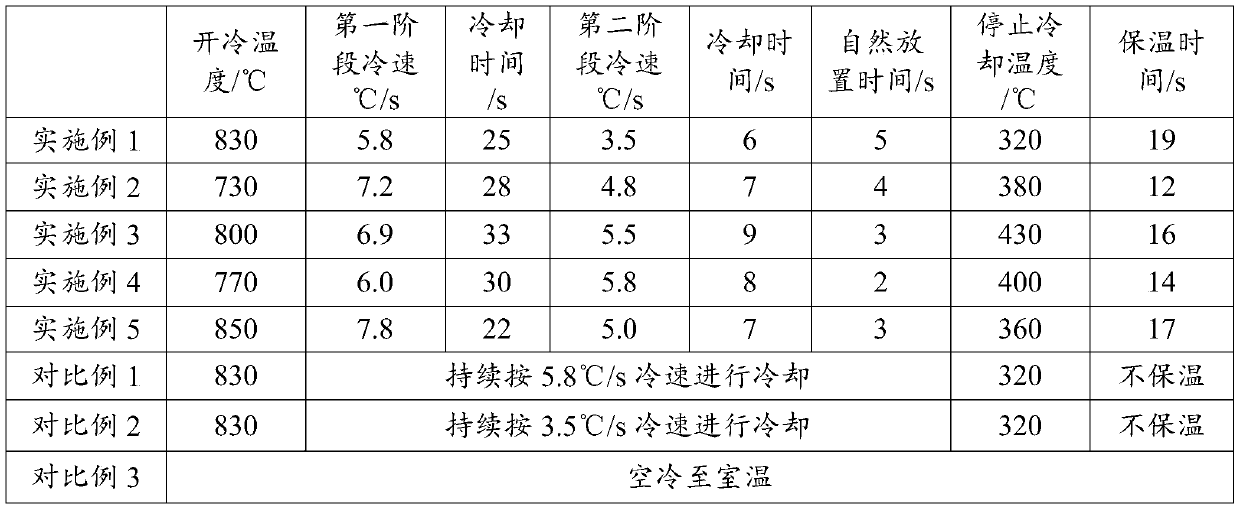

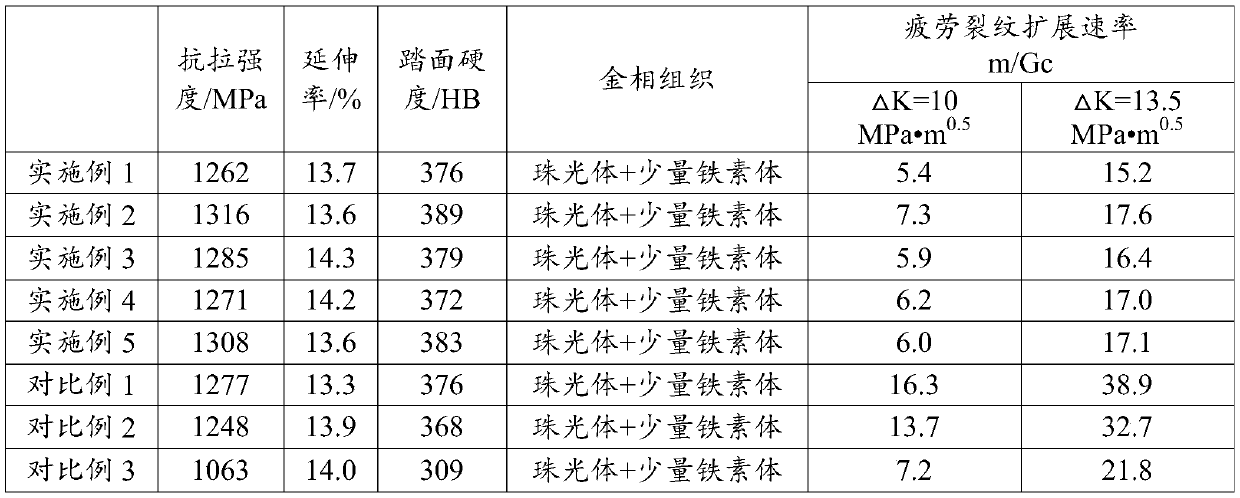

Embodiment 1

[0036] According to the conventional rail smelting and casting methods, the process includes converter smelting, LF refining, vacuum treatment, and continuous casting. Among them, the basicity of converter slag is controlled at 2.8-4.0; when the molten steel is about 1 / 4, alloys such as silicon, manganese, vanadium and recarburizers are added along with the steel flow, and when the molten steel reaches 3 / 4, the alloys and recarburizers are all Add; LF furnace treatment time should be greater than 35min; RH vacuum degree ≤ 90Pa, pure vacuum treatment time should not be less than 16min, the casting process should be carried out under full protection to prevent contact with air, and the cast billet should be slowly cooled. Then follow the conventional rail rolling method. The steel billet is sent into the walking beam heating furnace for heating and heat preservation. The heating temperature is 1200-1300 ℃, and the heat preservation time is 150-260min. ℃, the final rolling temper...

Embodiment 2-5

[0038] According to the method of Example 1, the difference is that the specific process parameters of accelerated cooling after rolling are as shown in Table 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com