Multi-leg linear piezoelectric driver and workbench

A piezoelectric driver and driver technology, applied in the field of microelectronics, can solve problems such as inconvenient installation, insufficient thrust, and excessive temperature rise, and achieve the effects of convenient installation, increased driving force, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

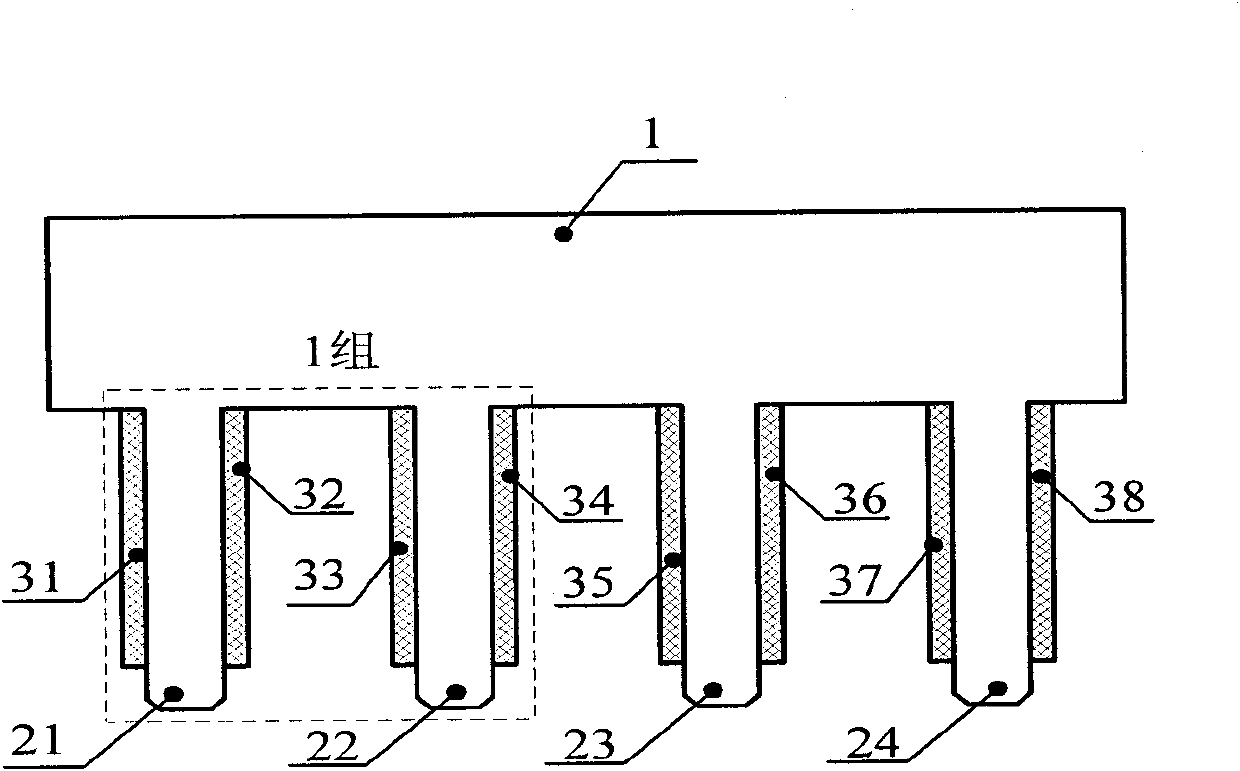

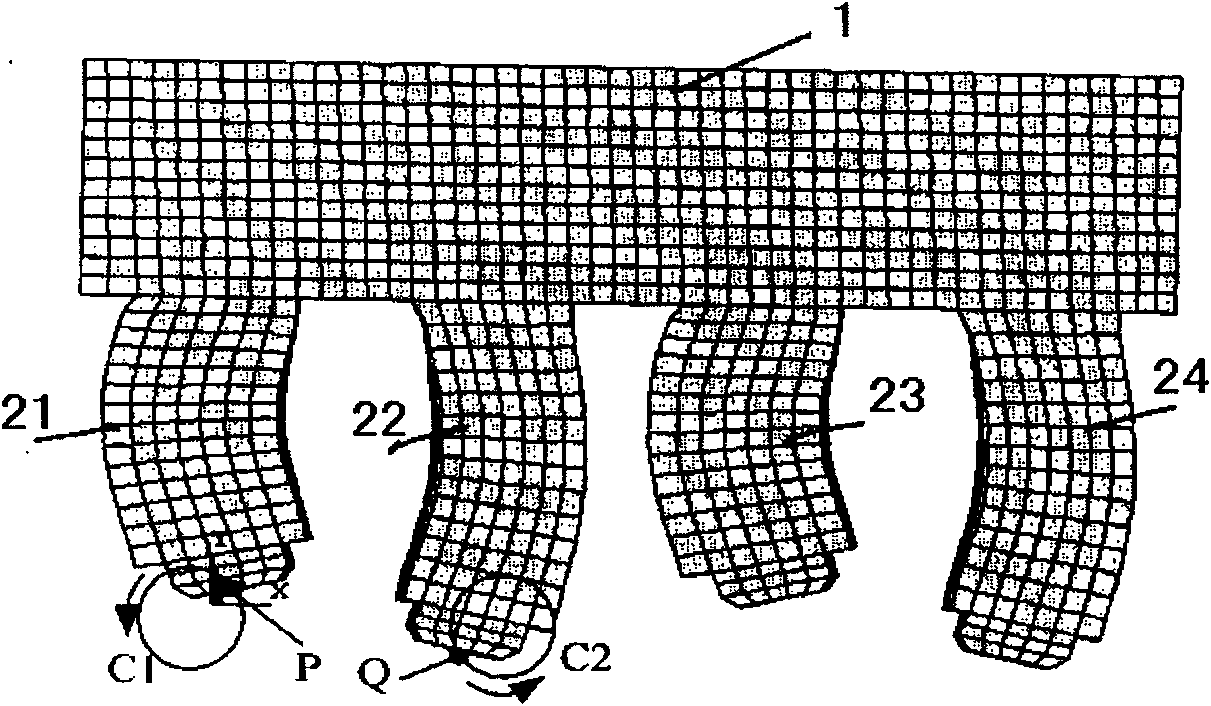

[0027] Such as figure 1 , 3 The structure of the multi-legged linear piezoelectric actuator shown in , 4 is comb-shaped, and a square first driving foot 21, a second driving foot 22, a third driving foot 23 and a fourth driving foot 24 are stretched out on the cuboid substrate 1 ; The number of driving feet is 4 and divided into two groups, and the two feet in each group are independent of each other. The square first piezoelectric ceramic sheet 31 and the second piezoelectric ceramic sheet 32 are bonded on the side of the first driving foot 21, and the square third piezoelectric ceramic sheet 33 and the fourth piezoelectric ceramic sheet are bonded on the side of the second driving foot 22. Electric ceramic sheet 34; the fifth piezoelectric ceramic sheet 35 and the sixth piezoelectric ceramic sheet 36 are bonded on the side of the third driving foot 23; the seventh piezoelectric ceramic sheet is bonded on the side of the fourth driving foot 24 37 and the eighth piezoelect...

