Three-dimensional elliptic motion generating method and device for diamond cutter

A cutting tool and elliptical motion technology, which is applied to driving devices, manufacturing tools, metal processing equipment, etc., can solve the problems of difficulty in obtaining high-order modes, lack of flexibility, and difficulty in autonomous control, and achieve a simple and easy-to-implement generation method and device. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

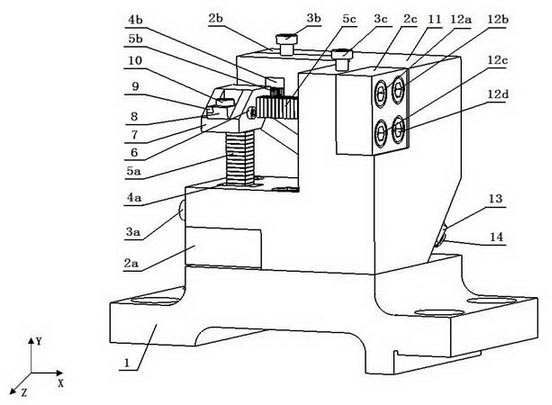

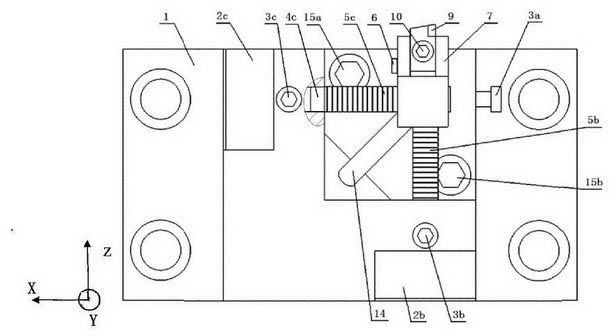

[0024] Include the following steps:

[0025] (1) The diamond cutting tool is directly driven by three piezoelectric stacks arranged vertically along the X direction, Y direction and Z direction respectively, and a sine wave driving signal is applied to the three piezoelectric stacks respectively; by actively adjusting the three piezoelectric stacks Initial phase of the piezo stack drive signal so that the displacement output of the diamond blade contact point always maintains the same phase between the X and Z directions , always maintain a certain phase difference with the X and Z directions in the Y direction , so as to realize the elliptical motion of the diamond blade in the X-Y plane and Y-Z plane respectively, and maintain linear motion in the X-Z plane;

[0026] (2) When the rake angle and edge inclination angle of the diamond cutting tool are non-zero, it also has cutting ability in the X-Z plane. At this time, it is only necessary to adjust the phase of the sine wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com