Three-degree-of-freedom piezoelectric drive platform

A piezoelectric drive, degree of freedom technology, applied in the direction of worktables, large fixed members, metal processing machinery parts, etc., can solve the problems that it is difficult to reach the "sub-nanometer" level and low positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The structure and working principle of the present invention will be described in detail below with reference to the drawings and specific embodiments.

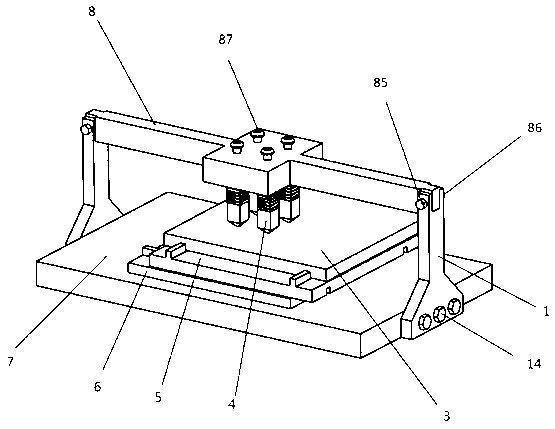

[0041] Such as figure 1 As shown, the present invention provides a three-degree-of-freedom piezoelectric drive platform, including a base 7, two side walls 1, a long beam 8, at least two piezoelectric stators 4 (four in this embodiment), an upper guide rail 3. The middle guide rail 5 and the lower guide rail 6 will be introduced separately below.

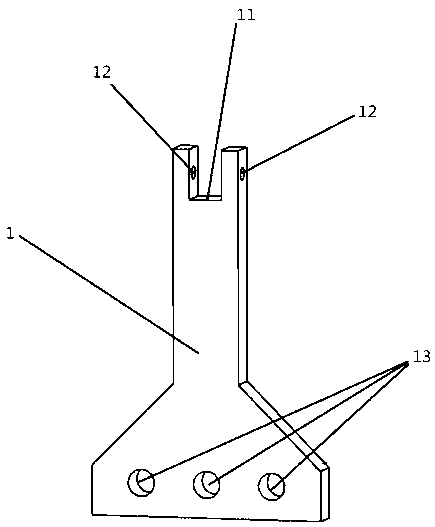

[0042] Such as Figure 8 As shown, the base 7 is a rectangular plate with a circular groove 71 in the center, and at least two threaded holes are provided in symmetrical directions on the two opposite short sides. In this embodiment, three threaded holes 72 are provided. These threaded holes 72 are in order to fix the side wall 1, and the threaded holes 72 are located on the short side to make the rotation range of the lower guide rail 6 larger, and avoid the influence of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com