Method for continuously outputting high power on basis of few-gear speed change mechanism for vehicle

A technology of speed change mechanism and high power, applied in vehicle components, transportation and packaging, control devices, etc., can solve the problems of increased machinery manufacturing cost, increased vehicle weight, complex mechanical structure, etc., and achieve the effect of improving torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

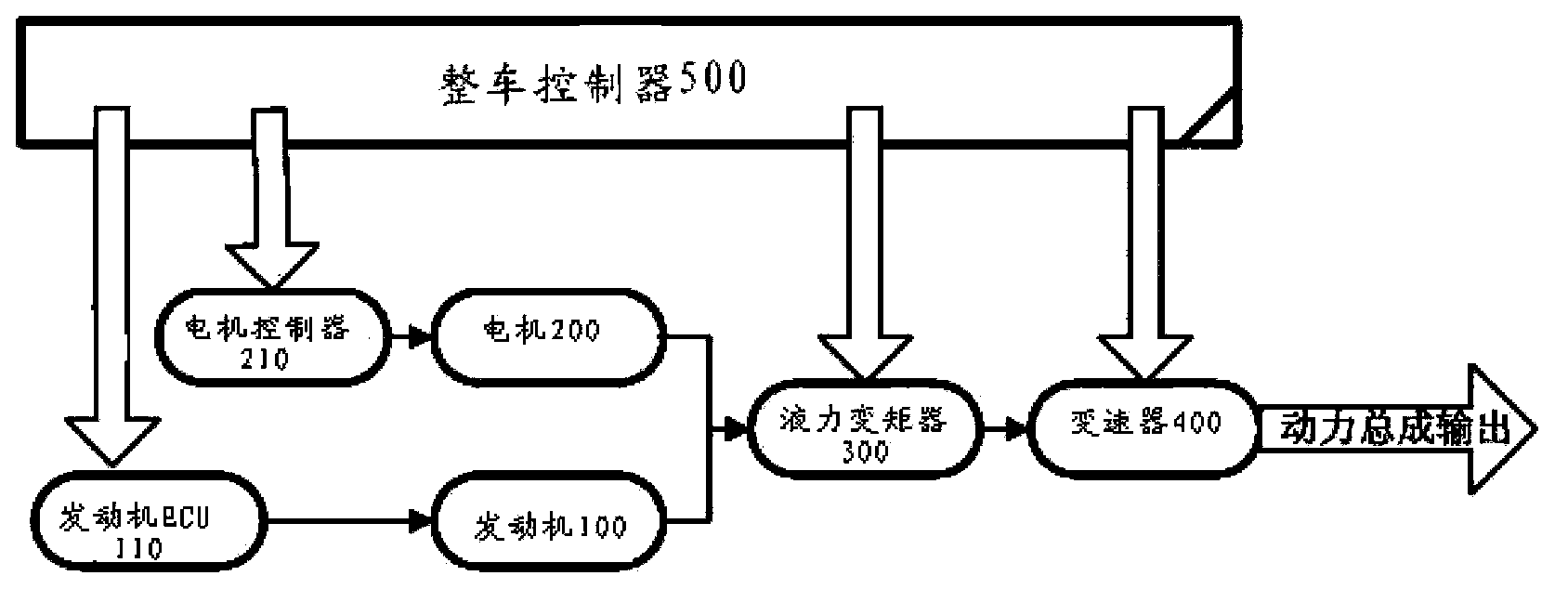

[0024] Such as figure 1 Shown, the power assembly of the present invention method comprises that internal combustion engine is referred to as motor 100 below, motor 200; 400 is the speed changer 400 of manual transmission, only uses the mechanical speed changer of a forward gear and a reverse gear.

[0025] The engine controller ECU110 is used to control the output of the engine, the motor controller 210 is used to control the output of the motor, and the vehicle controller 500 is used to control the engine controller ECU110, the motor controller 210, the torque converter 300 and the transmission 400 respectively .

[0026] The control method of the above structure in the vehicle running process is: that is, the method of the present invention is that when the vehicle starts, the engine speed rises rapidly from 0 to idle speed according to the requirements of the control system with the opening of the throttle valve. After the vehicle is started, the motor speed is synchroniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com