Linear motion stepping ultrasonic motor

A linear motion, ultrasonic motor technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve problems such as difficult implementation and complex system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

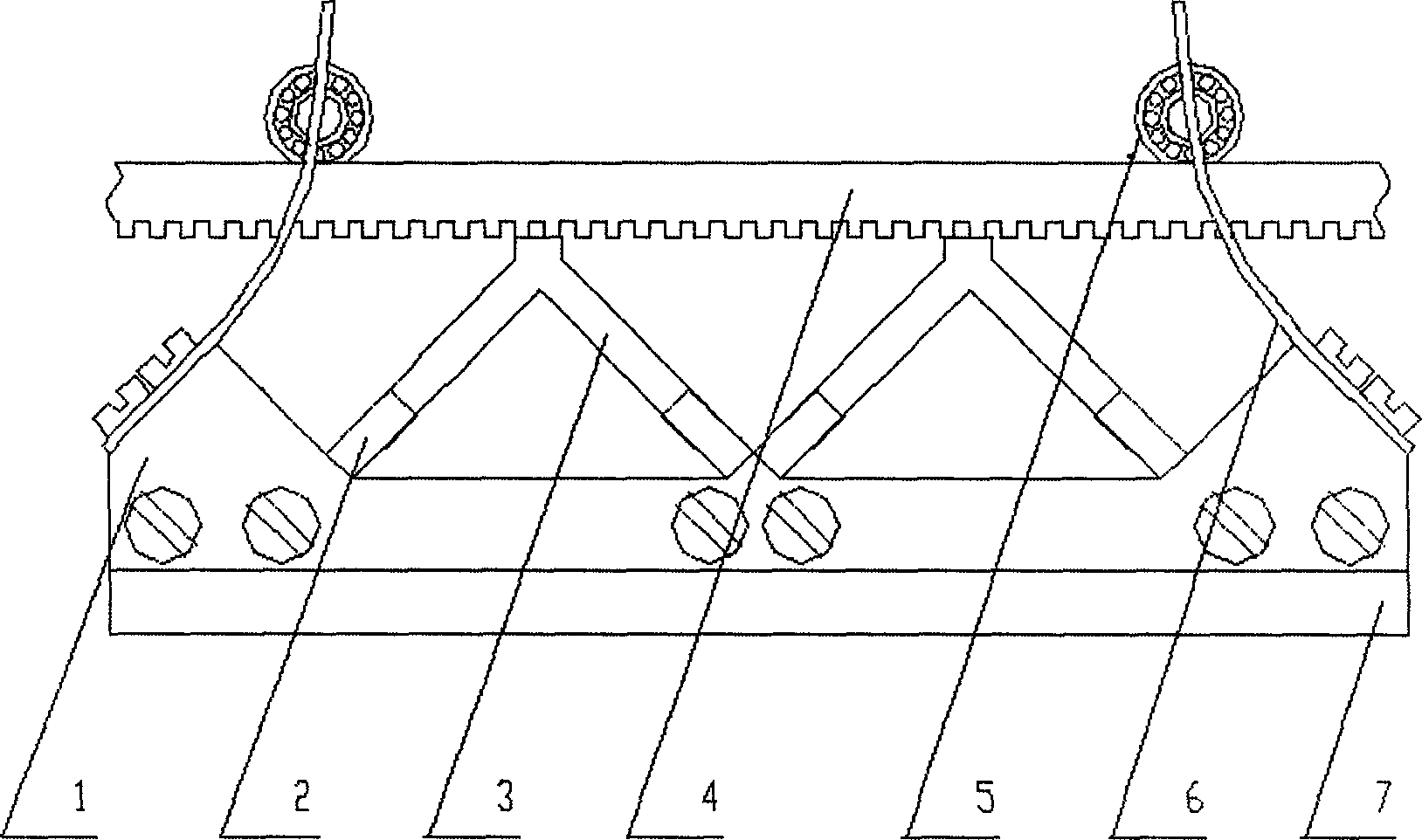

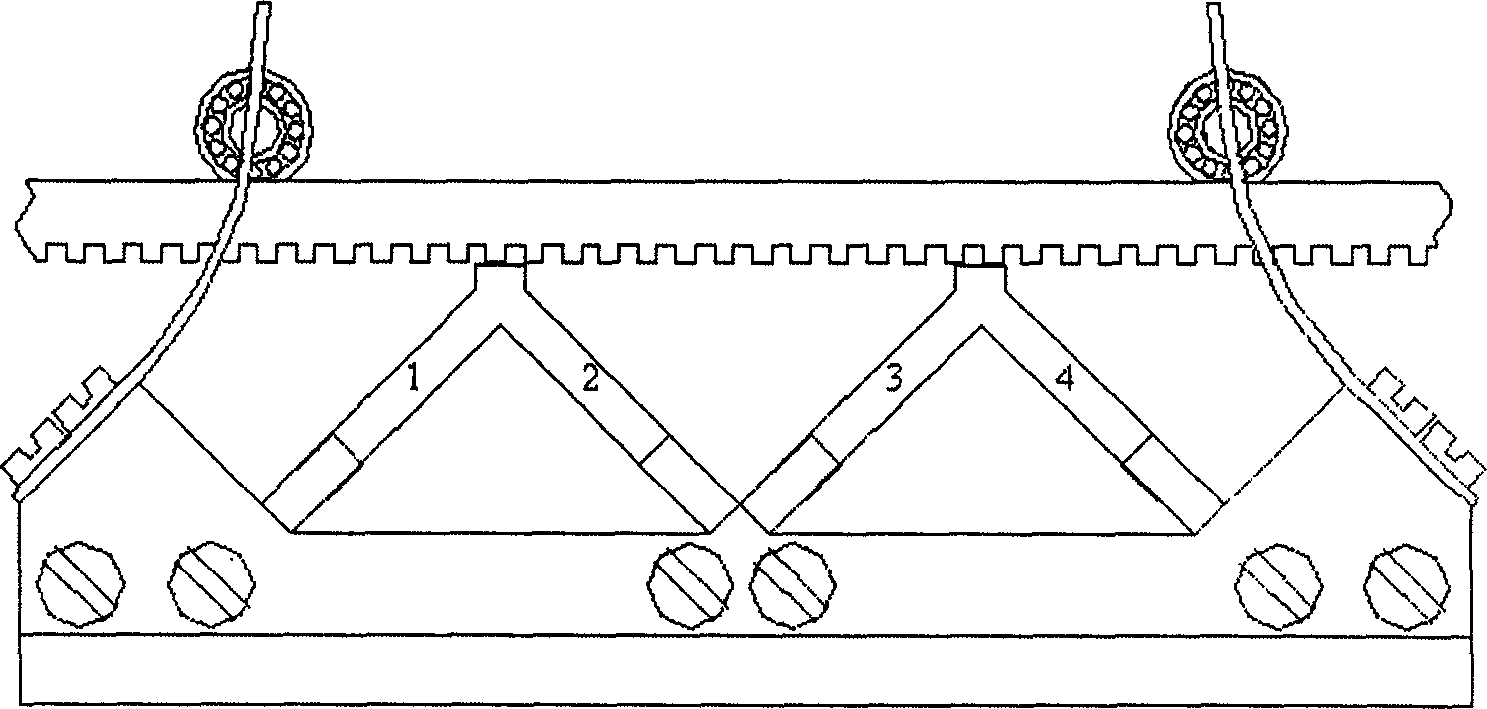

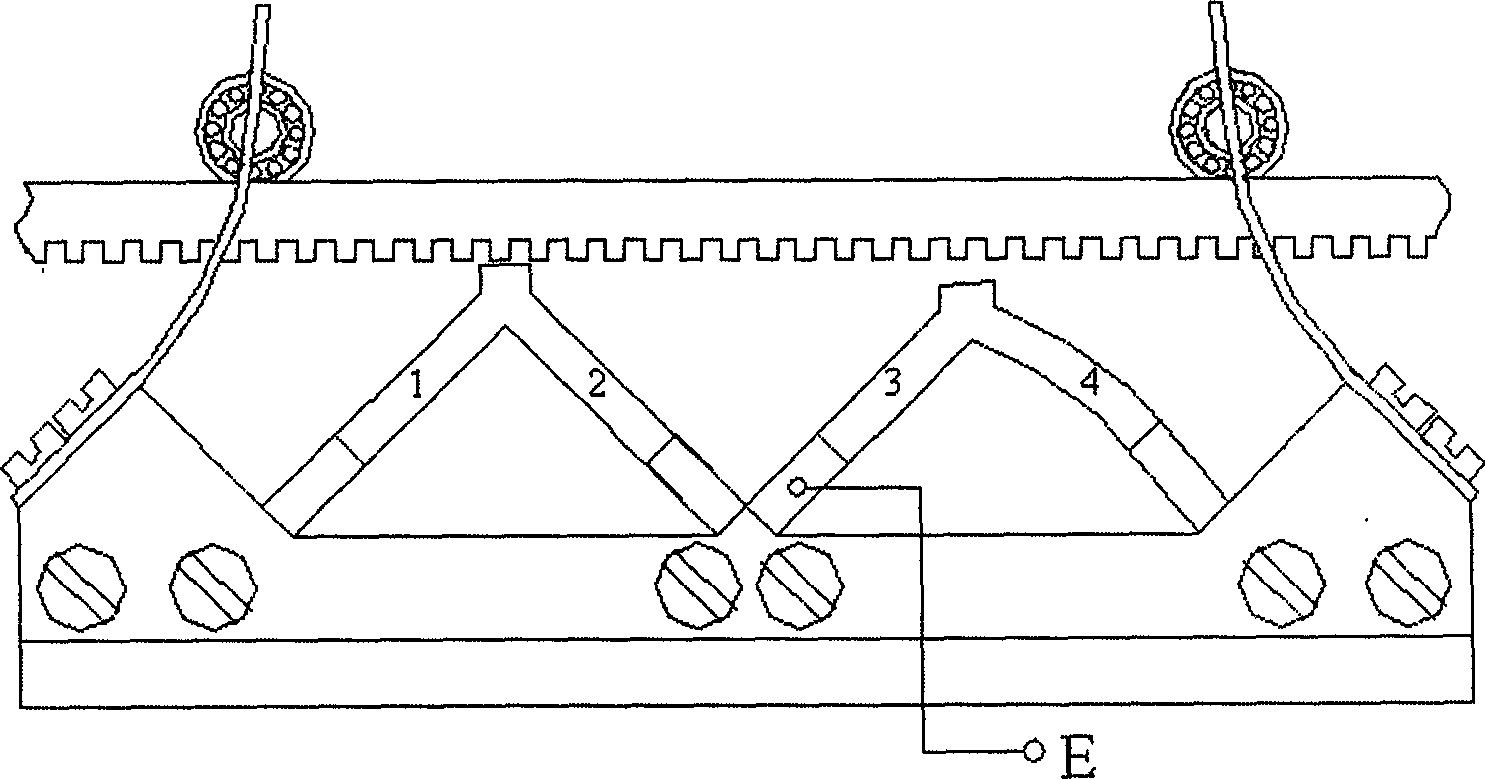

[0012] A linear motion stepping ultrasonic motor such as figure 1 shown. Its characteristics: the stator 1 is composed of metal elastic body 3 with two angular vibrators, and the root of the two arms of each angular vibrator is attached with piezoelectric ceramics 2, which are used to excite the vibrator arms to generate longitudinal vibration. The mover 4 is composed of a bar-shaped body with evenly graduated tooth grooves on the lower end surface; the surface of the bar-shaped mover with tooth grooves is pressed on the stator drive head; the longitudinal vibration of the vibrating arm of the stator angular vibrator is excited by piezoelectric ceramics. The joint effect of the longitudinal vibration with phase difference of the two vibrating arms can make the drive head produce elliptical motion to push the mover to move in a straight line to form a linear ultrasonic motor; the vibrating arms of the two angular vibrators work alternately in the same direction to drive the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com