Dual-driving foot longitudinal-vibration mode stacked linear ultrasonic motor and working mode and electric exciting manner

A mode superposition and ultrasonic motor technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems such as low speed, low efficiency, and small output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

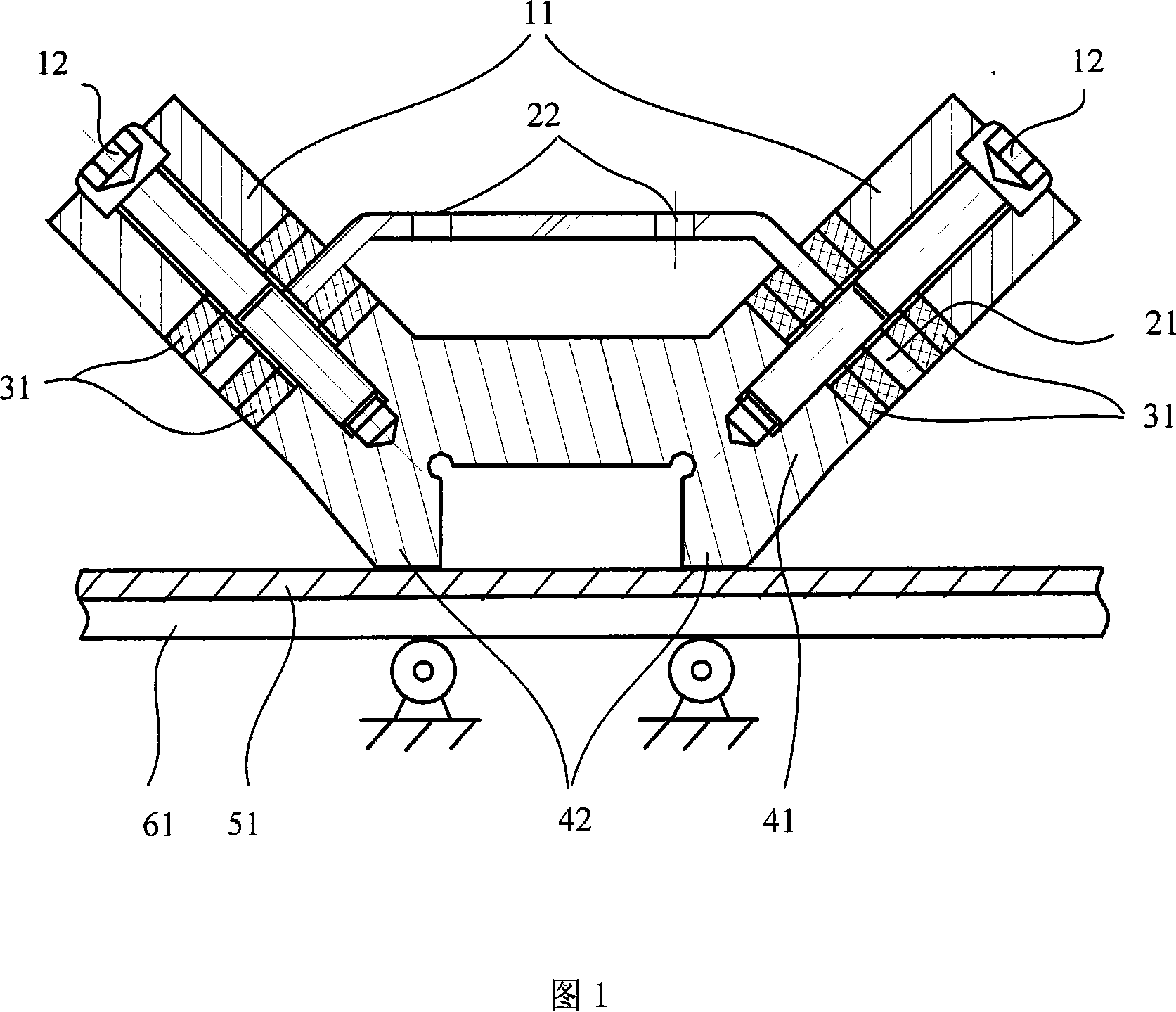

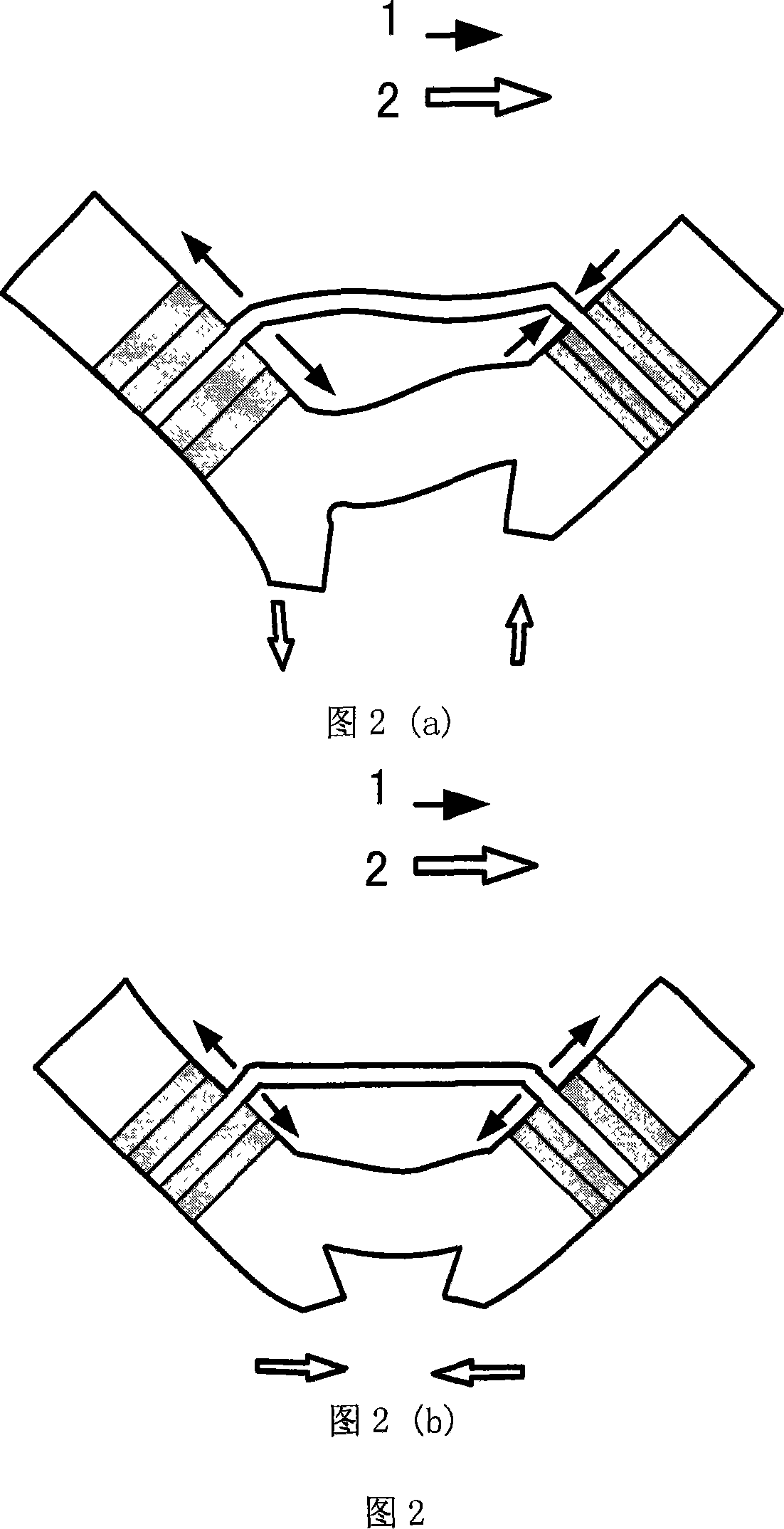

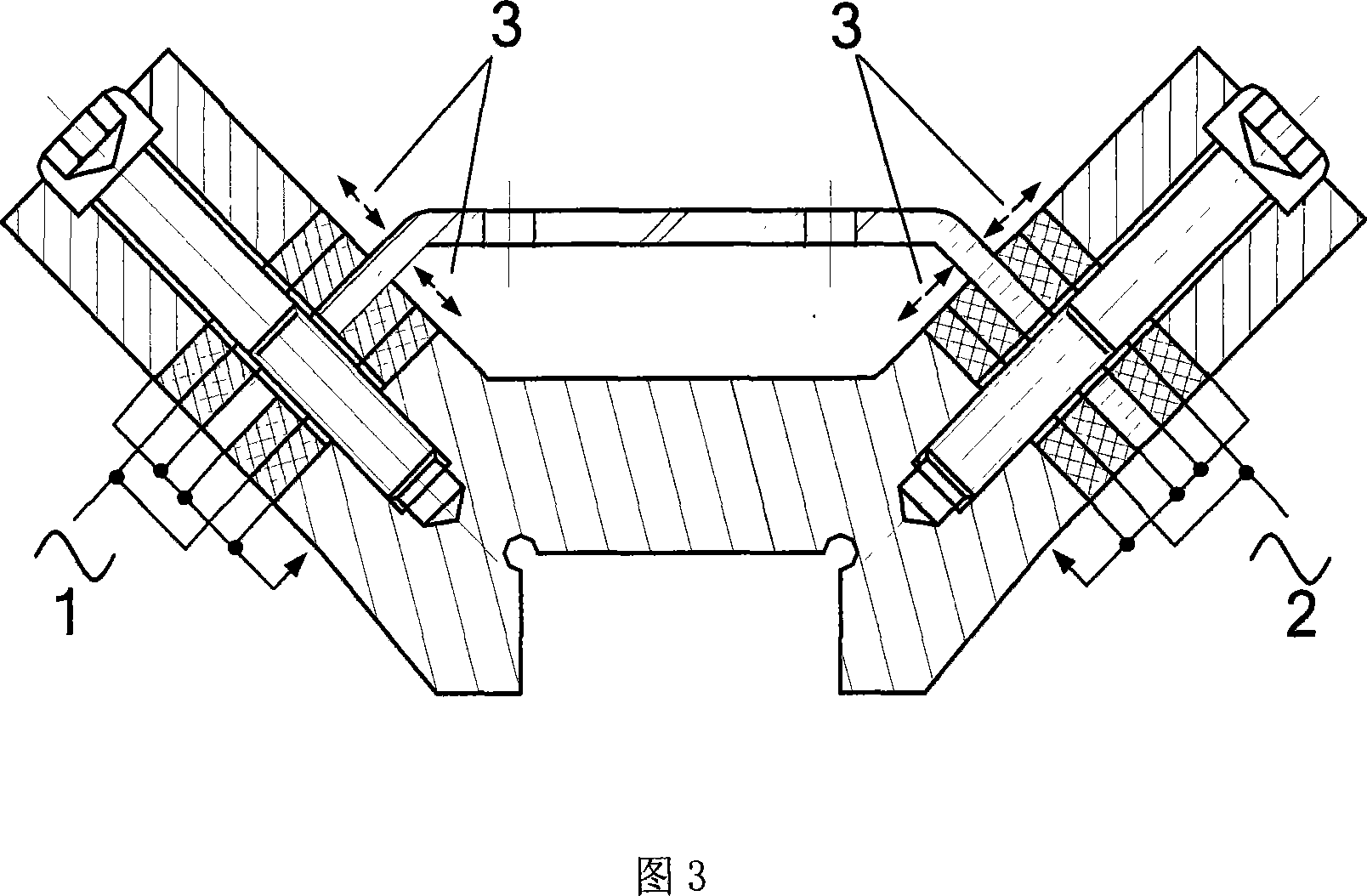

[0013] A dual-drive foot longitudinal vibration mode superimposed linear ultrasonic motor is shown in Figure 1. Its characteristics: The stator is composed of two piezoelectric vibrators connected symmetrically. Each piezoelectric vibrator is composed of a middle block 21, a front end cover 41, a rear end cover 11, and piezoelectric ceramics 31. The piezoelectric ceramics are distributed between both sides of the middle block and between the front and rear end covers, and are tightened by pressing bolts 12. Compression, used to excite the stator to vibrate. The front covers of the two piezoelectric vibrators are connected into one body, and two driving feet 42 are distributed on the lower end thereof. The mover is composed of a slide bar 61 , the upper surface of which is bonded with a friction layer 51 . Use the same frequency sinusoidal signal with a phase difference of π / 2 to simultaneously excite the left and right piezoelectric vibrators to respectively excite the two v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com