Double-rotar column travelling-wave type single-phase drive ultrsound electric machine

A single-phase drive, ultrasonic motor technology, applied in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the limitations of miniaturization and industrialization of traveling wave motors, The drive circuit is complex and the miniaturization is difficult to achieve the effect of simple structure, reduced complexity and good speed stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

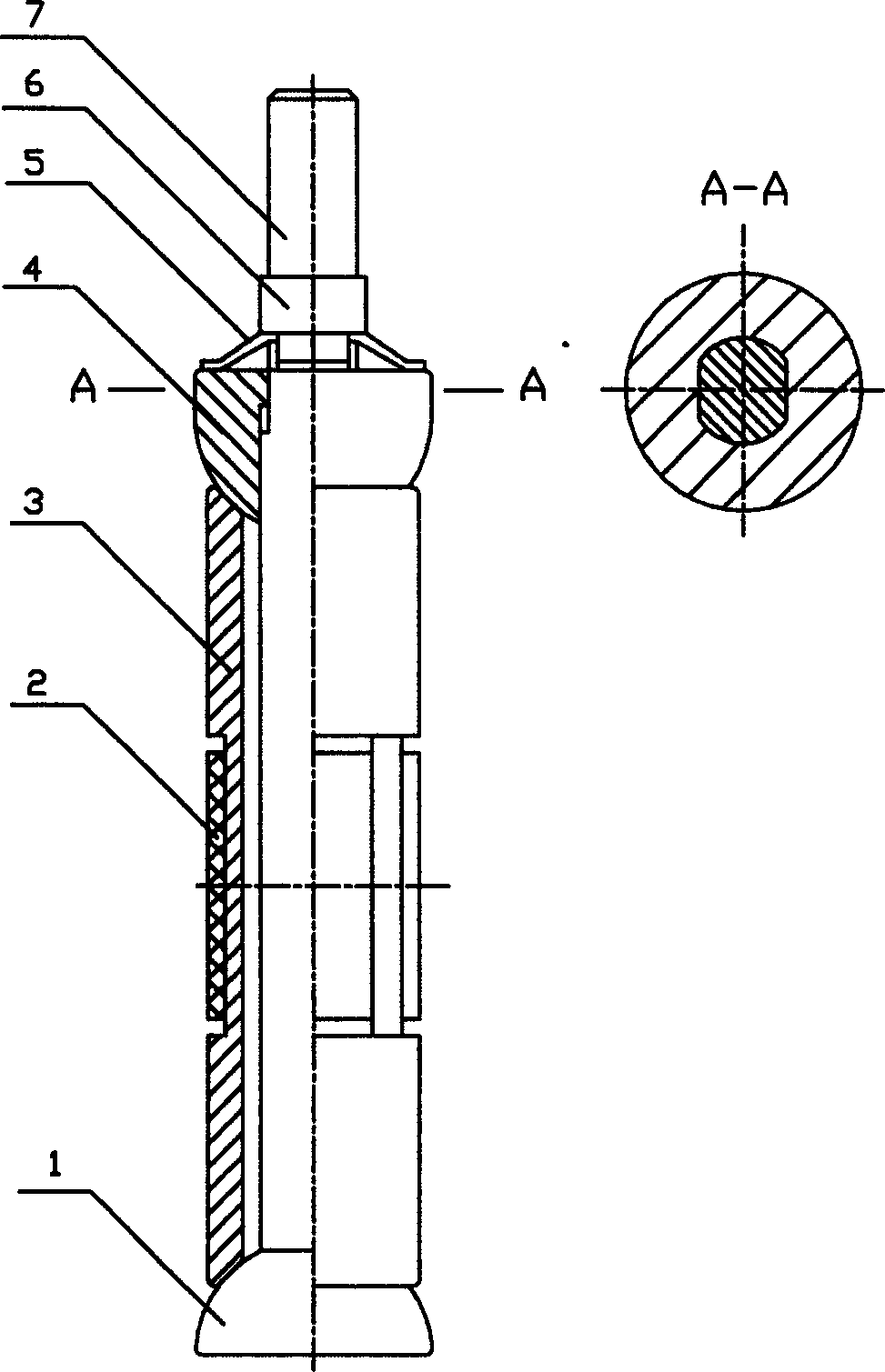

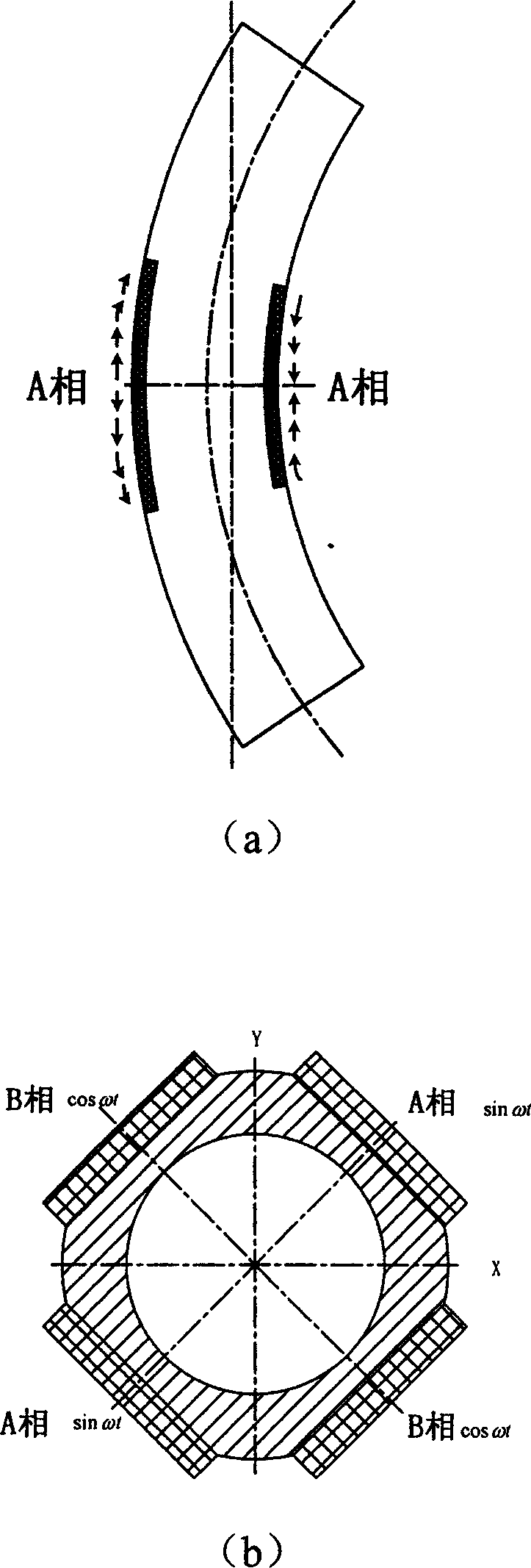

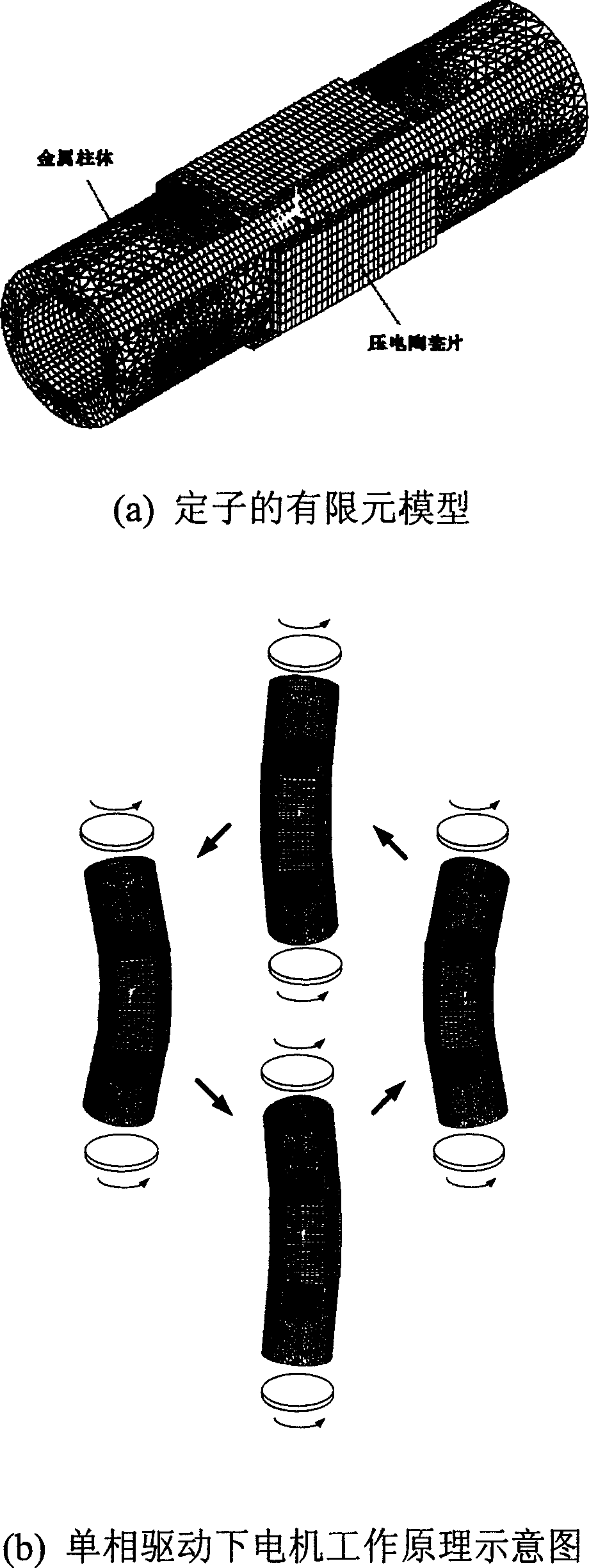

[0010] The invention is a novel ultrasonic motor developed based on the use of the piezoelectric effect of the piezoelectric ceramic sheet to excite the first-order bending vibration of the metal cylinder. It is mainly composed of stator, rotor and pre-pressure adjustment part. Fig. 1 is the specific structure schematic diagram of the present invention, as can be seen from the figure, the stator of motor is that four piezoelectric ceramic sheets 2 are mutually vertically bonded on the surface of metal cylinder 3 and constitutes, and the bonding of piezoelectric ceramic sheets 2 The position is located at the antinode of the first-order bending mode of the metal cylinder 3, and excitation at this position can effectively improve the working efficiency of the piezoelectric ceramic sheet. The fast heat conduction of the hollow metal body is used to solve the heat dissipation problem of the piezoelectric ceramic sheet and ensure the stable performance of the motor when it works fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com