Patents

Literature

159 results about "Elliptic motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

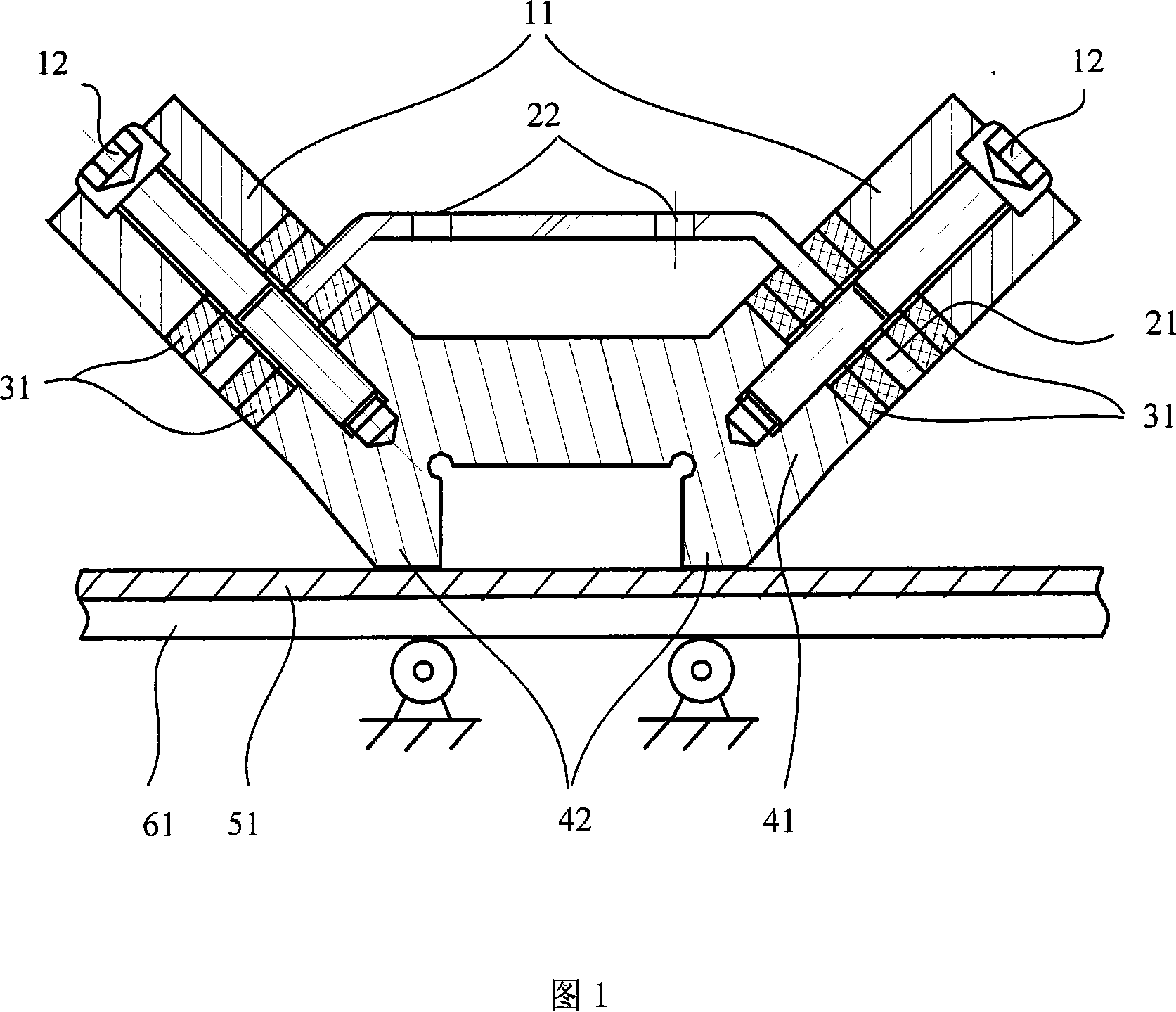

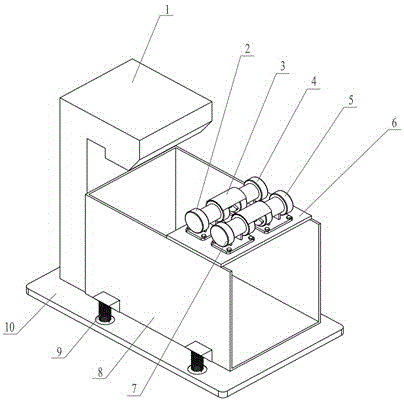

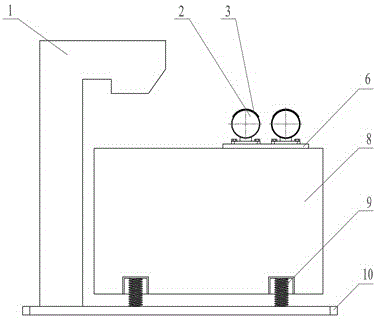

Three-dimensional elliptic motion generating method and device for diamond cutter

ActiveCN102059575AAchieve autonomous controlThe generation method is simpleDriving apparatusLinear motionElectricity

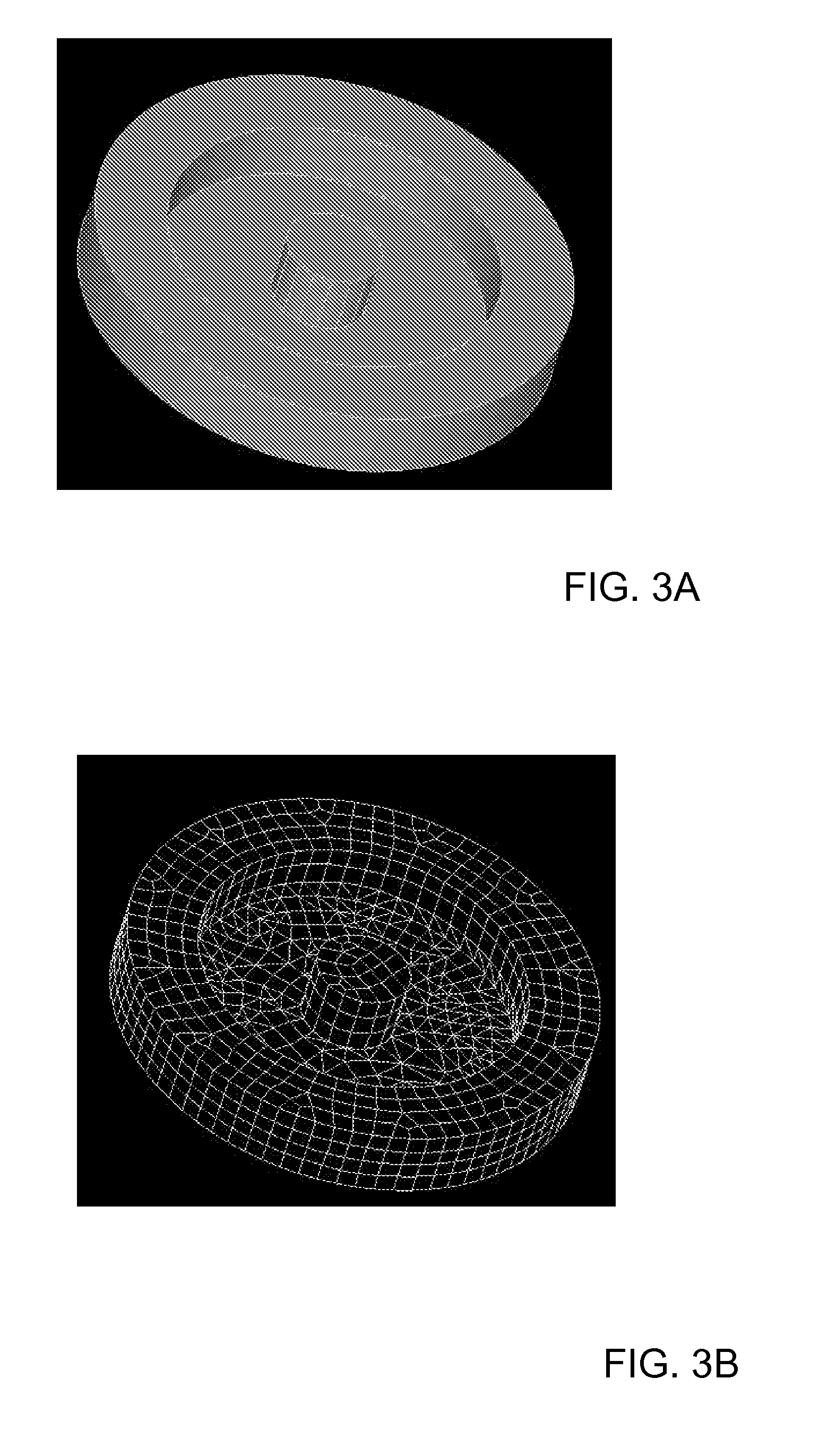

The invention relates to a three-dimensional elliptic motion generating method and a three-dimensional elliptic motion generating device for a diamond cutter, which belong to the field of ultraprecise cutting and cutting of materials difficult to machine. The diamond cutter is directly driven by three piezoelectric stacks which are arranged vertically, the three piezoelectric stacks are pre-tightened by a pre-tightening bolt at the same time, and the pre-tightening forces of the three piezoelectric stacks are finely adjusted by three wedge mechanisms respectively; by actively controlling the initial phase of a three piezoelectric stack driving signal, the projections of the motion of the diamond cutter on an X-Y plane and a Y-Z plane are elliptic motions, and the projection of the motion of the diamond cutter on an X-Z plane is a reciprocating linear motion; and by regulating the parameters such as frequency and amplitude of the three piezoelectric stack driving signal, the automatic control over the three-dimensional elliptic motion track parameter of the cutter is realized. The method and the device are very simple, easy to implement and favorable for obtaining the optimal cutting machinability of the diamond cutter.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

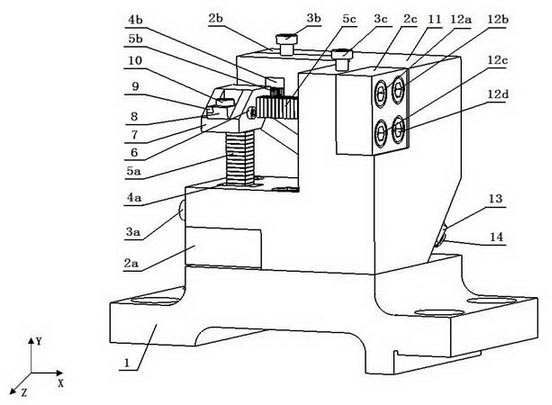

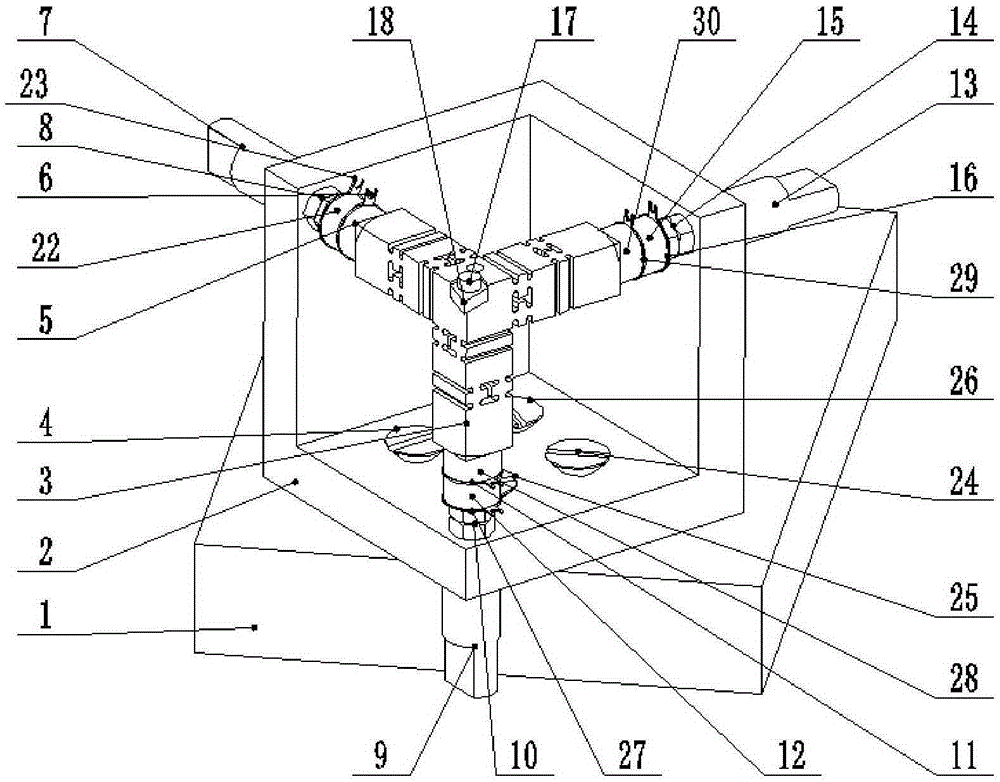

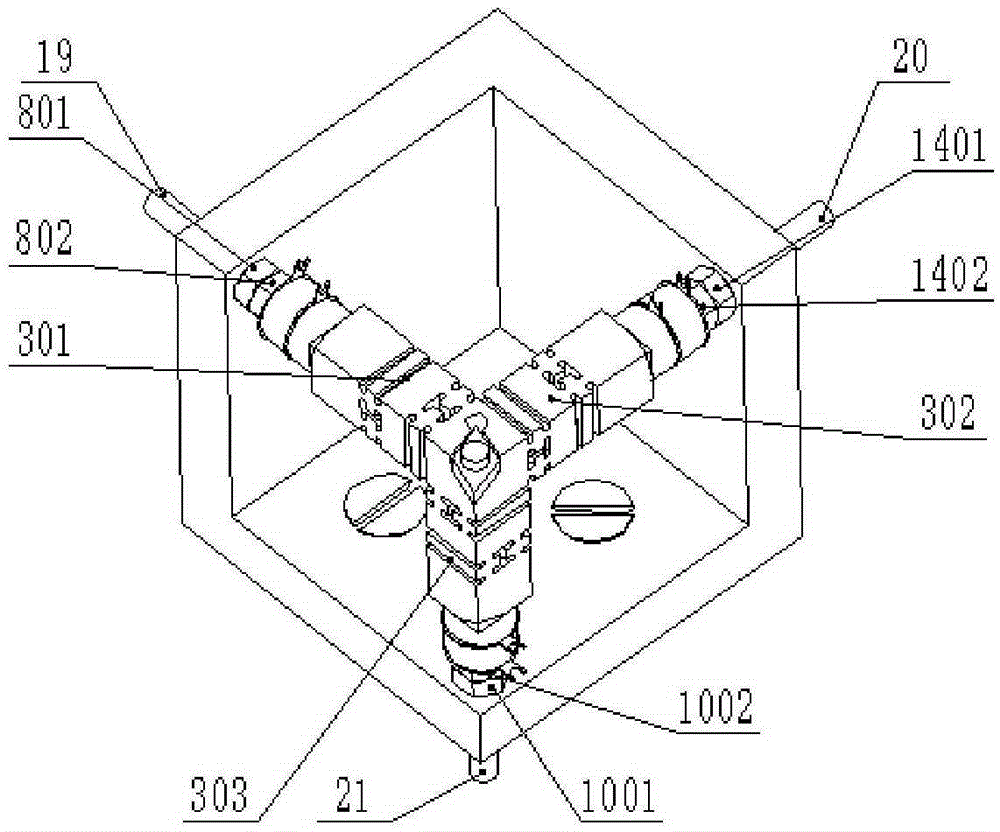

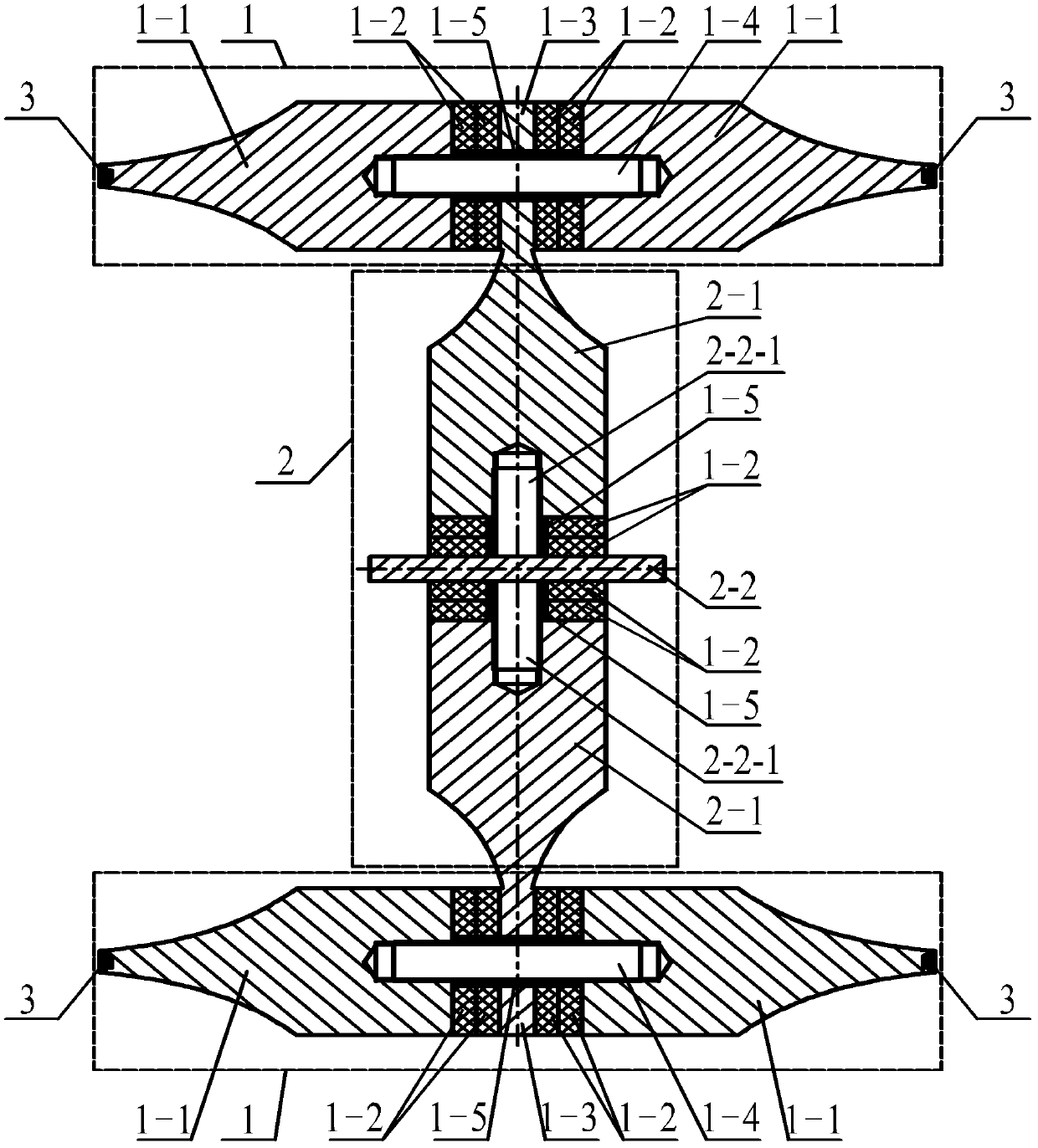

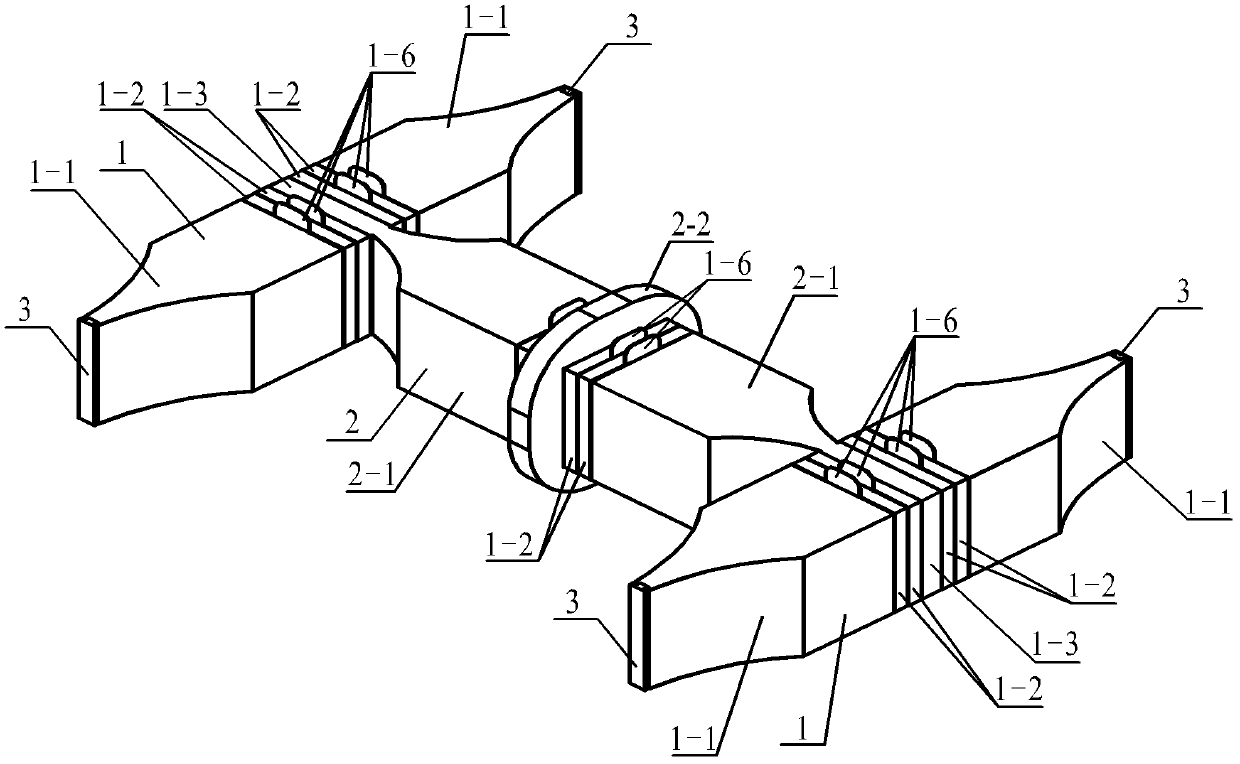

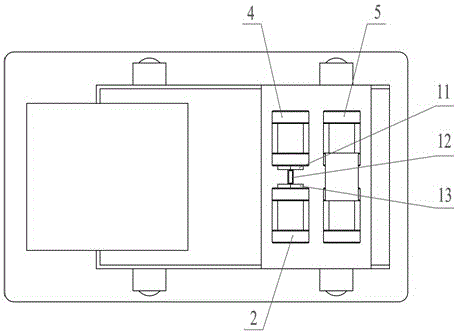

Three-dimensional ultrasound elliptical vibration assisted cutting device and elliptical orbit generation method

InactiveCN105312679AExcellent machinabilityFacilitates the realization of decoupled inputNumerical controlElectricity

The invention discloses a three-dimensional ultrasound elliptical vibration assisted cutting device and an elliptical orbit generation method thereof, and belongs to the field of numerical control machining. The device is composed of a multi-shaft flexible hinge, a base, a cutter pre-tightening screw, a connecting screw and a pedestal as well as piezoelectric ceramic plates, electrode plates, double-nut structures, connecting shafts and vibration frequency trimmers in the X direction, the Y direction and the Z direction. The multi-shaft flexible hinge is composed of three subchains perpendicular to one another and a cutter mounting frame. Each subchain is provided with a first flexible hinge unit and a second flexible hinge unit which are of the same structure and different in arrangement direction. A cutter is fixed to the cutter mounting frame. Displacement inputs are generated on all the subchains through the piezoelectric ceramic plates in the X direction, the Y direction and the Z direction, and after displacement amplification and superposition in the three directions, the multi-shaft flexible hinge is driven to generate an elliptical motion orbit in a three-dimensional space at the point of the cutter. The device is simple in structure, the inputs are mutually decoupled, the three-dimensional elliptical motion orbit is generated easily, and the device can be conveniently and directly integrated with a numerically-controlled machine tool for assisted precision machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

