Working method of plate type linear piezoelectric motor based on in-plane mode

A piezoelectric motor and working method technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of driving foot wear and shortening the life of piezoelectric actuators , serious problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

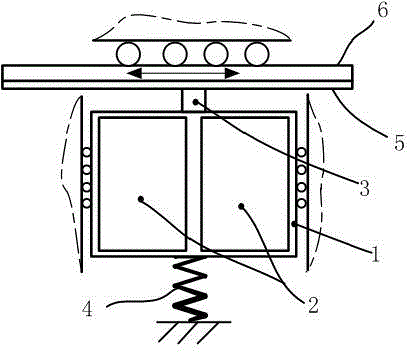

[0018] Such as figure 1 As shown, the present invention provides a plate-type linear piezoelectric motor based on in-plane modes, including a stator and a mover, and the stator is composed of a rectangular metal sheet 1 and two or four unidirectionally polarized piezoelectric ceramic sheets 2; The movable subassembly adopts a slide bar 6, and a friction strip 5 is pasted on the slide bar. The required preload between the stator and the mover is provided by the spring element 4 . Two or four piezoelectric ceramic sheets are respectively driven to make the driving foot of the stator generate an elliptical motion, and under the action of a certain preload, the slide bar is driven to move in a straight line. By switching the drive signal, this motor can achieve reverse linear motion.

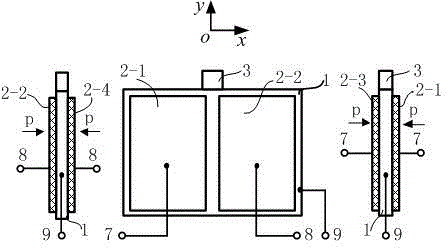

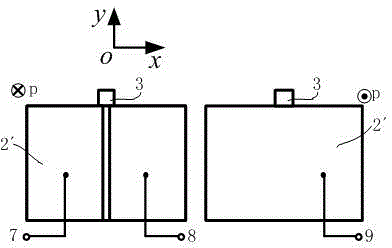

[0019] figure 2 It is the working mode diagram of the stator. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com