Square plate linear ultrasonic motor and electric exciting manner

An ultrasonic motor, linear technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. Not high, frequency consistency is not easy to ensure and other problems, to achieve the effect of easy frequency consistency, compact structure and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

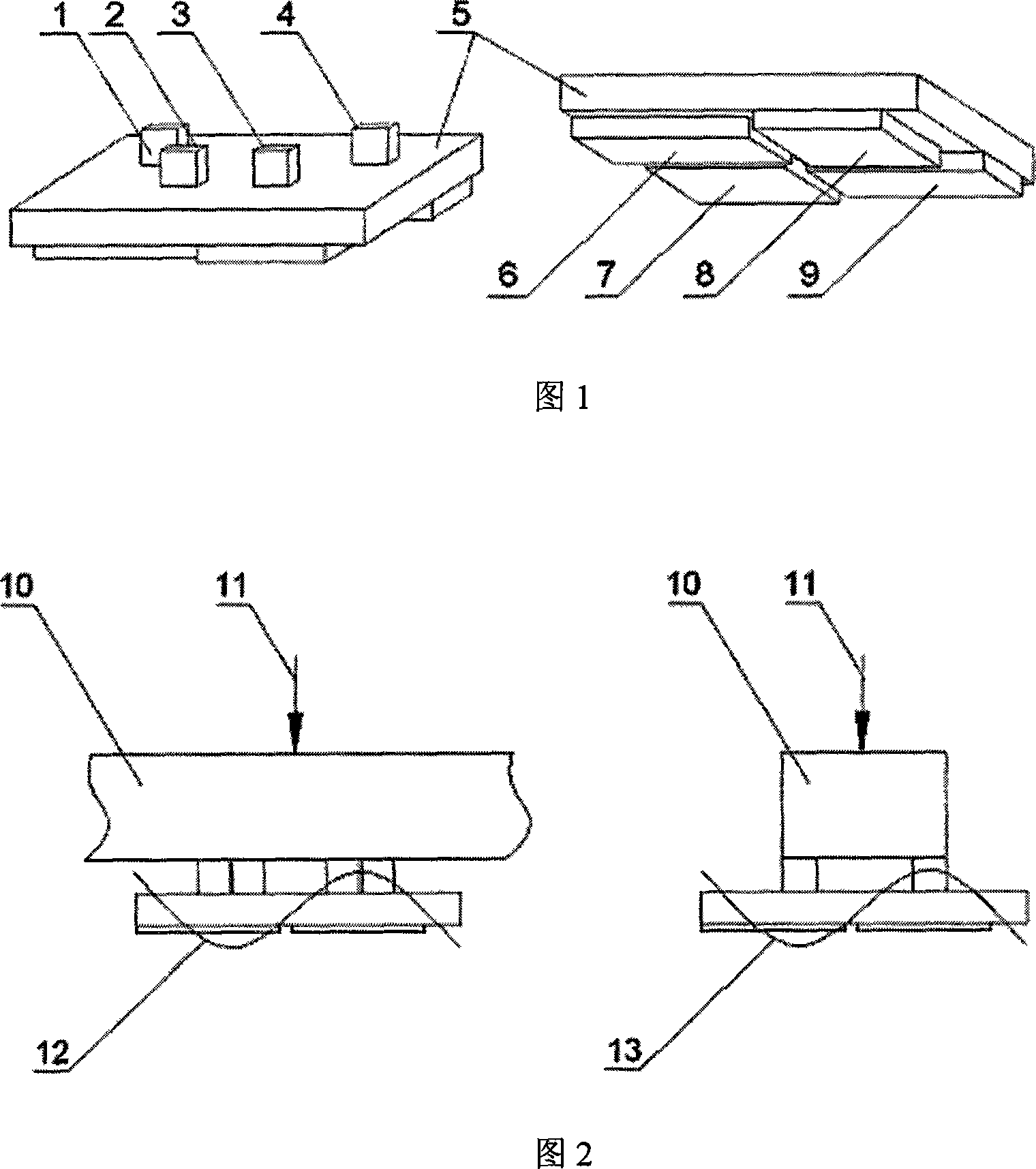

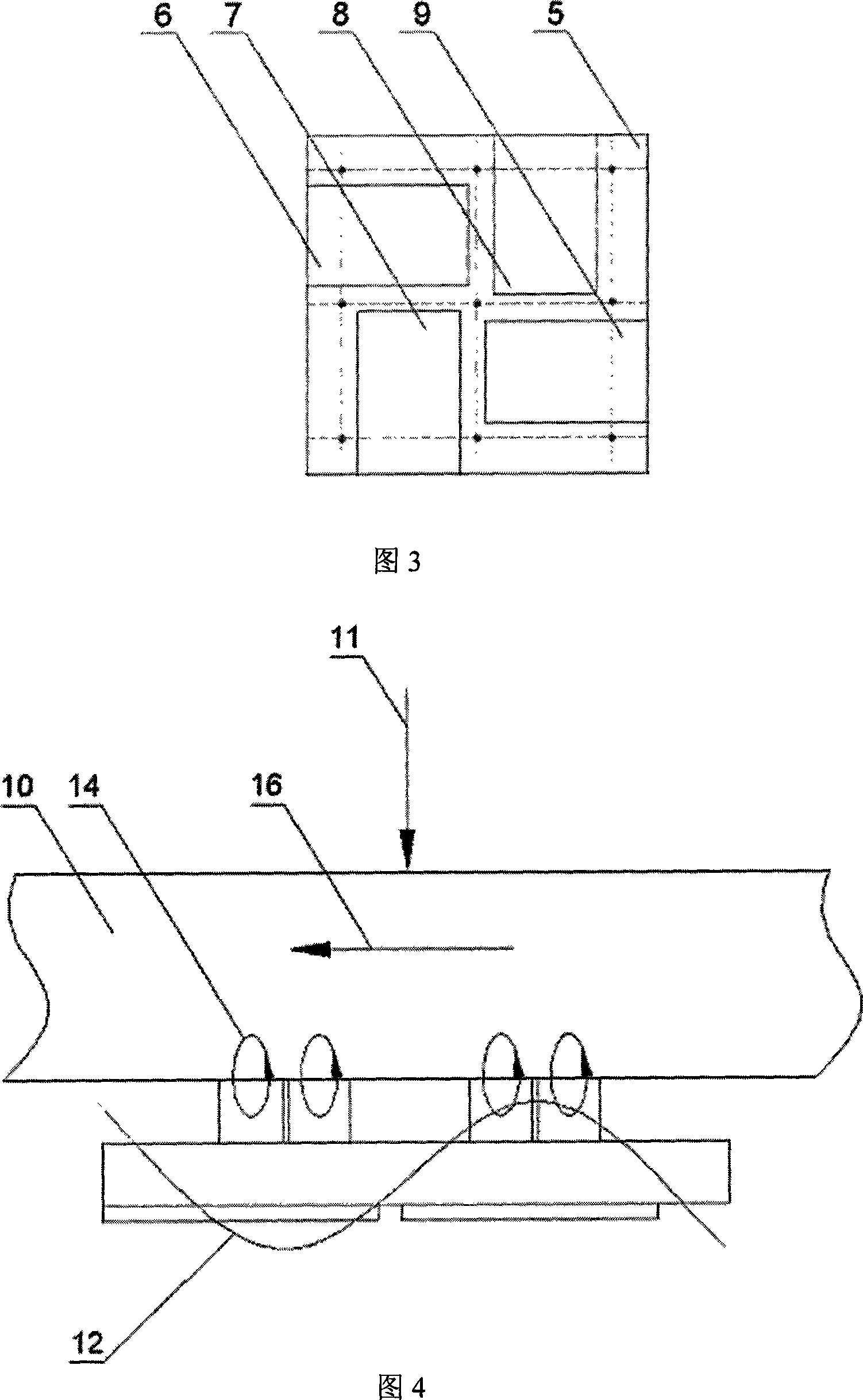

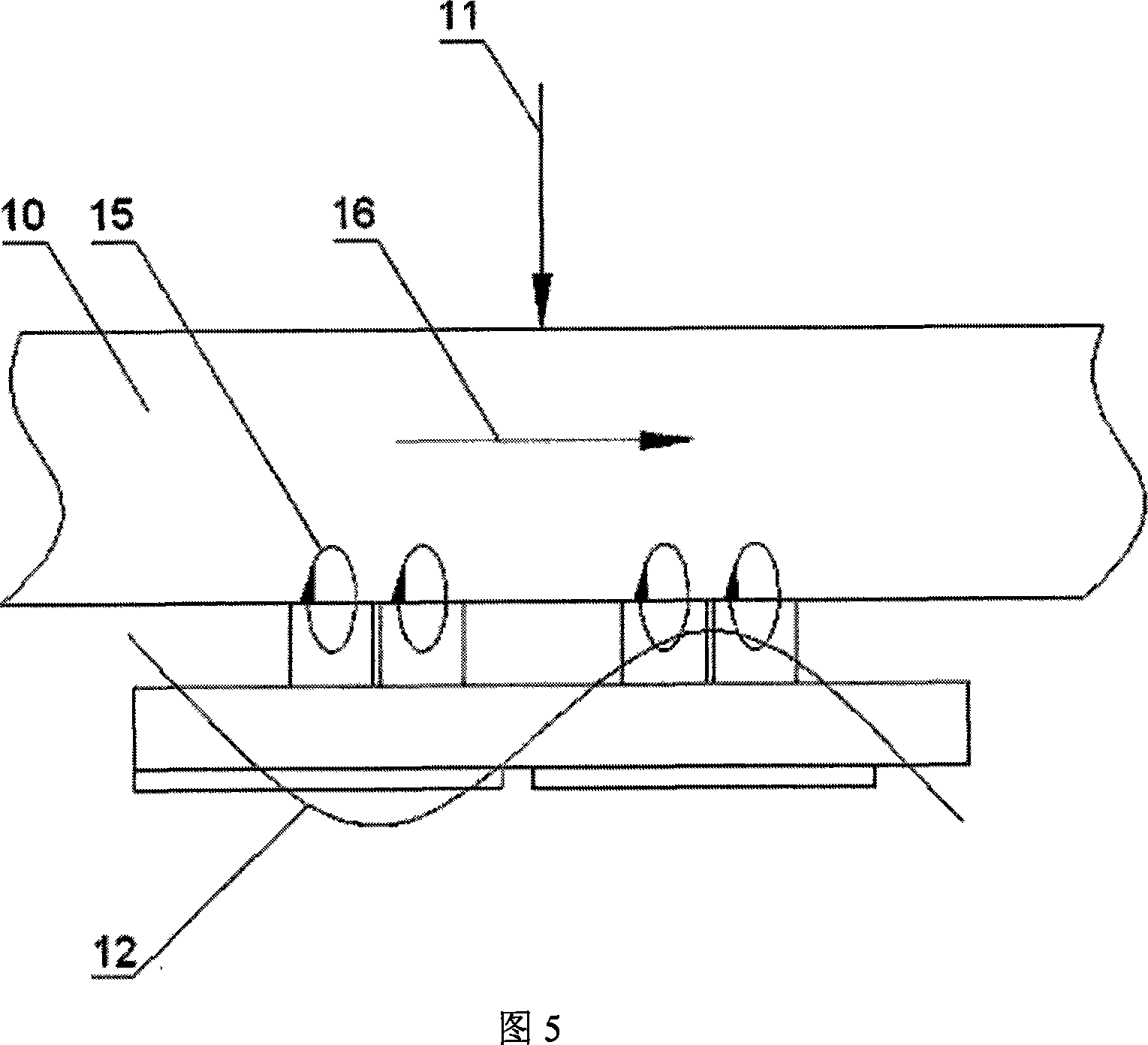

[0014] A linear motion ultrasonic motor is shown in Figure 2, and its stator is shown in Figure 1. Its characteristics: the stator is composed of a square metal plate 5 with four convex teeth 1, 2, 3, 4, and four pieces of piezoelectric ceramics 6, 7, 8, 9 are pasted on the back of the plate correspondingly to excite the stator Bending vibration of plate 5. As shown in Figure 3, wherein, piezoelectric ceramics 7, 8 are used to excite the second-order bending vibration mode 12 of the stator plate shown in Figure 2 in the x-z section; piezoelectric ceramics 6, 9 are used to excite the stator plate shown in Figure 2 The second-order bending vibration mode 13 of the stator plate in the y-z section is shown. Convex teeth 2 and 3 are located at the peak of the second-order bending vibration mode 13, and convex teeth 1 and 4 are located at the valley of the second-order bending vibration mode 13; convex teeth 1 and 2 are located at the valley of the second-order bending vibration mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com