Novel double-tooth-surface rotary ultrasonic motor stator and excitation way thereof

An ultrasonic motor, tooth surface technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the failure of the motor, increase the production difficulty of the whole machine, piezoelectric ceramics Fragile and other problems, to avoid influence, improve output stability, and low modal frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

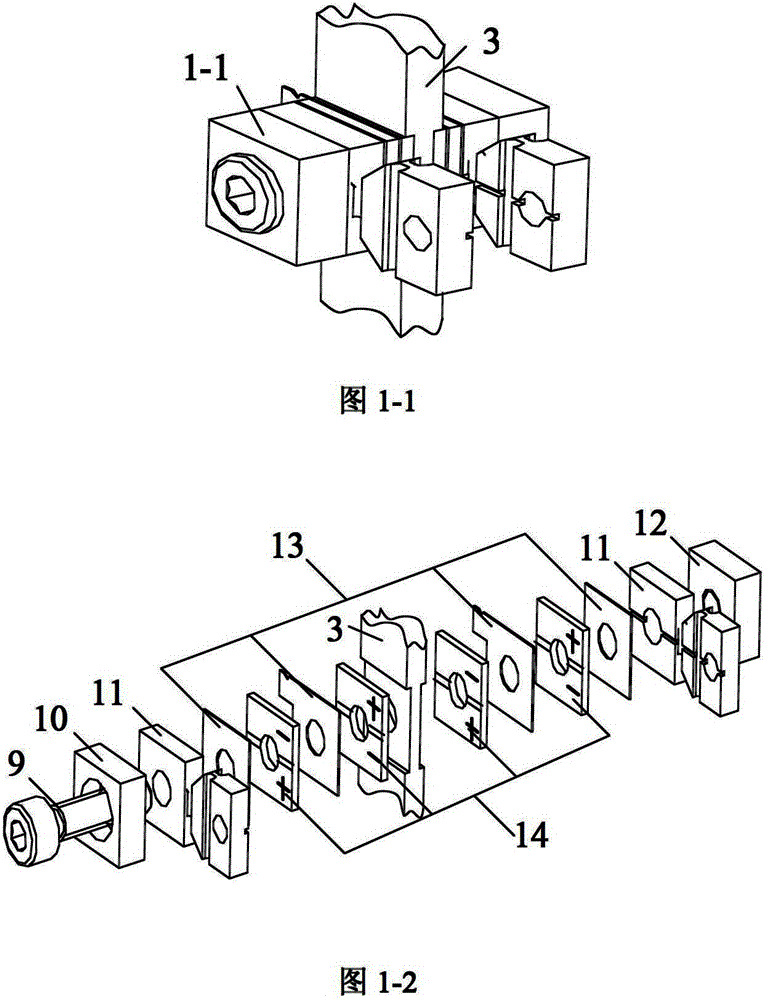

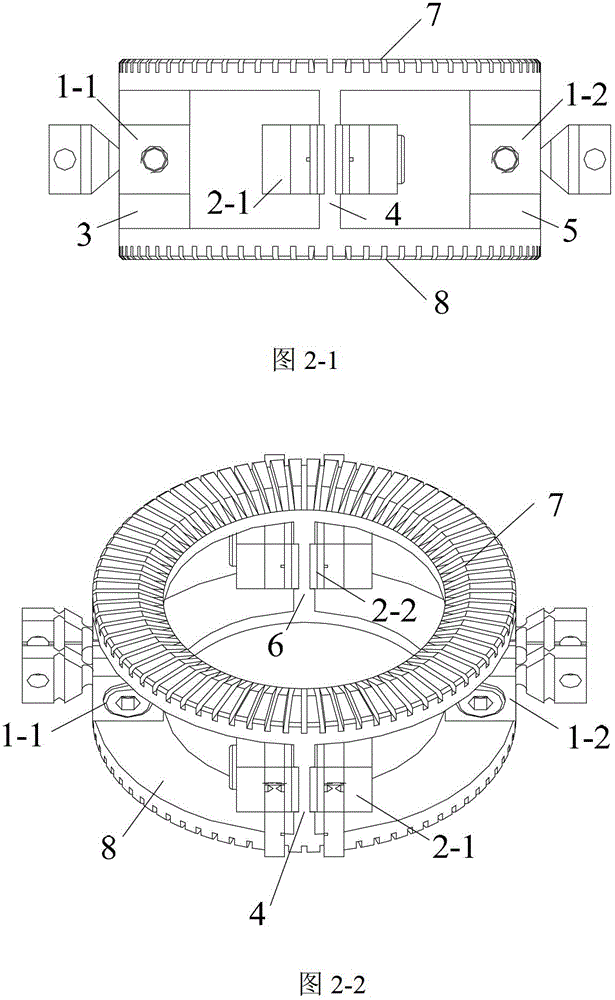

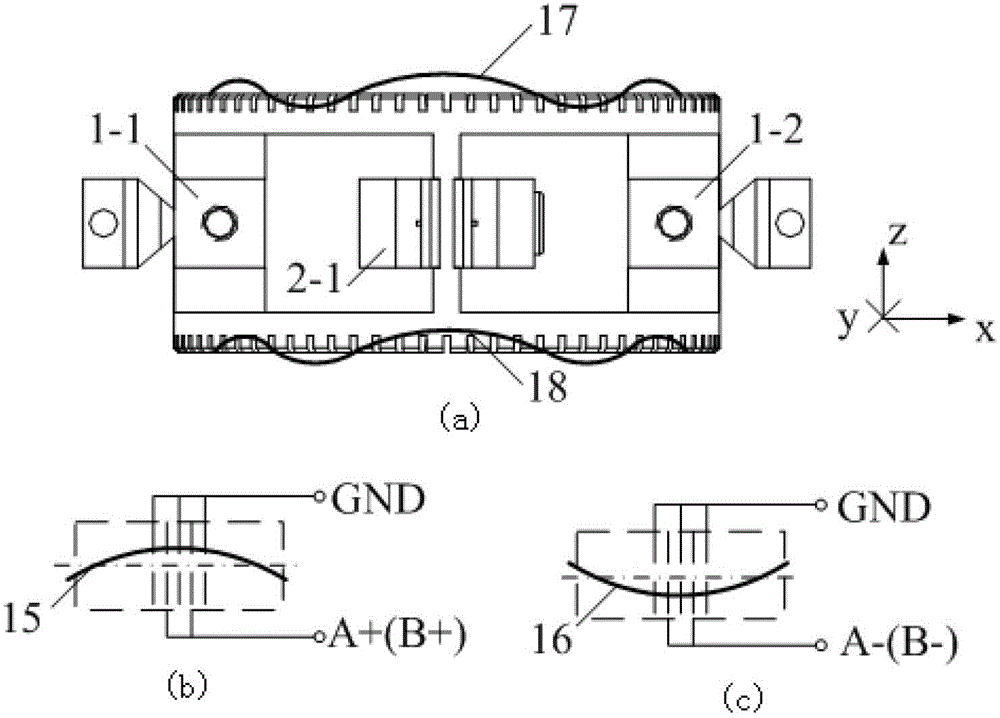

[0017] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Such as diagram 2-1 , 2-2, the novel double-tooth surface rotary ultrasonic motor stator of the present invention is mainly composed of a double-tooth surface stator ring and four bending vibrators 1-1, 1-2, 2-1 and 2- 2. The double-toothed stator ring includes an upper stator ring 7, driving columns 3, 4, 5, 6, and a lower stator ring 8. Among them, the driving end surfaces of the upper stator ring 7 and the lower stator ring 8 have a tooth-shaped structure; the bending vibrator is symmetrically installed on both sides of the driving column, and is perpendicular to the driving column in the length direction; the bending vibrator is a sandwich piezoelectric composite structure, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com