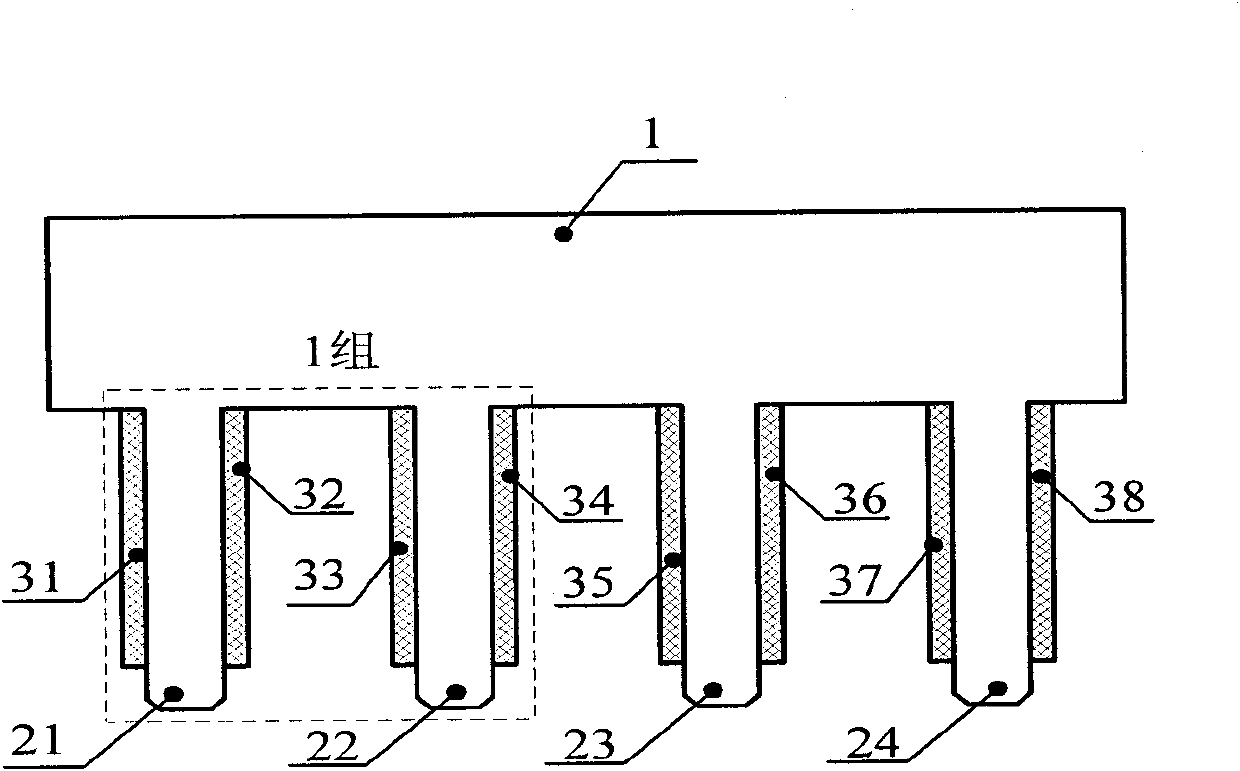

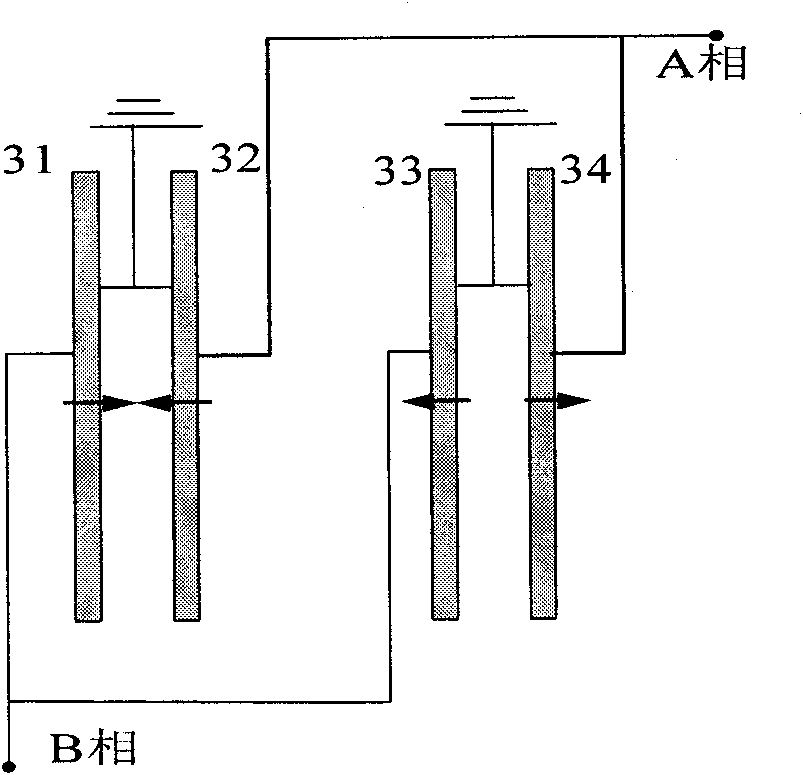

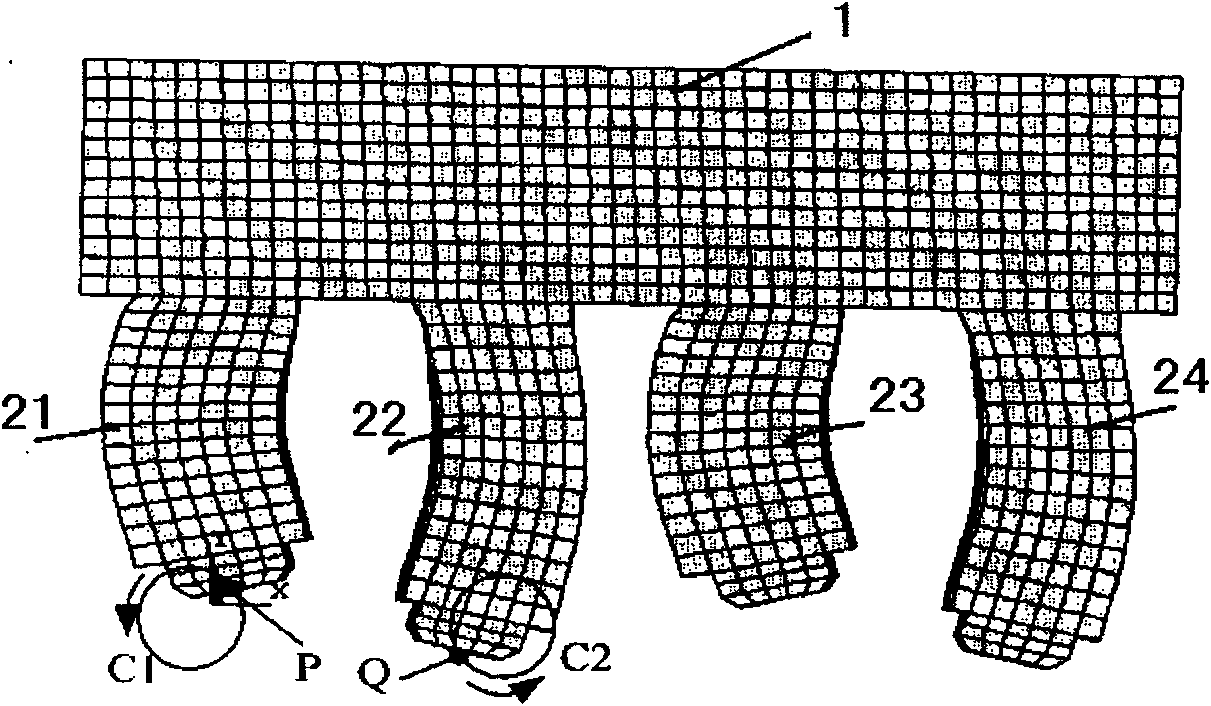

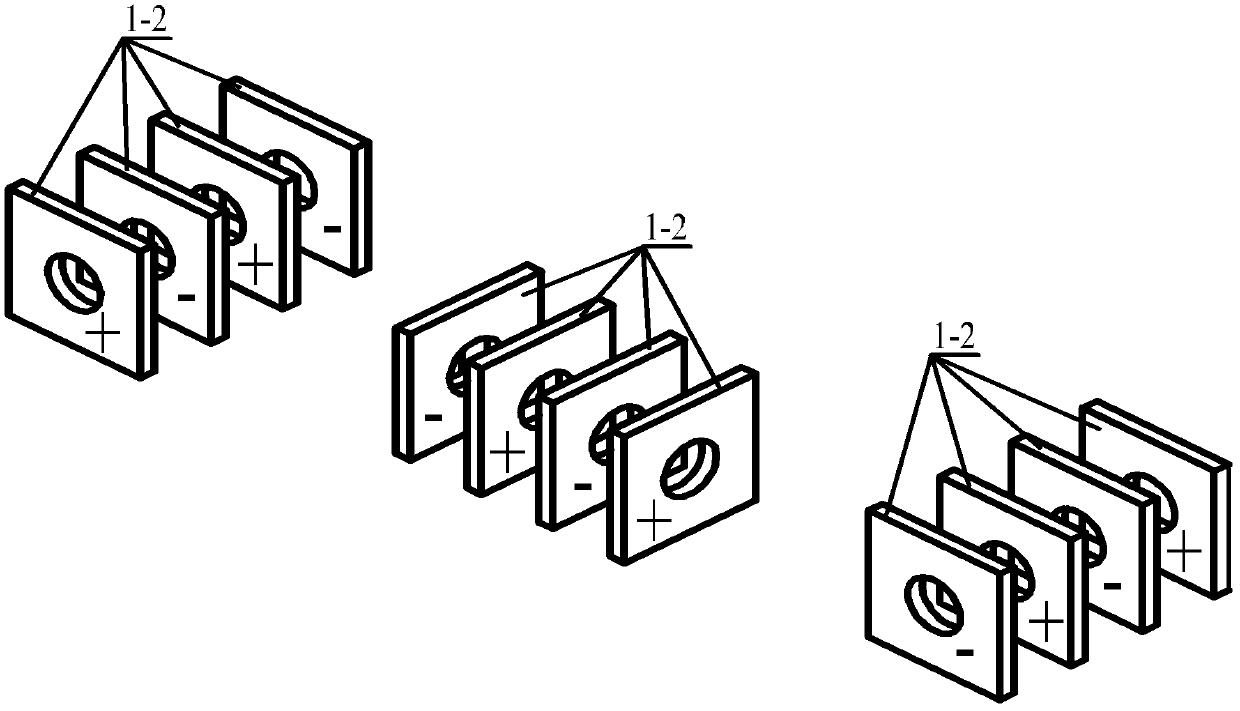

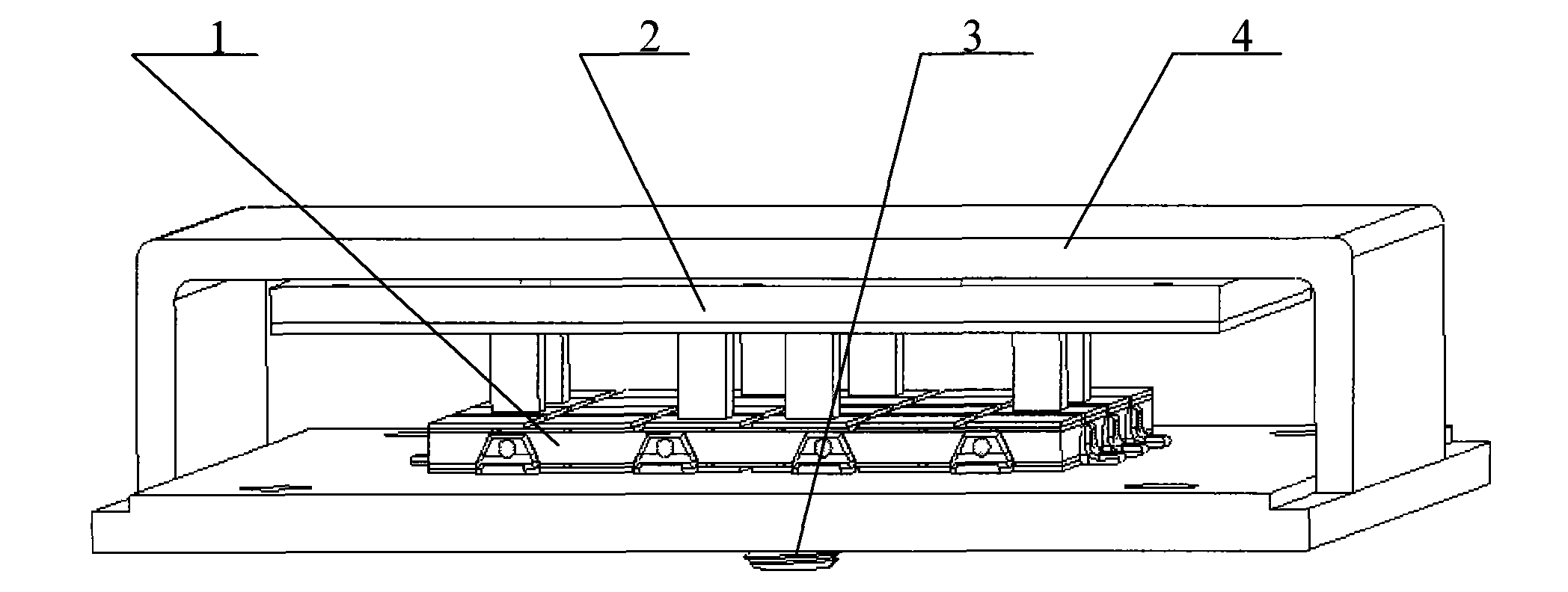

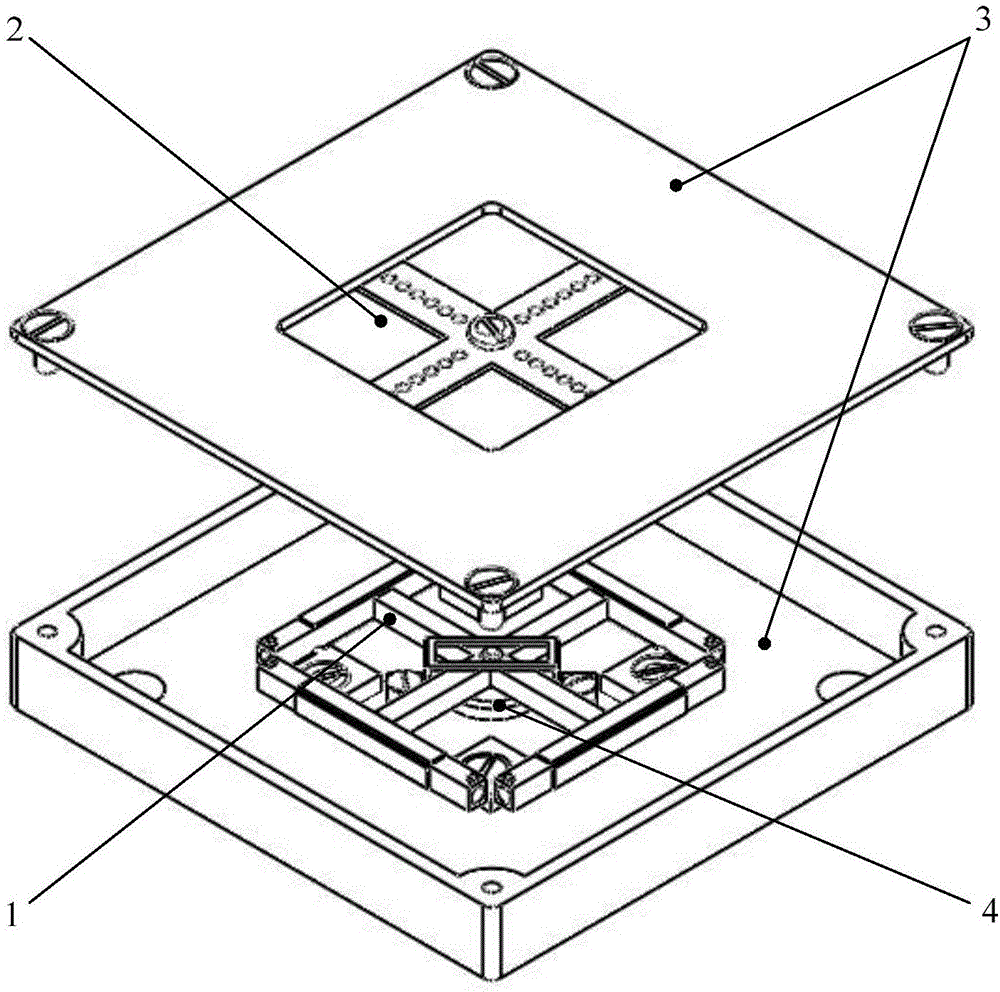

Multi-leg linear piezoelectric driver and workbench

ActiveCN101795088ASimple structureIncrease contact areaPiezoelectric/electrostriction/magnetostriction machinesElliptic motionControl system

The invention belongs to a multi-leg linear piezoelectric driver and a workbench in the field of micro drivers. Diamond-shaped driving legs extending from a substrate of a piezoelectric driver form a comb-shaped structure, and square piezoelectric ceramic plates are bonded on the side surfaces of the driving legs, wherein the piezoelectric ceramic plates are polarized along the thickness direction of the piezoelectric ceramic plates, and the end faces of all the driving legs are on the same plane. Electrical signals are introduced to the electrode surfaces of the piezoelectric ceramic plates,the first-order stretching vibrations and the first-order or second-order bending vibrations of the driving legs can be simultaneously excited, and the coupling action of the two vibrations ensures that mass points on the bottom surfaces of the driving legs do elliptic motions and the elliptic vibrations of a plurality of leg bottoms of the driver are accumulated and superposed into a macroscopiclinear motion. The driver is arranged on a base of the workbench, and a grating bar and a grating head which are arranged on the base are used for providing a precise position of the workbench to realize the closed loop control of the workbench. Because the driver adopts a multi-leg driving mode, the driving force is increased in multiples; the contact areas of the piezoelectric ceramic plates with air are large so as to be beneficial to radiating heat; the assembly is convenient, and the cost is lower.

Owner:TSINGHUA UNIV +2

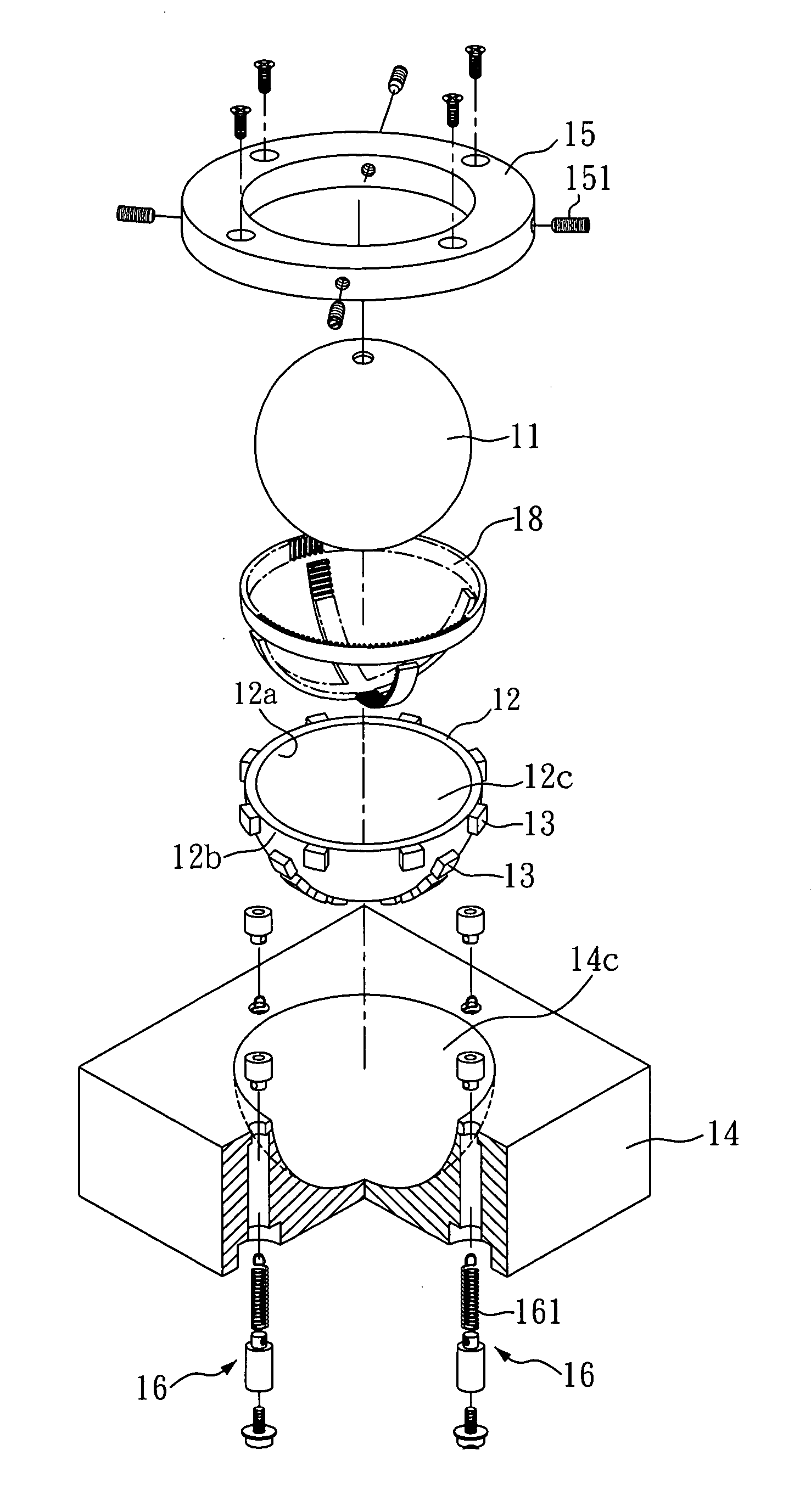

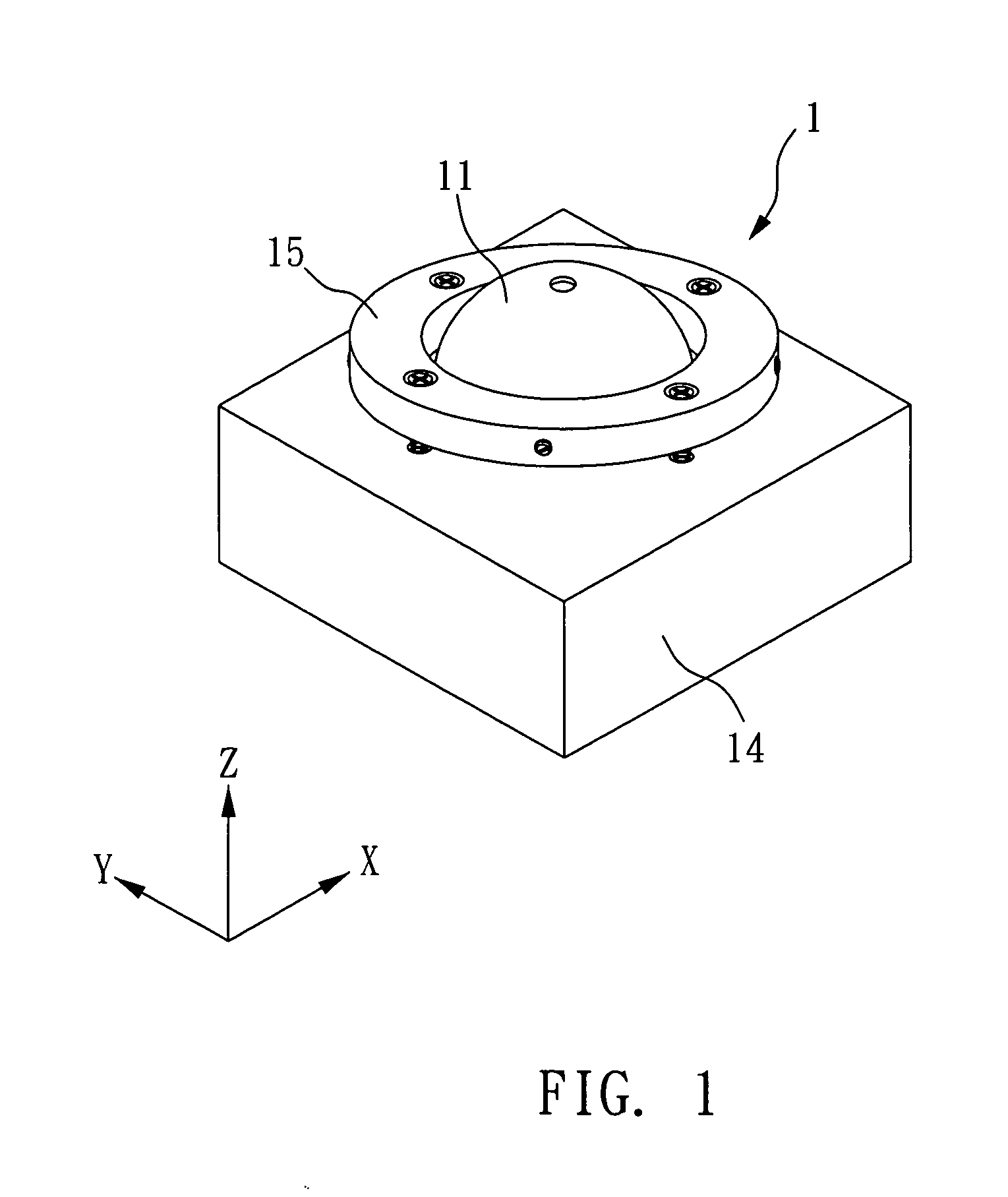

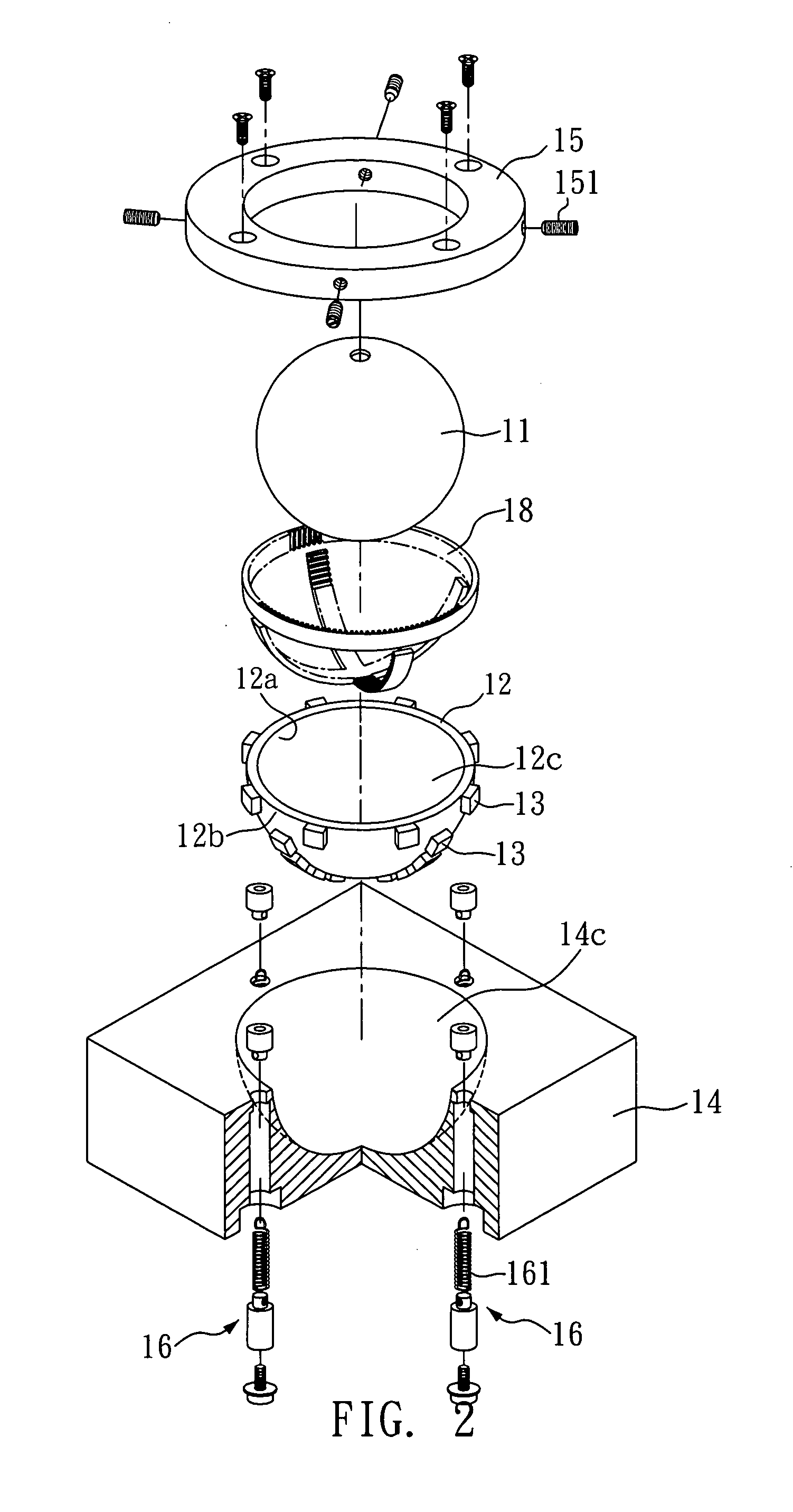

Spherical rotary piezoelectric motor

InactiveUS20100207488A1Improve conductivityEasy to controlPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesPiezoelectric actuatorsElliptic motion

A spherical rotary piezoelectric motor comprises a spherical rotor, a hemispherical stator, and a plurality of piezoelectric actuators. The hemispherical stator comprises an inner surface and an outer surface, wherein the inner surface forms a hemispherical hollow portion which substantially corresponds to the spherical rotor so as to contain a portion of the spherical rotor. The plurality of piezoelectric actuators is arranged on the inner surface (or the outer surface) of the hemispherical stator respectively so as to drive the hemispherical stator. The hemispherical stator generates traveling waves with a resultant elliptical motion, so the spherical rotor can be rotated accordingly with at least one degree of freedom.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

