Ultrasonic motor with two linear degrees of freedom based on flexural oscillation driving of rectangular plate

A technology of ultrasonic motor and rectangular plate, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., to achieve large thrust, reduce motor size, and simplify the structure of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

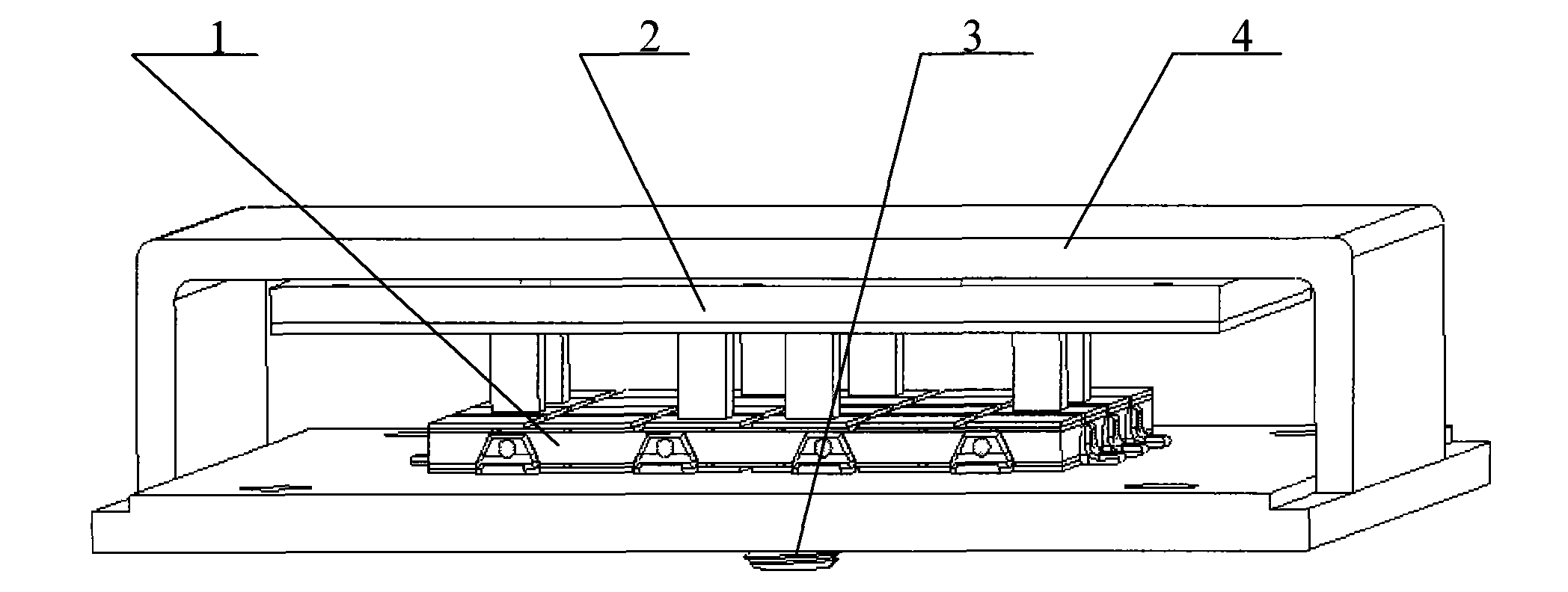

[0017] Such as figure 1 As shown, the present invention is realized in this way, and it includes a stator assembly 1, a mover assembly 2, a bearing assembly 3 and a preloading and pressing assembly 4, which is characterized in that the preloading and pressing assembly 4 is connected to the bearing assembly 3, and the supporting assembly The seat assembly 3 is connected with the stator assembly 1, and the stator assembly 1 is connected with the movable subassembly 2;

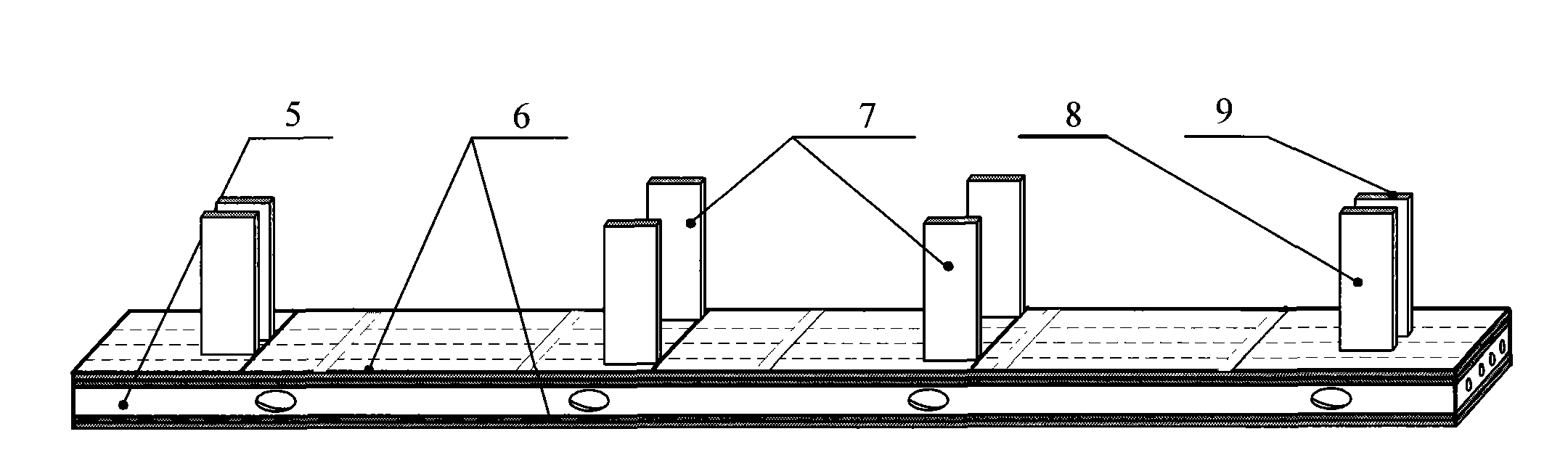

[0018] Such as figure 2 As shown, the stator assembly is composed of a rectangular plate 5, a piezoelectric ceramic 6, an X-direction driving tooth 7, and a Y-direction driving tooth 8. It is characterized in that the front and back sides of the rectangular plate 5 are respectively connected with two layers of piezoelectric ceramics. 6. Four X-direction drive teeth 7 and four Y-direction drive teeth 8 are symmetrically connected to the piezoelectric ceramic 6, and the top surfaces of the X-direction drive teeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com