Full-automatic woodworking numerical control engraving and milling machine

A router and milling machine, fully automatic technology, applied in the field of fully automatic CNC woodworking router and milling machine, can solve problems such as troublesome operation, dangerous tools, large dust, etc., achieve convenient disassembly and maintenance, increase output speed, and high processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

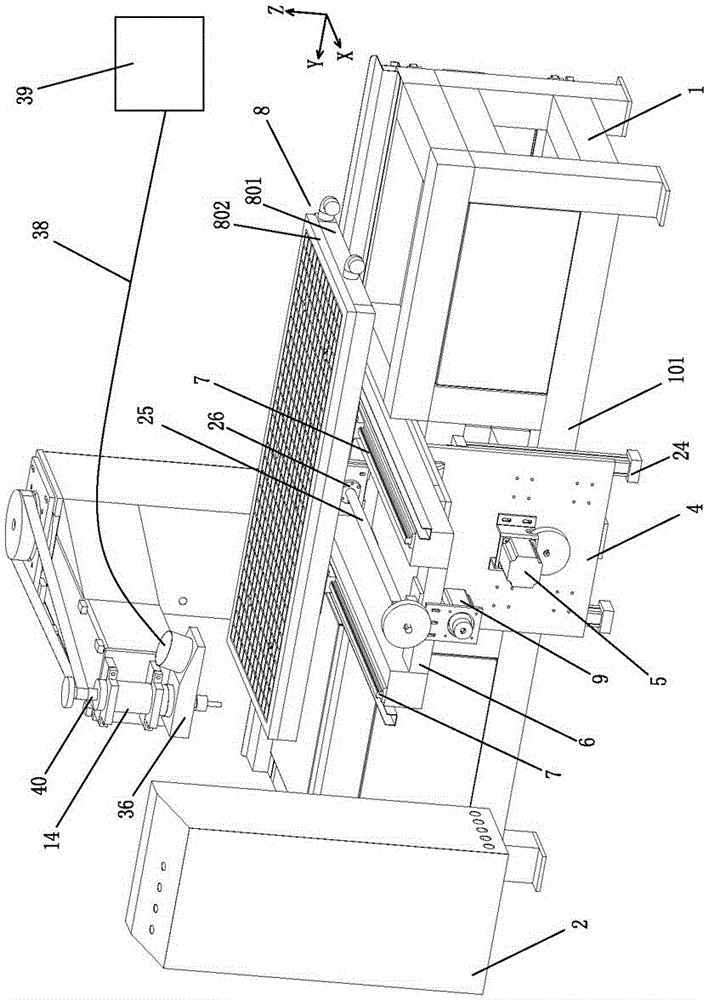

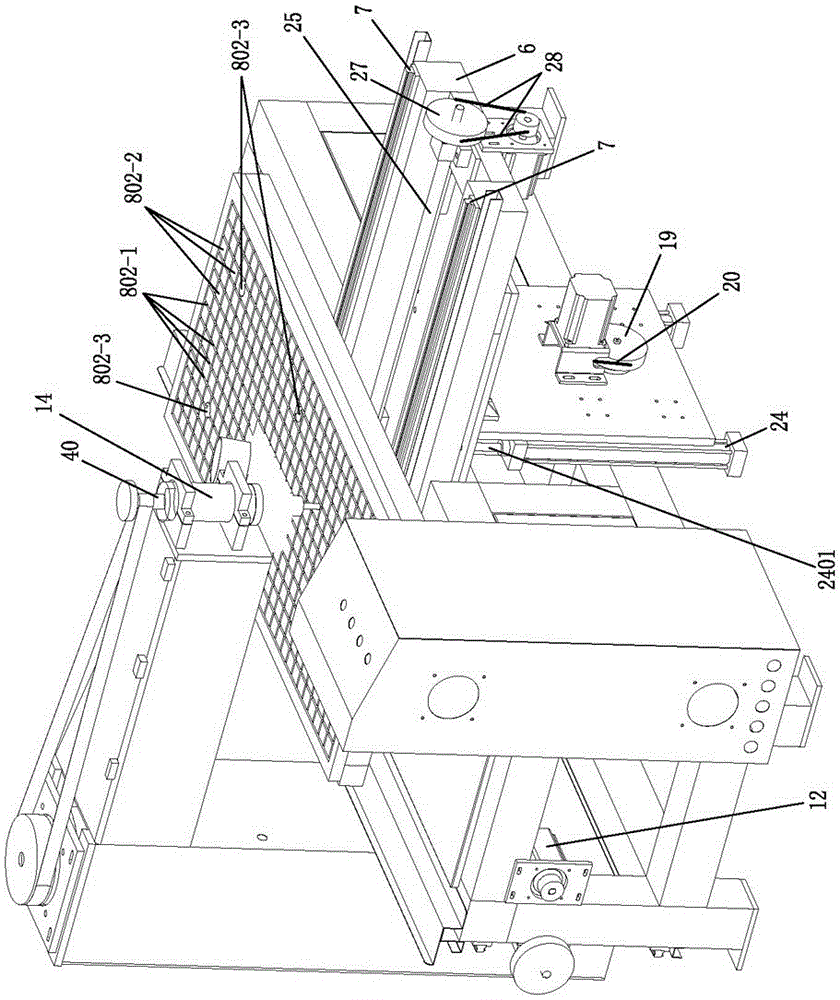

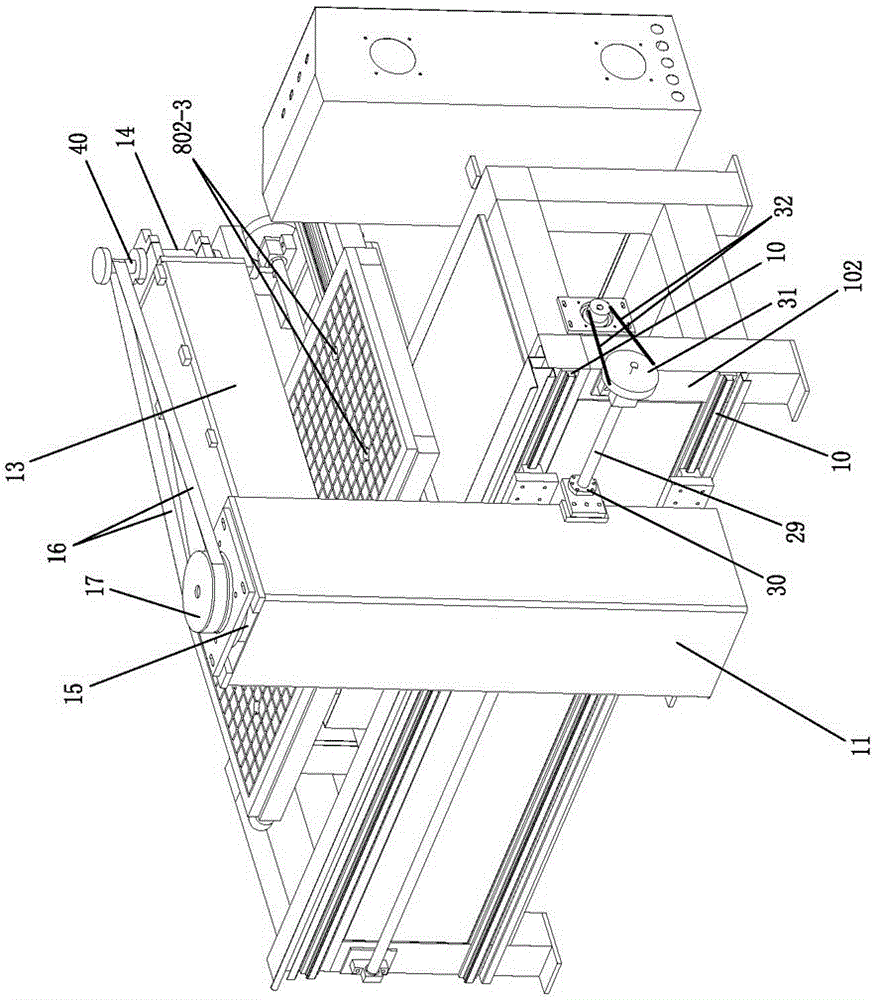

[0034] The first embodiment: as Figure 1 to Figure 7 As shown, a fully automatic CNC woodworking router, including a base 1 and a numerical control device 2, is characterized in that the front end surface 101 of the base 1 is fixed with a Z-axis guide rail 3 extending along the height direction (up and down direction), and the Z-axis A Z-axis skateboard frame 4 is slidably connected to the guide rail 3, and a Z-axis motor 5 is installed on the Z-axis skateboard frame 4 to move the Z-axis skateboard frame 4 up and down along the Z-axis guide rail 3;

