Planetary gear hydraulic speed changing system

A planetary gear system, hydraulic transmission technology, applied in the direction of belt/chain/gear, fluid transmission device, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

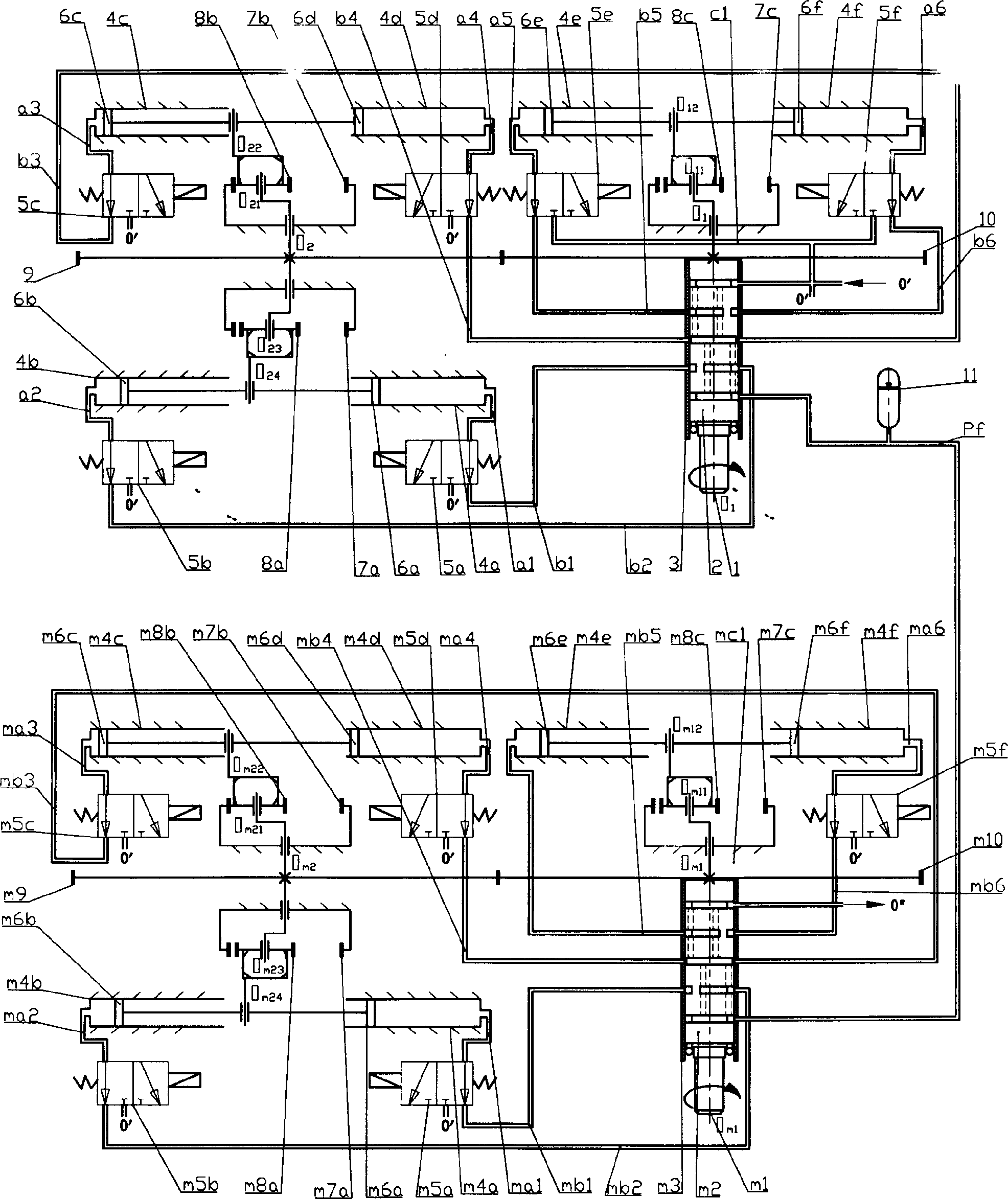

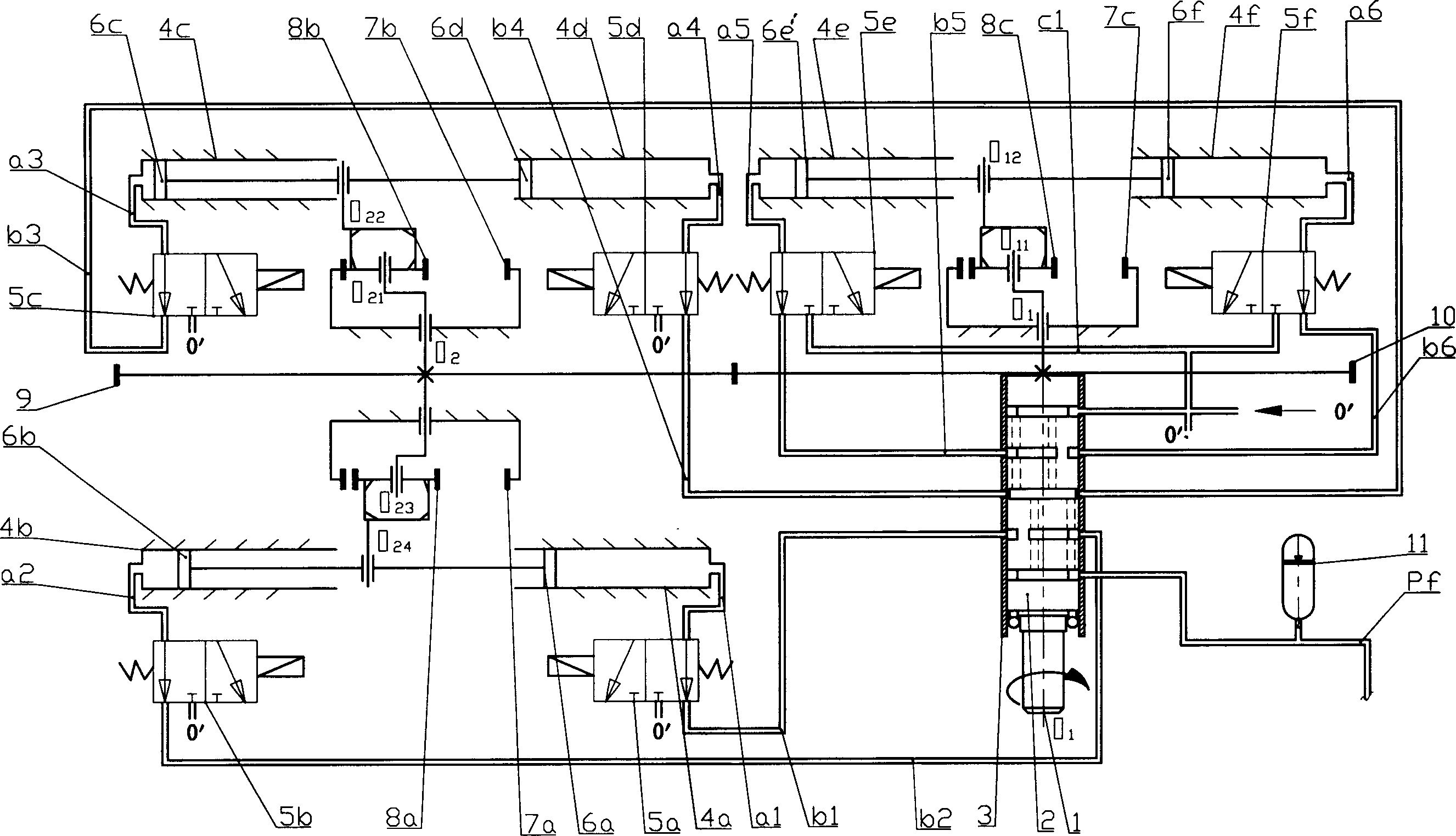

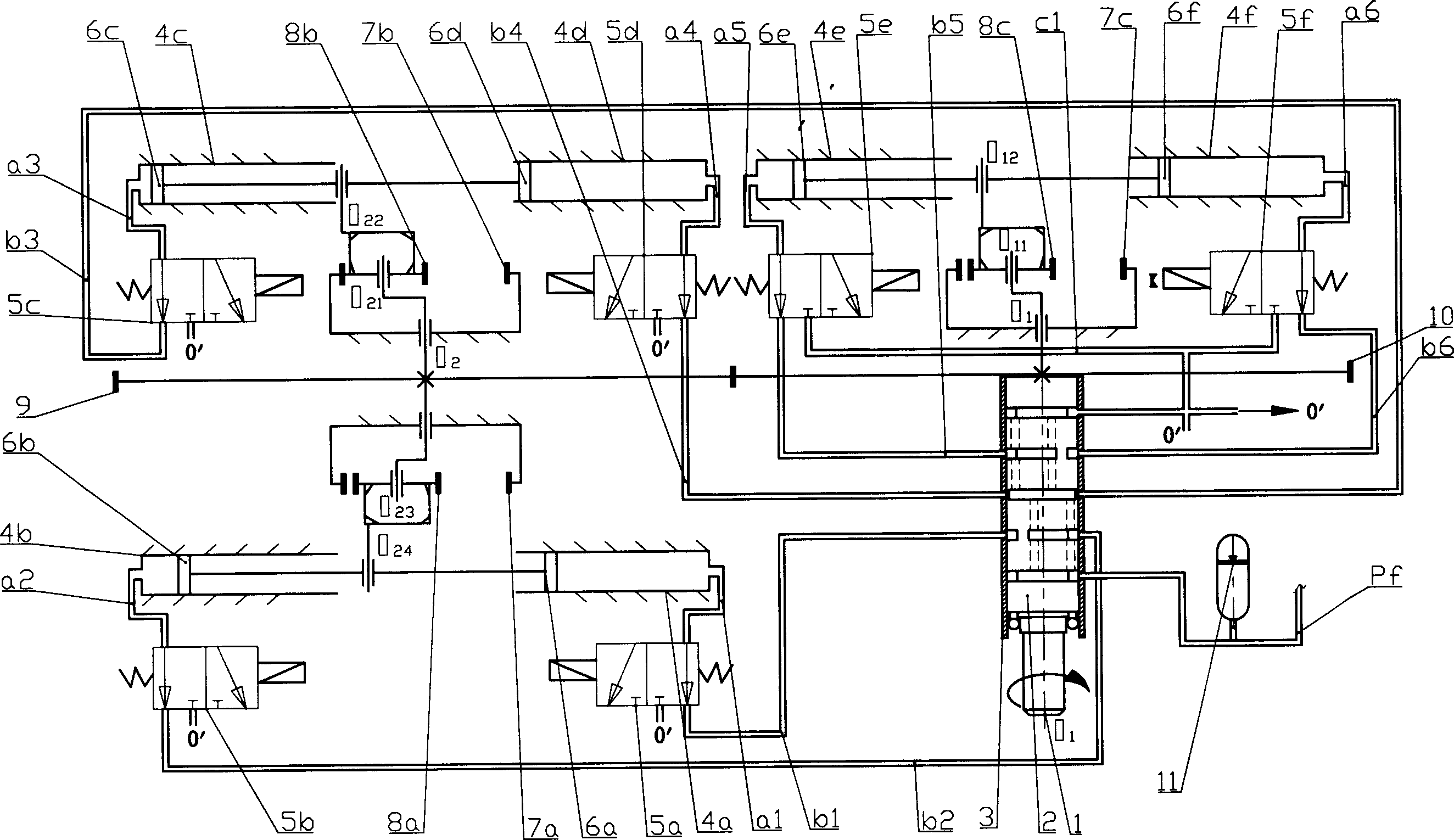

[0009] Such as figure 1 Shown is a schematic structural diagram of the planetary gear hydraulic transmission system of the present invention, and the pressure oil circuit (P f ) and the pressure oil circuit of the six-piston planetary gear hydraulic motor (P f ) in series.

[0010] Such as figure 1 As shown in (1), the transmission shaft (O 1 ) is driven by a motor to rotate, including a planetary gear train, a plunger and a plunger cylinder. Drive shaft (O 1 ), (O 2 ), driving the input drive shaft (O 1 ) on the fixed gear (10) and transmission shaft (O 2 ) on the fixed gear (9) meshing transmission, the gear ratio of gear (10) and gear (9) is 1: 1. The oil suction and discharge components of the hydraulic pump refer to the planetary gear train, the plunger (6 a ), (6 b ), (6 c ), (6 d ), (6 e ), (6 f ) and plunger cylinder (4 a ), (4 b ), (4 c ), (4 d ), (4 e ), (4 f ).

[0011] The hydraulic pump makes the plunger reciprocate linearly in the plunger cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com