Bicycle speed change system and speed change method for power-assisted bicycle comprising same

A bicycle and vehicle speed technology, which is applied in the field of bicycle speed change system and power-assisted bicycle speed change, can solve the problems of high price, narrow speed change range, and inability to achieve many levels of speed changes, so as to save costs, improve cruising range, and expand high speed. Efficiency Operating Area and Effect of Output Torque Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

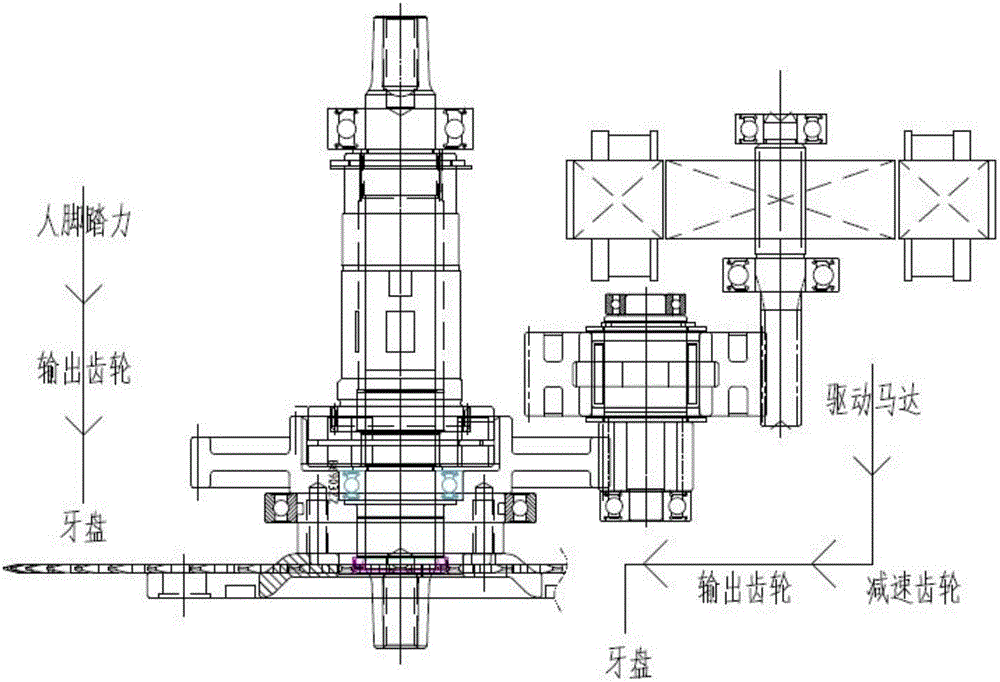

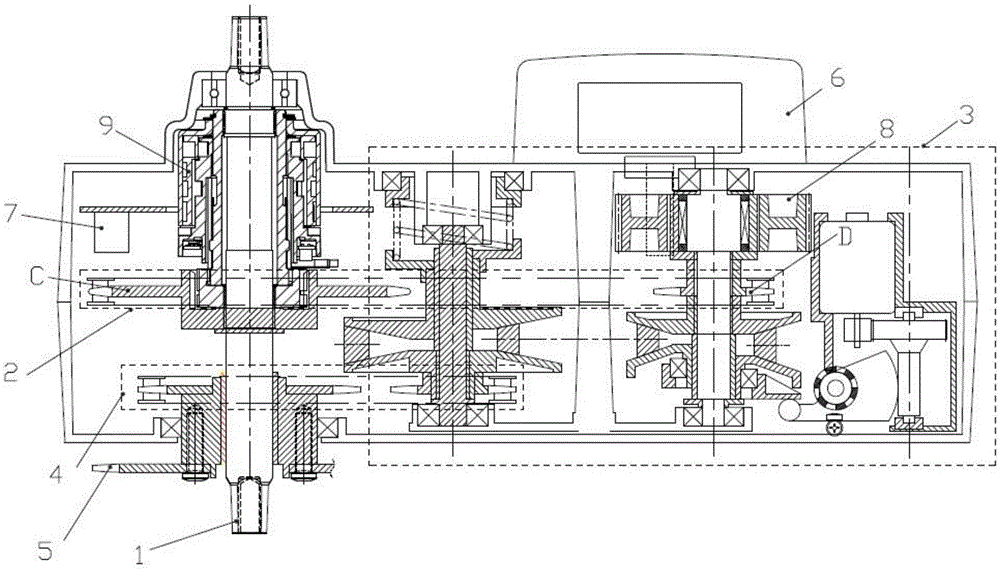

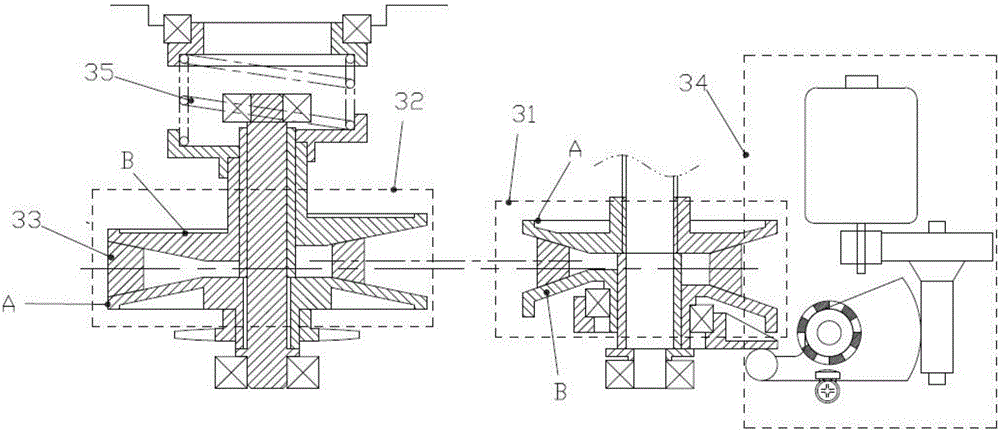

[0057] Please also see figure 2 , image 3 , as shown in the figure, a speed change system for a bicycle includes a drive mechanism and a speed change mechanism located at the output end of the drive mechanism. The speed change mechanism outputs the rotational speed to the bicycle crankset. Wherein the transmission mechanism is a continuously variable transmission mechanism 3, and the continuously variable transmission mechanism includes at least one group of transmission components, and each group of transmission components includes a driving cone wheel group 31, a driven cone wheel group 32, and is connected to the driving cone wheel group and the driven cone wheel group. The transmission belt 33 and the speed regulating assembly 34 on the driven cone wheel group, the driving cone wheel group 31 and the driven cone wheel group 32 all include two oppositely arranged cone wheels, which are respectively the fixed cone wheel A and the moving cone wheel B. The speed assembly ac...

Embodiment 2

[0108] See Figure 5 , the rest are the same as in Embodiment 1, the difference is that the speed regulating assembly includes a centrifugal ball 346, and a retaining cover 347 is fixed on the rear side of the movable cone wheel. A centrifugal ball moving chamber 350 is formed between the cover and the rear side of the movable cone wheel, and the space size of the moving chamber gradually increases from both sides to the middle; The centrifugal ball is set towards the middle to increase the assist ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com