Wind power gear box transmission structure

A wind power gearbox and transmission structure technology, applied in the direction of gear transmission, transmission, wind power generation, etc., can solve the problems of unsuitable for high-power wind turbines, small transmission, etc., to increase transmission ratio, increase output speed, and improve operating performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

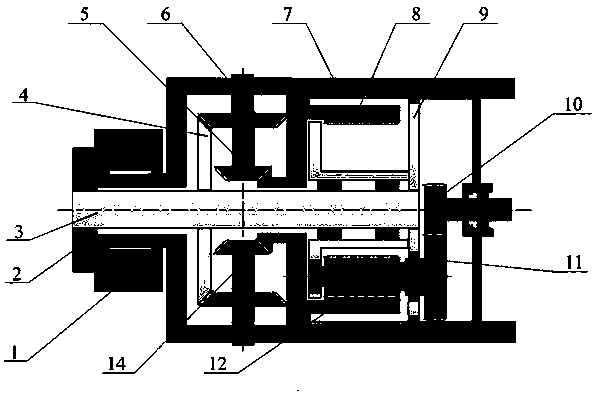

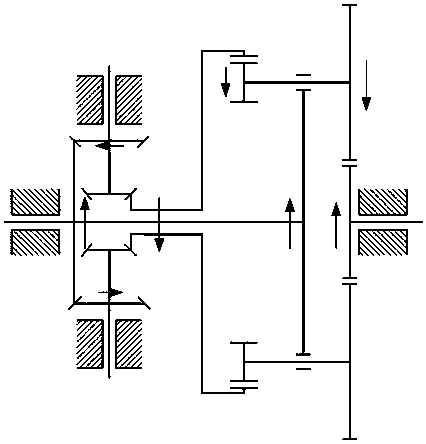

[0008] like figure 1 and figure 2 As shown, the present invention includes an impeller 1 and a casing 7, the impeller 1 is mounted on the outer ring of the casing 7 through a bearing, the side of the impeller 1 is connected with the main shaft 3 through the hub coupling 2, and the main shaft 3 passes through the casing 7 The convex neck extends into the box body 7, the tail end of the main shaft 3 is connected to the planetary carrier 9, the planetary carrier 9 is supported on the inner wall of the box body 7 through bearings, and the driving bevel gear 4 is installed on the main shaft 3 close to the front side wall of the box body 7, The driving bevel gear 4 is connected to the driven bevel gear 14 through the duplex bevel gear 6, 5, the duplex bevel gear 6, 5 is mounted on the inner wall of the box 7 by the bearing, and the driven bevel gear 14 is fixed on the inner ring gear 8 , the planetary gear 12 in the planetary carrier meshes with the ring gear 8, the planetary gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com