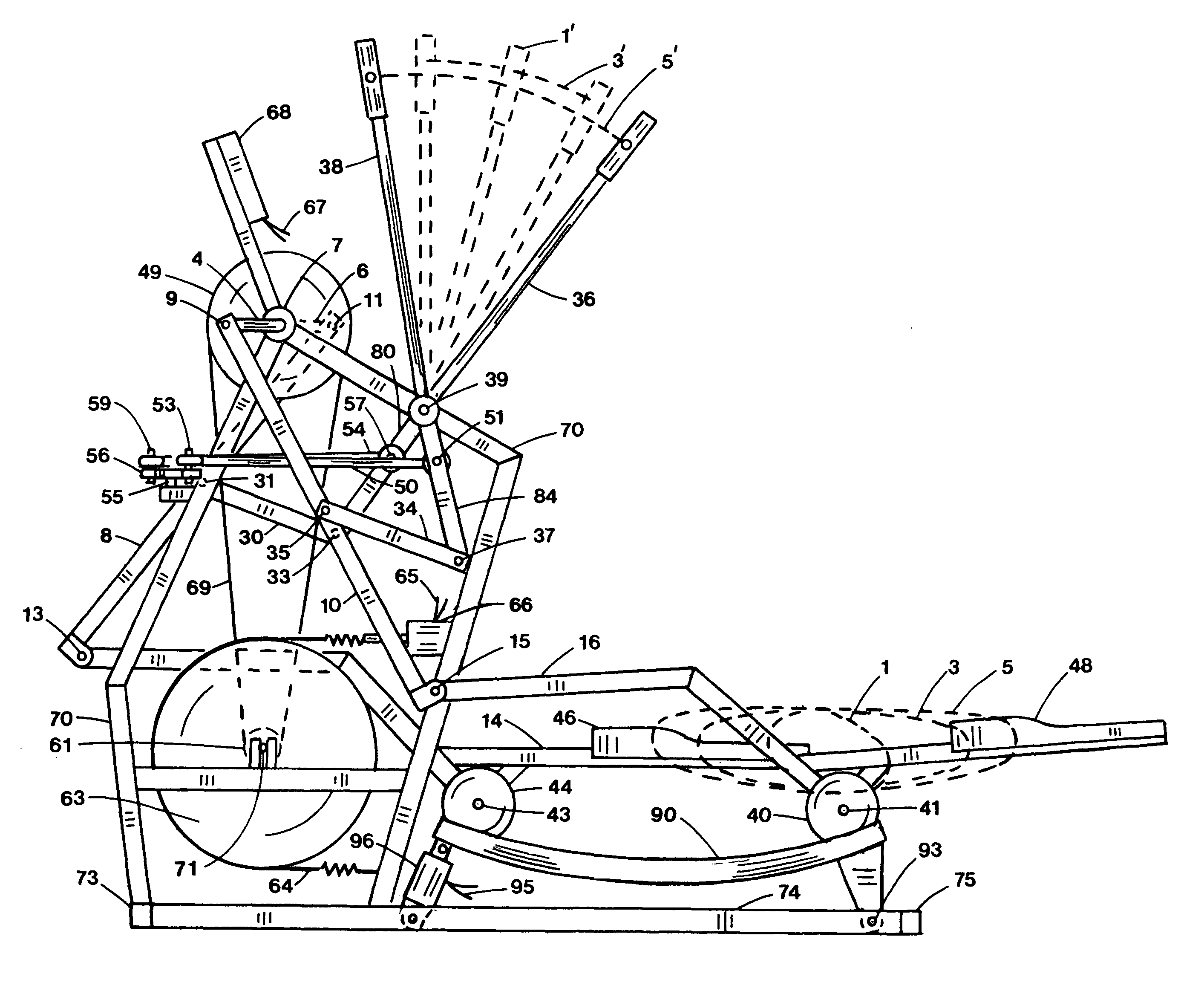

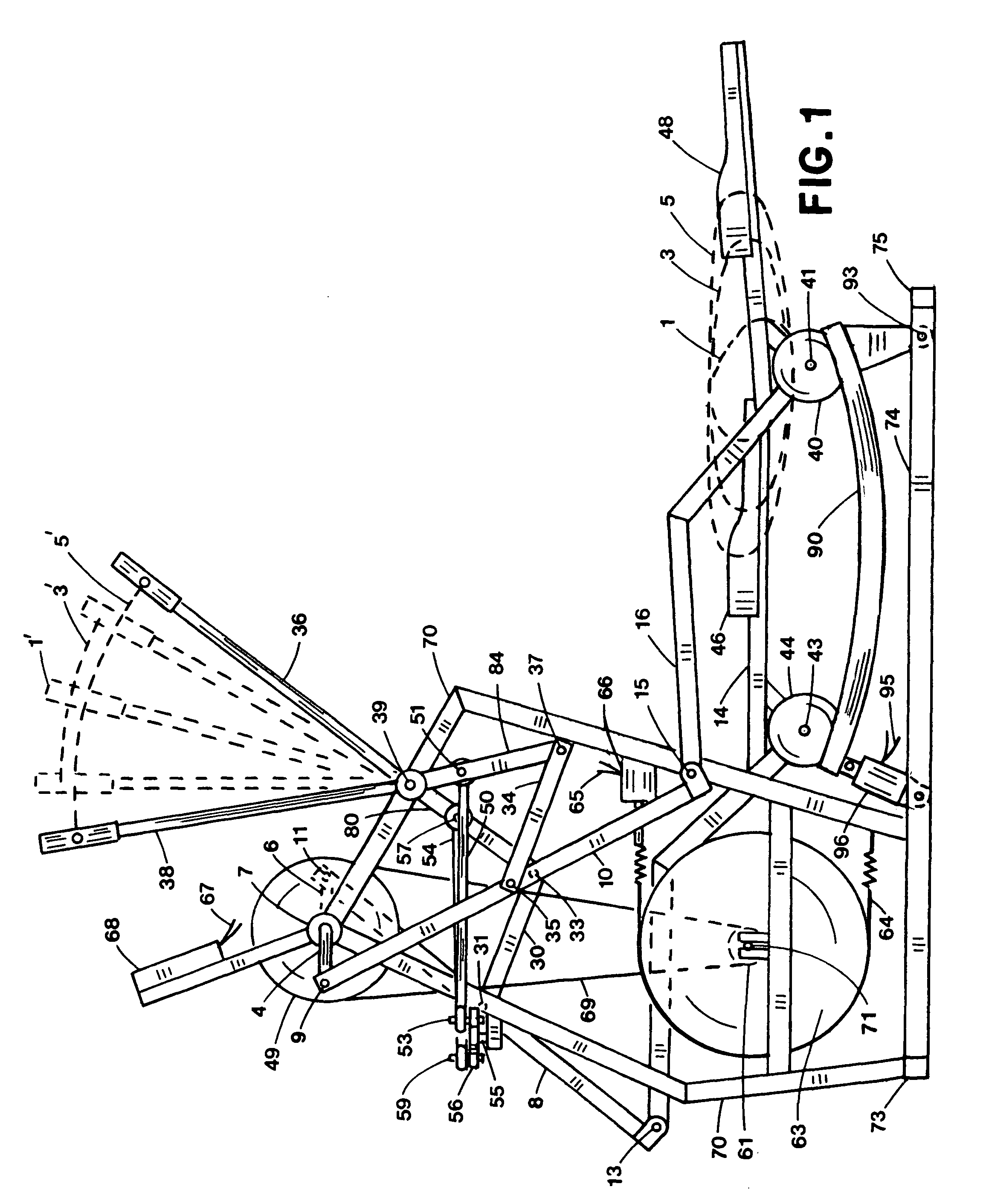

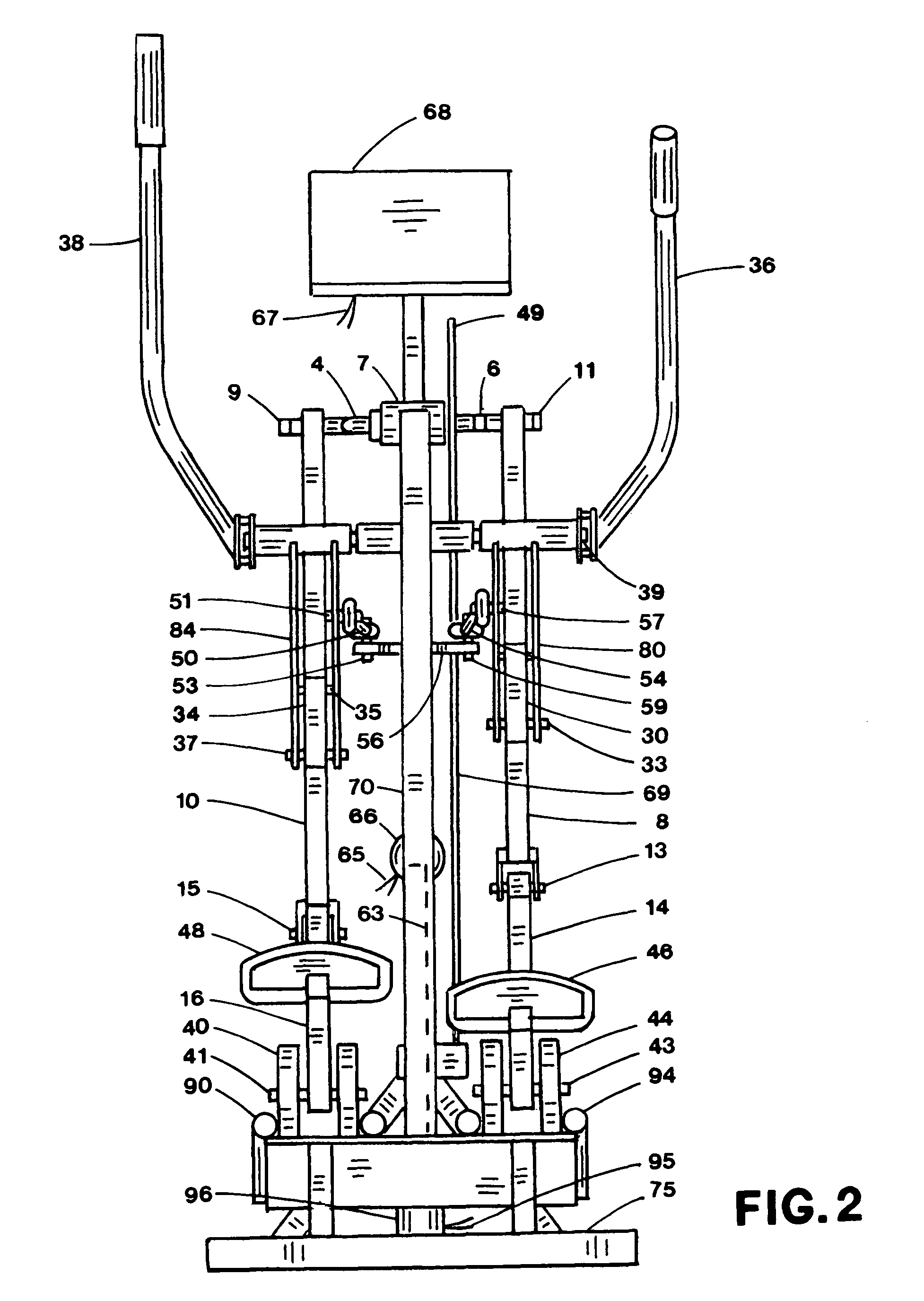

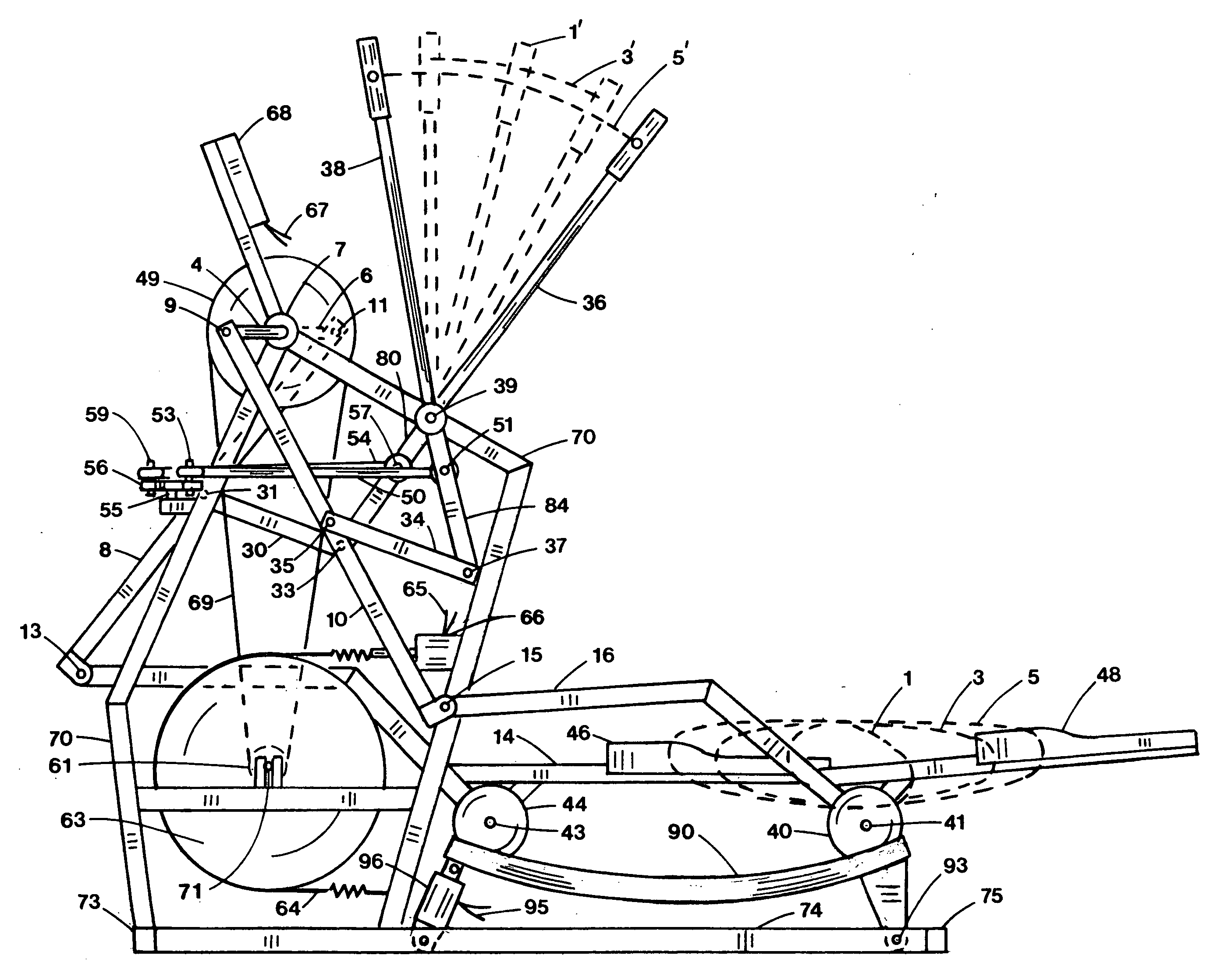

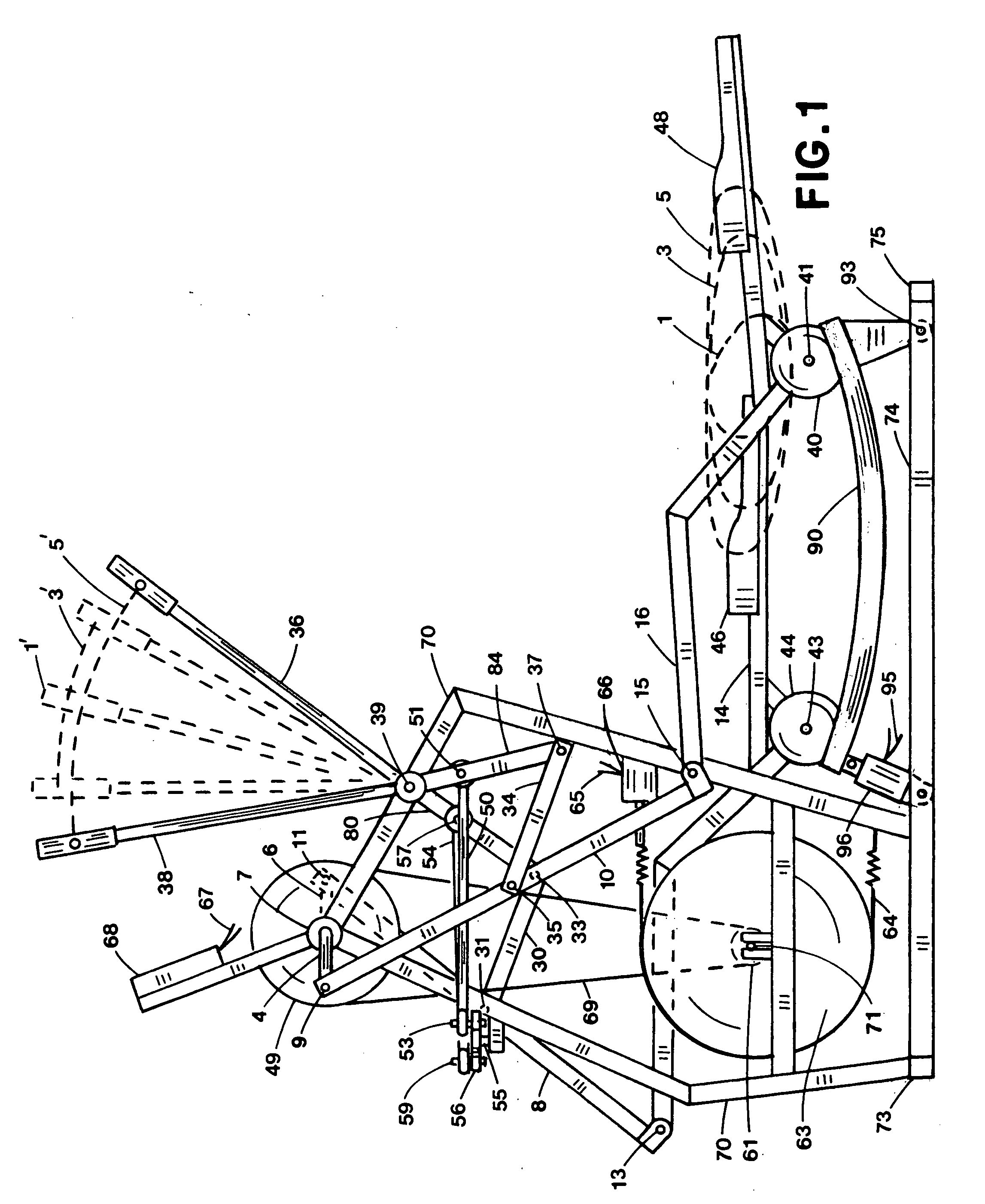

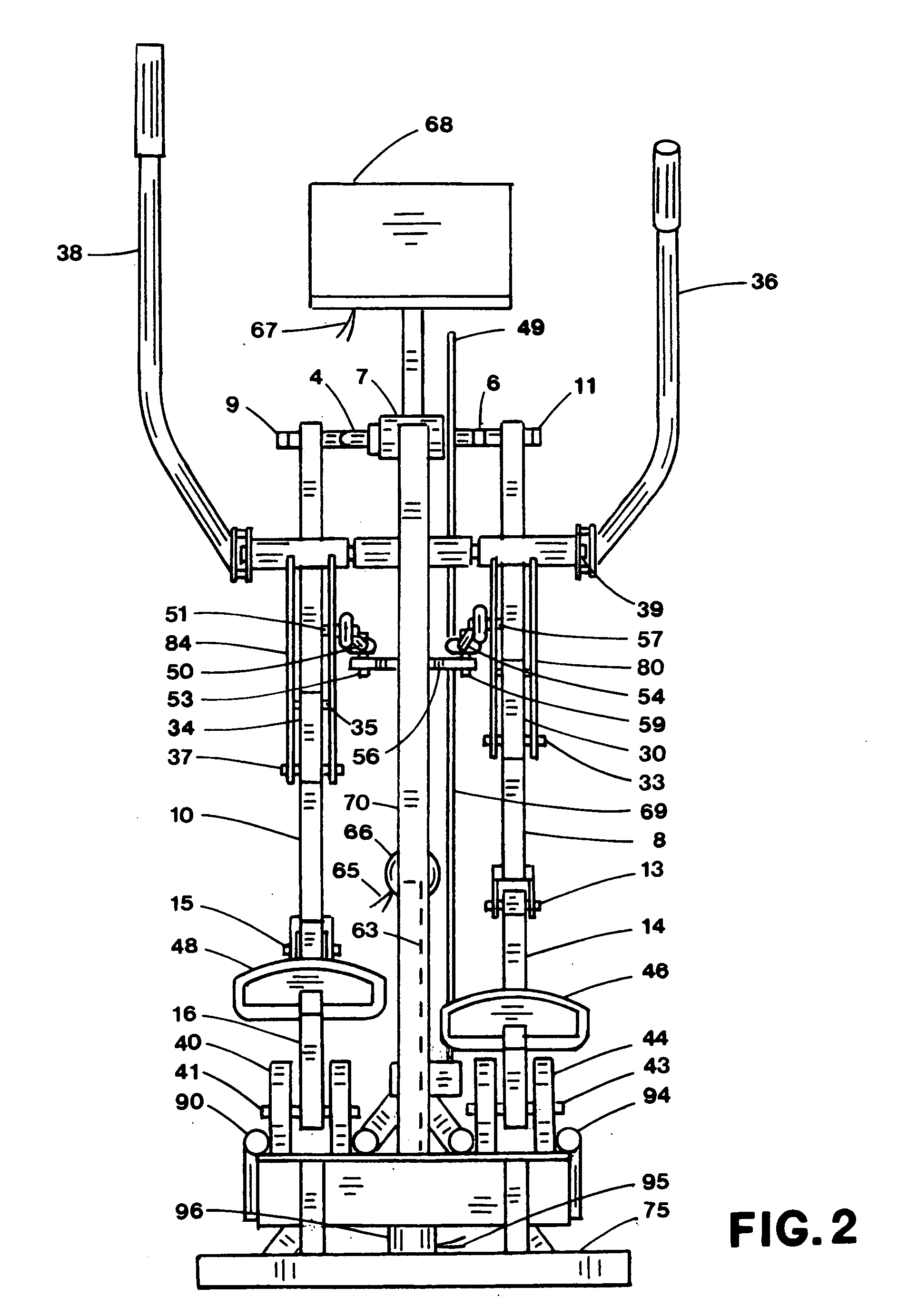

Free stride elliptical exercise apparatus

ActiveUS7938754B2Change the intensity of exerciseEasy to startFrictional force resistorsMovement coordination devicesArm exerciseElliptic motion

The present invention relates to a standup exercise apparatus that simulates walking and jogging with arm exercise. More particularly, the present invention relates to an exercise machine having separately supported pedals for the feet and arm exercise coordinated with the motion of the feet where the pedal stride length is determined by the movements of an operator. The exercise apparatus is easy to start and has generally elliptical shaped curves throughout stride variations.

Owner:ESCHENBACH PAUL WILLIAM

Dual-driving foot longitudinal-vibration mode stacked linear ultrasonic motor and working mode and electric exciting manner

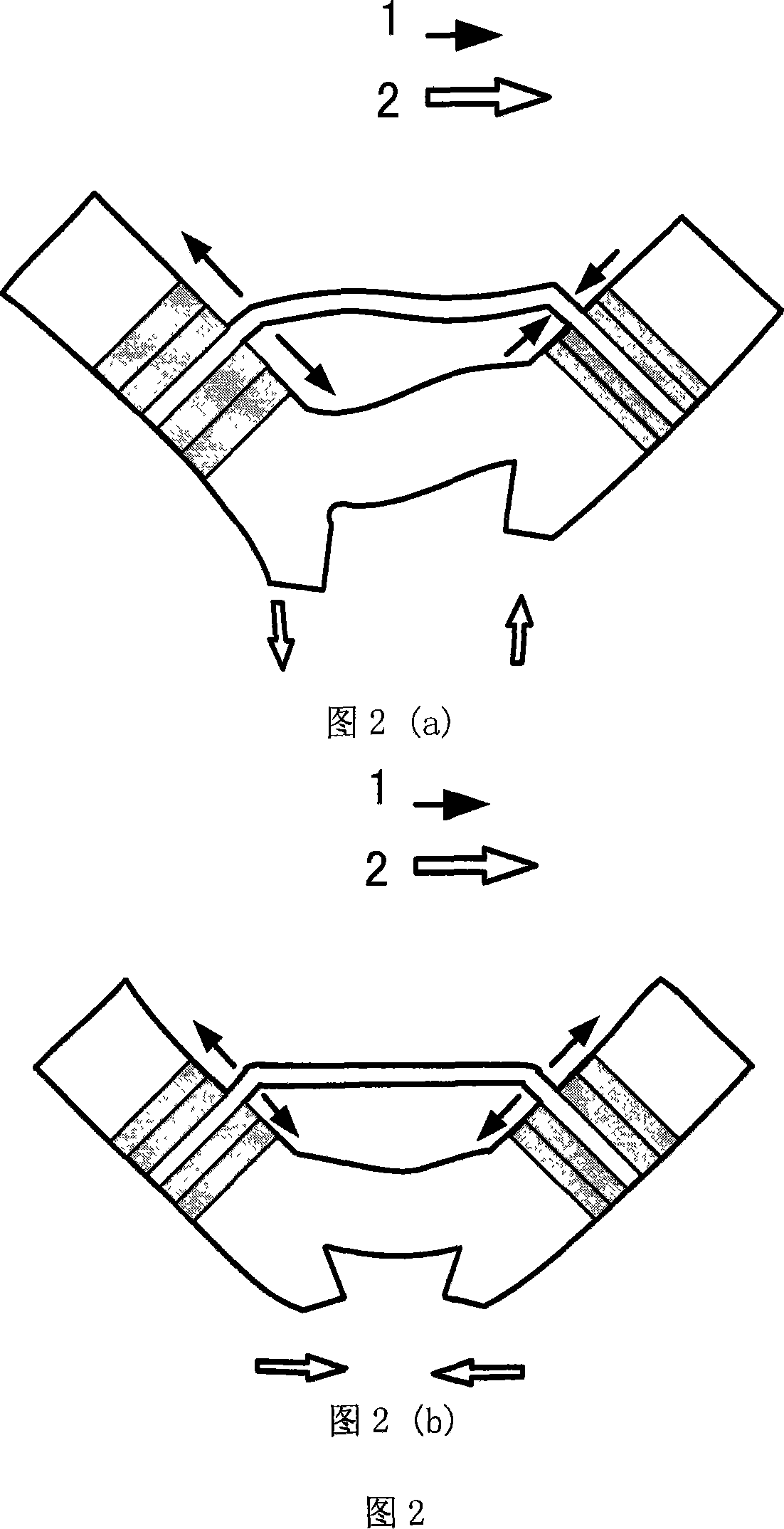

InactiveCN101071995ASimple structureSmall sizePiezoelectric/electrostriction/magnetostriction machinesPhase differenceElliptic motion

Stator of motor is composed of two identical piezoelectric vibrators (PV) connected symmetrically. PV includes back end-cover, front end-cover, intermediate block, and piezoelectric ceramics. Two PVs are connected symmetrically on the front end-cover, where there are two drive feet. Movers of the motor are slide bars with friction layer on surface. Working states include modes: when two PVs do longitudinal vibrations (LV) inverted each other, anti symmetrical vibration (SV) mode of the stator is excitated; when two PVs of the stator do in phase LV, SV mode is excitated. Using two sinusoid signals with phase difference (PD) as pi / 2 excites two PVs of stator simultaneously so as to excite mode of vibration of stator in co-frequency with PD as pi / 2. Thus, the up drive foot of the stator drives particle of the drive foot to do elliptic motion so as to drive movers to do rectilinear motion (RM) continuously. Advantages are: outputting RM in large moment, high speed and high efficiency.

Owner:JIANGSU FENGKE ULTRASONIC MOTORS TECH

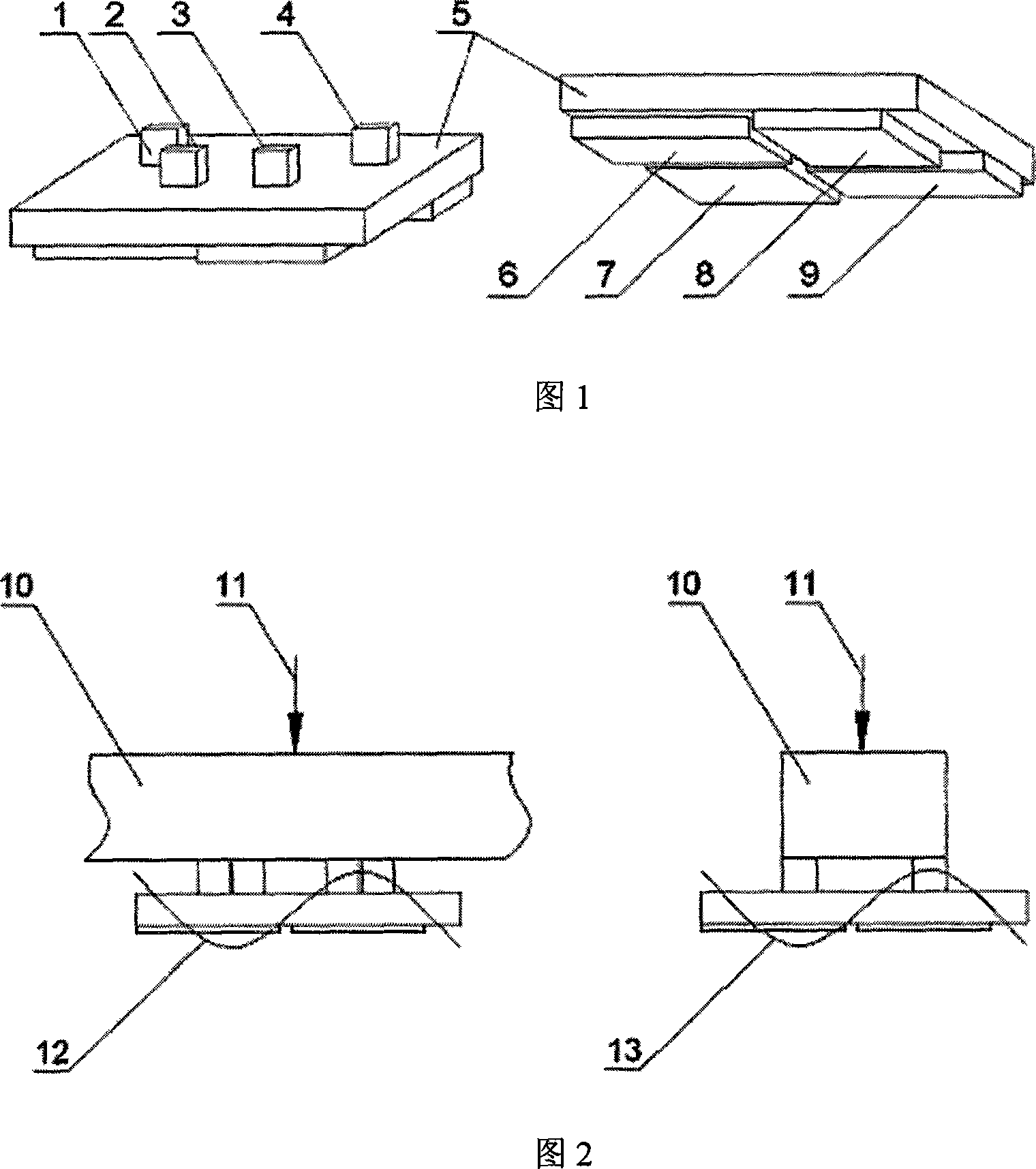

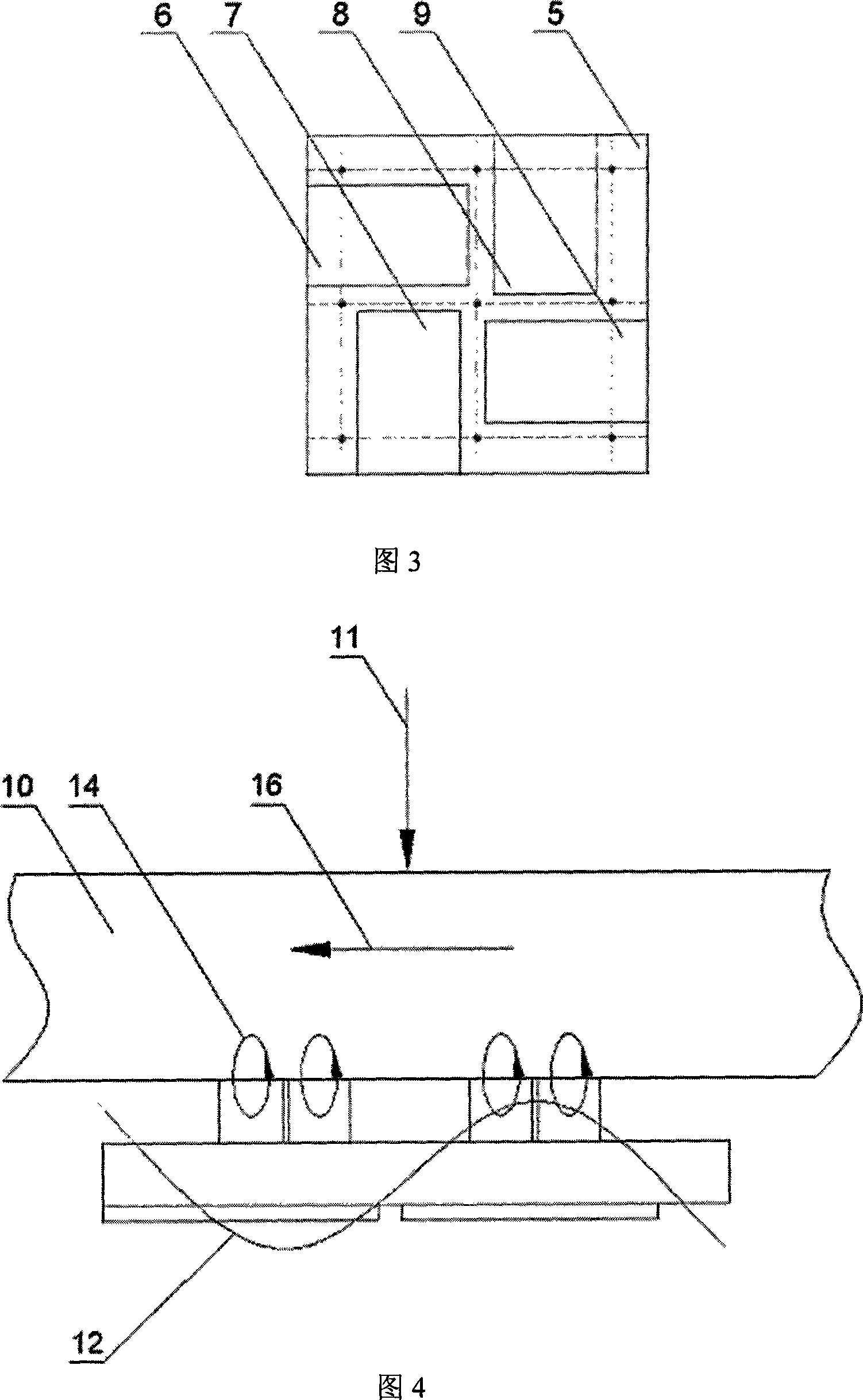

Working method of plate type linear piezoelectric motor based on in-plane mode

ActiveCN104467524AAchieve elliptical motionPiezoelectric/electrostriction/magnetostriction machinesLinear motionElectric machine

The invention discloses a working mode of a plate type linear piezoelectric motor based on an in-plane mode, and belongs to the technical field of piezoelectric motors. The plate type linear piezoelectric motor comprises a stator component and a rotor component, and the stator component is composed of a square metal sheet and two or four one-way polarization square piezoelectric ceramic pieces; or the stator component is a single one-way polarization two-partition square piezoelectric ceramic block; a sliding strip is adopted by the rotor component, and a friction strip is pasted on the sliding strip. Prepressure between a stator and a rotor is provided through a spring element, and the two or four piezoelectric ceramic pieces or two partitions of the one-way polarization two-partition square piezoelectric ceramic block are driven; an oval motion is generated on a driving foot of the stator; under the effect of a certain prepressure, the sliding strip is driven to move in a linear manner; a driving signal is switched, the motor can achieve reverse linear motion. The motor is simple in structure, small in size, light, high in precision, high in response speed and capable of being applied to precise electromechanical devices, laser tuning equipment and optical instrument equipment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Linear motion stepping ultrasonic motor

The motor includes stator, mover and stator frame. The stator is composed of metal elastomer with two angular vibrator. Piezoelectric ceramics are pasted on root part of two arms of each angular vibrator. The mover is composed of a bar shaped body with even graduated gullets on its low-end face. The face with gullets of bar shaped mover is pressed on the driving head of the stator. Combined action of longitudinal vibration of two vibrating arms with Pi / 2 phase difference in same vibrator makes driving head generate elliptic motion (or circular motion) to drive linear movement of the mover continuously so as to form linear ultrasonic motor. Two vibrating arms in two angular vibrators in same direction are operated alternately to drive stepping movement of the mover so as to form linear stepping ultrasonic motor. Features are: open loop control, simple drive circuit, no cumulative error, corotating / contrarotating stepping movement and continuous linear movement.

