Ultrasonic rotary motor by using longitudinal-torsional vibration converter with holes

A mode conversion, ultrasonic motor technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of high cost, unfavorable motor industrialization, torsional vibration ceramics Complicated chip processing technology and other issues, to achieve the effect of simple structure, conducive to industrialization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

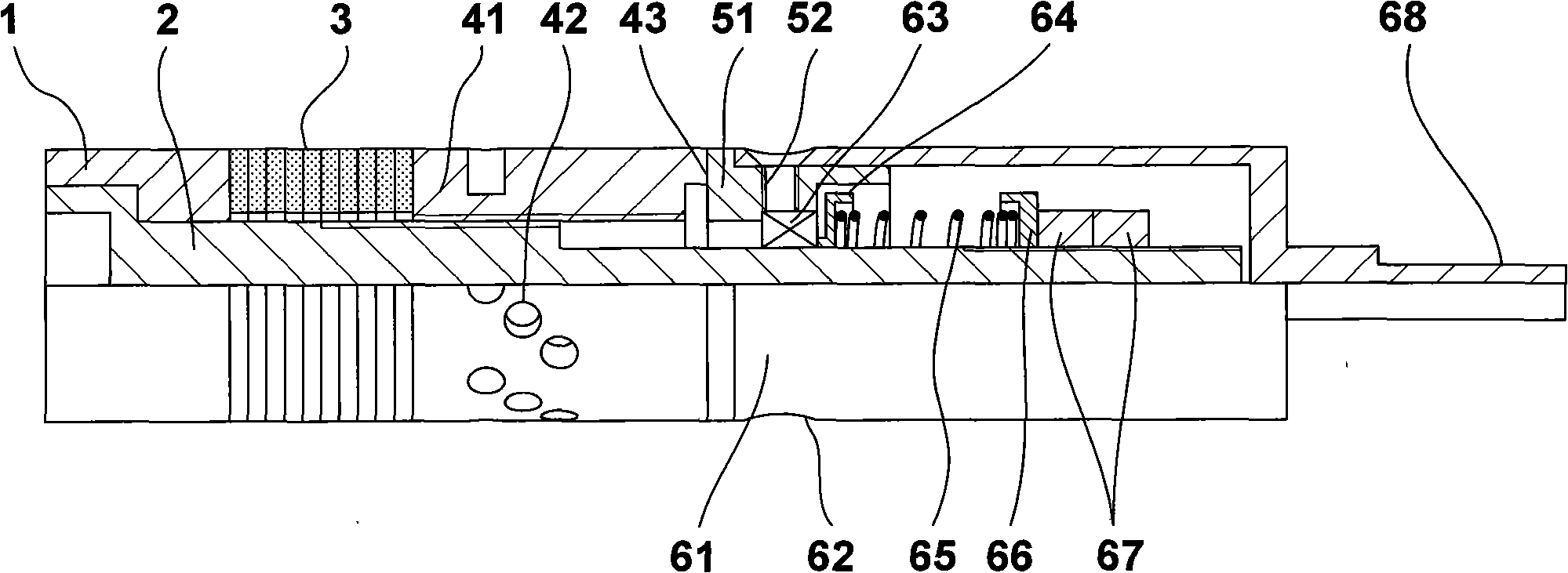

