Four-short shock exciting motor elliptical vibrating screen coupled with torsion springs

A technology of exciting motor and torsion spring, applied in the direction of filter screen, mobile filter element filter, grille, etc., can solve the problem that the effective exciting force of the vibrating screen is reduced, the electromechanical coupling cannot be avoided, and the effective exciting force cannot be increased. and other problems, to achieve the effect of close power consumption, low noise, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

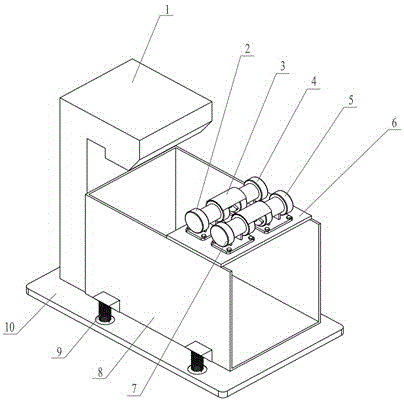

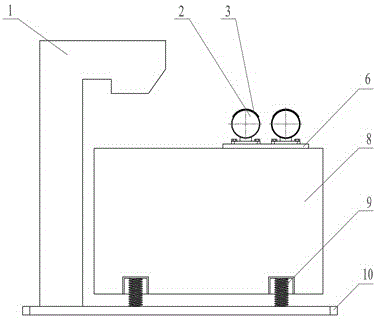

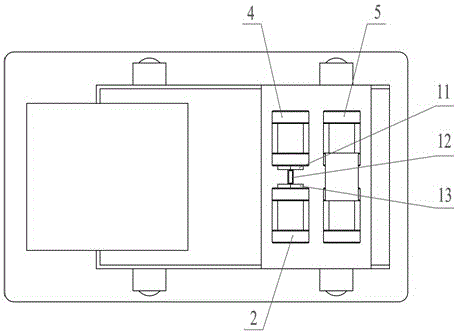

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the elliptical vibrating screen with four short excitation motors coupled by torsion springs of the present invention consists of a feed hopper 1, a first excitation motor 2, a shield 3, a second excitation motor 4, a third excitation motor 5, and a motor base 6. The fourth excitation motor 7, the screen box 8, the vibration isolation spring 9, the base 10, the second coupling eccentric mass 11, the first torsion spring 12, the first coupling eccentric mass 13, the fourth coupling eccentric mass 14, the second The torsion spring 15 and the third coupling eccentric block 16 are composed.

[0018] The plane on which the motor is installed on the motor base 6 is parallel to the screen surface, or at a smaller angle, the first vibration motor 2 and the second vibration motor 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com