Robot travelling platform traveling at constant speed in single-drive mode and based on centrifugation

A walking platform and robot technology, applied in motor vehicles, transportation and packaging, etc., can solve the economic losses of enterprises and individuals, increase the production cost of robot walking platforms, and the problems of robots not working properly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

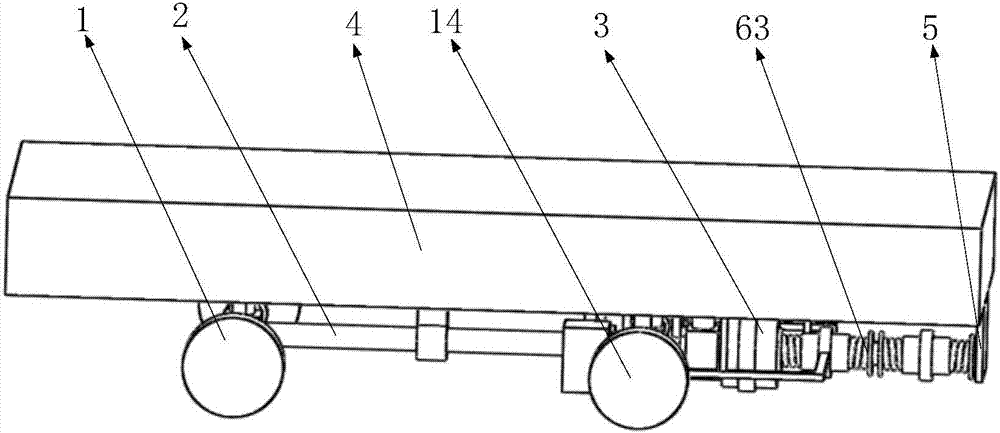

[0045] Such as figure 1 As shown, it includes a bearing plate 4, a running gear 14, and a transmission mechanism 63, wherein the transmission mechanism 63 is located at one end of the running gear 14;

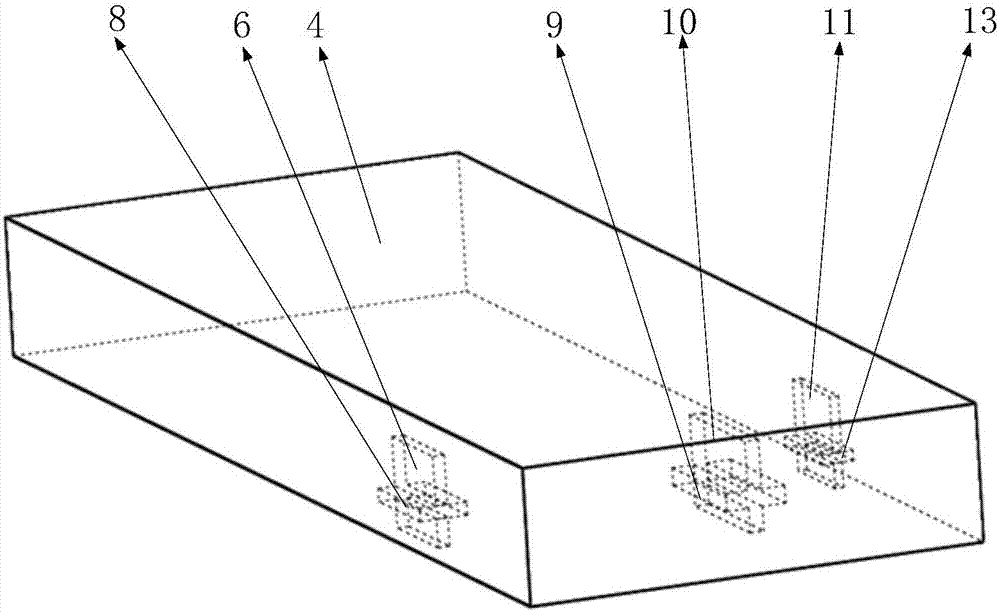

[0046] Such as figure 2 As shown, one end of the lower side of the above-mentioned carrying plate 4 is provided with a first moving groove 6, a second moving groove 10 and a third moving groove 11; Side; the second moving groove 10 is located between the first moving groove 6 and the third moving groove 11; both sides of the first moving groove 6 are provided with two symmetrical first guide grooves 8; both sides of the second moving groove 10 Two symmetrical second guide grooves 9 are formed; two symmetrical third guide grooves 13 are formed on both sides of the third moving groove 11 .

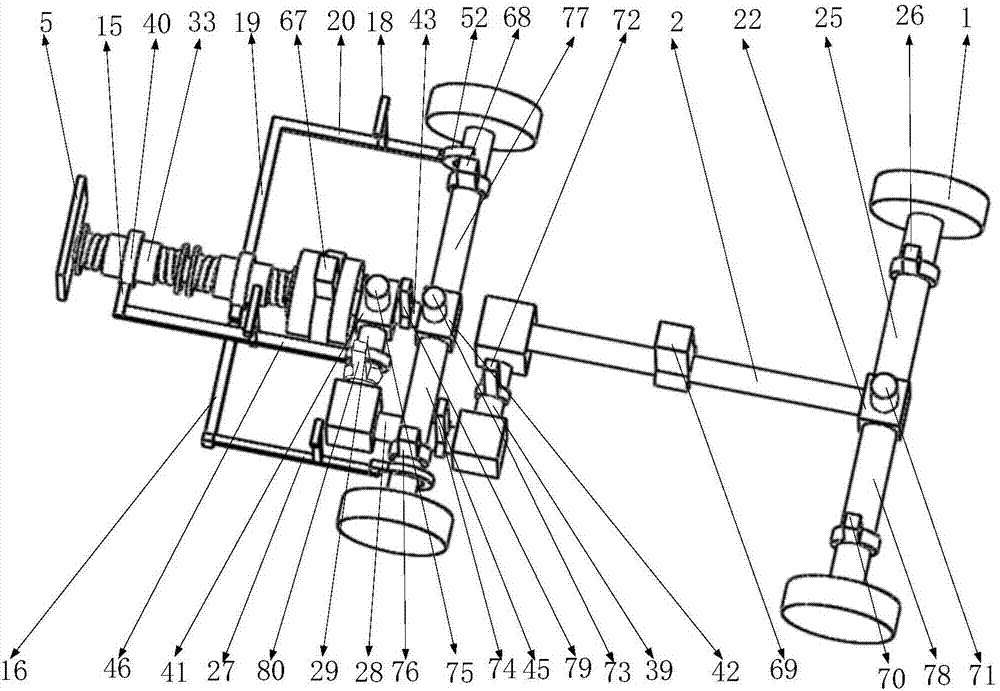

[0047] Such as image 3 As shown, the above-mentioned traveling mechanism 14 includes a traveling wheel 1, a fourth transmission shaft 25, a fifth transmission shaft 28, a fifth support 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com