Piezoelectric actuator in d15 shearing mode and precision micropositioner

A piezoelectric driver, d15 technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc., can solve the problem of low output force of piezoelectric drivers , Piezoelectric actuator size becomes larger, the frequency of vibration is large, etc., to achieve the effect of small size, eliminate the influence of piezoelectric actuator performance, and avoid limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the technical problems, technical solutions, and advantages to be solved by the embodiments of the present invention clearer, a detailed description will be given below with reference to the drawings and specific embodiments.

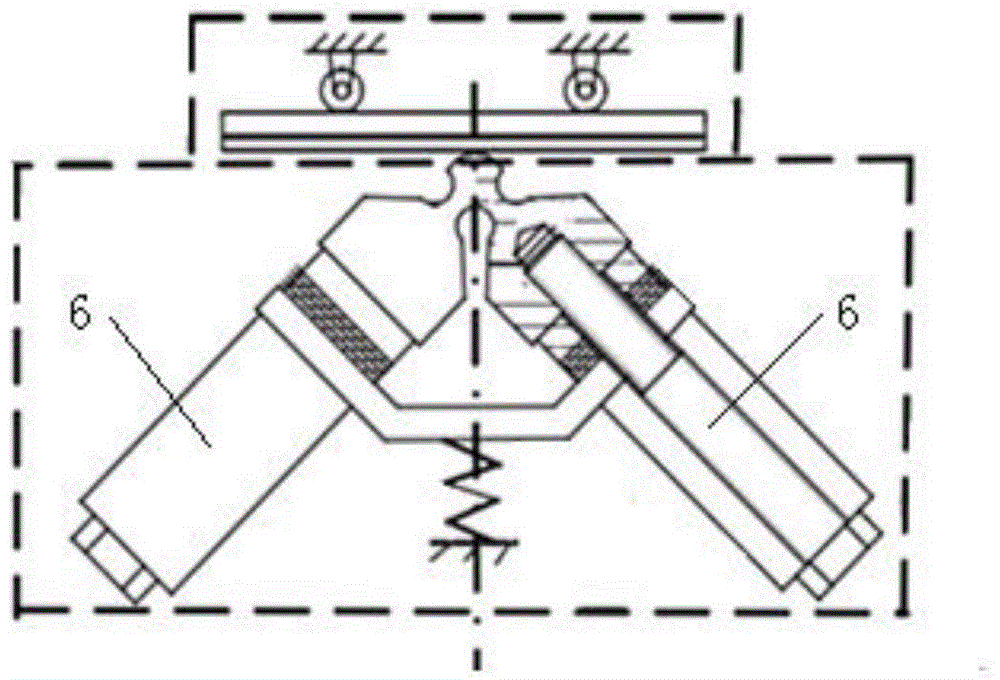

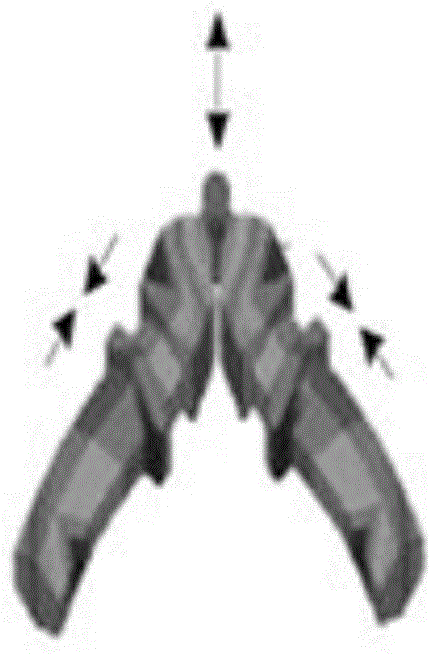

[0057] On the one hand, the present invention provides a method that uses d 15 Piezo actuators in shear mode, such as Figure 7 to Figure 15 As shown, a piezoelectric ceramic body 1 is included. The piezoelectric ceramic body 1 includes a substrate 11 and is located on the substrate 11 and can generate d 15 The first piezoelectric ceramic cantilever beam 12 and the second piezoelectric ceramic cantilever beam 13 deformed in the shear mode, the first piezoelectric ceramic cantilever beam 12 and the second piezoelectric ceramic cantilever beam 13 are vertically arranged and arranged along the length direction of the substrate 11 Cloth; the top end of the first piezoelectric ceramic cantilever beam 12 and the second piezoelectric ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com