[0035] The Z-axis skateboard frame 4 is fixed with an X-axis support 6, and the X-axis support 6 is fixed with an X-axis guide rail 7 extending along the X-axis direction (front and back direction), and the sliding seat on the X-axis guide rail 7 is provided with a fixed workpiece A The workbench 8 used, the bottom of the X-axis bracket 6 is equipped with an X-axis motor 9 that makes the workbench 8 slide back and forth along the...

no. 2 example

[0049] The second embodiment: its structure is similar to the above-mentioned embodiment, the difference is that, as Figure 8 As shown: the front end surface 101 of the base 1 is fixed with two Z-axis guide rails 3 extending along the height direction, the front end surface 101 of the base 1 between the two Z-axis guide rails 3 is equipped with a Z-axis screw rod 23, and the Z-axis skateboard frame 4 and Z The shaft screw rod 23 is connected, and the Z-axis motor 5 drives the Z-axis screw rod 23 to rotate, so that the Z-axis skateboard frame 4 can be lifted up and down along the two Z-axis guide rails 3; as another embodiment of the lifting function, the Z-axis skateboard frame 4 passes through The Z-axis nut is connected with the Z-axis screw rod 23, and the Z-axis slide frame 4 can also be lifted up and down through the traditional screw nut pair structure, and its lifting accuracy and error can also be effectively guaranteed.

[0050] The fully automatic numerically contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com