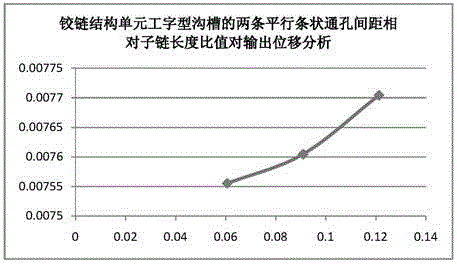

Three-dimensional ultrasound elliptical vibration assisted cutting device and elliptical orbit generation method

An elliptical vibration and cutting device technology, which is applied in the field of numerical control machining, can solve the problems of no amplified displacement, low device processing efficiency, and difficulty in cutting to complete the cutting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

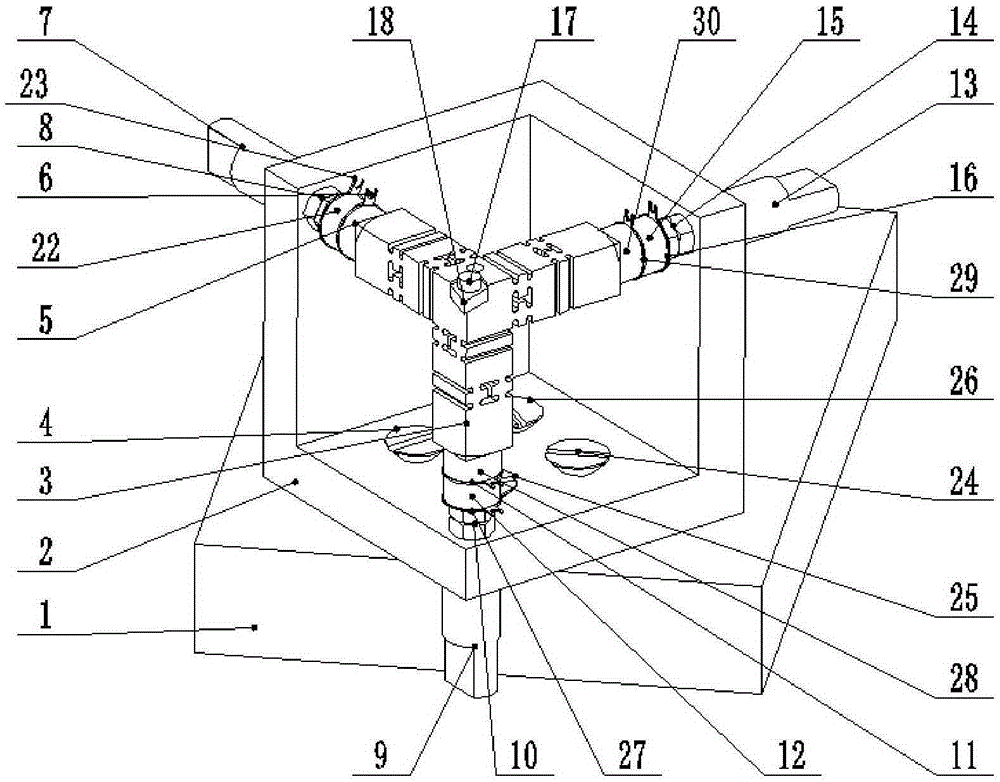

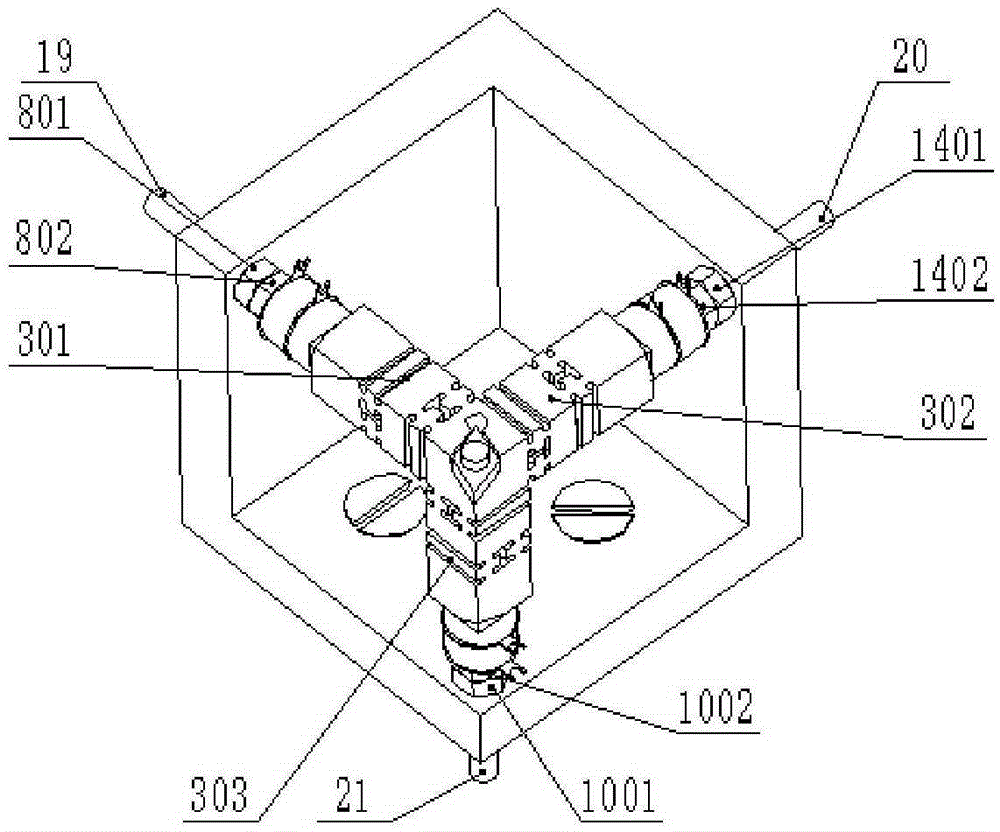

[0057] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0058] In order to achieve the above object, the solution of the present invention is:

[0059] 1. A three-dimensional ultrasonic elliptical vibration-assisted cutting device, characterized in that:

[0060] The auxiliary cutting device includes a multi-axis flexible hinge 3, a base 2, a diamond cutter 18, a diamond cutter pre-tightening screw 17), and a base 1;

[0061] The above-mentioned multi-axis flexible hinge 3 is an integral structure, which is composed of three mutually perpendicular intersecting rectangular sub-chains, and the tool mounting frame is processed at the intersection according to the installation size of the processing tool; the diamond tool 18 is pre-tightened by the diamond tool. installed on the tool mounting frame;

[0062] Define the XYZ coordinate system, where the coordinate origin O is the intersection point o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com