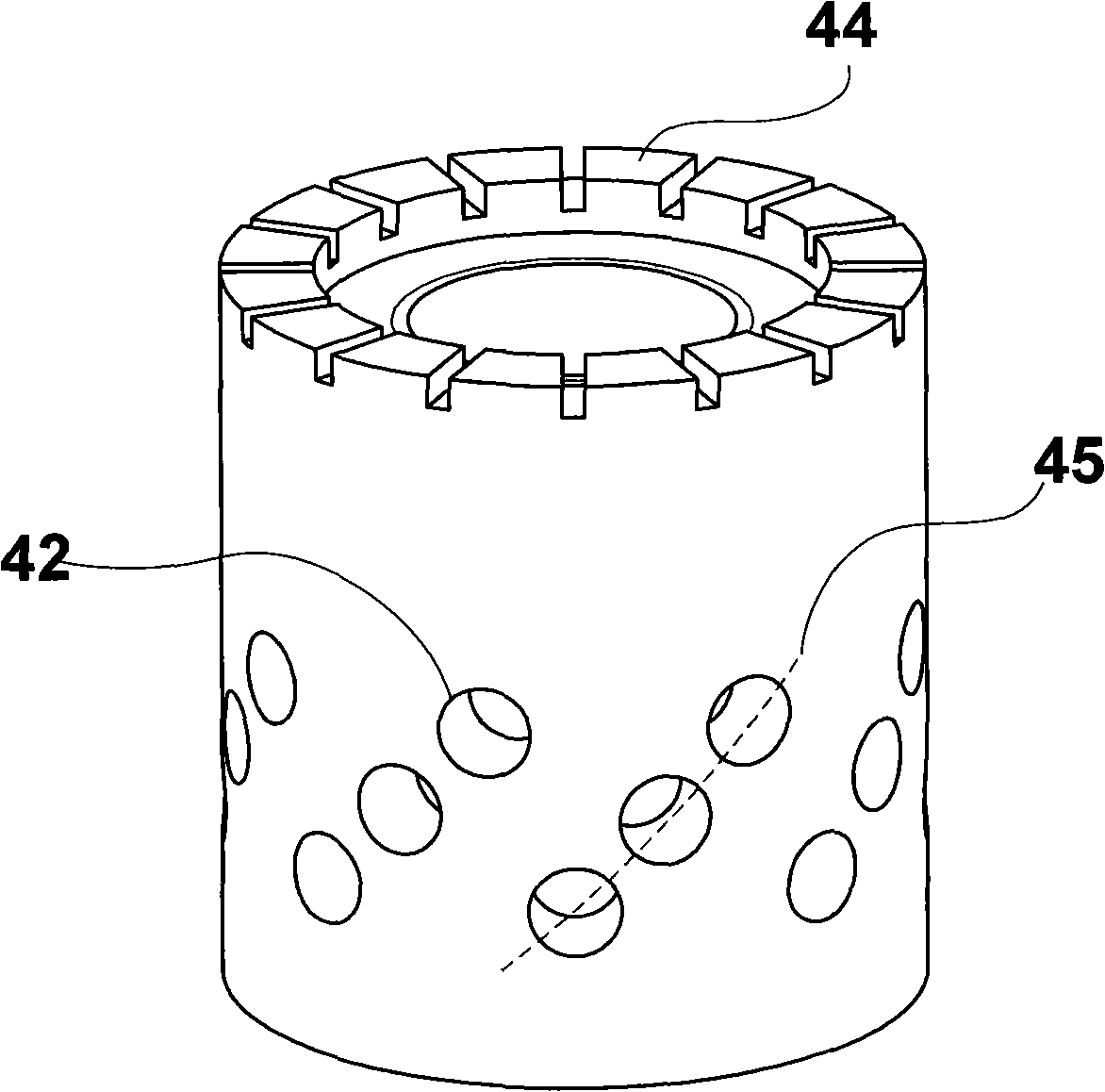

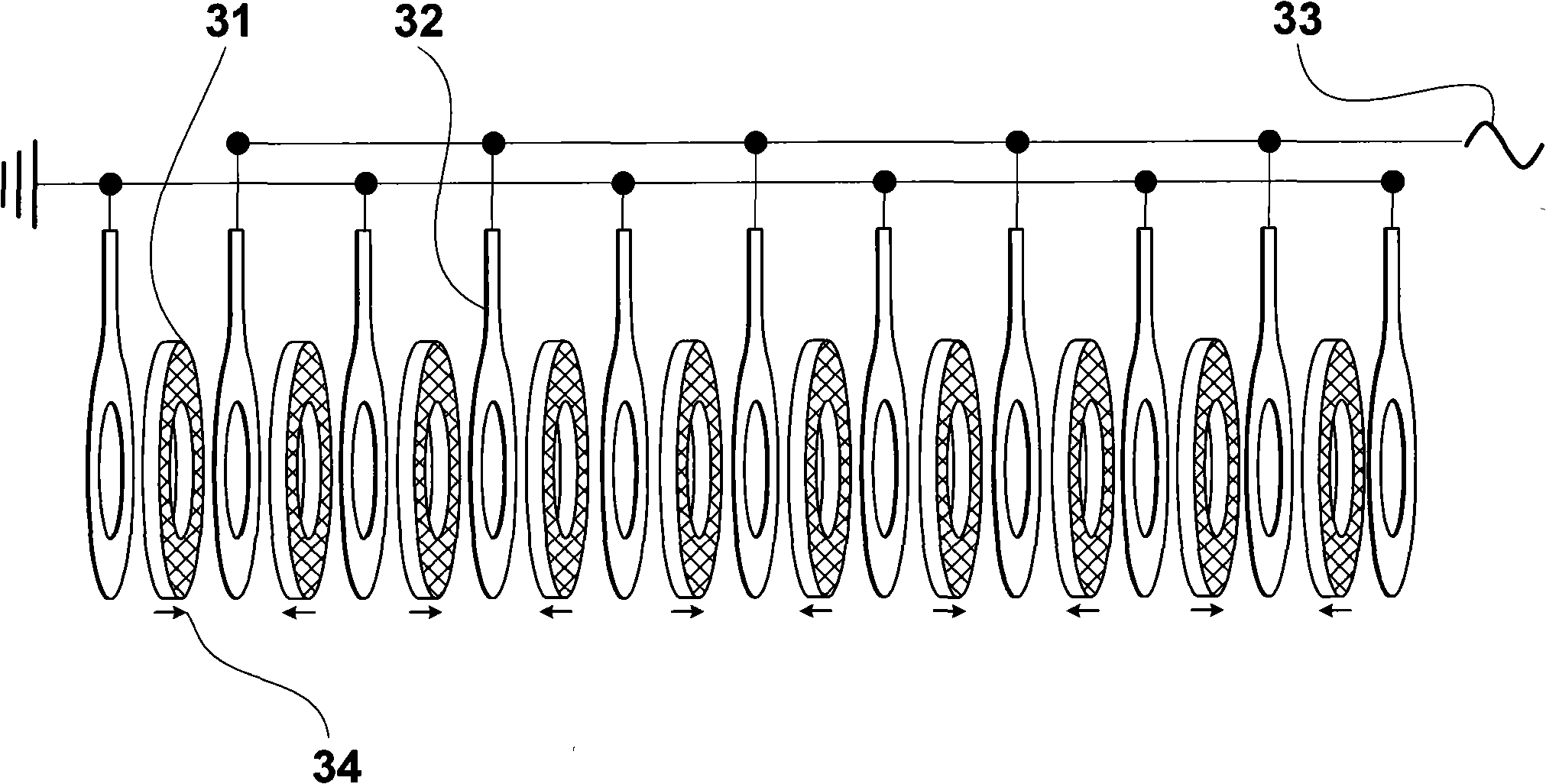

[0015] Hole mode conversion type ultrasonic motor of the present invention such as figure 1 As shown, it includes a stator assembly and a rotor assembly. It is characterized in that: the stator assembly is composed of a counterweight 1, fastening bolts 2, longitudinal vibration piezoelectric ceramic sheet group 3, and a hole mode converter 41; the rotor assembly is composed of a rotor 51, a torque output connector 61, a radial Bearing 63, first spring cover 64, spring 65, second spring cover 66, lock nut 67 form. Among them, the counterweight 1, the longitudinal vibration piezoelectric ceramic sheet group 3 and the hole mode converter 41 are sequentially arranged into a rod-type sandwich structure, and are pressed and fixed by fastening bolts 2 to form a stator body. Electrode sheets 32 are spaced between the piezoelectric ceramics 31 for applying an electrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com