Distributed cooling of arrayed semi-conductor radiation emitting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]A purpose of the presently described embodiments is to apply a properly sized cooling system to solid state, semi-conductor based electromagnetic irradiation device arrays used in heating and curing applications. One such application involves systems for cooking food. Another application of the presently described embodiments is to systems using narrowband semi-conductor based radiant heating of plastic components, such as PET bottle preforms in a bottle blowing process.

[0040]The contemplated cooling system may take a variety of forms including heat transfer fluid systems such as state change cooling systems (including vapor phase (or two phase) cooling systems), water based cooling systems (including systems using water mixtures including, e.g. ethylene glycol), air cooling systems or common refrigerant cooling systems (e.g. systems using chlorofluorocarbons (CFCs), hydro chlorofluorocarbons (HCFCs), butane, or propane).

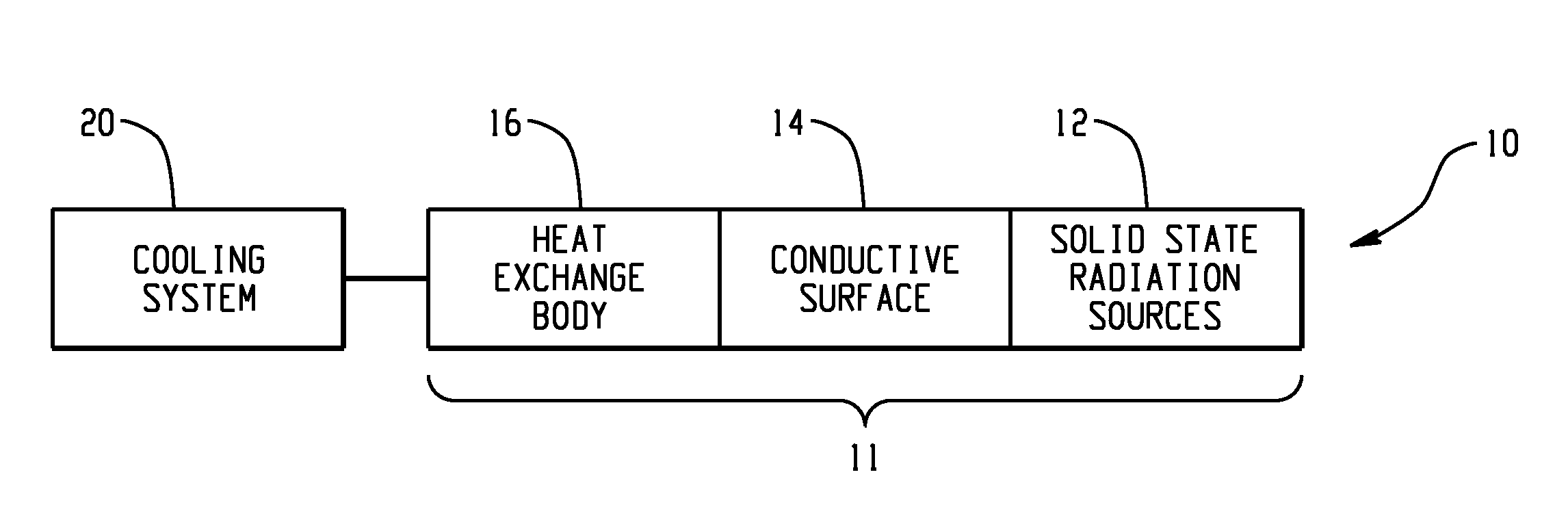

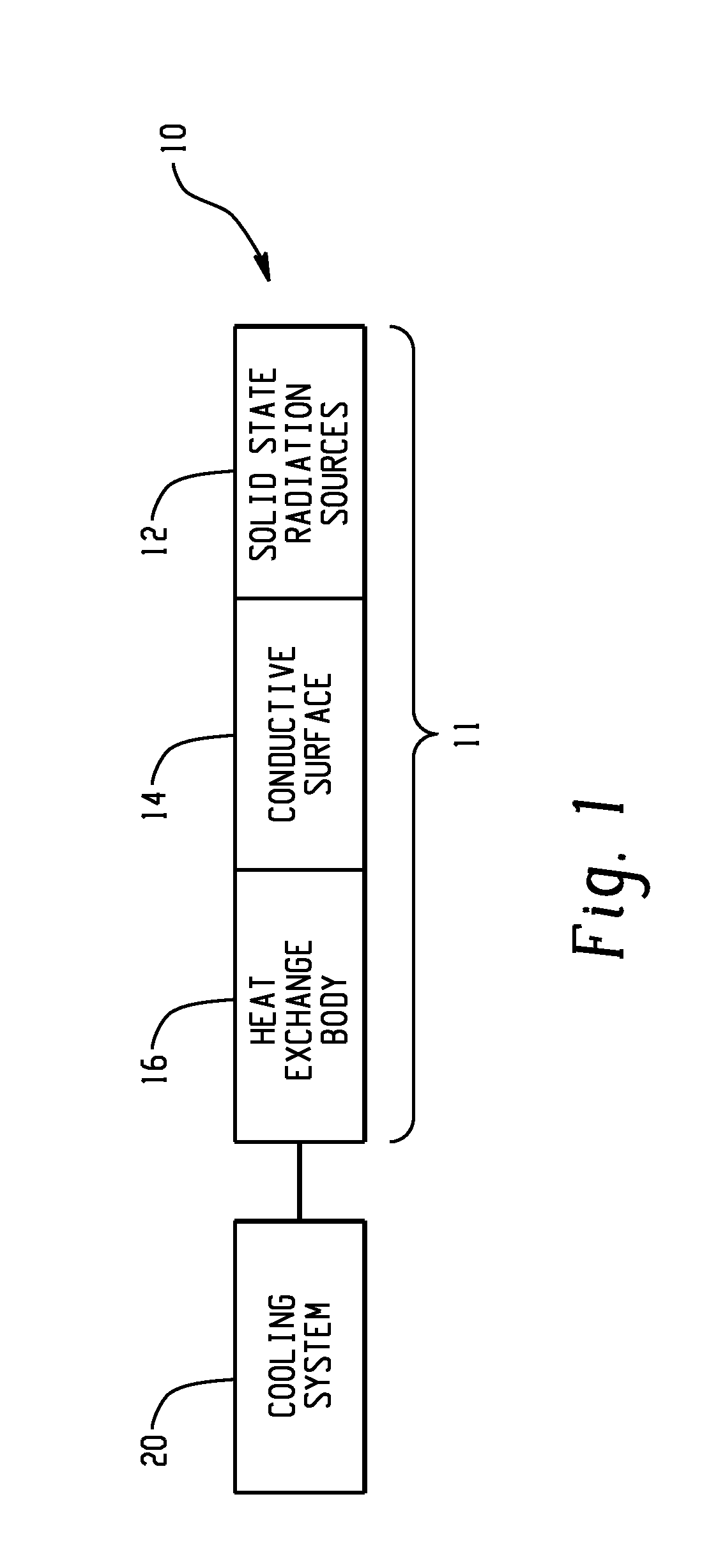

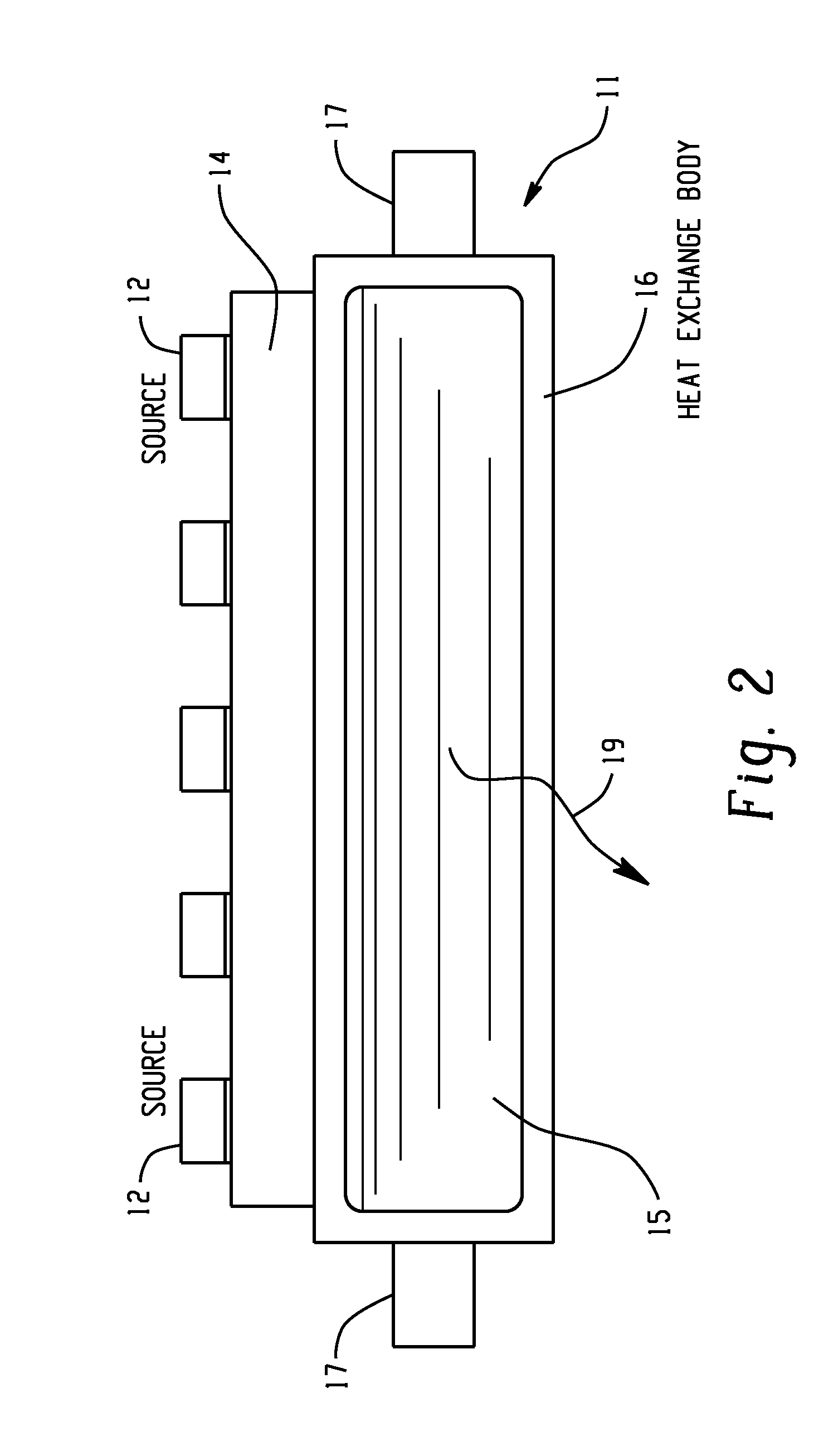

[0041]With reference to FIG. 1, a system 10 includes sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com