Owner:JIANGSU FENGKE ULTRASONIC MOTORS TECH

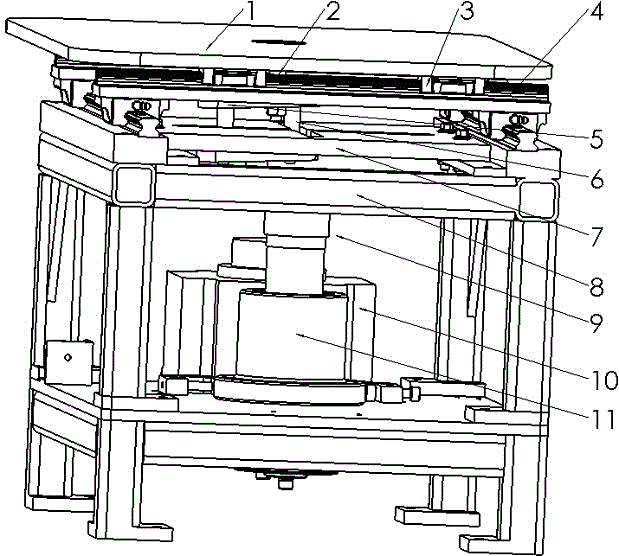

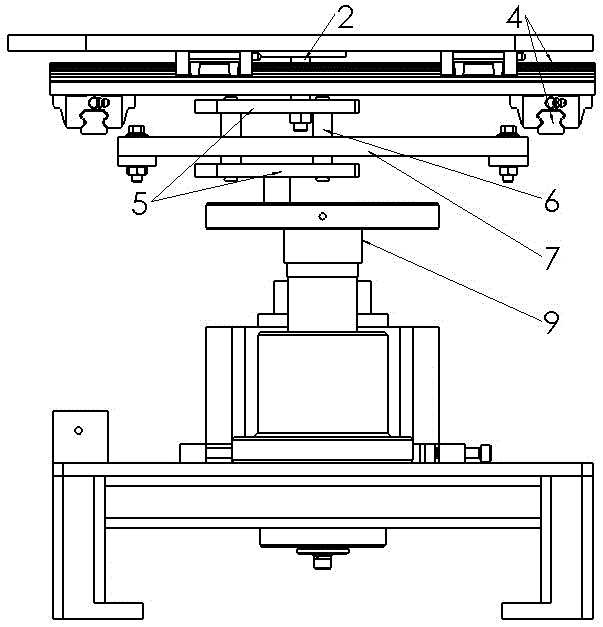

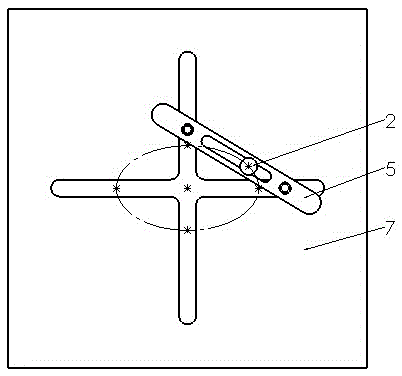

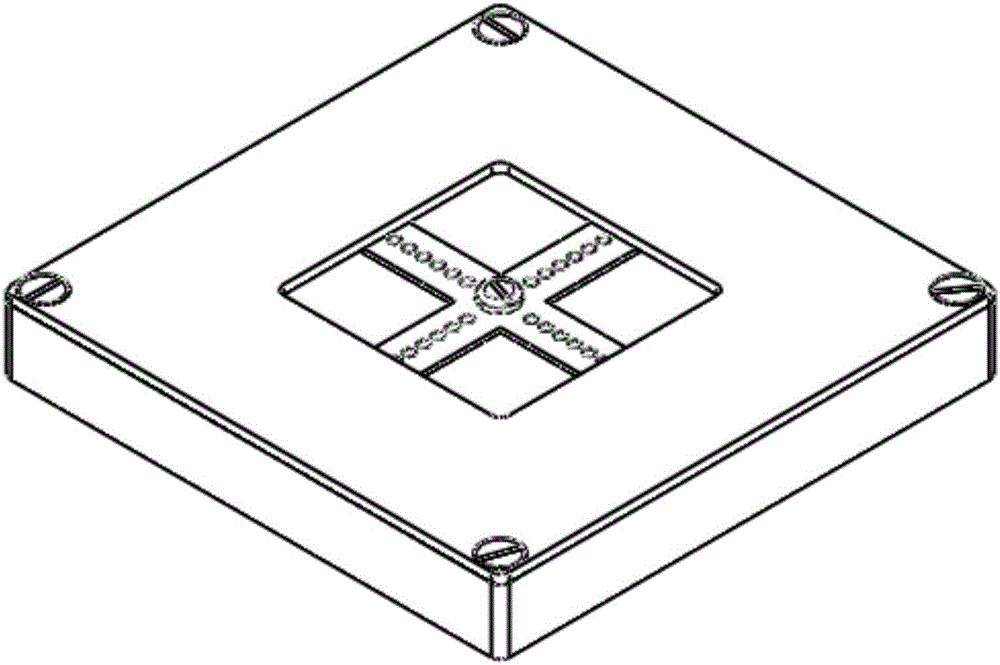

Guide rail type elliptic oscillating mechanism adjustable in eccentricity

InactiveCN105537093AHigh working reliabilityAdjustable eccentricityMechanical vibrations separationElliptic motionEllipse

The invention discloses a guide rail type elliptic oscillating mechanism adjustable in eccentricity. The guide rail type elliptic oscillating mechanism comprises a work plate, a driven shaft, a guide rail sliding block, a groined guide rail, an upper connecting rod, a lower connecting rod, cylindrical sliding blocks, a cross-shaped sliding groove, an upper machine frame, a driving shaft, a motor and a bearing base. When the driving shaft rotates, the cylindrical sliding blocks move along the cross-shaped sliding groove, each point of the upper connecting rod and the lower connecting rod generates an elliptical orbit, the driven shaft drives the work plate to do elliptic motion on the groined guide rail under the driving effect of the upper connecting rod, the position of the driven shaft in an adjusting groove of the upper connecting rod is changed, then the major axis and the minor axis of an ellipse can be changed, and therefore the eccentricity of the elliptic motion can be adjusted. The guide rail type elliptic oscillating mechanism is compact in structure, rigid connection is adopted, and an oscillating system is safe and reliable.

Owner:SHANGHAI UNIV

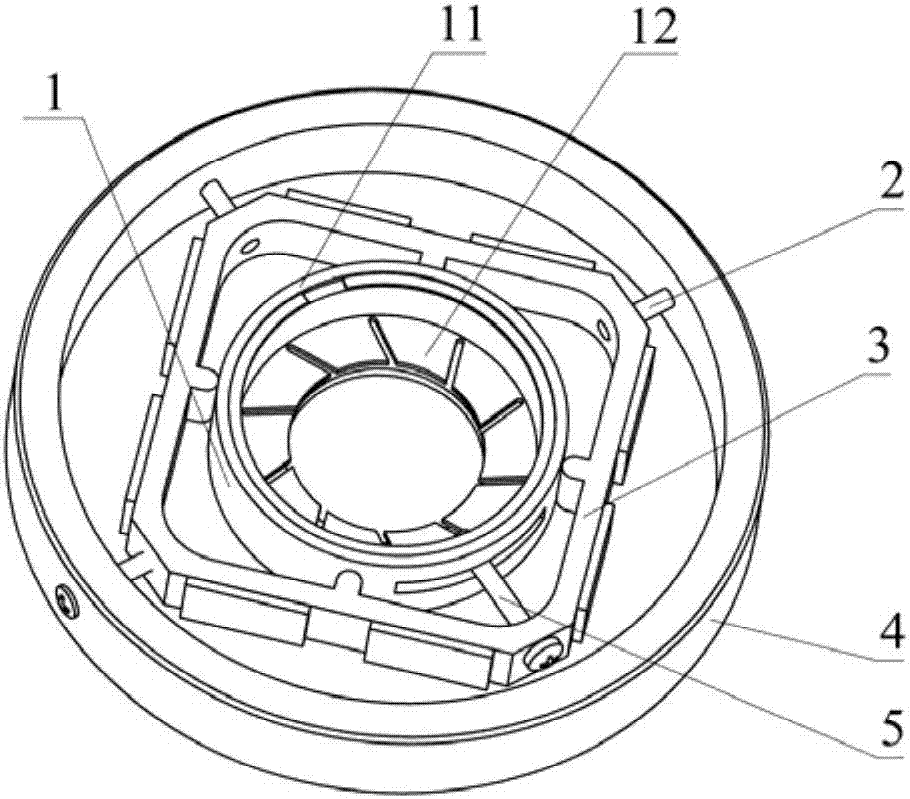

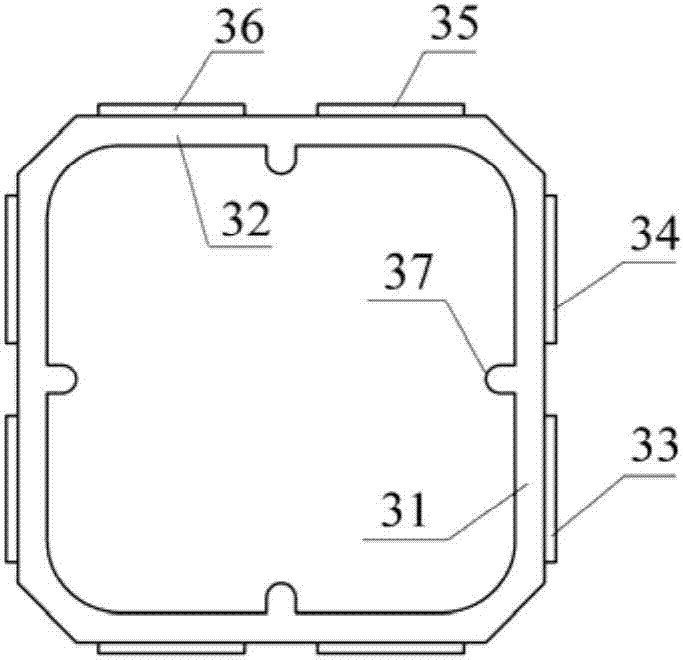

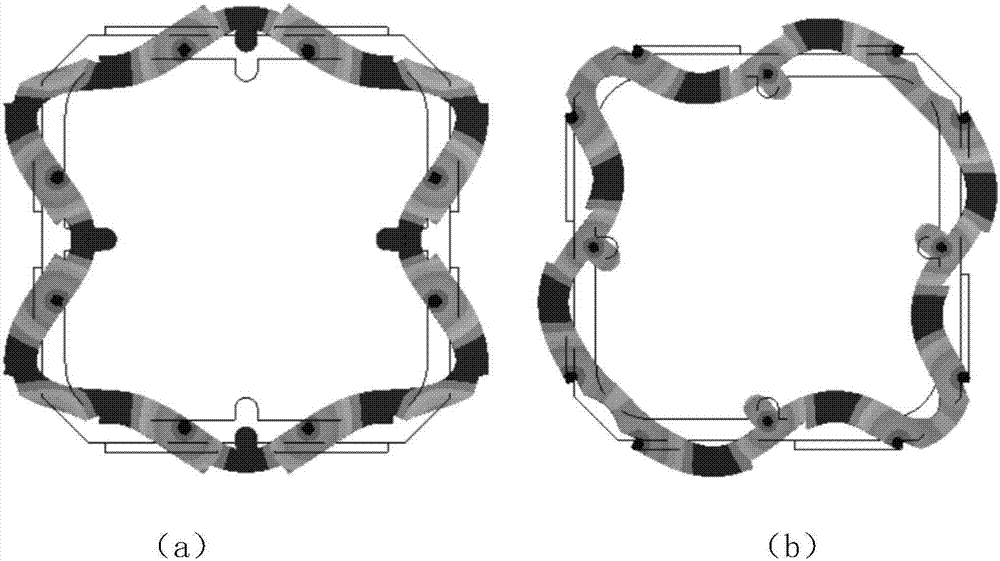

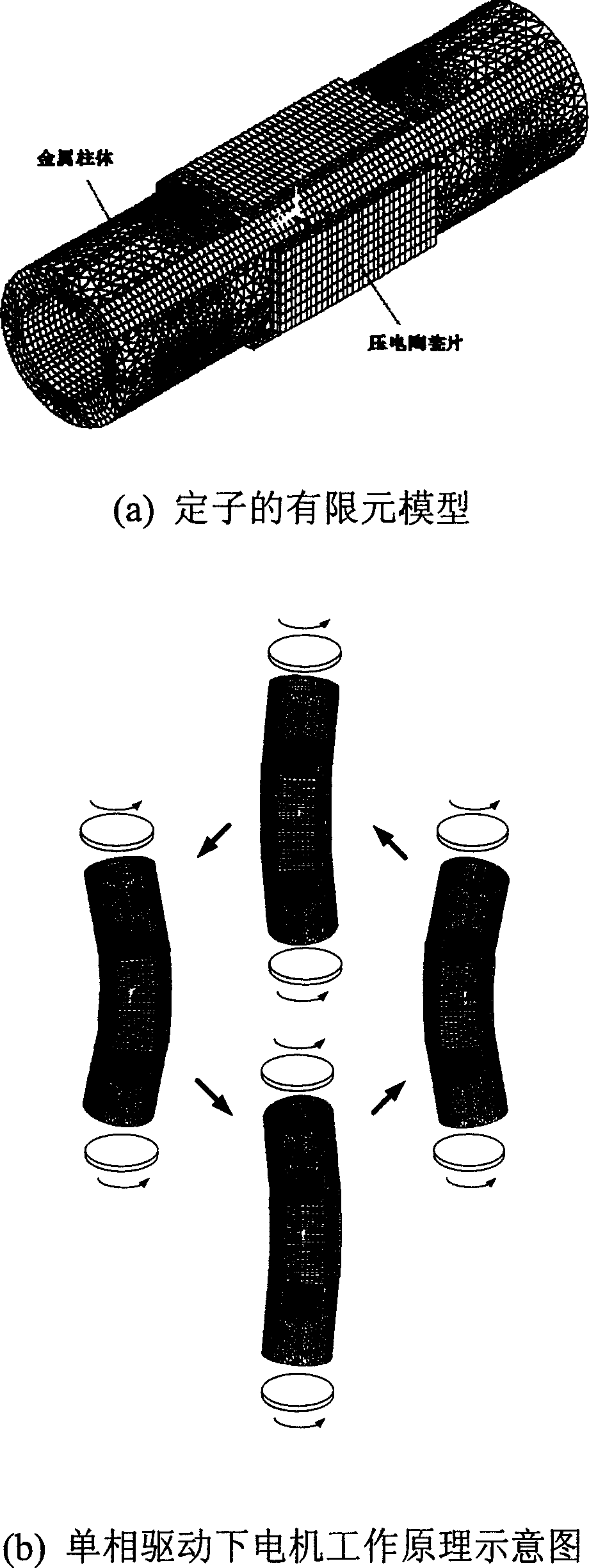

Piezoelectric driving type variable-diaphragm dimming apparatus and method

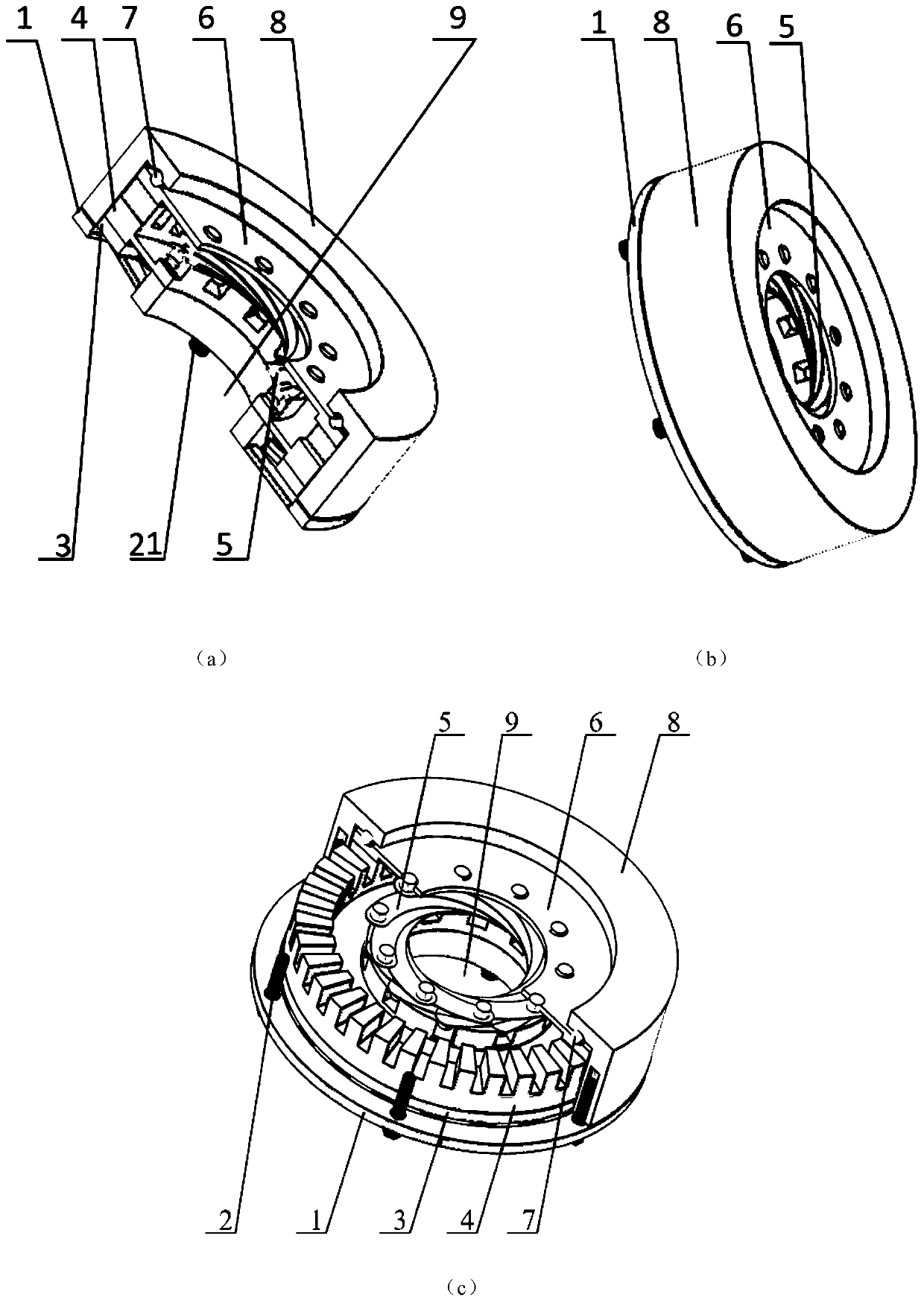

ActiveCN107462963ADimming method is simpleFlat and compact structureMountingsInterference fitCantilevered beam

The invention discloses a piezoelectric driving type variable-diaphragm dimming apparatus and method. The apparatus is composed of a variable diaphragm unit, a piezoelectric actuator and a pedestal. The piezoelectric actuator consists of four cantilever beams and eight piezoelectric ceramics; the four cantilever beams employ square ring beam structures formed by end-to-end connection of metallic elastic base bodies; driving feet in an interference fit relationship with the outer wall of a moving ring of the variable diaphragm unit are arranged at the midpoints of the inner wall of the four cantilever beams; and the eight piezoelectric ceramics are arranged on the outer wall of the two sides of the midpoints of the four cantilever beams correspondingly. When the apparatus works, excitation signals with a phase difference of 90 degrees are applied to the two piezoelectric ceramics on each beam, elliptic motion is caused at the driving feet, the moving ring is driven to make rotation, and thus a diaphragm piece is driven by the moving ring to rotate, so that expansion or contraction of the aperture of a through hole is realized. According to the invention, with piezoelectric driving, the piezoelectric driving type variable-diaphragm dimming apparatus has advantages of flat and compact structure, small size, light weight, high adjustment precision, fast speed, and high reliability; the performances of the optical instrument are improved; and the production cost is lowered.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

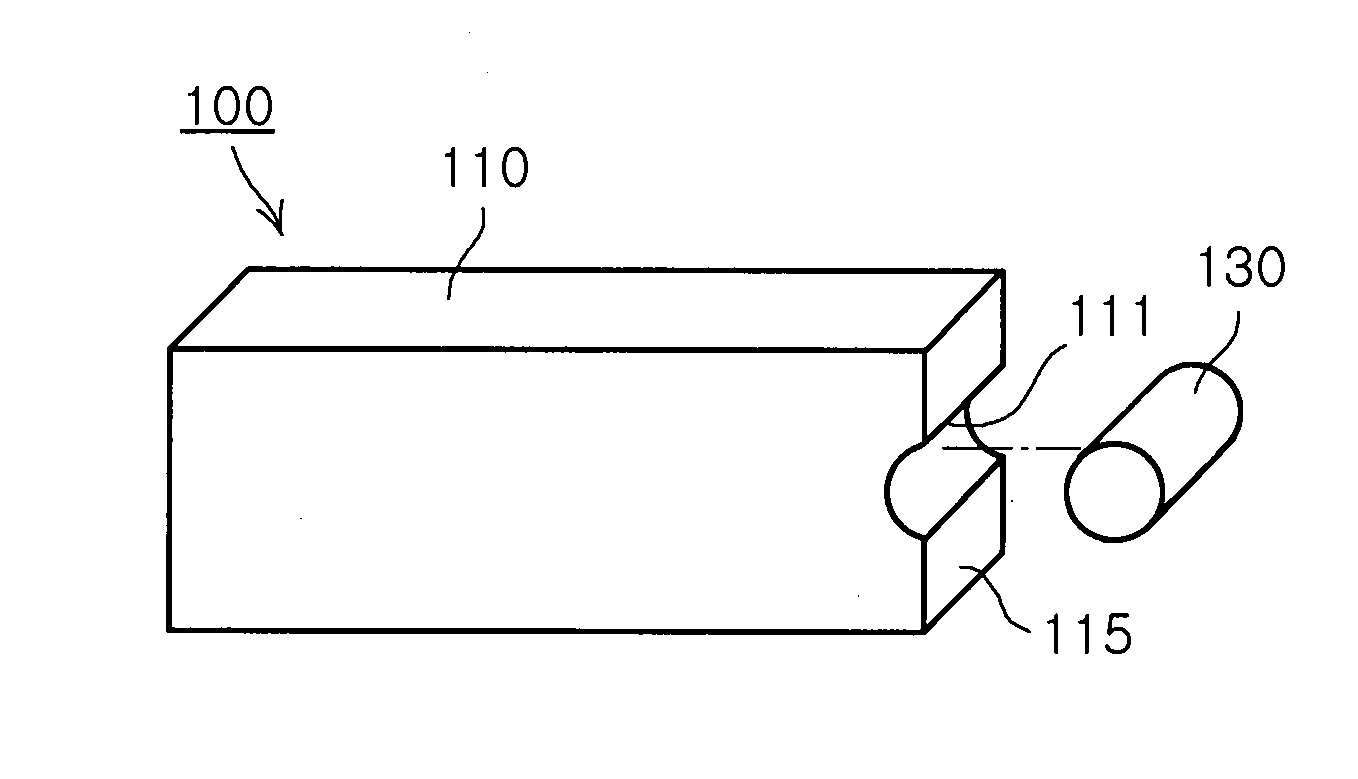

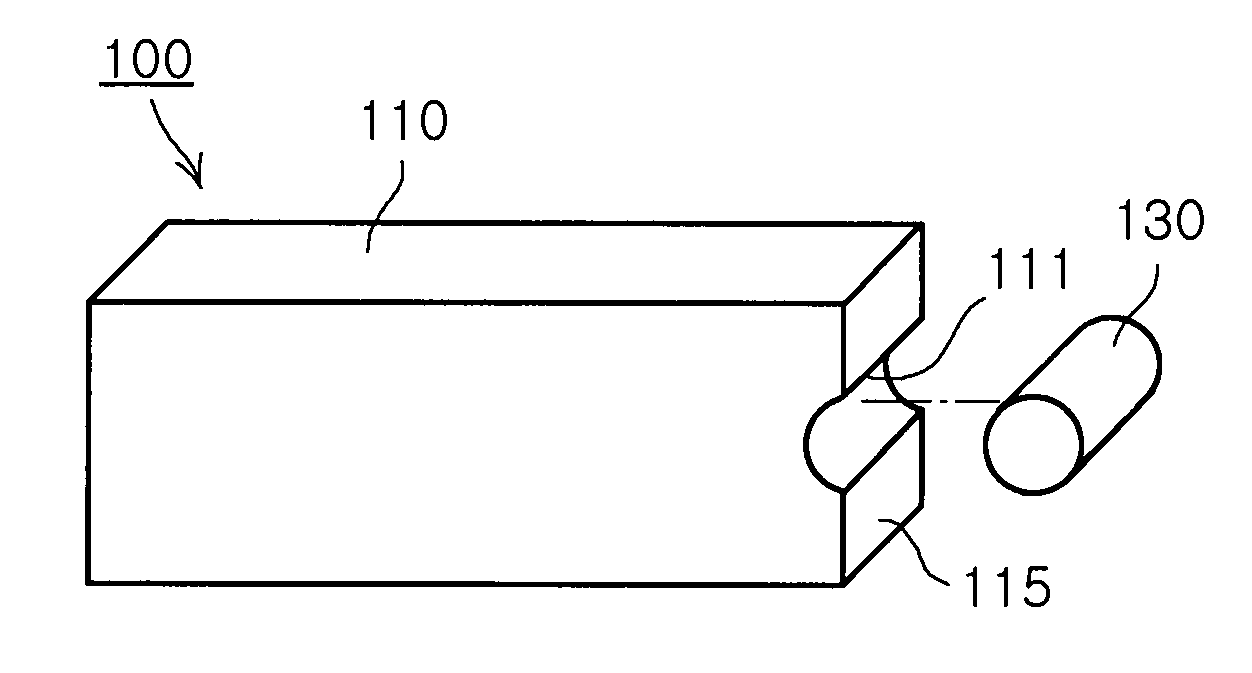

Piezoelectric motor

ActiveUS20080093953A1Minimize impactImprove adhesion strengthPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesResonanceElliptic motion

A piezoelectric motor for generating an elliptic motion by adding a longitudinal vibration to a bending-direction vibration is provided. The piezoelectric motor includes a piezoelectric member which generates a first vibration mode and a second vibration mode simultaneously by an applied power and a frictional member of which a portion is insertedly attached into a concave portion indentedly formed on one side of the piezoelectric member, wherein the frictional member is in an elliptic motion by the vibration generated by the piezoelectric member, so that an influence of the attachment of the frictional member to a resonance frequency can be minimized. Accordingly, a driving efficiency of the piezoelectric motor can be improved. In addition, attachment strength of the frictional member can be improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