Embodiment approach 2

[0031] Such as Figure 4 As shown, the difference from the first embodiment is that the first driving foot 21 and the second driving foot 22 of the first group of the driver are connected by the first beam 401, and the third driving foot 23 and the fourth driving foot 24 of the second group are connected by The second beam 402 is connected; the side of the first beam 401 is pasted with the piezoelectric ceramic sheet 309 on the first beam and the piezoelectric ceramic sheet 310 under the first beam, and the side of the second beam 402 is pasted with the piezoelectric ceramic sheet on the second beam 311 and the piezoelectric ceramic sheet 312 under the second beam.

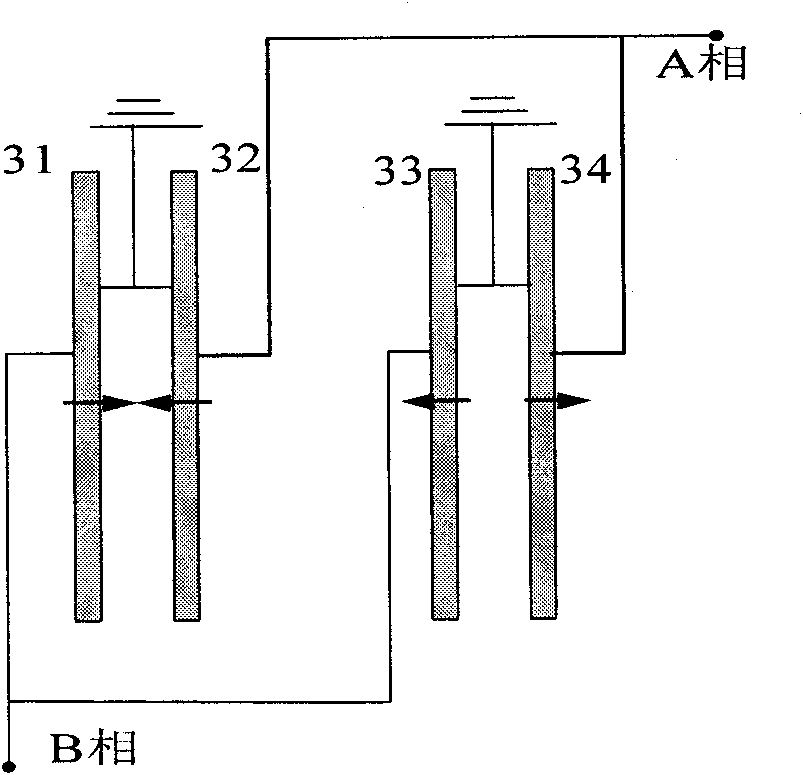

[0032] Such as Figure 5 As shown, the arrow indicates the polarization direction. In a group of driving feet, the polarization directions of the first piezoelectric ceramic sheet 31 and the second piezoelectric ceramic sheet 32 on both sides of the first driving foot 21 are opposite to each other, and the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com