Motor drive fault-tolerant control device and electric device

A fault-tolerant control, electric drive technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problem of inability to apply and popularize, increase cost, difficulty and complexity, restrict high-power motors, electric drives and electric components. Equipment electric military equipment development and other issues, to avoid sudden changes in performance indicators, improve reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0026] The electric drive fault-tolerant control device 10 is set in electric equipment such as electric tools, quadcopters, electric vehicles, electric ships, electric forklifts, and electric military equipment, and is used to drive electric equipment.

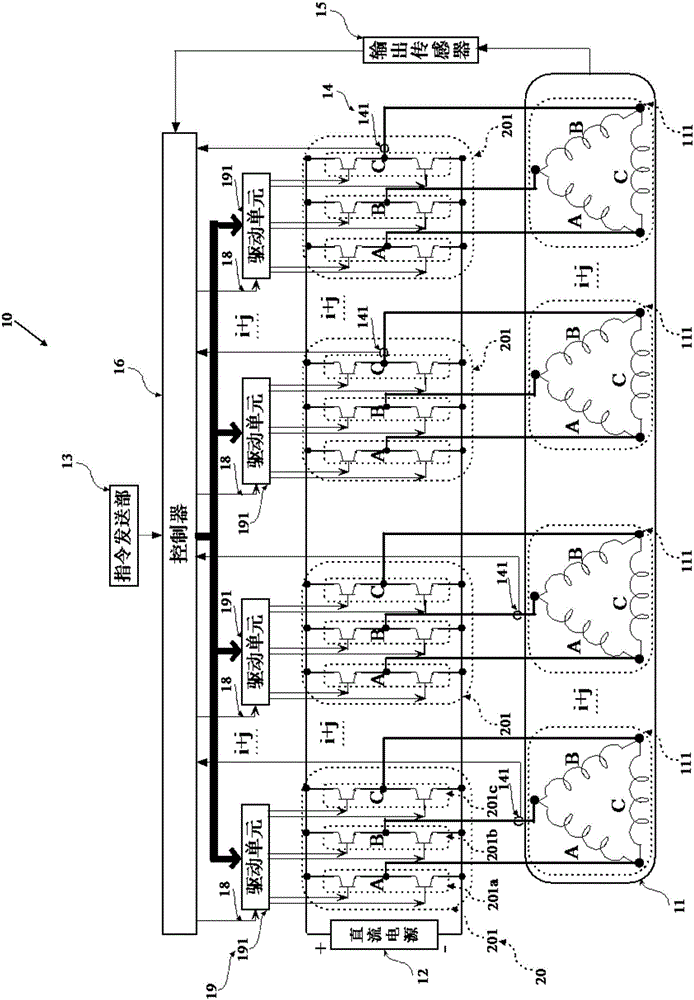

[0027] figure 1 It is a schematic diagram of the circuit structure of the electric drive fault-tolerant control device in this embodiment.

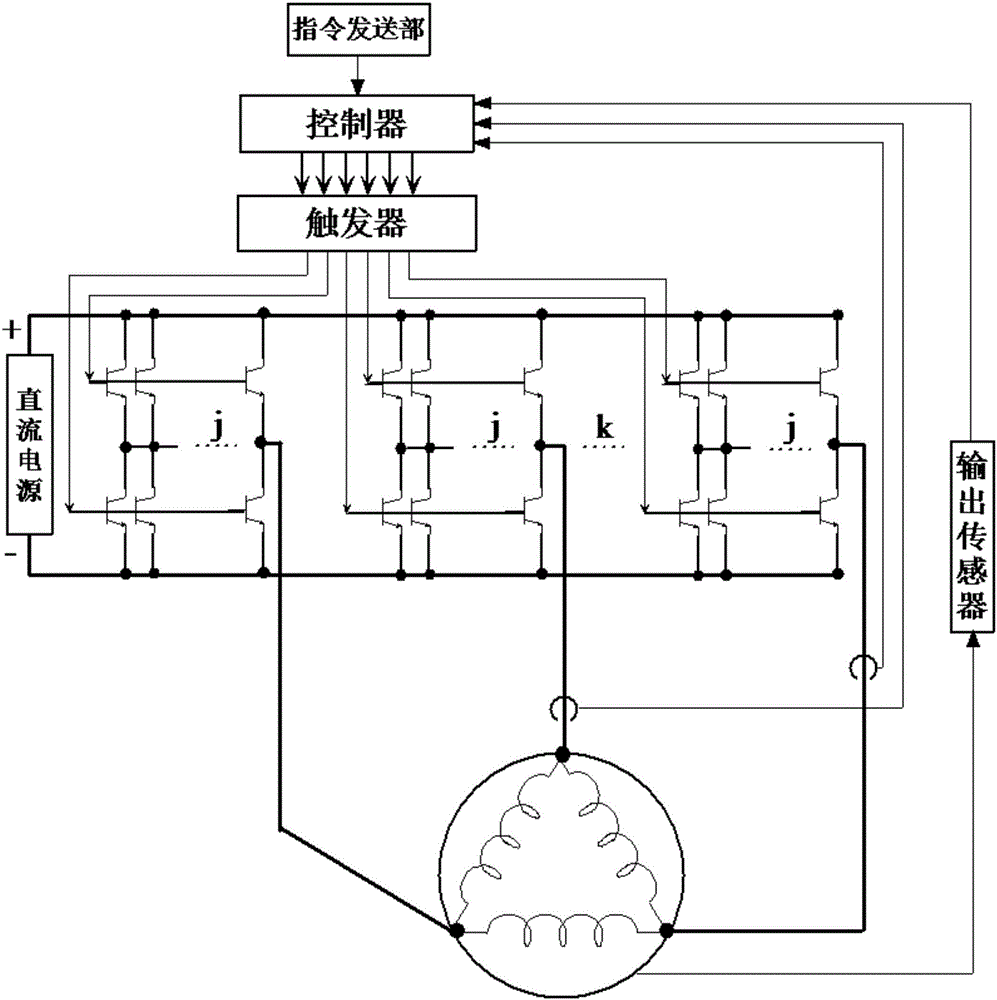

[0028] Such as figure 1 As shown, the electric drive fault-tolerant control device 10 includes a multi-phase motor 11 , a DC power supply 12 , a command sending unit 13 , a current sensor 14 , an output sensor 15 , a controller 16 , a driver 19 and a power converter 20 .

[0029] The multi-phase motor 11 has k phases and has a rated line voltage and a rated line current. The multi-phase motor 11 is any one of an asynchronous motor, a synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com