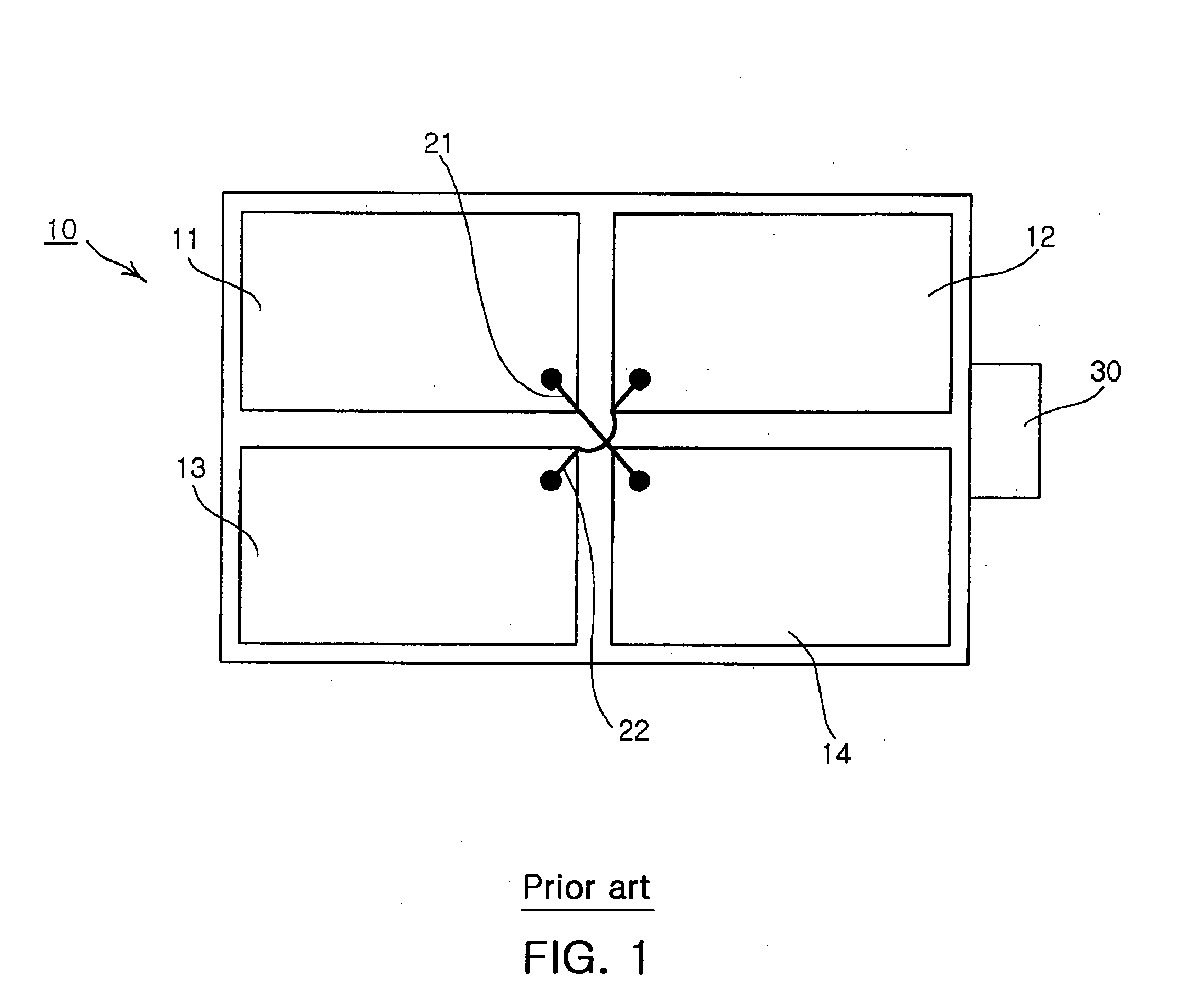

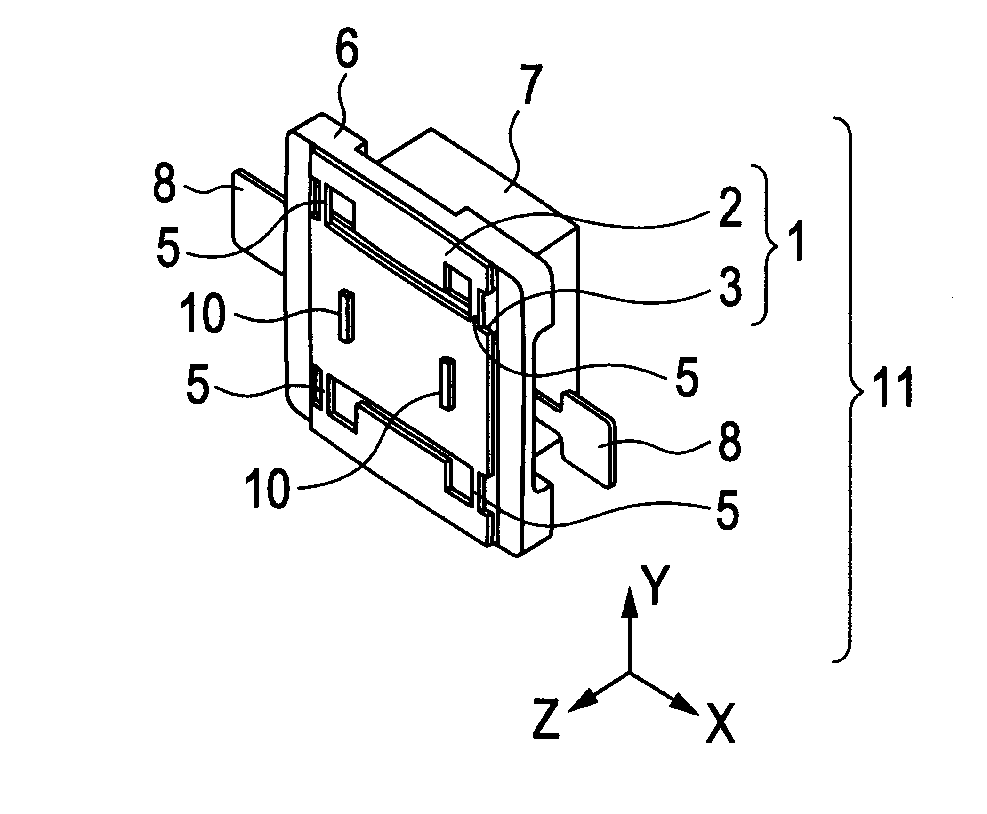

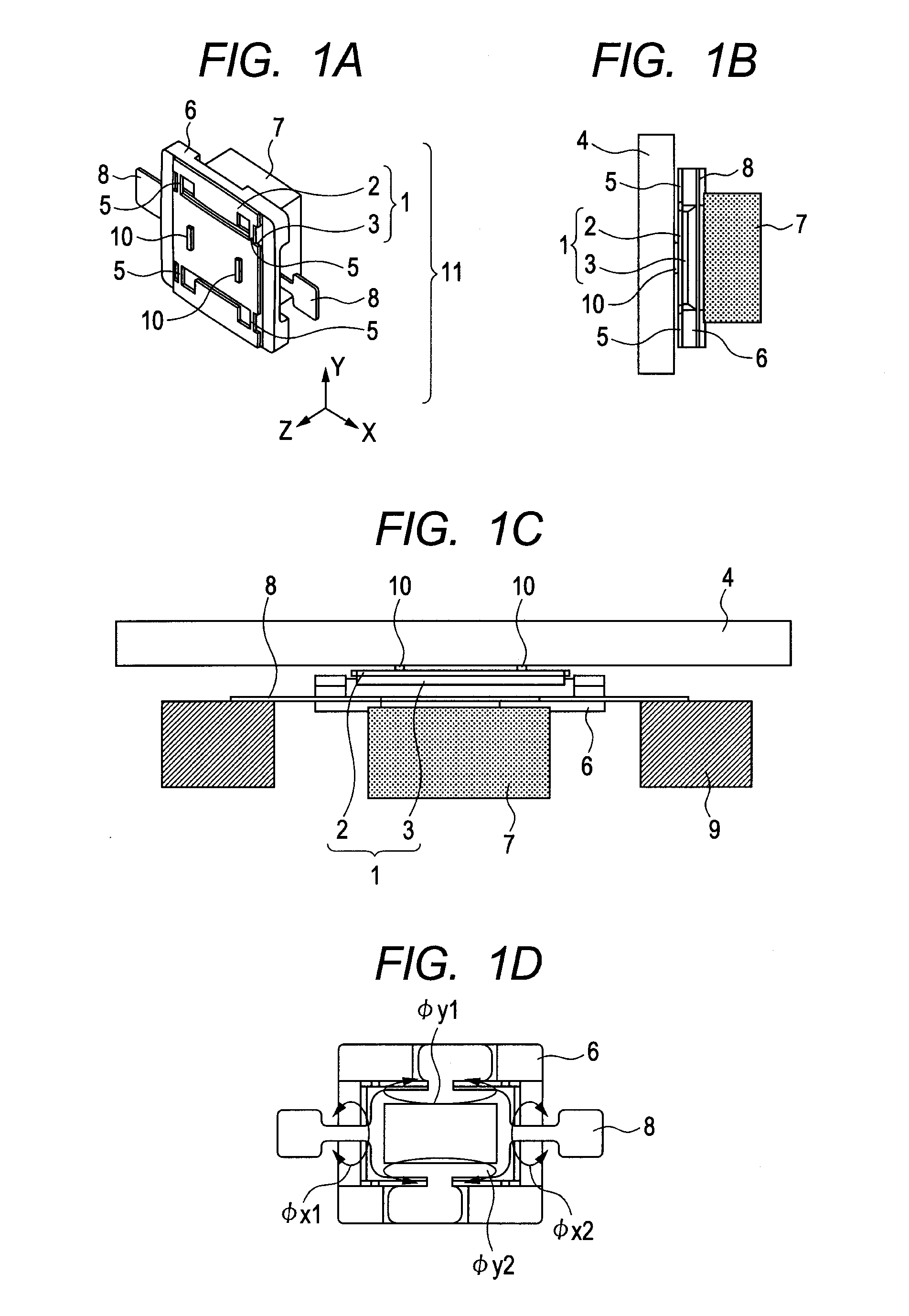

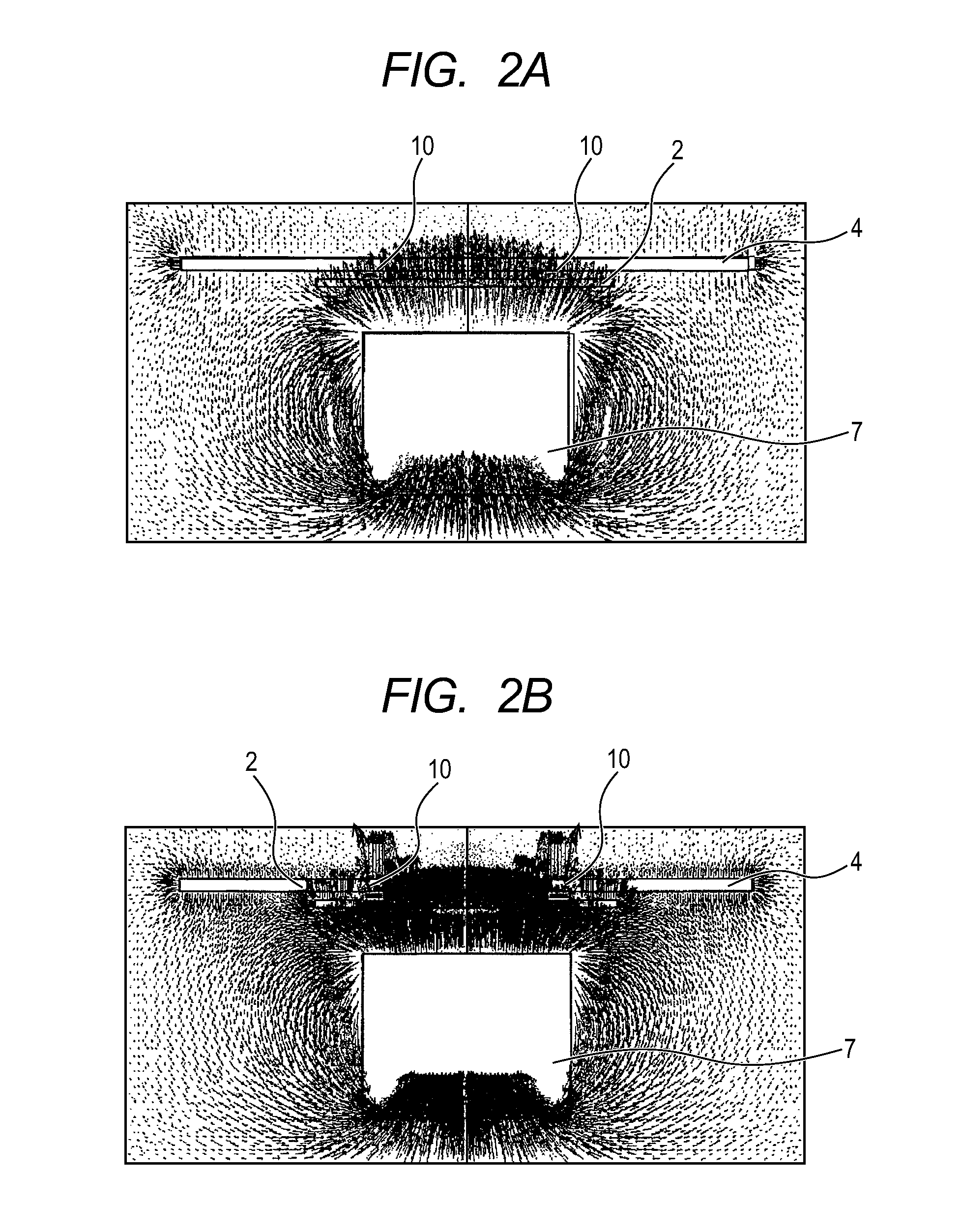

Vibration wave actuator

InactiveUS20110278987A1Enhances pressure-contact forceSimple structureTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElliptic motionMechanical energy

Provided is a vibration wave actuator including: a vibrator including at least an electro-mechanical energy conversion element and an elastic body to which the electro-mechanical energy conversion element is joined, the elastic body including a contact portion formed therein, the vibrator being configured to provide elliptic motion to the contact portion; and a driven element that is in pressure contact with the contact portion of the vibrator, the driven element being moved by the elliptic motion, wherein the vibration wave actuator includes a vibrator holding portion that holds the vibrator via a first elastic member having a stiffness lower than that of the vibrator; and wherein a magnet is arranged on the vibrator holding portion, the driven element includes a magnetic substance, and the contact portion of the vibrator and the driven element are brought into pressure contact with each other by an attraction force of the magnet.

Owner:CANON KK

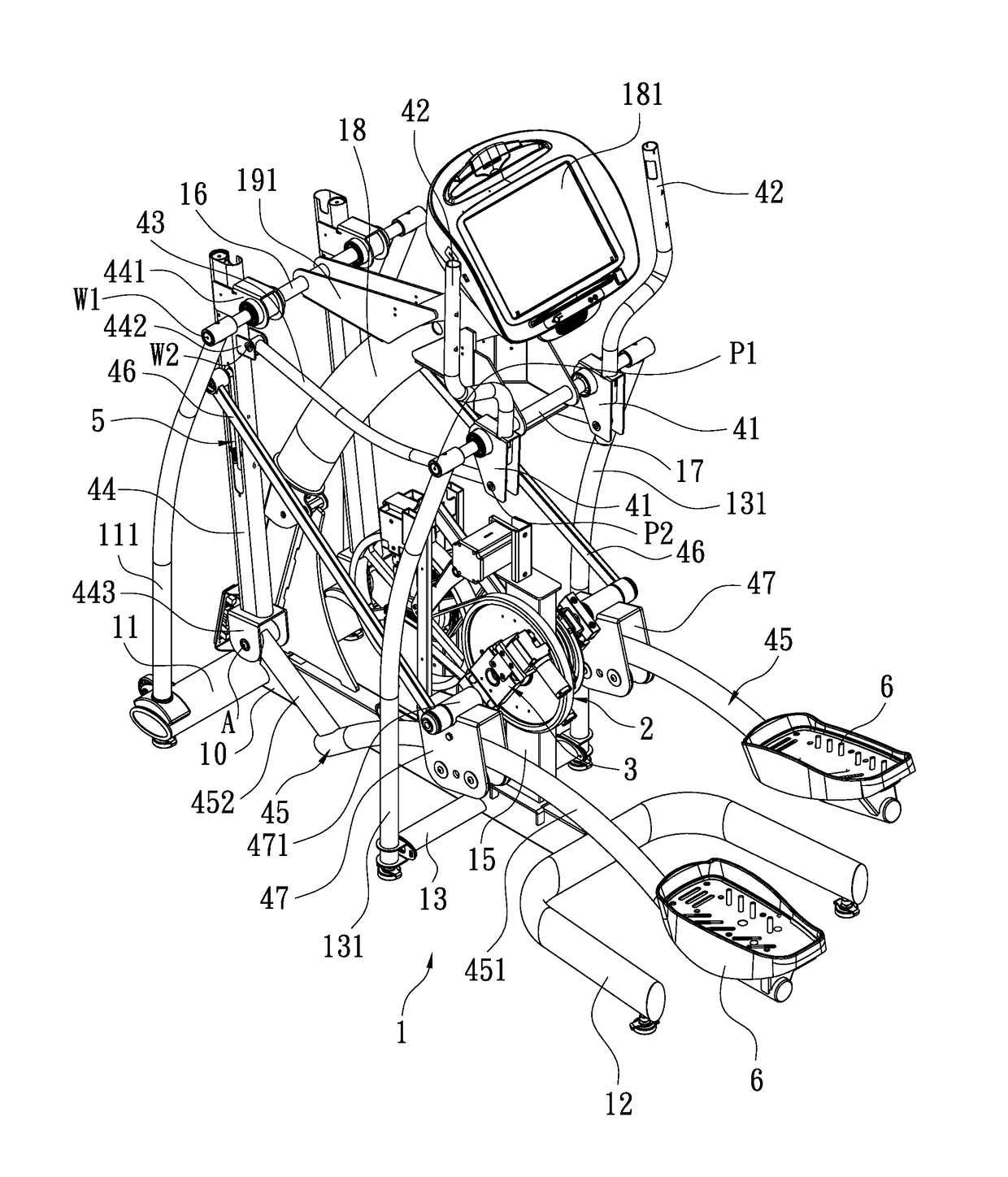

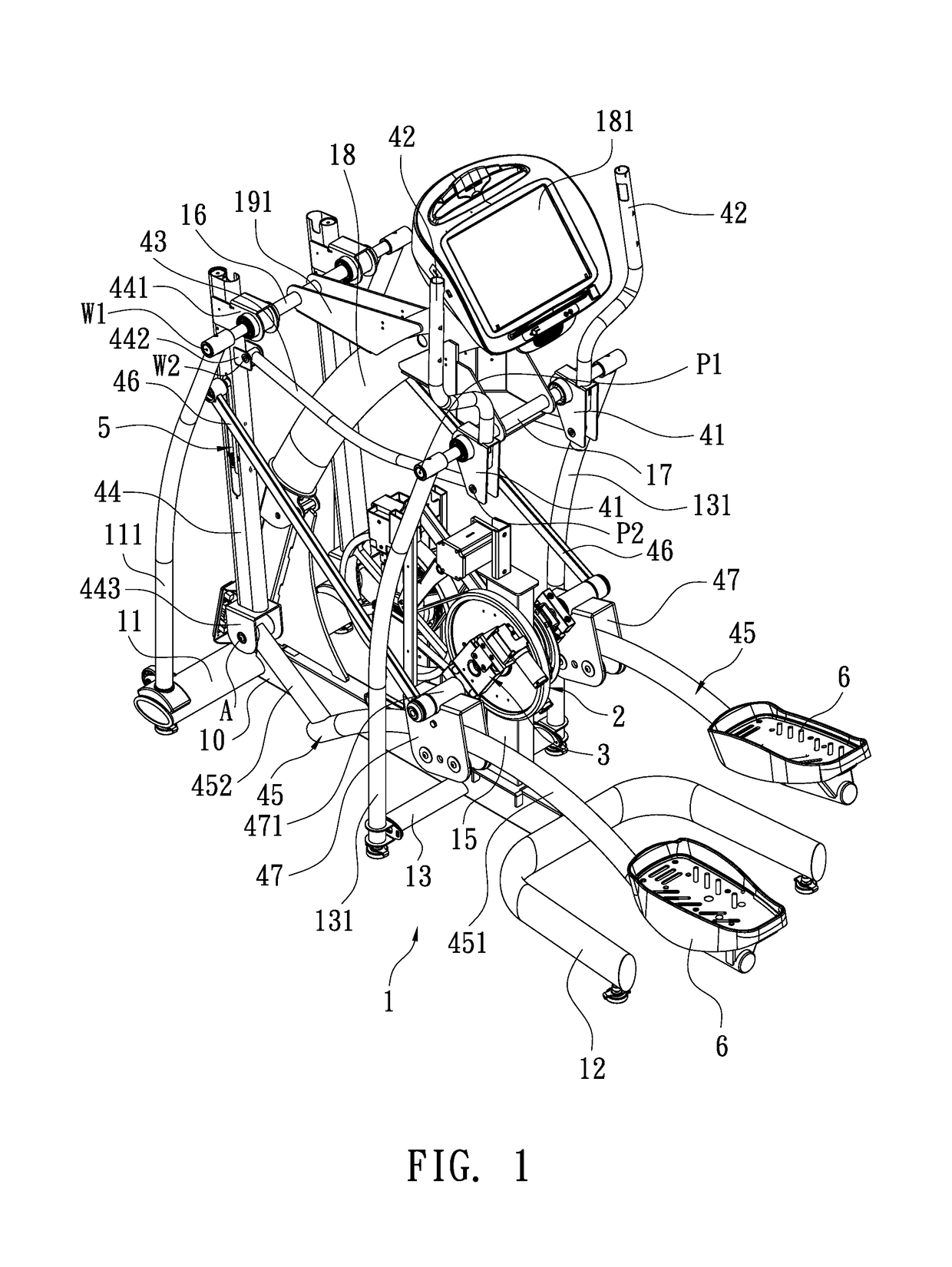

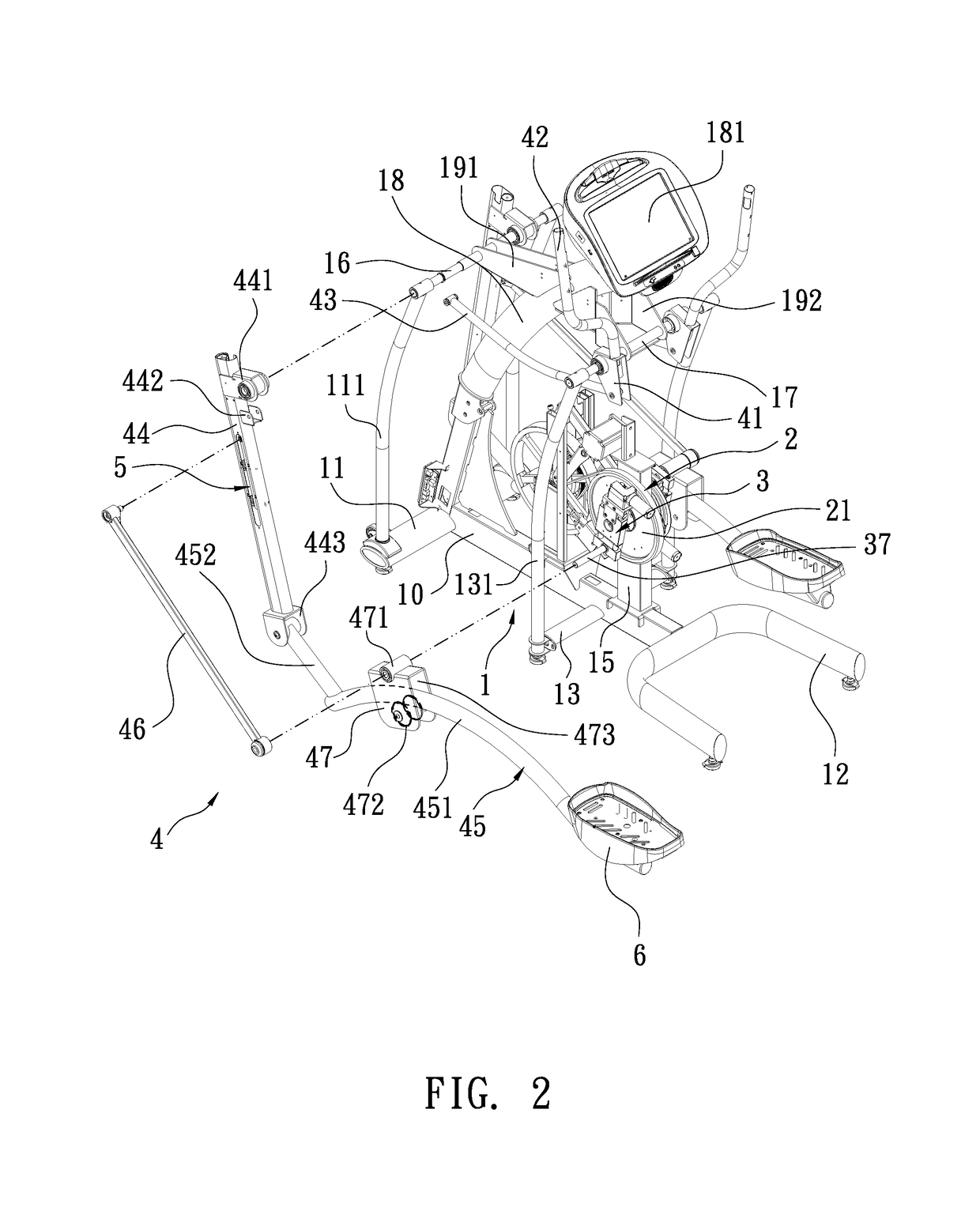

Arm and leg compound exercise machine

InactiveUS9873014B1Avoid injuryMuscle exercising devicesMovement coordination devicesLeg exerciseElliptic motion

Disclosed is an arm and leg compound exercise machine using a pair of crank units and a lifting device to adjust leg motion track and exercise tension and allow users to timely adjust the exercise strength for leg exercise. When a foot pedal installed onto the arm and leg compound exercise machine is operated, the motion track produced by the foot pedal is an elliptic motion path, and the elliptic motion track is flat and gentle at the top and arc shaped at the bottom, so that the motion track produced by the users' stepping motion is ergonomic for preventing sports injuries.

Owner:SPORTS ART IND

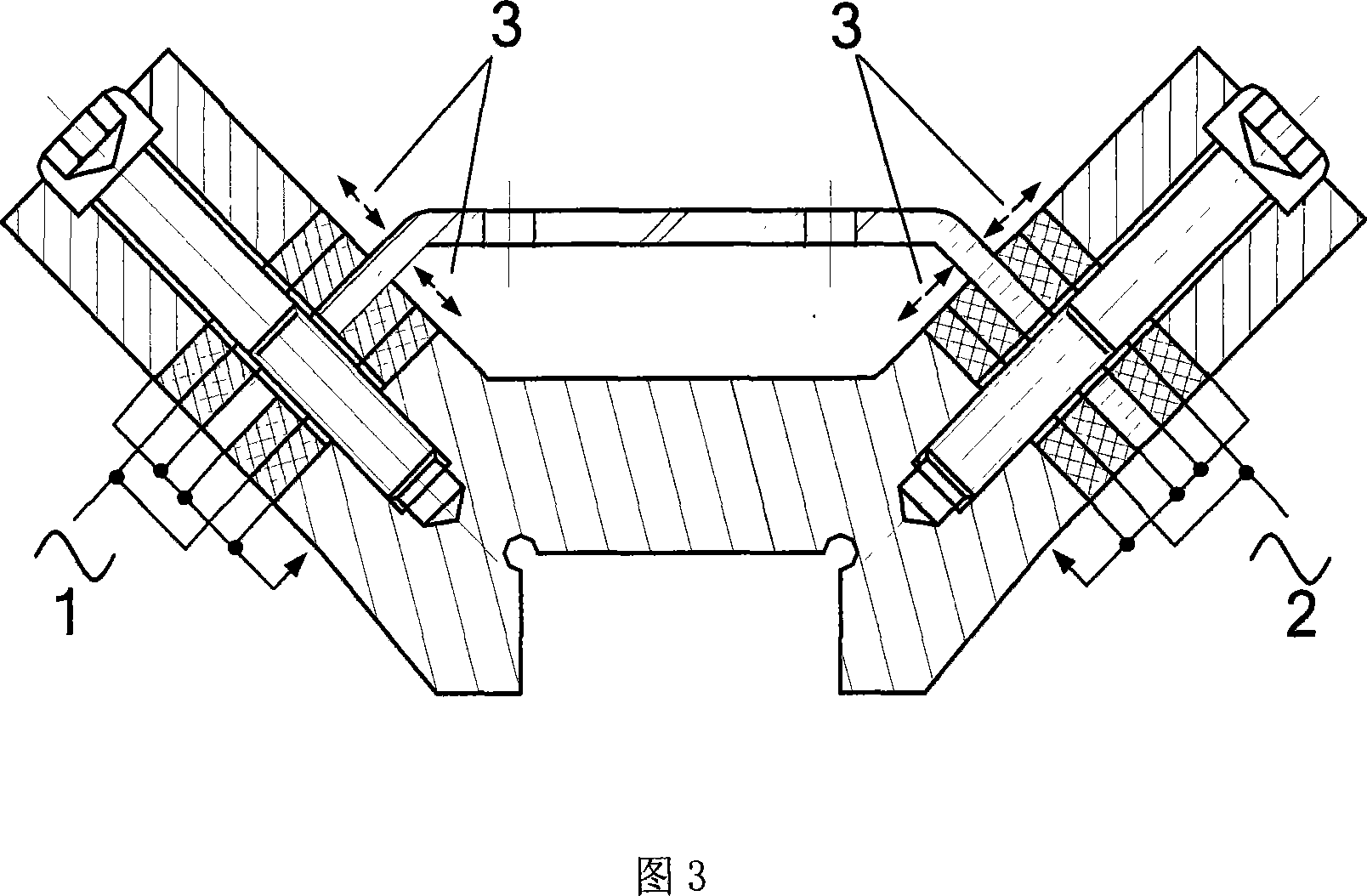

Piezoelectric actuator in d15 shearing mode and precision micropositioner

ActiveCN104104267ASmall sizeHigh outputPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesCantilevered beamPiezoelectric actuators

The invention discloses a piezoelectric actuator in a d15 shearing mode and a precision micropositioner comprising the piezoelectric actuator and belongs to the technical field of precision driving. The piezoelectric actuator in the d15 shearing mode comprises a piezoelectric ceramic main body, and the piezoelectric ceramic main body comprises a substrate, a first piezoelectric ceramic cantilever beam and a second piezoelectric ceramic cantilever beam, wherein the first piezoelectric ceramic cantilever beam and the second piezoelectric ceramic cantilever beam are located on the substrate and can generate d15 shearing mode deformation. The first piezoelectric ceramic cantilever beam and the second piezoelectric ceramic cantilever beam are vertically arranged and are positioned in the length direction of the substrate, the top end of the first piezoelectric ceramic cantilever beam and the top end of the second piezoelectric ceramic cantilever beam are connected with a first flexible inversely V-shaped frame for being connected with an active cell, and the first flexible inversely V-shaped frame converts d15 shearing mode deformation of the first piezoelectric ceramic cantilever beam and the second piezoelectric ceramic cantilever beam into an elliptic motion track. The piezoelectric actuator in the d15 shearing mode has the advantages of being small in size, large in deformation and high in output force.

Owner:PAIHE SCI & TECH HLDG CO LTD BEIJING

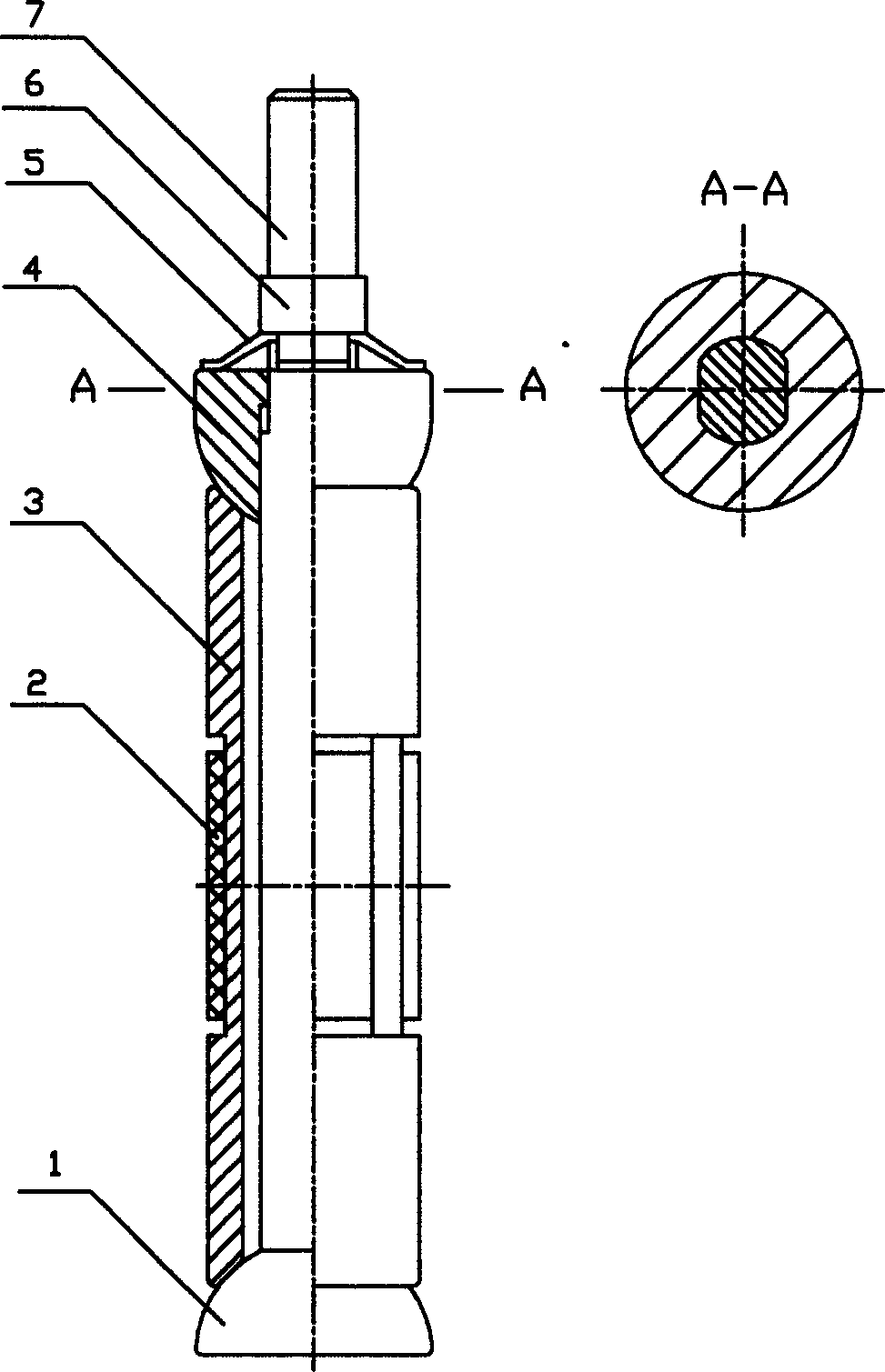

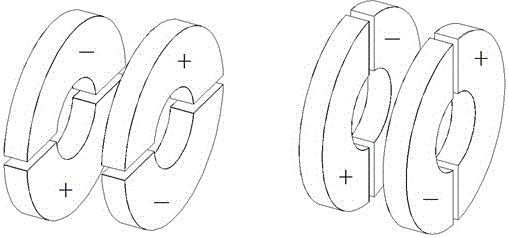

Double-rotar column travelling-wave type single-phase drive ultrsound electric machine

InactiveCN1610238AReduce complexitySimple structurePiezoelectric/electrostriction/magnetostriction machinesElliptic motionElectric machine

The present invention is double rotor column traveling wave type monophase driving ultrasonic motor, and belongs to the field of miniature motor. The ultrasonic motor consists of mainly metal column, piezoelectric ceramic chip, rotors, output shaft, butterfly spring and pressing nut. The piezoelectric ceramic chip is adhered to the flat surface in the middle part of the metal column. The output shaft has one end in semi-spherical structure pressed directly onto the inner conic surface of the metal column while the butterfly spring presses the other semi-spherical rotor onto the other inner conic surface of the metal column. The pre-pressure between the stator and the rotor is obtained via regulating the pressing nut to change the deformation of the butterfly spring. When AC voltage is applied, the points on two ends of the metal column generate elliptic motion and friction force is generated between the stator and the rotor to rotate the rotor, with the motion being output via the shaft.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

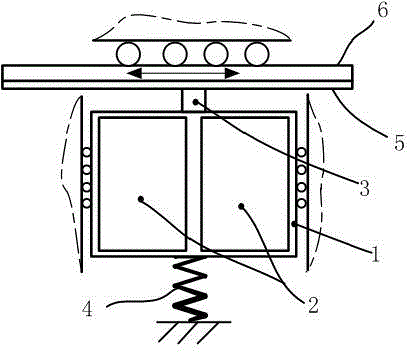

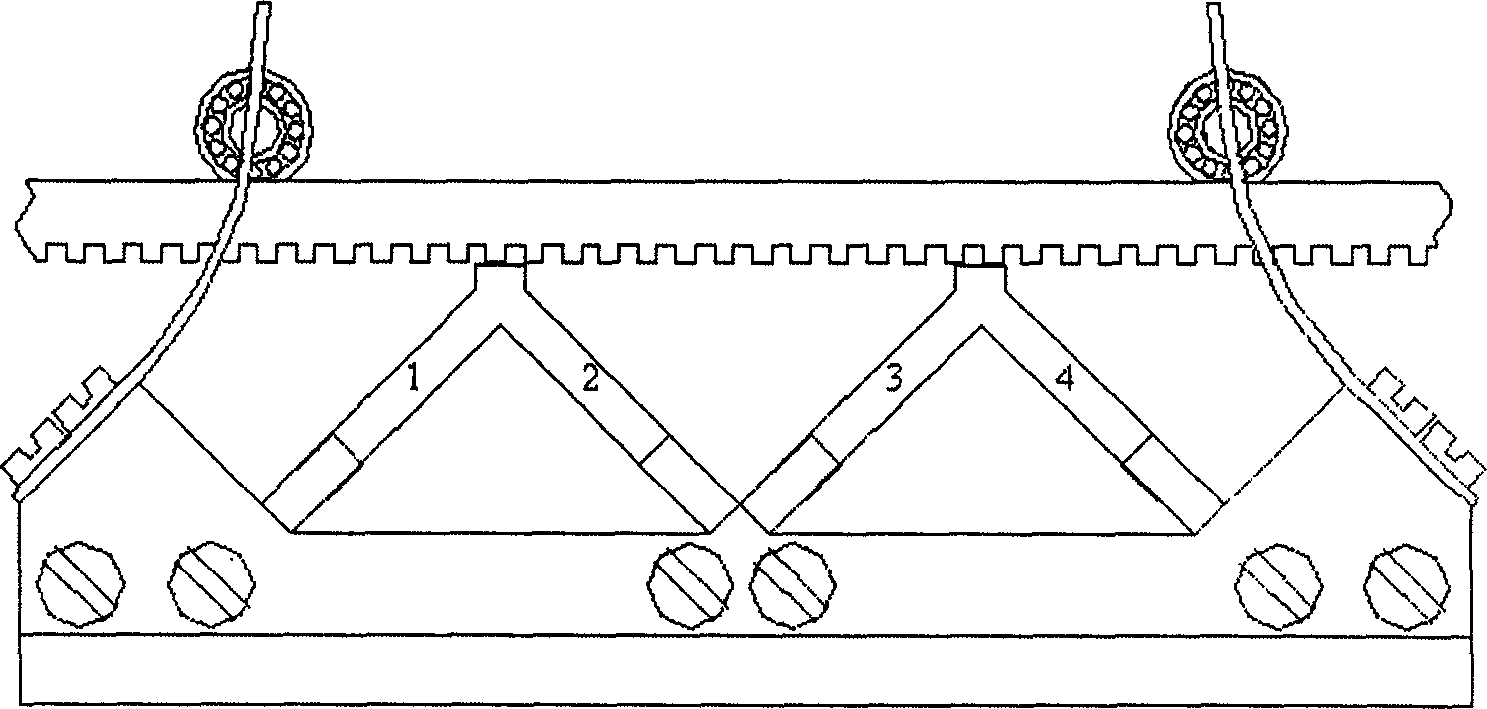

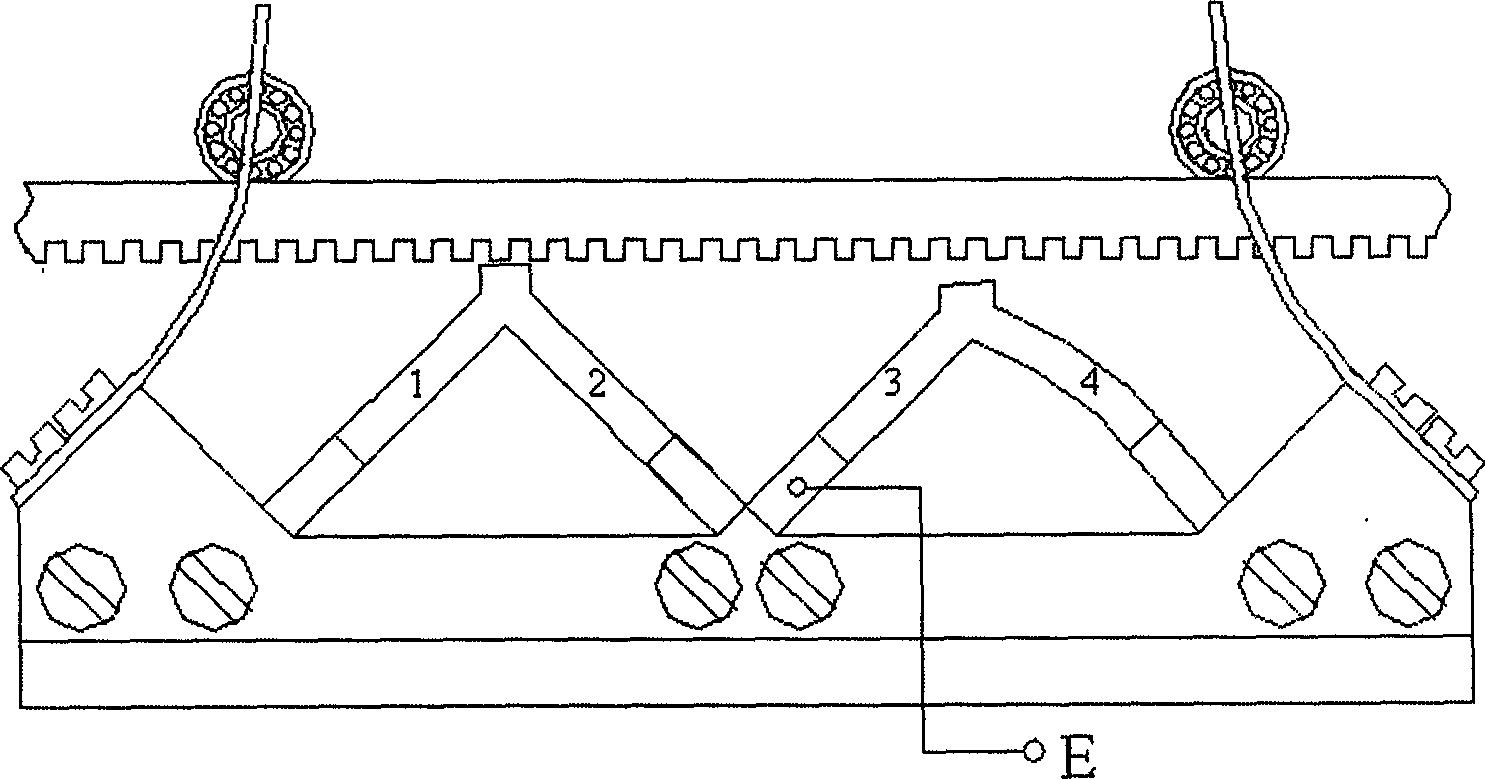

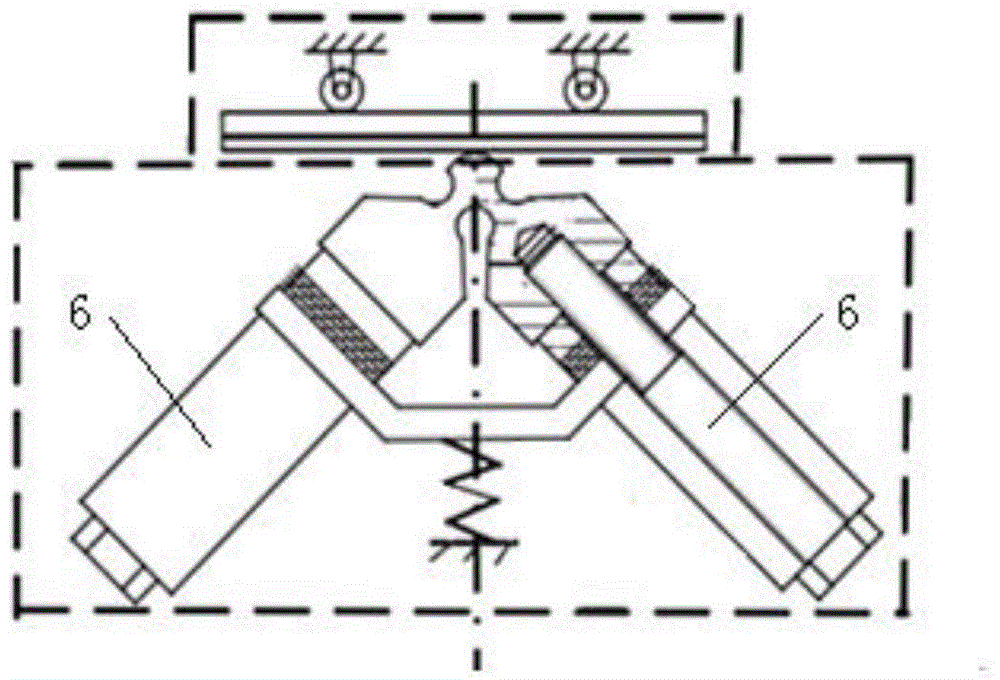

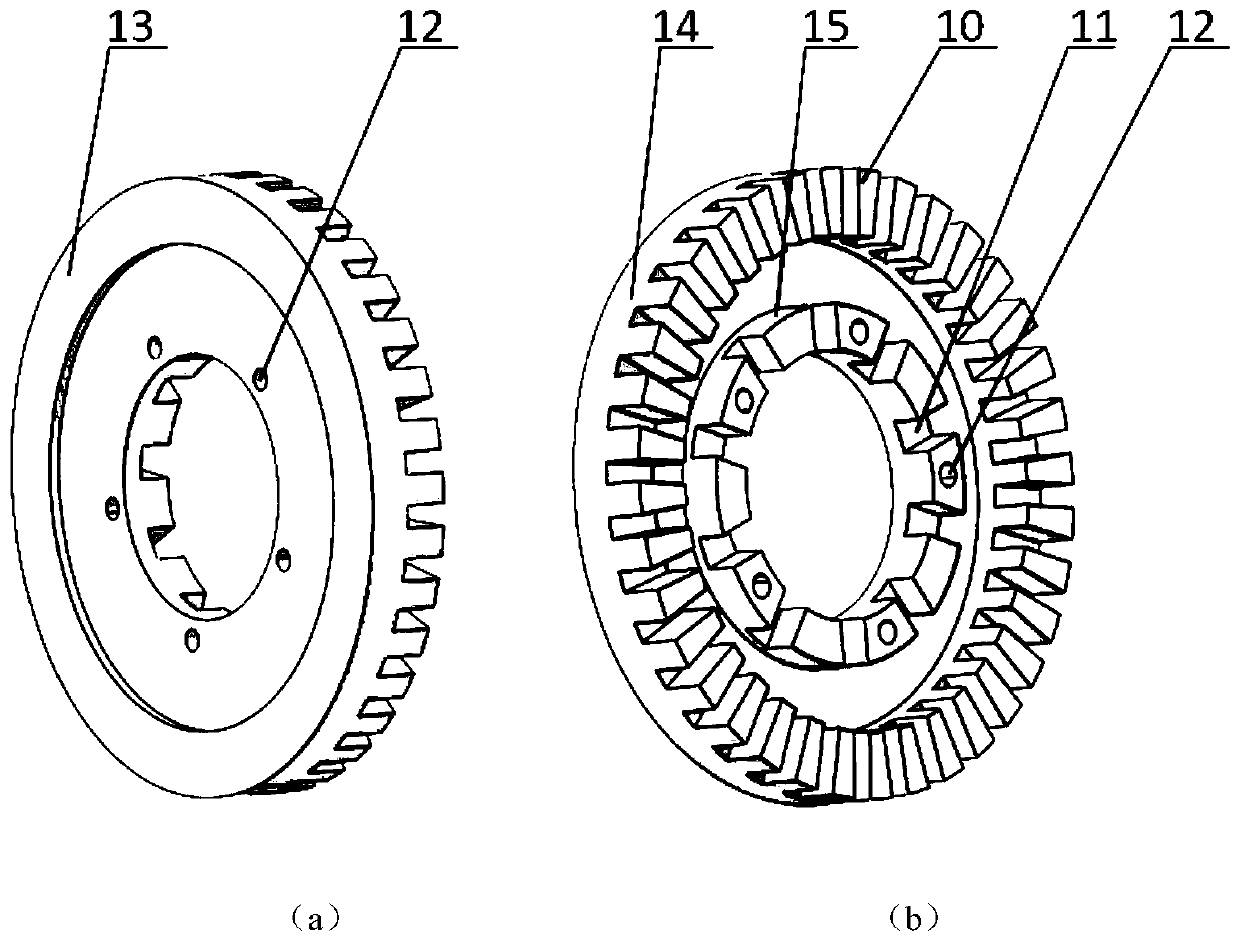

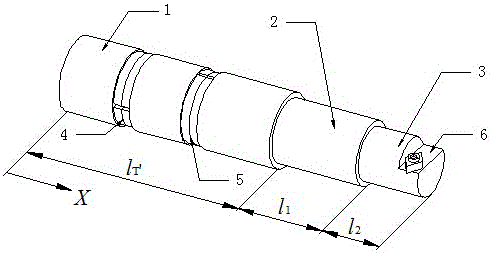

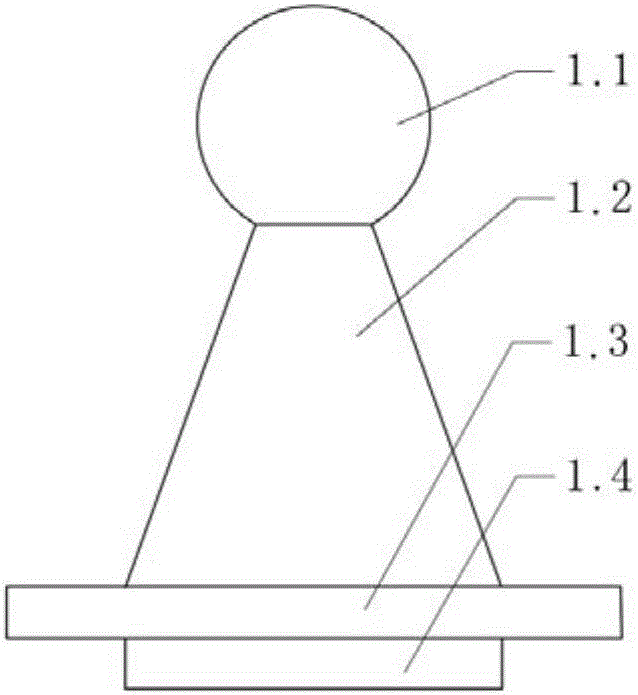

Vertical-bending-twisting compound rotary type ultrasonic motor piezoelectric vibrator

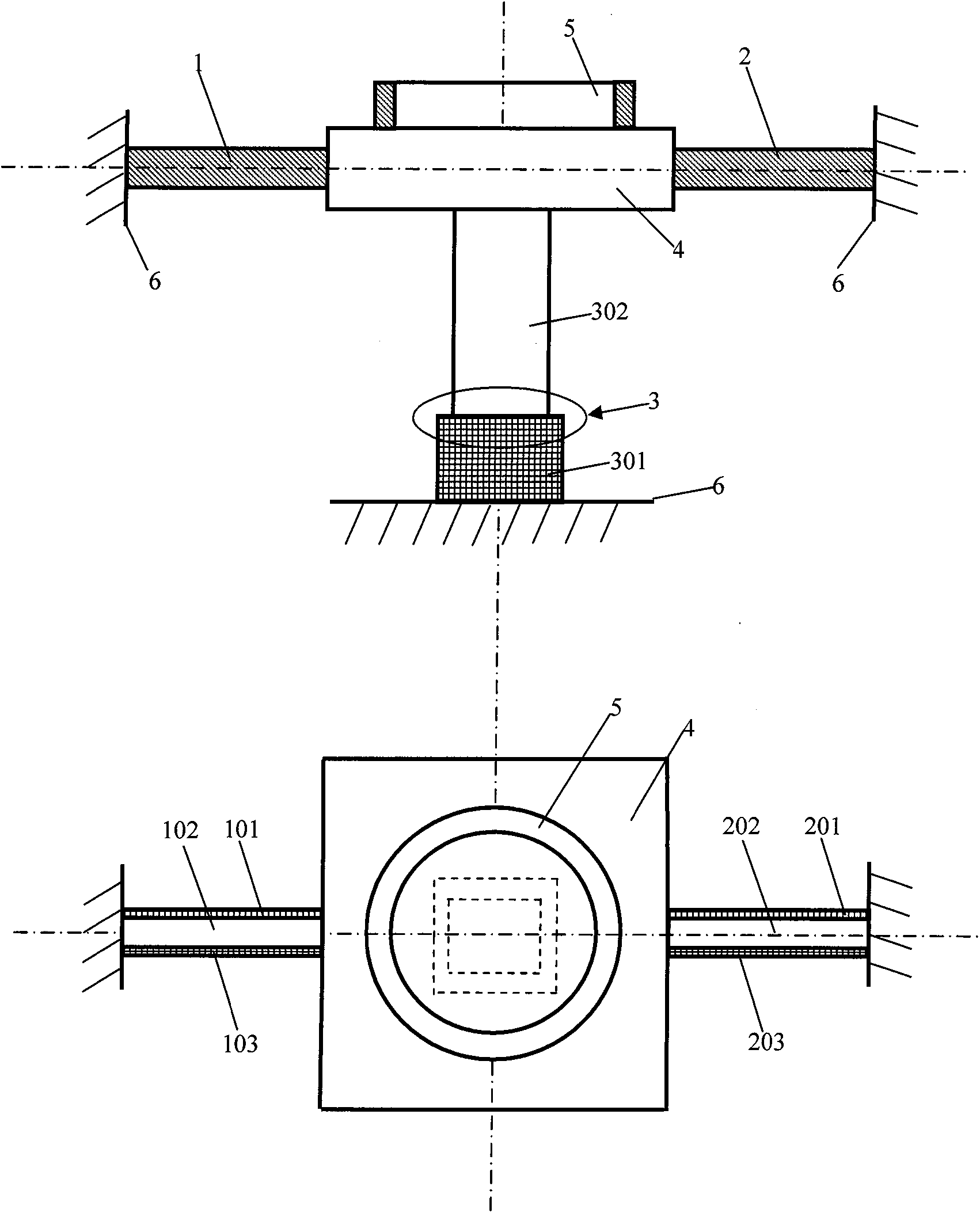

InactiveCN103516251APiezoelectric/electrostriction/magnetostriction machinesElliptic motionClassical mechanics

The invention relates to a vertical-bending-twisting compound rotary type ultrasonic motor piezoelectric vibrator, and belongs to the technical field of ultrasonic motor manufacture. The vibrator is formed by bimorph cantilever beams (1, 2), a piezoelectric stacking-metal compound elastic beam (3), a mass block (4), a circuit contactor (5) and a base (6). The bimorph cantilever beams (1, 2) are arranged at the left side and the right side of the mass block (4) respectively. The piezoelectric stacking-metal compound elastic beam (3) is arranged at the lower end of the mass block (4) and is connected with the base (6). The bimorph cantilever beams (1, 2), the piezoelectric stacking-metal compound elastic beam (3) and the mass block (4) form a T-shaped structural in space. The reverse bending vibration of the bimorph cantilever beams (1, 2) is used and the upward and downward longitudinal vibration of the piezoelectric stacking-metal compound elastic beam (3) is used for enabling the mass points on the surface of the circuit contactor (5) to generate elliptic motion tracks, and the twisting drive to a rotor is realized.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

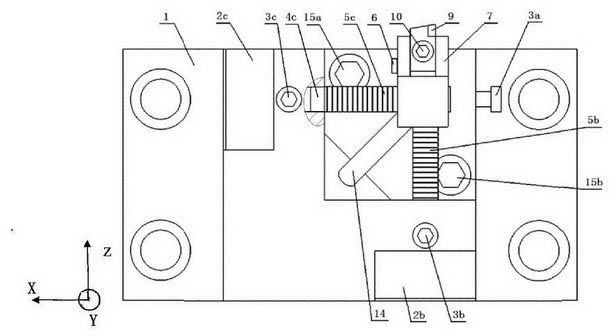

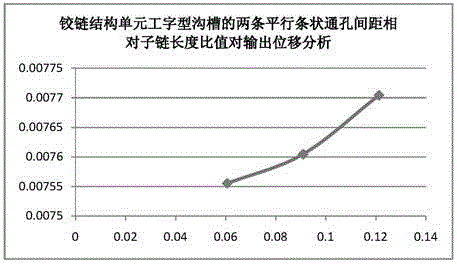

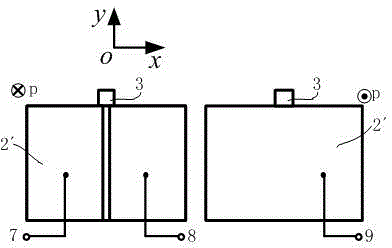

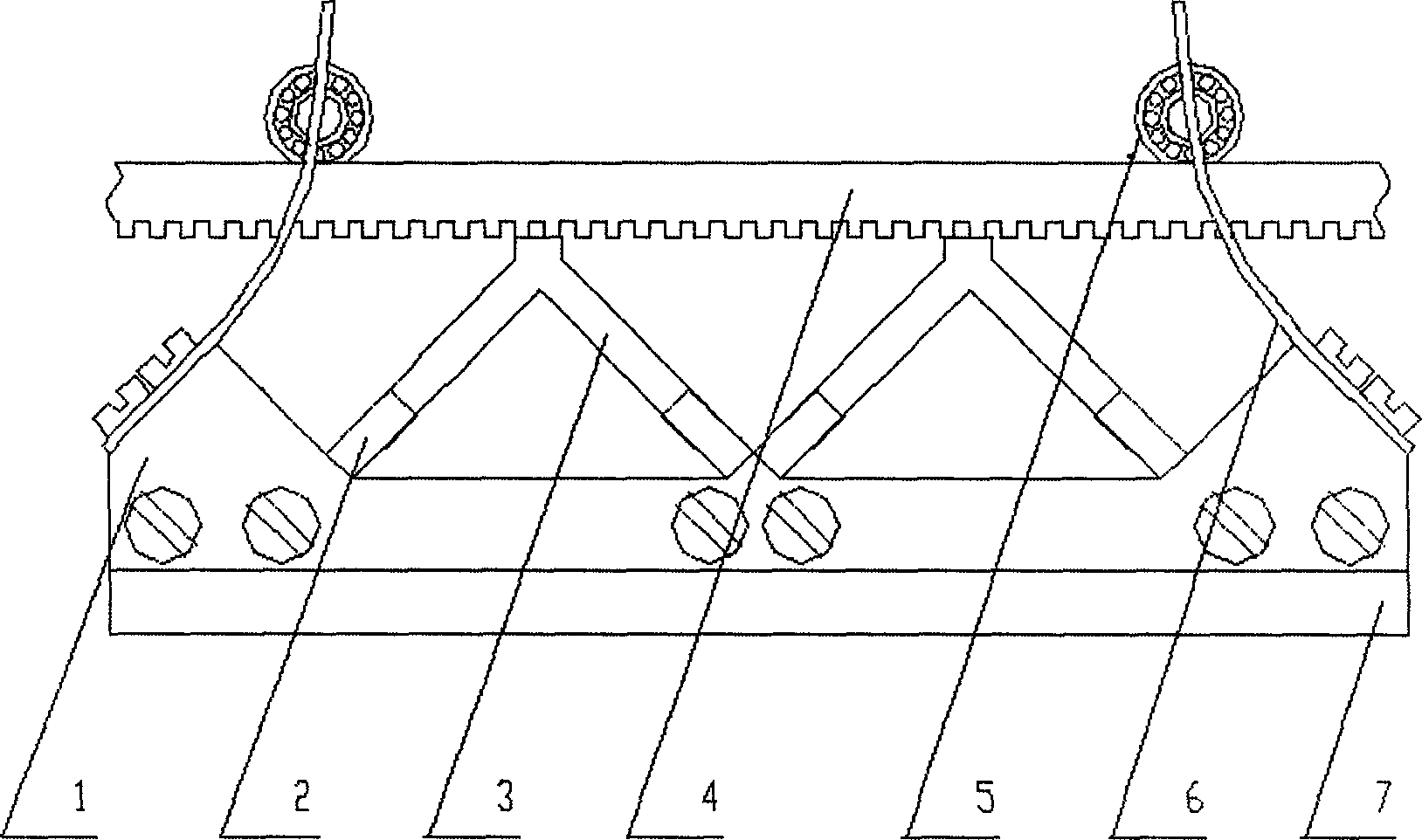

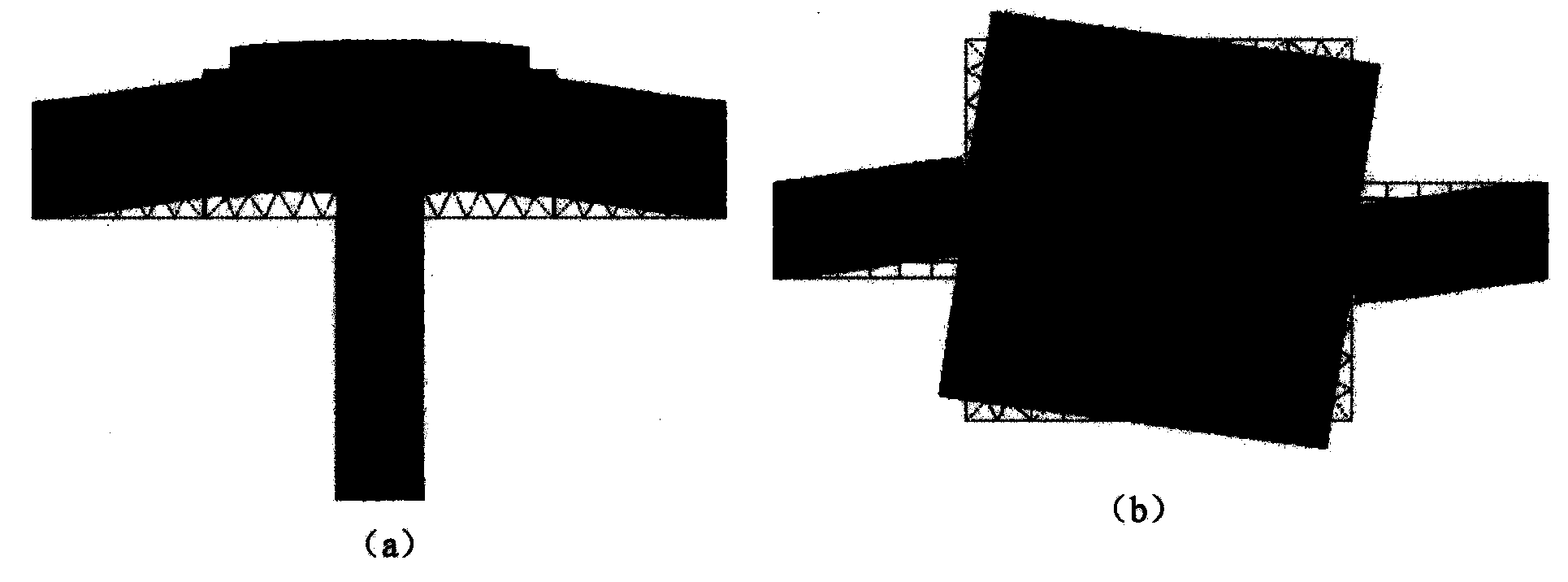

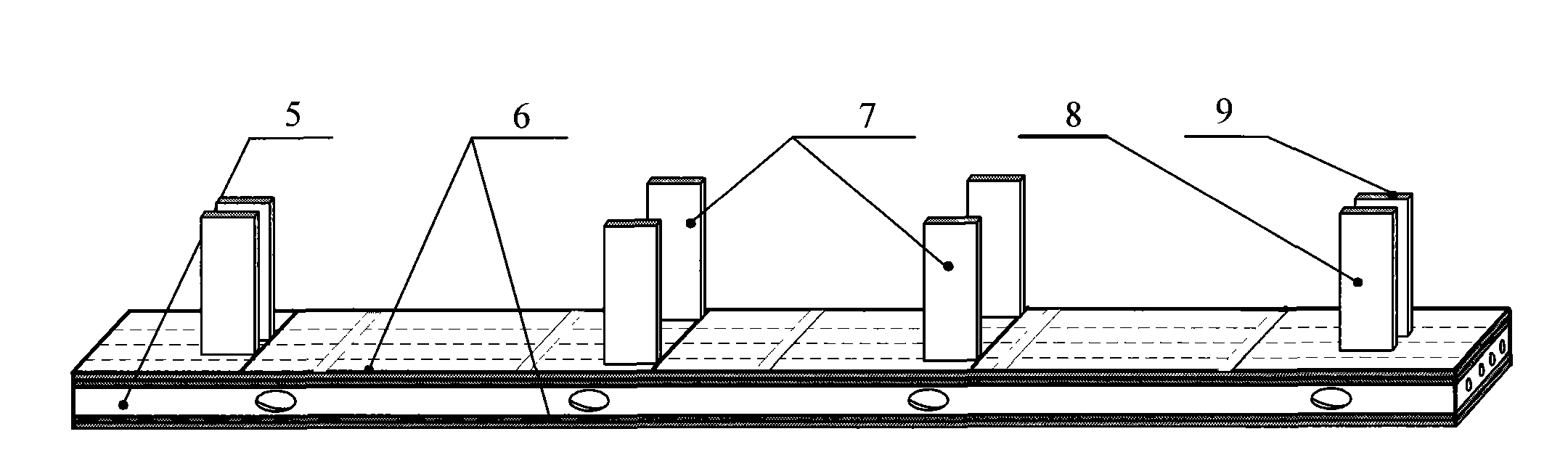

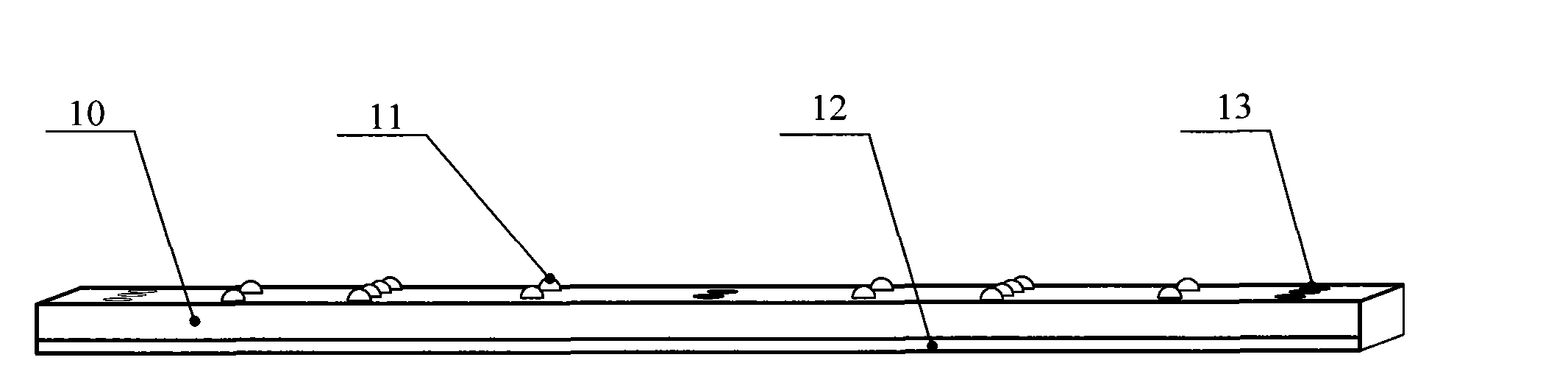

Sandwich I-shaped four-footed linear ultrasonic motor vibrator

ActiveCN102437782AAchieve macro motion outputIncrease amplitudePiezoelectric/electrostriction/magnetostriction machinesElliptic motionTransformer

The invention relates to a sandwich I-shaped four-footed linear ultrasonic motor vibrator, belonging to the technical field of piezoelectric ultrasonic motors. The sandwich I-shaped four-footed linear ultrasonic motor vibrator provided by the invention eliminates various adverse impacts caused by coupling bending vibration in the traditional rectangular four-footed linear ultrasonic motor vibrator. The sandwich I-shaped four-footed linear ultrasonic motor vibrator comprises two horizontal compound beams and one vertical compound beam, wherein the two horizontal compound beams and the vertical compound beam are arranged in an I shape, piezoelectric ceramic wafers on the horizontal compound beam and the vertical compound beam are respectively excited by adopting two-phase voltage, stretching vibration of the piezoelectric ceramic wafers is used for exciting two vibration modes during vibration, the two vibration modes are superposed onto four driving feet, namely terminals of four horizontal amplitude transformers, surface material points of the driving feet generate an elliptic motion trail, and when the four driving feet and an active cell at the two sides of the four driving feet are contacted under certain pre-pressure, macroscopic motion output of the active cell is realized by virtue of friction coupling between the driving feet and the active cell. The sandwich I-shaped four-footed linear ultrasonic motor vibrator provided by the invention is applicable to manufacturing of ultrasonic motors.

Owner:HARBIN INST OF TECH

Piezoelectric motor

ActiveUS7576474B2Minimize impactImprove adhesion strengthPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesResonanceElliptic motion

A piezoelectric motor for generating an elliptic motion by adding a longitudinal vibration to a bending-direction vibration is provided. The piezoelectric motor includes a piezoelectric member which generates a first vibration mode and a second vibration mode simultaneously by an applied power and a frictional member of which a portion is insertedly attached into a concave portion indentedly formed on one side of the piezoelectric member, wherein the frictional member is in an elliptic motion by the vibration generated by the piezoelectric member, so that an influence of the attachment of the frictional member to a resonance frequency can be minimized. Accordingly, a driving efficiency of the piezoelectric motor can be improved. In addition, attachment strength of the frictional member can be improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

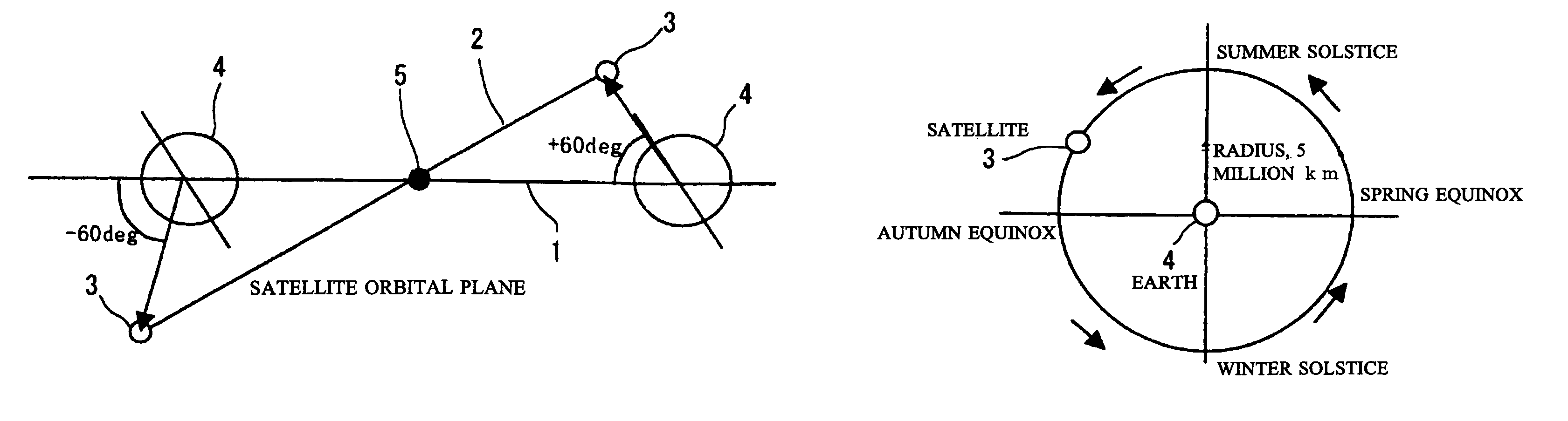

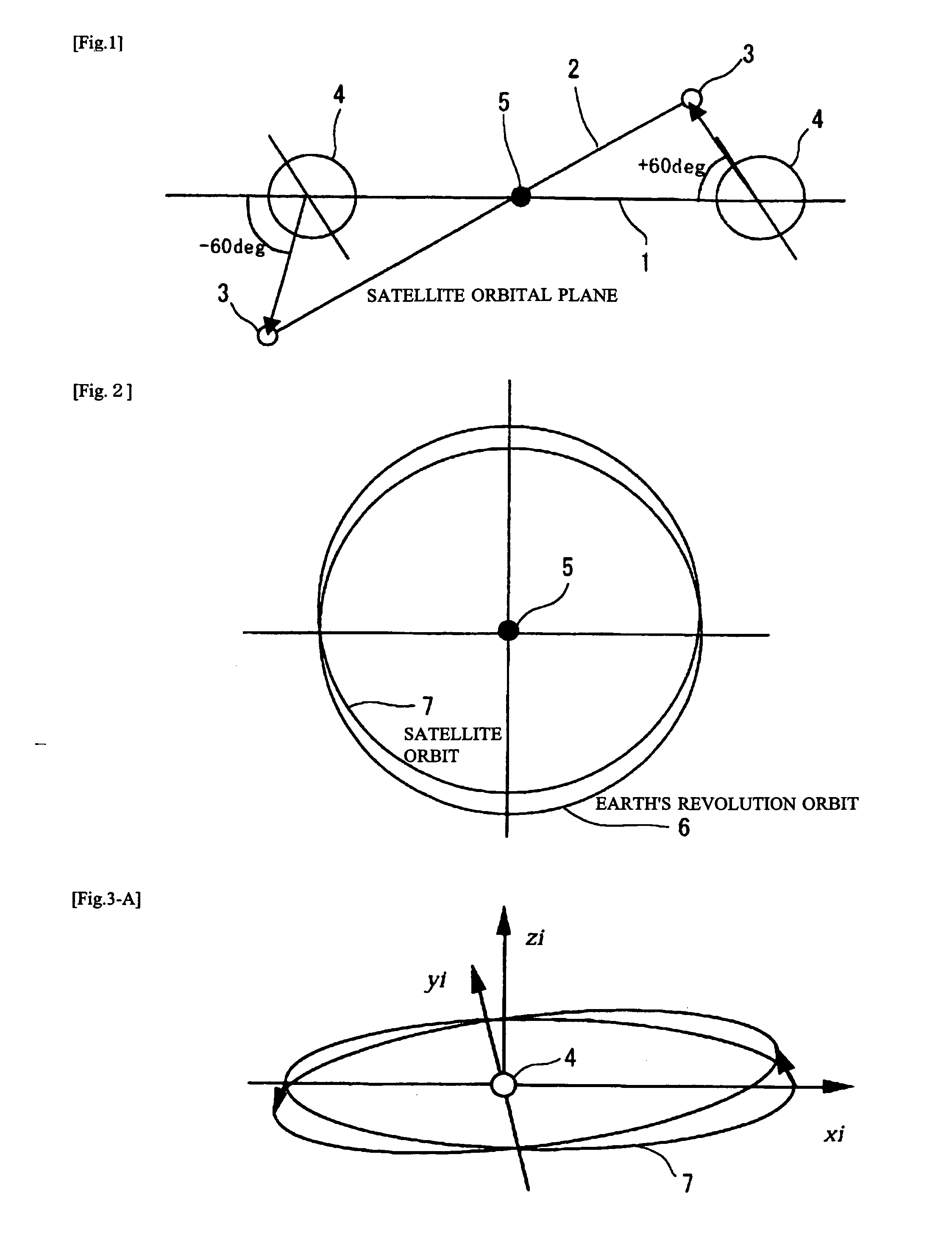

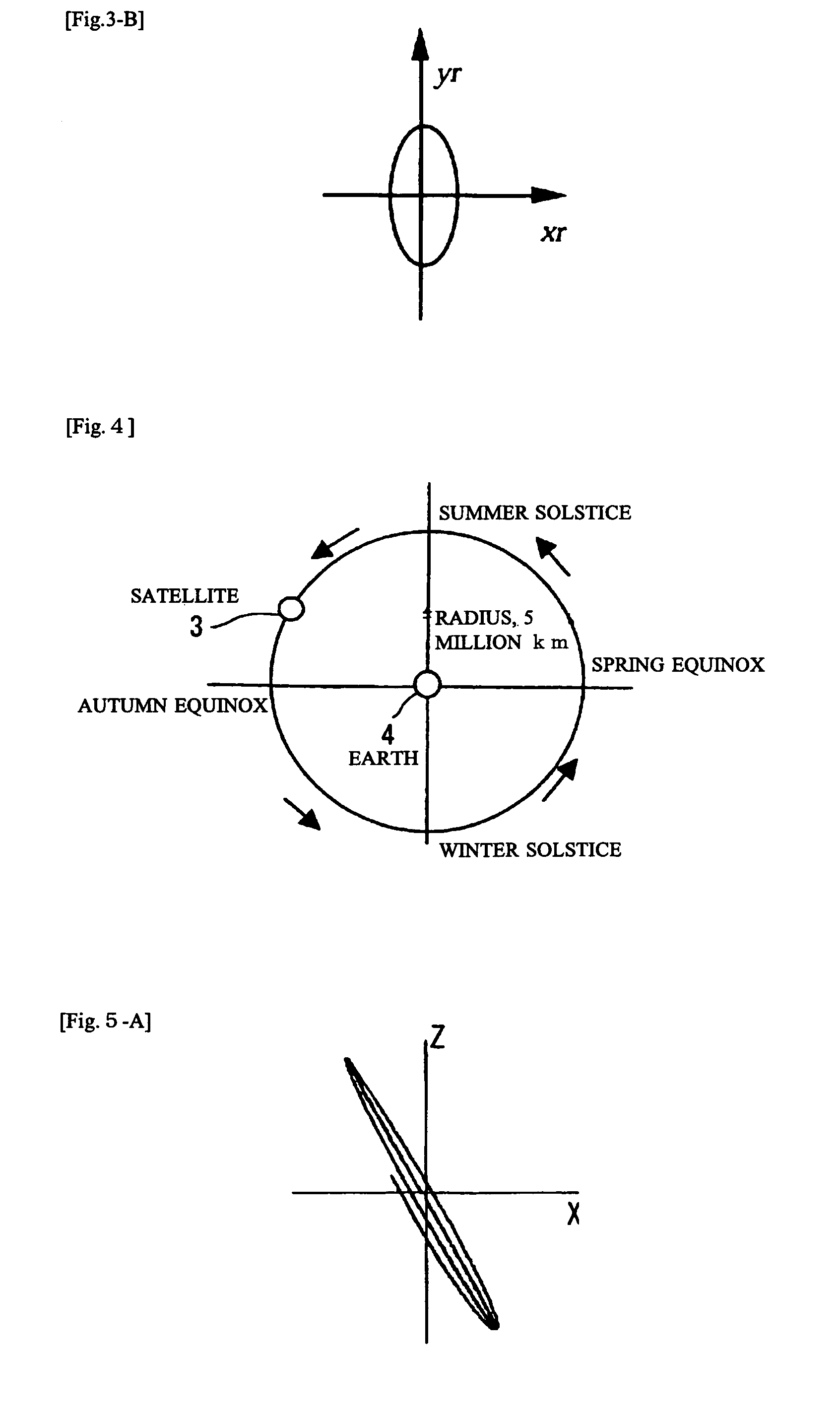

Ultrahigh altitude sun-synchronous orbit satellite system

InactiveUS7806369B2Increase distanceImprove accuracyArtificial satellitesSpacecraft guiding apparatusNatural satelliteElliptic motion

An ultrahigh altitude sun-synchronous orbit satellite system having one or plural satellites orbiting the sun such that the satellites revolve around the earth in a substantially circular or elliptic motion at an altitude of several million kilometers from the earth, beyond the sphere of earth gravity influence. The satellites are placed on an orbital plane relative to both the sun and the earth and keep a distance and geometry between the satellites, sun and earth substantially constant. The satellite system performs any one of the services of space observation, global observation, and satellite communication. The satellites orbit the sun with both inclination and eccentricity distinct from those of the revolution of the earth and revolve around the earth with a sun synchronous property in which the local solar time is kept constant at a point on the surface of the earth directly beneath the satellite.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

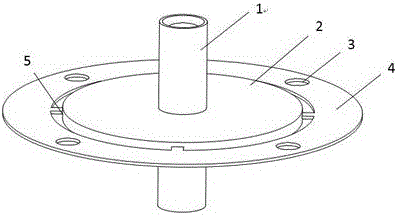

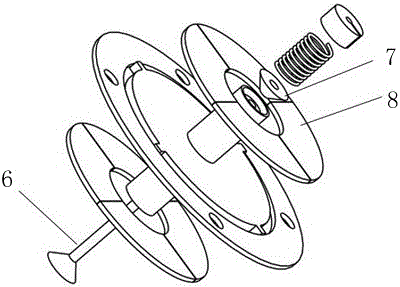

Piezoelectric actuated integral diaphragm

The invention discloses a piezoelectric actuated integral diaphragm. An outer boss of a fixed coil generates a travelling wave by applying two-phase voltage through an inverse piezoelectric effect ofpiezoelectric ceramic; drive teeth of the fixed coil are in direct contact with a movable coil; elliptic motion on the drive teeth is converted into rotation of the movable coil through a friction effect; reverse motion of the movable coil can be achieved through changing a phase difference of voltage; the movable coil, the bottom surface of a fixed shell and balls form a bearing, so that assemblyof an additional bearing is avoided and the size of the integral diaphragm is reduced; diaphragm blades are hinged with the movable coil and are connected with an inner ring of the fixed coil throughsliding chutes; uni-circumferential motion of the blades is controlled through rotation of the movable coil; a plurality of blades are staggered with one another to form a round iris diaphragm; and abottom cover is connected with the fixed coil and a housing through bolts to play a role in applying prepressure. According to the piezoelectric actuated integral diaphragm, the volume of the diaphragm is reduced and the piezoelectric actuated integral diaphragm has the characteristics of being high in adjustment accuracy, fast in response, high in stability and high in reliability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Ultrasonic motor with two linear degrees of freedom based on flexural oscillation driving of rectangular plate

InactiveCN101582653AAvoid delivery errorsAccurate and fast positioningPiezoelectric/electrostriction/magnetostriction machinesElliptic motionEllipse

An ultrasonic motor with two linear degrees of freedom based on flexural oscillation driving of a rectangular plate is characterized in that a stator component is connected with a support component and is matched with a rotor component by a driving tooth; the rotor component and the support component form a high pair connection; the mainbody of the stator is a rectangular plate; the driving tooth is arranged on the plate; and the motor adopts the B and B in the X direction and the B and B in Y direction of the rectangular plate as a working mode, and activates the modes to drive the particles on the driving tooth to carry out elliptic motion respectively along the X direction and Y direction. The linear ultrasonic motor with two linear degrees of freedom has the technical effects of: 1. utilizing single slab stator to realize the direct driving of two linear DOF simultaneously, avoiding the motion transmission error of the traditional XY movement device and leading the motor to have quick and precise positioning; 2. adopting a sheet-type stator to facilitate the thinning and lightening of the motor; and 3. flexible motion, double functions, large thrust and more stable performance.

Owner:NANCHANG HANGKONG UNIVERSITY

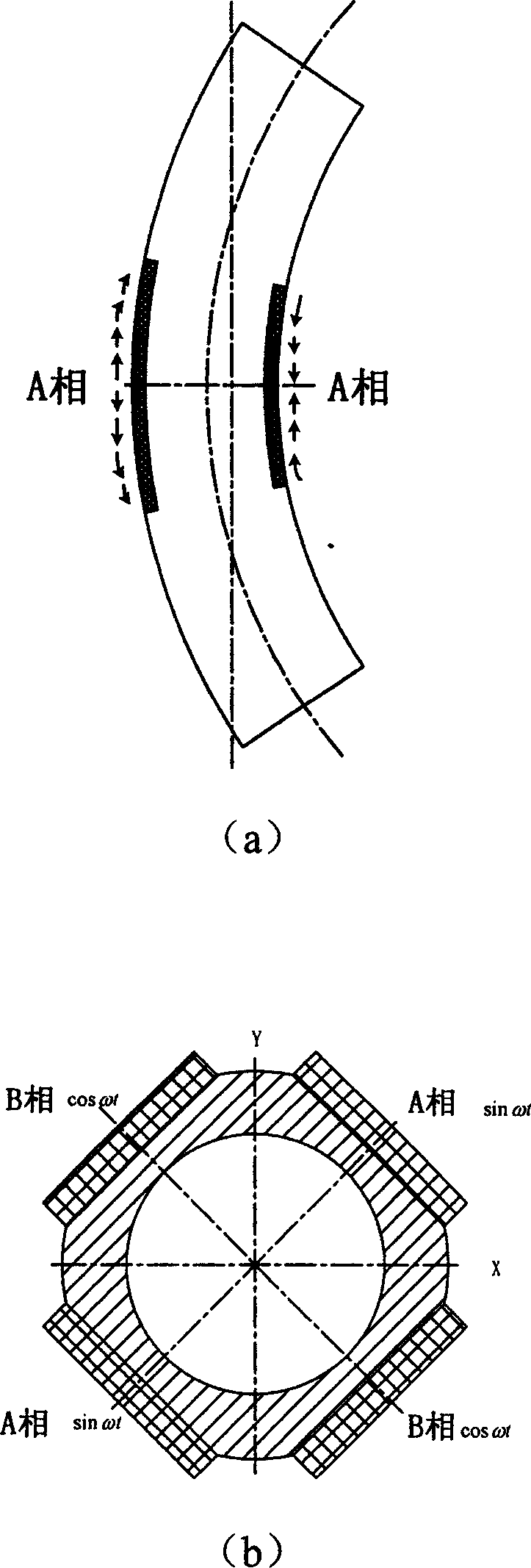

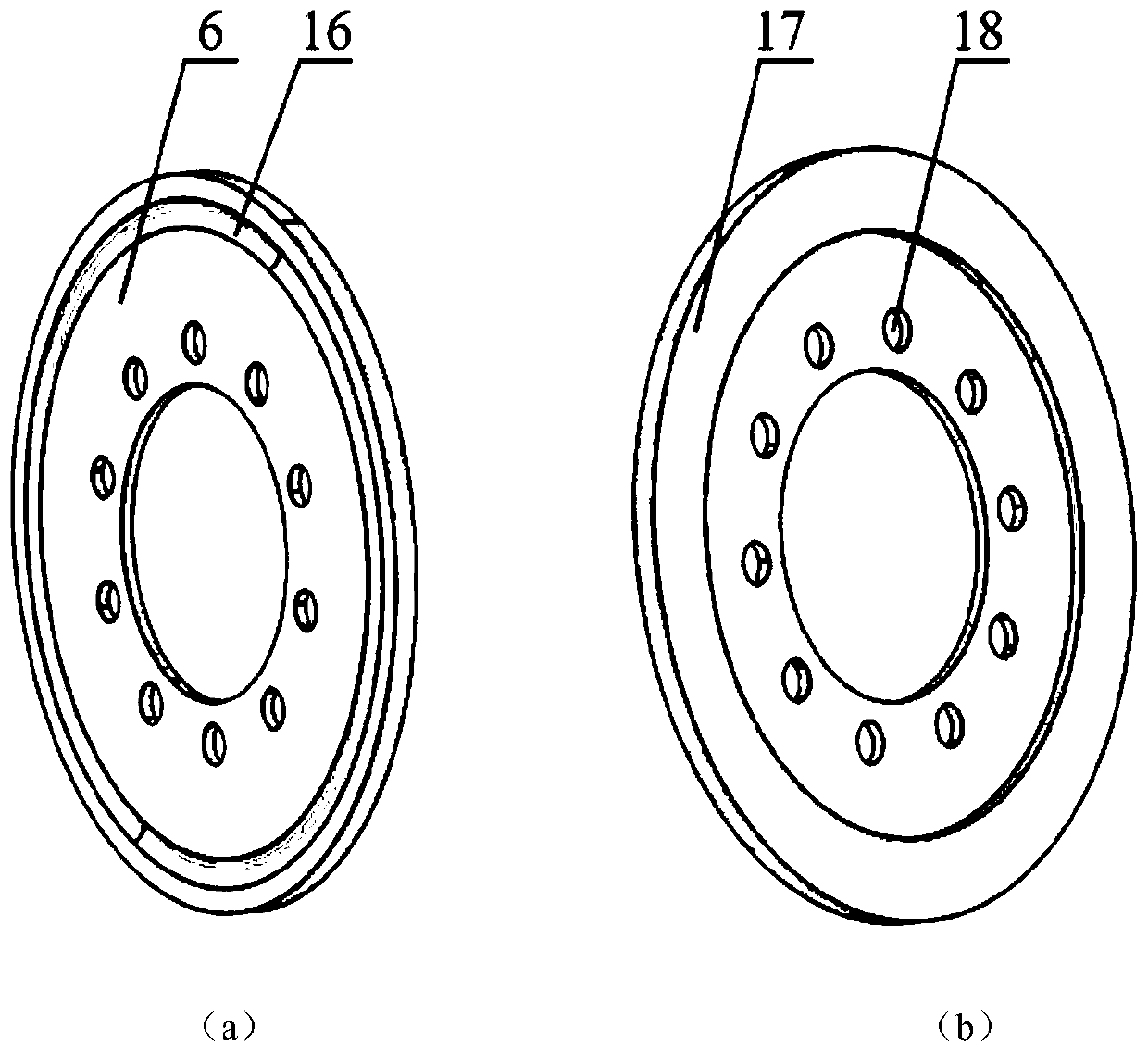

High-speed rotating ultrasonic motor and electric excitation method of stator of high-speed rotating ultrasonic motor

ActiveCN106208804ASimple structureGuaranteed uptimePiezoelectric/electrostriction/magnetostriction machinesFiberElectricity

The invention provides a high-speed rotating ultrasonic motor and an electric excitation method of a stator of the high-speed rotating ultrasonic motor. A stator main body of the motor comprises a metal disk and a carbon fiber tube; the stator comprises the metal disk, the carbon fiber tube and piezoelectric ceramics; four ceramic wafers are used for exciting two out-of-plane bending working modes, of which the space phase difference is pi / 2, of the lower end surface of the stator; and two paths of sine signals of which the time phase difference is pi / 2 are utilized for simultaneously exciting two orthogonal working modes, so that elliptic motion is generated on inner bevels of two ends of the carbon fiber tube; and the rotor is pushed to move through a friction effect. The ultrasonic motor has the characteristics of being simple in structure, high in rotating speed, light in quality and the like, and a bearing is not needed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

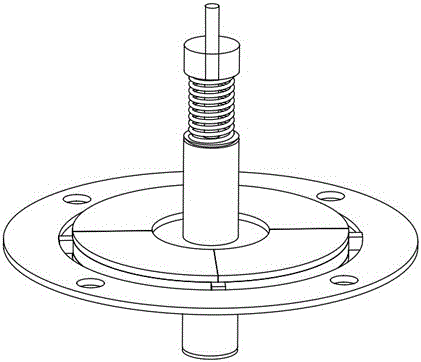

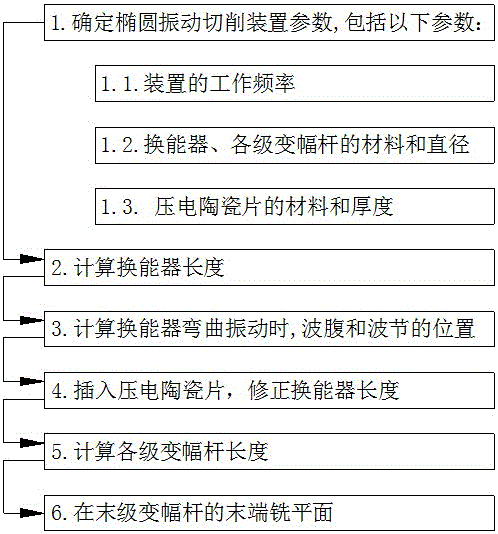

Design method of ultrasonic elliptic vibration cutting device

ActiveCN106239230AMechanical vibrations separationFeeding apparatusEnergy converterMathematical formula

The invention provides a design method of an ultrasonic elliptic vibration cutting device and belongs to the technical field of precise machining. The design method of the ultrasonic elliptic vibration cutting device comprises the following steps that firstly, the parameters of the ultrasonic elliptic vibration cutting device are determined; secondly, the length of an energy converter is calculated; thirdly, the positions where a wave loop and a wave node are located when the energy converter conducts bending vibration are calculated; fourthly, a piezoelectric ceramic piece is inserted, and the length of the energy converter is corrected; fifthly, the lengths of amplitude-change poles of all the levels are calculated; and sixthly, according to the shape of a cutter, a plane is milled at the tail end of the amplitude-change pole of the last level. According to the design method of the ultrasonic elliptic vibration cutting device, the cutter can generate elliptic movement path on a two-dimensional plane. In addition, in the design method, mathematical formula deduction is adopted, and empirical design and simulating optimization design are avoided.

Owner:SICHUAN UNIV

Square plate linear ultrasonic motor and electric exciting manner

InactiveCN101071997AFrequency Consistency GuaranteeWork reliablyPiezoelectric/electrostriction/magnetostriction machinesElectricityElliptic motion

The motor includes stator, mover and piezoelectric ceramics. The stator is a quadrate plate. There are four dogteeth on one face of the plate; and there are pieces of piezoelectric ceramics pasted on the other face of the plate. The pieces of piezoelectric ceramics are in use for exciting 2-ordered bending vibration mode of the plate. Using sinusoidal signals with pi / 2 phase difference excites two inter orthogonal 2-ordered bending vibrations of the stator plate so that four dogteeth on the plate generate elliptic motions with pi / 2 phase difference. The elliptic motions through friction drive motions of mover pressed on dogteeth on the plate. When using sinusoidal signals with - pi / 2 phase difference generates excitation, the invention makes motions of mover in inverse direction. Under working state, there are nine nodes on surface of the stator plate, and the three nodes are as supporting points for stator. Features are: compact structure, high driving efficiency, larger thrust force, and reliable operation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

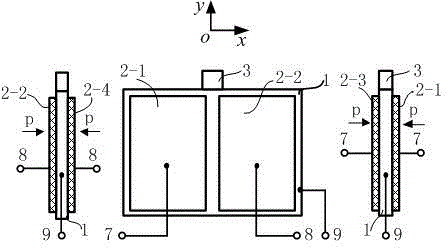

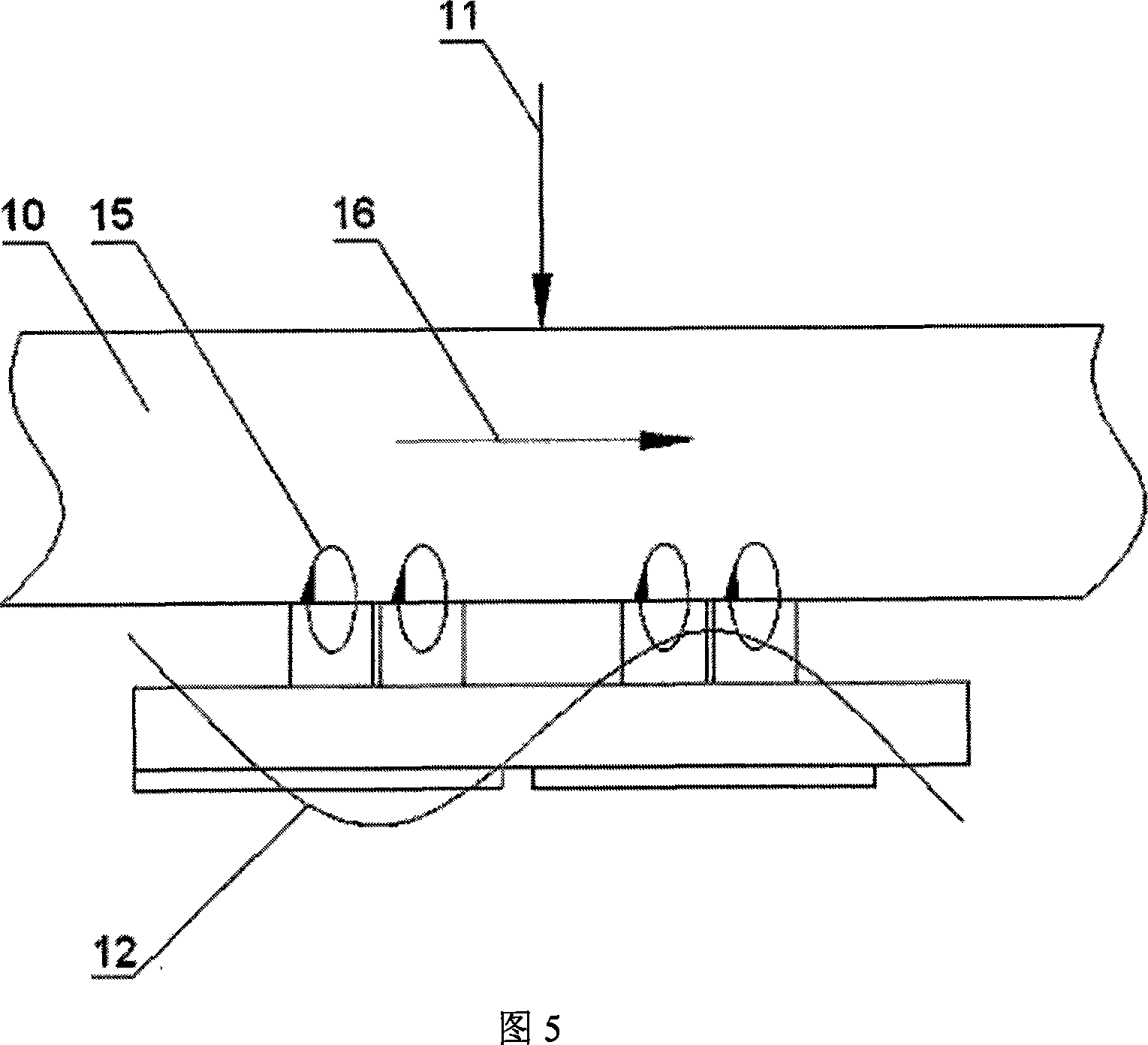

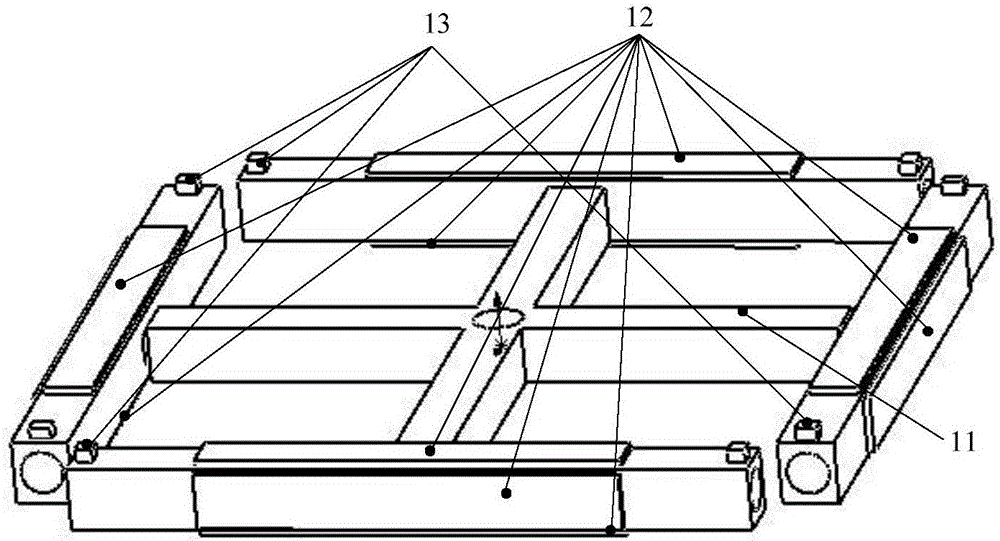

Planar motor driven based on piezoelectric vibrator shaped like Chinese character tian and drive method

InactiveCN106787933AGuarantee normal implementationAvoid motion errorsPiezoelectric/electrostriction/magnetostriction machinesCompound aIn plane

The invention relates to the technology of multi-degree-of-freedom piezoelectric ultrasonic motors, in particular to a planar motor driven based on a piezoelectric vibrator shaped like a Chinese character tian and a drive method. The planar motor comprises a stator component, a rotor component, a support component and a pre-tightening component, wherein the quasi-tian-shaped stator component is adopted is connected with the support component through the pre-tightening component; the rotor component is connected with the stator component and the support component. The motor is used to compound a two-phase elliptic motion trail through exciting vibration or near resonance of three modes comprising out-of-plane first-order symmetric bending vibration of the quasi-tian -shaped stator component, left-and-right surrounding rod in-plane first-order bending vibration and front-and-back surrounding rod in-plane first-order bending vibration, so that the rotor component is pushed to alternately move along an x direction and a y direction. The micron-grade or even higher-accuracy-grade planar motion can be realized, motor output power and speed are greatly increased, so that the motor operates stably; the motor utilizes an in-plane drive foot to push the rotor component, so that a thin and planar design of the planar motor is realized.

Owner:WUHAN UNIV

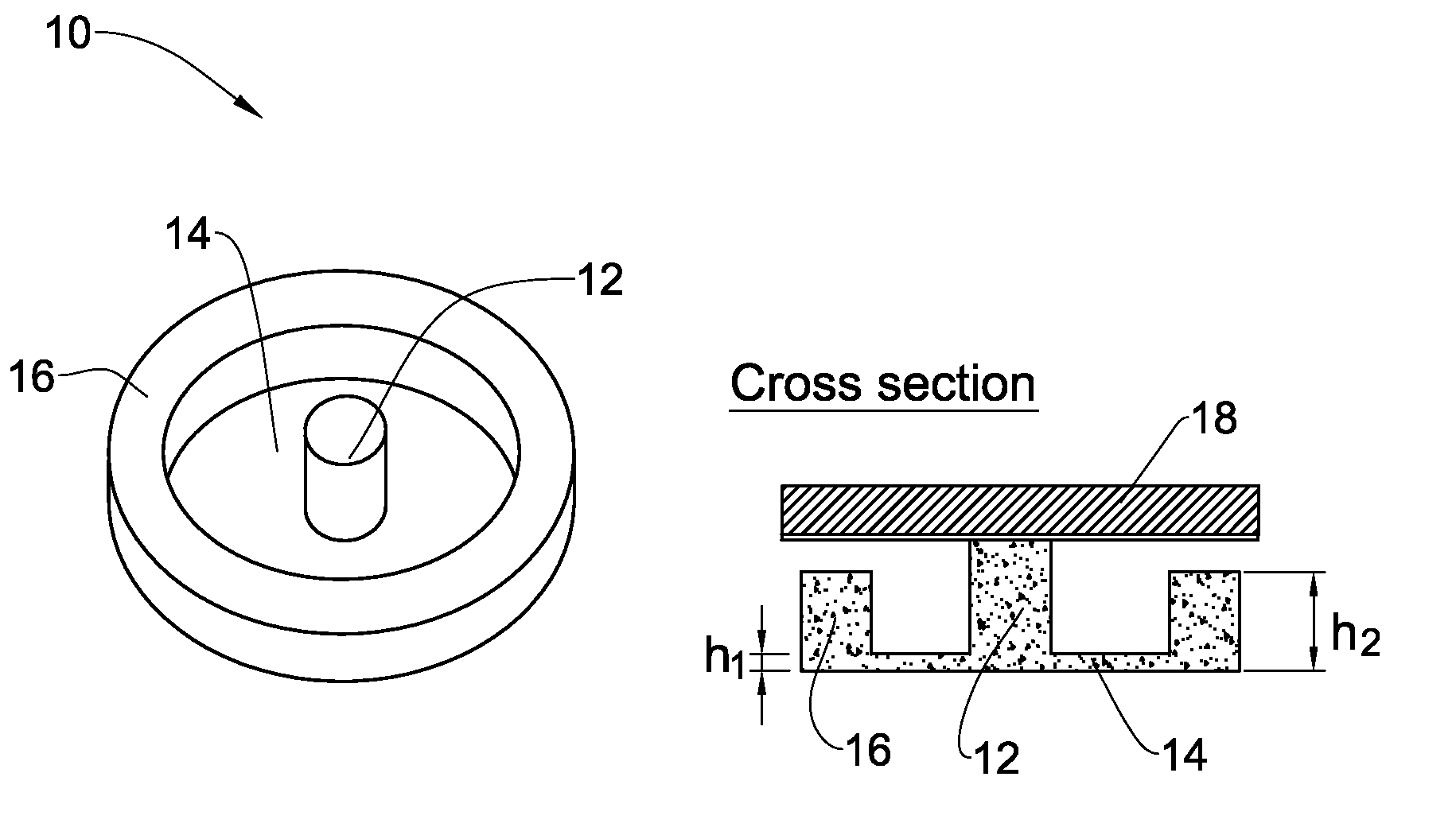

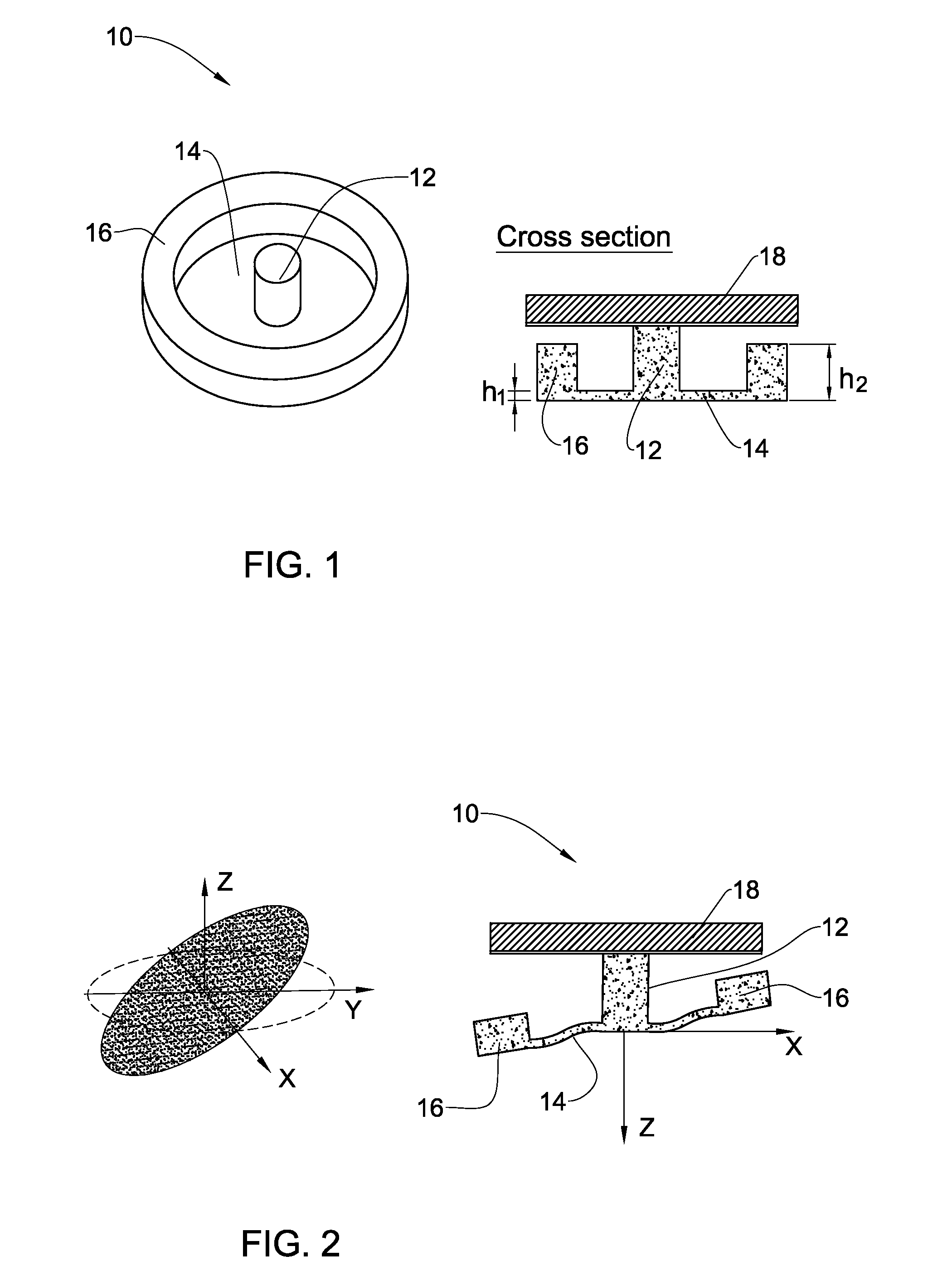

Micro Scale Mechanical Rate Sensors

InactiveUS20110048130A1High precisionReduce uncertaintyAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsElliptic motionPrecession

An angular rate sensor device is presented. The sensor device comprises a disk-shaped structure having a proof mass region and a flexible portion. The disk-like structure is coupled to a substrate in a manner enabling a wave type precession motion such that during the wave type precession motion each material point of the proof mass performs elliptic motion.

Owner:RAMOT AT TEL AVIV UNIV LTD

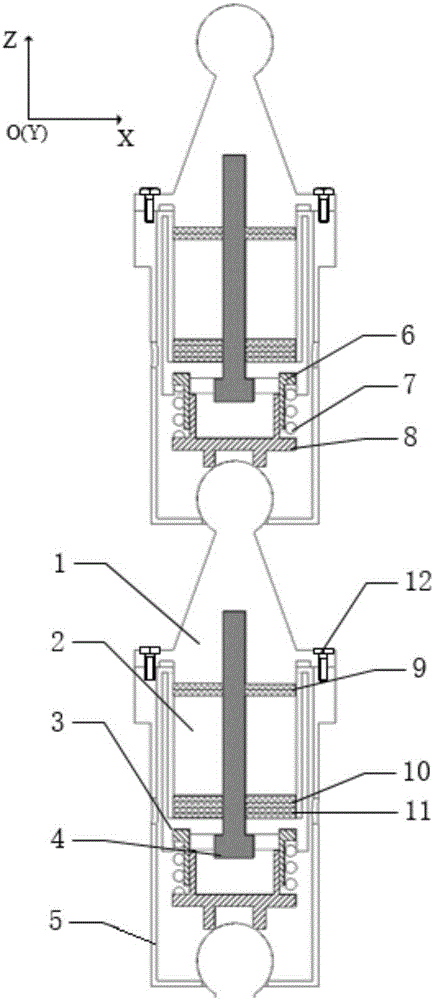

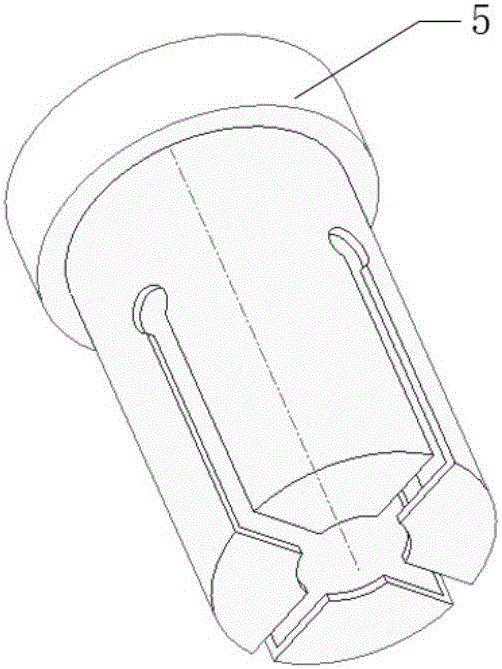

Three-degree-of-freedom manipulator joint and working mode thereof

ActiveCN106514699ASimple structureQuick responseProgramme-controlled manipulatorJointsThree degrees of freedomEngineering

The invention discloses a three-degree-of-freedom manipulator joint and a working mode thereof. The three-degree-of-freedom manipulator joint comprises at least two joint units, wherein each joint unit comprises an acting head, a metal mass block, a base, a longitudinal vibrating piezoelectric ceramic assembly, a first bending vibrating piezoelectric ceramic assembly, a second bending vibrating piezoelectric ceramic assembly, a pre-tensioning bolt, a spring chuck, a bottom cover, a spring and a contact block; the upper end joint unit is used for locking a driving head of the acting head of the lower end joint unit through the corresponding contact block and the corresponding spring chuck and can apply a certain pre-pressing force to the driving head of the lower end joint unit through the corresponding spring and the corresponding spring chuck; any two of the three groups of ceramic assemblies of the joint units can be correspondingly excited to generate two-phase vibration modes; the two-phase vibration modes are coupled through the driving heads of the acting heads so as to drive a material point to elliptically move, and thus the front end joint unit can rotate around X, Y and Z axes under the frictional effect. The three-degree-of-freedom manipulator joint is fast to respond, high in accuracy, simple in structure, and wide in prospect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

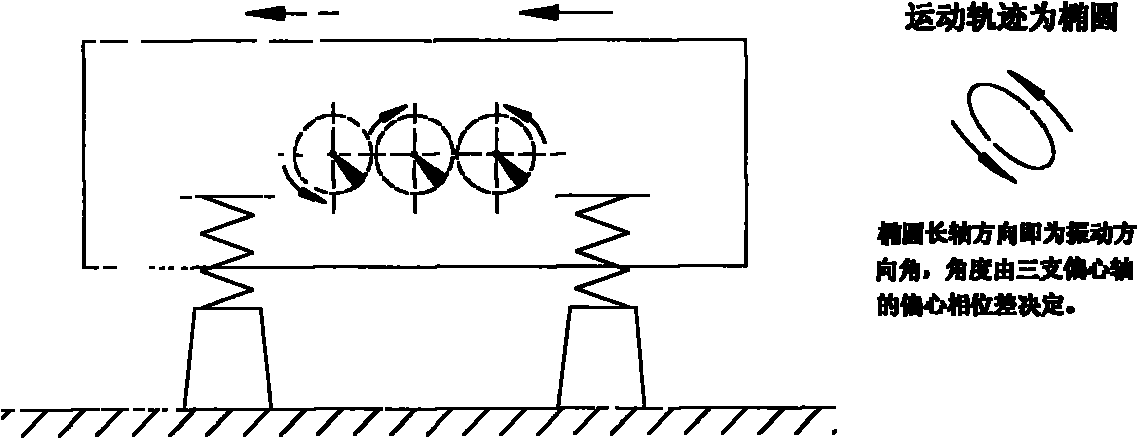

Four-short shock exciting motor elliptical vibrating screen coupled with torsion springs

The invention discloses a four-short shock exciting motor elliptical vibrating screen coupled with a torsion spring. The four-short shock exciting motor elliptical vibrating screen coupled with the torsion spring mainly consists of a feed hopper, four shock exciting motors, a protective cover, a motor base, a screen box, a vibration isolation spring, a base, coupling eccentric blocks and the torsion springs. The shock exciting motors are pairwise coaxially mounted on the motor base in parallel; and the torsion springs connect the coupling eccentric blocks of two shock exciting motors with overlapped axes to absorb shock caused by starting of the two and to realize zero-phase synchronization of the two. Two coupled shock exciting motors adopt the same mass torques, and are synchronously started in the same direction. Two shock exciting motors near a feed end use higher eccentric mass torques; two shock exciting motors near a discharge end use lower eccentric mass torques; the two sets of shock exciting motors reversely rotate at the same speed; and the generated shock exciting force realizes an elliptic motion of the vibration screen. After stable operation, one of two coupled shock exciting motors is electrified. The vibrating screen can fully exert the shock exciting force of the shock exciting motors, realizes high vibrating amplitude, and is low in energy consumption and noise.

Owner:SOUTHWEST PETROLEUM UNIV

Free stride elliptical exercise apparatus

ActiveUS20110065551A1Low joint impactEasy to startFrictional force resistorsMovement coordination devicesArm exerciseElliptic motion

The present invention relates to a standup exercise apparatus that simulates walking and jogging with arm exercise. More particularly, the present invention relates to an exercise machine having separately supported pedals for the feet and arm exercise coordinated with the motion of the feet where the pedal stride length is determined by the movements of an operator. The exercise apparatus is easy to start and has generally elliptical shaped curves throughout stride variations.

Owner:ESCHENBACH PAUL WILLIAM

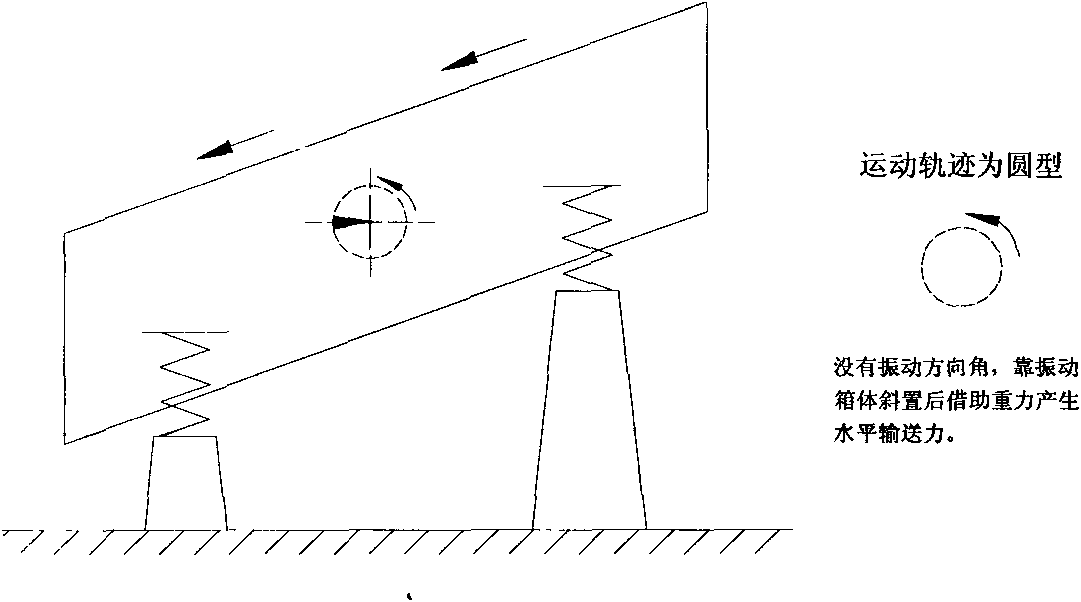

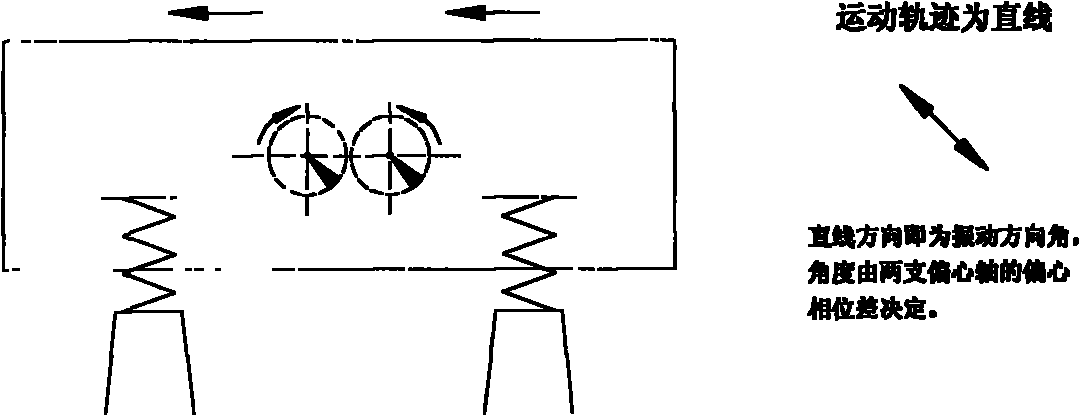

Single-shaft horizontally-arranged variable-track vibration exciter

InactiveCN102247944AEnhanced vibration balanceMechanical vibrations separationLinear motionElectricity

The invention discloses a single-shaft horizontally-arranged variable-track vibration exciter which comprises a vibrating case body, a spring and a base. The vibration exciter is characterized in that two telescopic rods are arranged on each side of the vibrating case body; the two telescopic rods are hinged with an upper connecting rod and a lower connecting rod to form a parallelogram mechanism; the two ends of the upper connecting rods, which are positioned on the two sides, are hinged with the upper pivot points of four telescopic rods and respectively fixed on a bearing seat and the vibrating case body which are positioned at the two ends of an eccentric shaft; and the two ends of the lower connecting rods are hinged with the pivot points of the lower ends of the four telescopic rodsand fixed in four arc-shaped adjuster slot holes which are formed on the base respectively. The invention has the most significant effect that different motion tracks, such as circular motion track, linear motion track and elliptic motion track, can be achieved in the same device by adjusting the slippage interval of the telescopic rods so as to meet the needs for different working conditions in the screening and feeding procedures. The vibration exciter disclosed by the invention has good excitation work-doing effects, high efficiency, low electricity consumption and low manufacturing cost, good vibration equilibrium, is convenient for maintenance, can be arranged horizontally during use and is convenient for adjustment. Besides, the traditional product can be transformed technically according to the technical scheme provided by the invention for improving the product performance.

Owner:ZHEJIANG SHENGDA MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com